4

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

AUTOMATED PETROL PUMP USING RFID TECHNOLOGY

1Rohith .S, 2Akilan .K, 3Murali Krishna. M, 4Dr.Kandasamy .V

123

Abstract In Today’s world almost all the sectors and industries have been automated. Petroleum industries are not an exception to that. Petrol pumps have been very much automated, they have microcontrollers to monitor the outlet of petrol and display the appropriate amount to the customer. Even though everything is automated, customers have to collect the money and there is a high possibility of human error while handling hard cash. Our Project is designed in such a way that the person need not worry about carrying the cash with himself/herself. A Smart card, which contains an RFID tag is given to the customers and the petrol pump will have an RFID Reader and payment can be made through the RFID Technology without any hard cash or Human interaction. In this way, human errors in calculation can be saved and efficient transactions can be carried out. These types of cards have been used in lots of applications including attendance management and employee registration systems in schools, workplaces, and large industries. The Smart card contains an AT89C51 Microcontroller, a voltage regulator. serial cable connections and an LED connection. LED works when information are been passed from the microcontroller when the RFID card is been scanned

Keywords: AT89C51 Microcontroller, MAX232 IC, RFID Card, RFID Reader

1. INTRODUCTION

Uncontrolled increase in the vehicle population in the world is giving an alarming threat to fuel resources. Dispensingfuelsatthefuelstationstothelargeamountof customers has caused a lot of complication .The Petrol is oneofthemostimportantresourceintheworld.Notonly the Proper use of these products, but also the effective utilization of these products are very much important . A fuel station is a facility which sells fuel and lubricants via fuel dispensers which pump fuels into vehicles and calculatethefinancialcostoftheproductthusdispensedIt is important that we find some important methods to dispense the fuel wisely and efficiently In the existing systems, every petrol pumps have a single unit that is responsible for controlling the whole process of filing the petrol. This process involves tasks like displaying the amountandquantityofpetrol,electricalpumpdrivingand turning ON and OFF of petrol pump accordingly An important drawback here is that there are a lot of petrol theft in recent times. A secure system is needed to

***

dispense one of the most important fuel source like Petroleum A recent research study states that 30ml of every1000mlisbeingstolenfromcustomers.

2. LITERATURE SURVEY

A. Monitoring Customer data using web server : According to Fawzi Mohammed Munir and Mohannad M Hasan(2015) : Inthisstudy, aRFIDbasedfueldispensing System was proposed which involved controlling the customer database using web server. Here a database created using MYSQL contains all datas of the customers. Customers using this system for the first time hastocreateanaccountwheretheadminhastostorethe datas of customer including the Vehicle Id , Customer name and their unique id which will later be utilized by RFIDreaderinbunks.

B. Fingerprint based RFID : According to Anjali et al. (2020): In this Study , Self service petrol bunk with a Fingerprint based RFID technology was proposed . Here the customer has to set the fingerprint on the module , after that complete identity of the person is stored in databasealongwithhis/herfingerprintasuniqueidentity So unauthorized personals can be ceased from usage also theamountofpetrolinletandoutletalongwithmoneycan managed.

C. RFID & GSM Technology system : According to Naresh Jogi et al. (2012) : In this Study , a smart petrol pump which uses RFID and GSM technology was proposed. Here every customer will be given a PF Card called Petrol Filling card , they have to swipe that card inordertoproceedfurther.TheincorporatedLCDDisplay will prompt the user for password . If user enters wrong password , “WRONG PASSWORD” will be displayed else LCD will prompt the user for amount . If there is low balanceincards ,“LOWBALANCE“textwillbedisplayed onLCD

4. Automated petrol pumps using Node MCU and Arduino Mega: According R.Deepa et al. (2019)In this study, a RFID based petrol pump involving , ardunio mega and Node MCU was proposed. In this Project , IOT technology is used to monitor the petrol and maintain them.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

3. METHODOLOGY

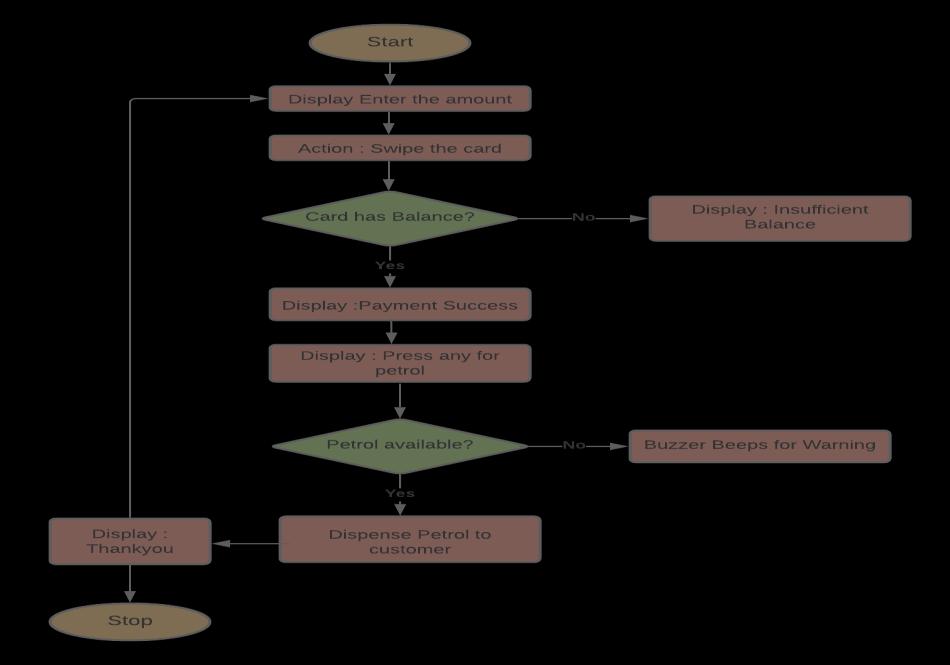

Thebelowflowchartdescribestheworkingofourproject. TheuserscanstheirRFIDcardthroughtheRFIDreader.If the card doesn’t have required amount, the message stating , “Insufficient balance” will be displayed and the buzzerblows.Elseifthepaymentissuccessful,itprompts fortheuserinput.Iftherequiredpetrolisavailableinthe tank,itdispensesthepetroltothecustomerandthecycle repeats.

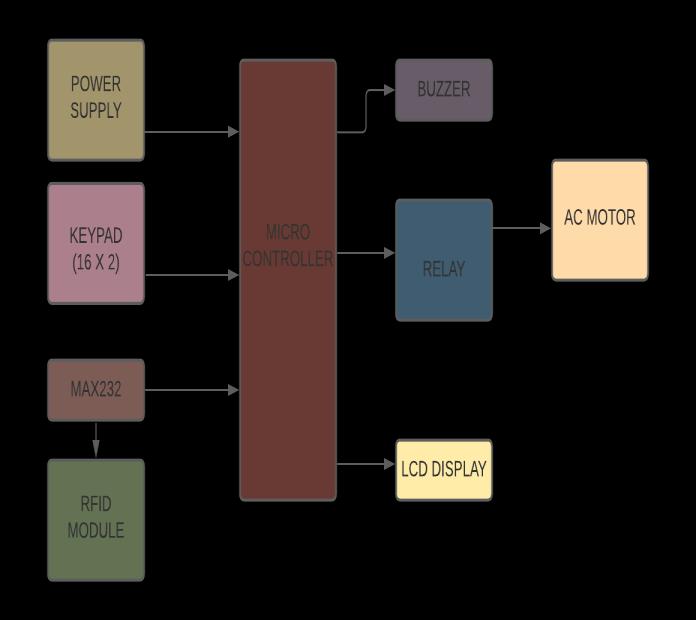

Block A of the diagram is the input part, where the user interacts with the system. That is , the user enters the amount details, passwords through the keypad, after scanning their RFID card through tag Reader. Block B is the Brain of the system, that is the microcontroller part. The inputs entered by the user are processed by the microcontrollerandconveyedtotheoutputpart,whichis Block C. Block C is the output part of the system. The informationprocessedbythemicrocontrollerisconveyed totheoutputpart

5. HARDWARE

5.1. 8051 Microcontroller :

4.BLOCK DIAGRAM:

The 8051 is a family of microcontrollers. The microcontrollers which we've used in our design is the AT89S52 microcontroller which belongs to the 8051 family of microcontrollers. These are manufactured by ATMEL. The AT89S52 is an 8 bit microcontroller. It's a low power, high performance CMOS. This device is compatible with the assiduity standard 80C51 instruction set and pinout 9843. These microcontrollers are manufactured using Atmel’s high viscosity non volatile memorytechnology

FEATURES

256bytesofRAM

8KbytesofFlash

twodatapointers,

32I/Olines,

Watchdogtimer

three16 bittimer/counters

a six vector two level interrupt architectures clockcircuitry

TheProposedblockdiagramhasthreepartsnamely:

Block A: RFIDModule,MAX232,Powersupply,Keypad

Block B: Microcontroller

Block C: RelaysandOutput

5.2.

LIGHT EMITTING DIODE :

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

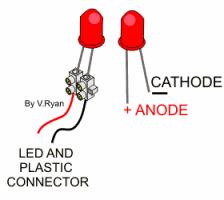

Alight emittingdiode(LED)isasemiconductordiodethat emits incoherent slim spectrum light when electrically biased in the forward direction of the PN junction, as in the common LED circuit. This impact is a form of electroluminescence. While sending a message in the structureofbitssuchas1,theinformationisdispatchedto the receiver aspect correspondingly the LED glows representing the statistics are being obtained concurrently,theLEDblowsoffwhendataissentas8

5.3

RELAY MODULE :

Arelayisanelectricallyoperatedswapusedtoisolateone electrical circuit from another. A relay consists of a coil used as an electromagnet to open and close switch contacts. Since the two circuits are remoted from one another, a low voltage circuit can be used to time out a relay,whichwillmanageaseparatecircuitthatrequiresa higher voltage or amperage. Relays can be discovered in early cellphone change equipment, in industrial control circuits, in auto audio systems, in automobiles, on water pumps, in high power audio amplifiers, and as protection devices.

5.4

MAX232 IC:

TheRS232is notcompatiblewithTTL.Therefore MAX232 chip, a line driver is required to convert RS232 voltage levels to TTL Levels. The 8051 microcontrollers have two pins called TXD and RXD , that are mainly used fortransmittingandreceivingthedataserially. Thesepins arepartofport3groupthatis, pins(P3.0,P3.1).Pin11of 8051 microcontrollers is TxD and pin 10 is RxD. As they areTTLCompactabletheyrequireanRS232linedriverto

make them RS232 Compatible. These line drivers are calledMAX232. Theserequire4capacitorsrangingfrom1 to22nf.

5.5

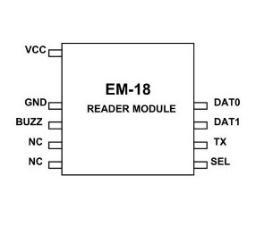

EM 18 RFID READER MODULE

SPECIFICATON OF EM18:

DefineOperating voltageofEM 18 +4.5Vto+5.5V

Currentconsumption 50mA

Poweroperation LOWpower Operatingtemperature 0ºCto+80ºC Operatingfrequency 125KHz

Communicationparameter 9600bps IntegratedAntennae

6. SIMULATION AND RESULTS :

6.1 SIMULATION DESIGN :

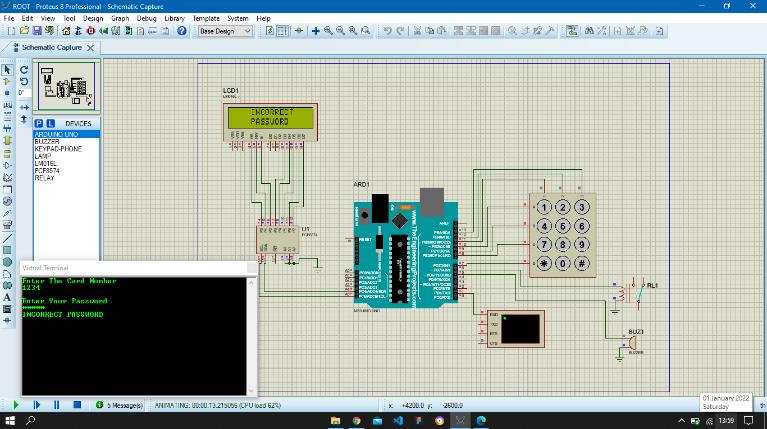

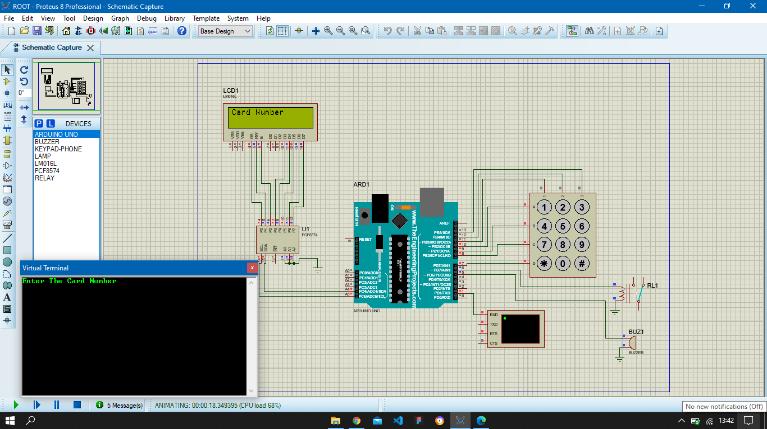

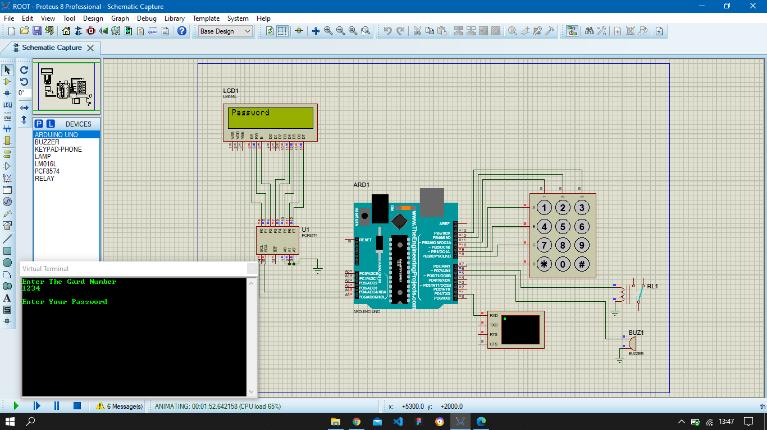

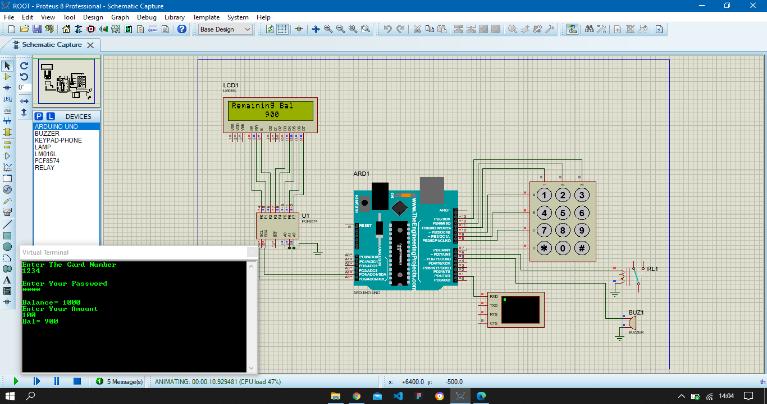

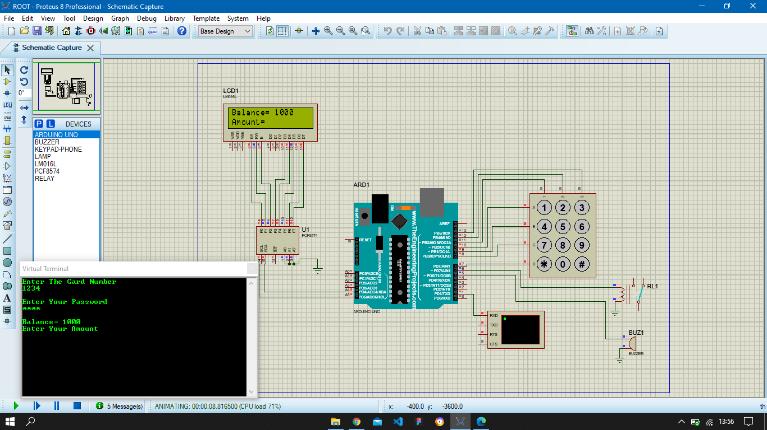

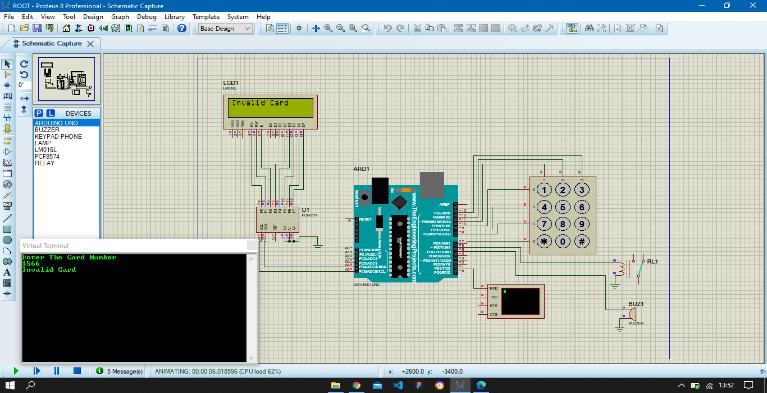

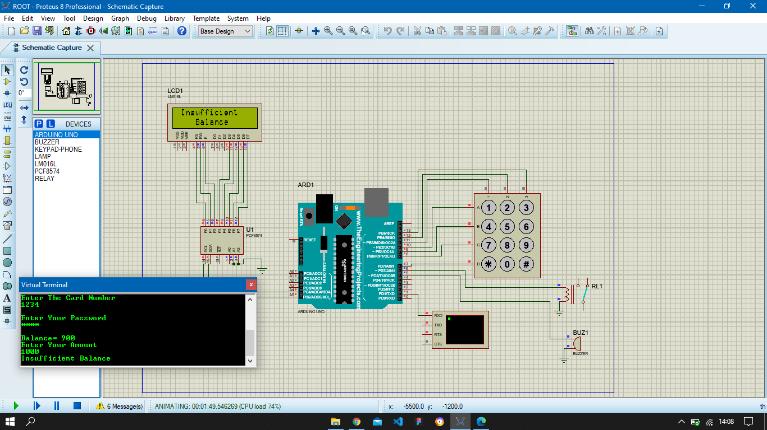

Arduino UNO is used as a microcontroller for the simulationprocess.PinA4,A5(SDAandSCL)isconnected to pin A4, A5 (SDA and SCL ) of PCF8574 (I2C Chip).LCD supports only parallel communication, but in this simulation, we are using serial communication. So to convertserialtoparallelcommunicationwehaveusedI2C Chip.Arduino supports both serial and parallel communication, for ease of work we have used serial communication.We have used a matrix keypad in simulation,whichisusedby userstoentercardnumbers, passwords, and amounts. Pin 7,8,9,10 of Arduino UNO is connected to rows A,B,C,D of matrix keypad and pins 11,12,13 is connected to columns 1,2,3 of matrix keypad. Pin5ofArduinoUNOisconnectedtothebuzzerandpin6 is connected to the relay. The transmitter (TxD) pin of ArduinoUNOisconnectedtothereceiver(RxD)pinofthe serial monitor which transmits the user input to the microcontroller

6.2 SIMULATION PROCESS:

STEP 1:

The user enters the unique card number through the Keypad.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

STEP-2 :

A) If the card numberiscorrect, the user will beasked to enterthepasswordoftheircard.

B) Else if the password is incorrect a message stating “Incorrect password” willbedisplayedin16x2LCDDisplay andbuzzerblows.

B) Else a message stating “Invalid card” will be displayed in16x2LCDDisplayandbuzzerblows

STEP: 4

A) Ifa Sufficientbalanceispresentontheuser’scard,the relay starts and petrol proceeds to fill, and appropriate funds get deducted from the card and a new balance will bedisplayed.

B) Else if there are insufficient funds, a message stating “Insufficient funds” will be displayed in 16x2 LCD Display, andbuzzerblows

STEP 3 :

a)If the password is correct, the balance on the card will be displayed and the user will be asked to enter the amount,forwhichhe/sheneedsthepetrol.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

STEP : 5

Afterpetrolgetsfilled,thisprocessisrepeatedagain

Engineering & Technology, vol. 6, no. 6, pp. 2408 2415, January2014.

[2]. Fawzi Mohammed Munir Al Naima and Mohannad M Hasan, “Design and implementation of RFID Based fuel dispensingsystem”,Researchgatepublication,September 2015.

[3]. P. Anjali, G. Navya Jyothi, and Yalabaka Srikanth, “Self Service Automated Petrol Pump Using Fingerprint Based RFID Technology”, Journal of Mechanics of continua and mathematicalsciences”,Vol. 15,No. 6,June(2020)pp82 88.

[4]. S. Ponmalar, K. Bhuvaneswari, and S. Preethi, “RFID based Petrol Pump Automation System, International Research Journal of Engineering and Technology (IRJET), Volume:07Issue:02|Feb2020.

7. CONCLUSION :

RFID systems dispenses accurate amount of fuel as required by the user. In this way the efficiency is maintained. Also as everything is automated, the labour pressure is reduced. Also as only authorized users may enterorleavethesystem,thissystemismoresecurethan present ones. To make this system more efficient, greater quality of RFID cards must be produced. Thus the design and simulation part of our project is complete in the first phaseoftheproject.Inthe second phase,weaimtowork on the hardware design of our project and implement everythingwediscussedinthereportsofar.

8. FUTURE SCOPE :

1. Automation plays a vital role in the future. This type of automated petrol pump proves effective consideringthepresentsystem.

2. It is considered efficient since there is no cash involved in the whole process and can reduce fuel theftandmoneytheft.

3. Further, this system can be improvised by involving a biometric system to authorize the customers.soonlyunauthorizedpersonalsmaybe ceasedfromusingit.

4. Since everything is digitalized, each transaction is recorded and any suspicious activity may be detectedeasilywhichmakesitmoresecureandwe cankeepatrackofeveryprocess.

9. REFERENCES

[1]. O. O. Edward, "A research using remote monitoring technologyforpumpoutputmonitoringindistributedfuel stations in Nigeria," International Journal of Advances in

[5]. R Deepa, Roshni A Ramesan, Navya V, Rajesh Kumar Choudhary, Vivek Hegde, “Automated Petrol Bunk”, JETIR May2019,Volume6,Issue5,2019

[6]. Sudeshna Dutta, Smarajit Pal, Subhankar Majumder, and Mrs.Pratyusha Biswas Deb, “SELF SERVICE PETROL PUMP USING AUTOMATION TECHNOLOGY”, I3SET2K19: INTERNATIONAL CONFERENCE ON INDUSTRY INTERACTIVE INNOVATIONS IN SCIENCE, ENGINEERING, ANDTECHNOLOGY3.

[7].Estherkani,“Slideshare”,July2012.

[8].ShaanuShaan, “SCRIBD”,March25,2012.

[9].GandhaDhairyaP,Dr.Tejas,V.Shah,andDr.DeepaliH. shah, “RFID based fuel station using Arduino UNO”, International journal of creative research thoughts, Vol 8, Issue10,October10,2020.