International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

1PG Student, Department of Civil Engineering, Nova College of Engineering and Technology, Affiliated to JNTU Kakinada, Vegavaram, Jangareddygudem, West Godavari (District), A.P 534447.

2Guide, Assistant Professor of Civil Engineering, Nova College of Engineering and Technology, Affiliated to JNTU Kakinada, Vegavaram, Jangareddygudem, West Godavari (District), A.P 534447

***

Abstract - Millions of reinforced concrete structures are being constructed every year throughout the world. Almost all the designers are not able toadopt economical aspects related to the design and results. Hence, in this economical investigationhas been tried and studied of the important parameters in design of the RC members and structures. The study has gone through simply supported rectangular slabs (SSRS), T Beam and RC portal frames. The research gap studied of relative moment capacities along the shorter and longer directions in RC Slab, spacing of ribs in a low cost manner in T Beam and influence of span, spacing of frames and the relative moments of inertia of beam and column members on the lowest cost of unit area covered in this study. The above mentionedstudyhas beentakenlimit state method for design has been adopted. The recommendations of all the relevant Indian Standard Codes of Practice have been incorporated wherever necessary. All the conclusions that have been arrived at based on this study will be very useful to the designers of RC structures to accumulation economical designs.

Key Words: M 25 to M 50 Grade of Concrete, Ultimate moment,EconomicalDesign.

Millions of concrete structures such as dwellings units, Multistoreyed buildings, bridges, industrial structures, commercial buildings and other structures have been constructed in the past, are being constructed at present andwillbecontinuedtobeconstructedinthefuturealso. Researchworkspertainingtoconcretetechnology,designof concrete elements and execution of concrete structures havebeencarriedoutforthe pastoveronehundredand fiftyyears.Researchworkersinthepasthaveconcentrated on the properties such as strength and durability of concrete. Very little information is available on the economicaldesignofreinforcedcementconcretestructural membersandstructuresmadeofit.Asmallsavingeffected inthedesignofaRCstructuralmemberwillresultinthe hugesavingwhennumbersofsuchelementsareadoptedin thewholestructure.

Almostallofthestructuralconcretedesignerssimplyfollow the codal provisionsand donotexplorethepossibilityof reducing the cost within the limitations of the codal provisions.Hence,atpresent,ahugeamountof moneyis being wasted in the uneconomical design of RC elements and their structures. Considering all these factors, in this theoretical investigation, an attempt has been made to arriveateconomicaldesignsforthefollowingRCstructural components/structures.

The aims of the investigation can be briefly stated as follows:

To find out the effect of the relative moment capacities aboutthexandyaxesofsimplysupportedRCslabsonthe minimum cost of these slabs. To investigate the effect of gradesofconcreteandsteel,spacingofT Beamsandspan on the lowest cost per unit area covered by simply supportedT beamandslabstructureandbycontinuousT Beamandslabstructure.Inthecaseofslabsupportedby RCPortalframes,tofindouttheeffectofspacingofframes, span and the relative dimensions of beam and column membersonthecostperunitareacoveredbythestructure.

Gradesofconcrete: M25,M30,M35,M40,M45andM50

Gradesofsteel : Fe250,Fe415,Fe500andFe550. Liveload : 2.5kN/m2

µ : 0,0.2,0.4,0.6,0.8,and1

L/bratio : 1to2.2

MethodofDesign: Yield line theory for analysis and limit statemethodforDesign

Spanofbeams : 8,12,16,20,22m

Gradesofconcrete : M25,M30,M35,M40,M 45andM50

Gradesofsteel : Fe250,Fe415,Fe500and Fe550.

SpacingofT Beams :3,4,5,6m

MethodofDesign :LimitstateDesign

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

Spacingofframes : 3.5,4.5,5.5,6and7m

Spanofframe :8,12,16,20and25m

Gradesofconcrete :M 25, M 30, M 35, M 40, M 45 andM50

Gradesofsteel :Fe250,Fe415,Fe500andFe550. Safe bearing capacity of soil : 200kN/m2 .

Method of Design :Elastic analysis and Limit state design

Onehundredandforty fivesimplysupportedRCslabshave been designed adopting M 25 grade concrete and Fe 500 grade steel and using yield line theory and Bacterial Foraging Optimization Technique. A live load of 2.5kN per squaremetrewasconsidered.TheratioofUltimatemoment ofresistanceofslabwithrespecttoxandyaxis,µ,wasvaried from0to1.Thelengthoftheslabwasvariedfrom3mto6m andL/bratiofrom1to2.0.Thevalueofµthatresultsinthe mosteconomicalsolutionhasbeenfoundout.

Assuming b/d=35forsimplysupportedtwowayslabas perIS456:2000,tosatisfystiffnesscriterion4200/d=35 Therefore d=4200/35=120mm, Assuming10mmdiameter barsandclearcoverof20mm,Overalldepth, D=effectivedepth+clearcover+ +(10/2) =145mm, DeadLoadofslab =0.145*1*1*25=3.625kN/m2Live load =2.5kN/m2 , Totalload =6.125kN/m2 Factoreddesignload =1.5*6.125=9.187kN/m2

Estimationofsteelcost:

Volume of steel, Vs = (284.37/106)*6*4.2 + (174/106)*4.2*6 =0.01155m3 Cost of steel = 0.01155*280614=Rs3236.7.

Estimationofconcretecost:

Volumeofconcreteforthewholelengthoftheslab= (L*b*D) Vs=(6*4.2*0.145) 0.01155=3.64m3

Costofconcreteofslab=3.64*4015=Rs14624.43

Estimationofformworkcost:

Perimeter area= 2(L+b)*D= 2(6+4.2)*0.145= 2.958m2 Formworkareaforbottomofslab=6*4.2=25.2m2 Total formworkarea=2.958+25.2=28.158m2

Costofformworkforslab=28.452*350=Rs9855.3

TotalcostofSlab=Concretecost+steelcost+formworkcost =14624.43+3236.7+9855.3=Rs.27716.3

e ISSN: 2395 0056

p ISSN: 2395 0072

Table 1: Comparisonofcostforaspan3m

S.no Length of slab, m a µ D in mm

Ast in shorter direction in mm2/m

Ast in longer direction in mm2/m

Cost in Rs

1 3 1 0 67.86 199.1817 51.42857 3266

2 0 67.86 152.2164 51.42857 3197

3 0 67.86 136.4324 53.25361 3205

4 1 67.86 125.5613 73.93517 3214.8

5 1 67.86 117.1574 92.42261 3224.9

6 1 67.86 110.2862 109.2057 3234.8

7 3 1 0 76.43 251.8841 61.71429 4181.2

8 0 76.43 182.409 61.71429 4065.9

9 0 76.43 160.0722 62.54785 4071.7

10 1 76.43 145.03 85.521 4081.3

11 1 76.43 133.6075 105.5673 4091.6

12 1 76.43 124.4093 123.3919 4102

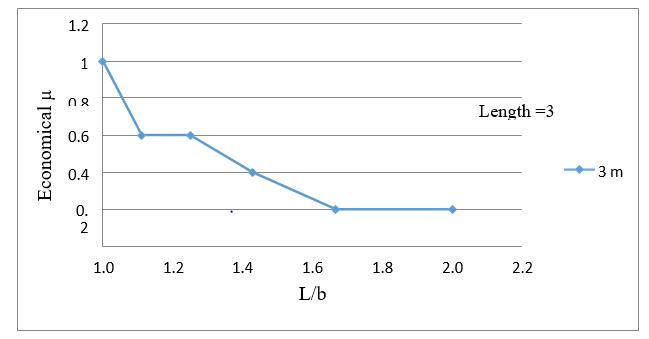

The various values of µ that results in the least cost of simply supported slabs for different L/b ratios are graphicallygiveninaboveChart

When the L/b ratio is 1 the economical value of µ is one. NowwhenL/bratiois2,i.e.,whentheslabbecomes onewayslabtheeconomicalvalueofµisnotzerobecause aminimumreinforcementof0.12%ofbDisprovidedand thisgivesrisetocertainvalueofmomentofresistance.

3.1 The Table below gives the results obtained by using BacterialForagingoptimizationtechnique.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Table 2: ComparisonofDepthofthesection

Span of Beam, m Total

Table 3: ComparisonofAreaoftensionsteelinbeam whenFe250gradesteelisadopted

Span of Beam,m Total Depth of the sectionas per BFO in mm

12

16

20

22

Table -4: ComparisonofAreaoftensionsteelinbeam whenFe415gradesteelisadopted

Span of Beam, m Total Depth of the section as per BFO in mm 8

12

16

20

22

Table 5: ComparisonofAreaoftensionsteelinbeam whenFe500gradesteelisadopted

Span of Beam, m Total Depth of the section as per BFO in mm 8

12

22

steelisadopted

Span of Beam, m Total Depth of the section as per BFO in mm

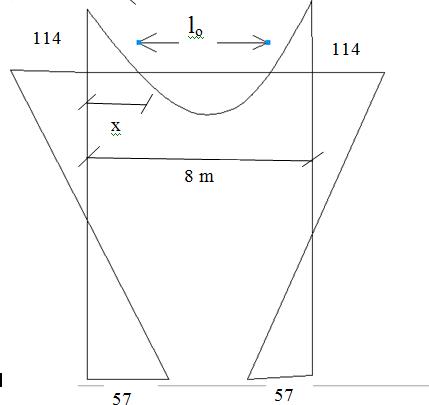

RCslabsupportedbyRCPortalframesre widelyused in industries, community halls and shopping complexes. In thisinvestigationtheeffectsofspanoftheframes,spacing oftheframesandrelativedimensionsofbeamandcolumn memberstocoveronesquaremetreareaofthebuildingis studiedandconclusionsusefulfortheeconomicaldesignof suchstructureswillbeusefulforthefuturedesigners.

Totally ten frames were designed and the cost of each framesincludingthatoffoundationhas beenestimated.The effect of spacing of frames on the cost per unit area coveredhasbeenfoundout.Further,theeffectoftheratioof themomentofinertiaofbeamwiththatofcolumnonthecost hasbeenfoundoutandthemosteconomicalratiohasbeen identified.

Loadonbeam: Asthespacingbetweentheportalframeis 3.5m,theloadtransmittedbytheslabononemetrelengthof thebeamis calculated

The portal frame is assumed to be fixed at the ends and isanalyzed bymomentdistributionmethod

Joint Member k Sk D.F

B BA 393.99*103 6483*103 0.78 BC 1083*103 022

C CB 1083*103 6483*103 022 CD 39399*103 078

Joint A B C D Member AB BA BC CB CD DC

DF 0.78 0.22 0.22 0.78

129.69 129.69

Balance 101.72 27.97 27.97 101.72

CO 50.86 13.98 13.97 50.86

Balance 10.97 3.02 3.02 10.97

CO 5.49 1.51 1.51 5.49

Balance 1.18 0.33 0.33 1.18 CO 0.59 0.16 0.16 0.59

Balance 0.13 0.035 0.035 0.13

CO 0.06 0.0175 0.0175 0.06

Balance 57 114 114 114 114 57

Factor value:

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

Thevariationofcost with D/bwratio Itcanbeconcluded thatasD/bwratioincreases thecostgets reducedandthe variation is non linear. The reduction in cost is due to increaseinquantityofsteelrequiredbecauseofincreasein lever arm. Also it is clear that, as the gradeof concrete increases the cost increases. The cost decreases with increaseingradeofsteel.AboveFe415grade,thevariation issmall.Herealsoitisclearthat,asthegradeofconcreteis increased,thetotalcostgetsincreased.

Whenthe L/b ratio is 1, the economical value of µ is one. Now when L/bratio is 2, i.e., when the slab becomes one way slab, the economical value ofµ is not zero because a minimumreinforcementof0.12%ofbDisprovidedandthis gives rise to certain value of moment of resistance. The variationofCostwithgradeofsteelisgraphicallyshownfor slabs having L=3m and L=6m respectively. From these figures itisclearthatasthegradeofsteelisincreased,the totalcostoftheslabgetsreduced.Thevariationsofcostwith µareshown.Itisclearthat,asthevalueofratio,µ,increases thecostdecreasesfordifferentgradesofsteelexceptforFe 250.

Theanalysisanddesignof113RCPortalframessupporting RC slab,the following conclusions could be drawn. As the spanoftheframeincreases,thecostperunitareacoveredin planalsoincreases Whenthespacingbetweenframesis5m thecostperunitareacoveredistheleastforallspansofthe frames.AstheratioofI1/I2increases,thecostgetsreduced asshown

e ISSN: 2395 0056

p ISSN: 2395 0072

[1] Abobak,AA,AgaFathelrahman&DamMA2015,‘Design optimization of Reinforced concrete Frames Open’, JournalofCivilEngineering,vol.5,pp.74 83.

[2] ACI Committee 318, Building Code Requirements for Reinforced Concrete, American Concrete Institute, Detroit2005.

[3] AdelAl Assaf,Hassan,S&Saffarini2004,‘Optimization ofslabsusingobjectorientedprogramming’,Computers andStructures, vol.82,pp.741 752.

[4] Akin, A & Saka, MP 2015, ‘Harmony search algorithm based optimumdetailed design of reinforced concrete plane frames subject to ACI 318 05 provisions’, ComputersandStructures,vol.147,pp.79 95.

[5] Andreas Guerra & Panos D Kiousis 2006, ‘Design Optimization of reinforced concrete structures’, ComputersandStructures,vol.3no.5,pp.313 334.

[6] Ashhad Imam, Fatai Anifowose & Abul Kalam Azad 2015, ‘Residual strength of corroded reinforced concrete beams using an adaptive model based on ANN’, International Journal of Concrete Structuresand Materials,vol.9,pp.159 172.

[7] Ashok K Jain 2010, ‘Reinforced concrete Limit state design’,NemChand&Bros,Roorkee.

[8] Bandyoadhyay,JN2010,‘DesignofConcreteStructures’, PHILearning,NewDelhi.

[9] CoelloCoello,CA,Christiansen,AD&SantosHernández, F 1997, ‘Asimple genetic algorithm for the design of reinforced concrete beams’, Engineering with Computers,vol.13,no.4,pp.185 196.

[10] DaneMiller,Jeung Hwan&DohMitchellMulvey2015, ‘Concrete slab comparison and embodied energy optimization for alternate design and construction techniques’,ConstructionandBuildingMaterials,vol.80, pp.329 338.

[11] Davis,L1991,‘HandbookofGeneticAlgorithms’,Van NostrandReinholt,NewYork.

[12] Deb,K2000, ‘An efficientconstrainthandlingmethod for genetic algorithms, Computer Methods in Applied Mechanics andEngineering',vol. 186,pp.311 338.

[13] EN1992 I I and EN1992 I 2, EUROCODE 2: Design of concrete structures design of concrete structures generalrulesandrulesforbuildingsandstructuralfire design.

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

[14] Fadaee,MJ&Grierson,DE1996,‘Designoptimizationof 3D reinforced concrete structures’, Structural Optimization,vol.12,pp.127 134.

[15] IS456:2000,CodeofPracticefoePlainandReinforced Concrete,BureauofIndianStandards,NewDelhi.

[16] Kaveh,A.&Behnam,AF2013,‘DesignOptimizationof RC3Dstructuresconsideringfrequencyconstraintsviaa chargedsystemsearch’,vol.20,no.3,pp.387 396.

[17] Krishnaraju, N 2009a, ‘Advanced Reinforced concrete design’,CBSPublishersandDistributors,NewDelhi.

[18] Krishnaraju,N2009b,‘Reinforcedconcretedesign’,CBS PublishersandDistributors,NewDelhi.

[19] Luisa Maria Gil Martin 2010, ‘Optimal Design of RC Columnsforbiaxialbending’,MaterialsandStructures, vol.43,pp.1245 1256.

[20] Mahomoud Maher Jahjouh 2012, ‘Design of Reinforcement Concrete frames using ABC’, Project Report.

[21] Manickarajah, D, Xie, YM & Steven, GP 2000, ‘Optimisationofcolumnsandframesagainstbuckling’, ComputersandStructures,vol.45,pp.45 54.

[22] Matej Leps & Sejnoha S 2003, ‘New approach to optimization ofreinforcedconcretebeams’,Computers andStructures,vol.81,pp.1957 1966.

[23] Nilson Darwin & Dolan 2004, ‘Design of Concrete Structures’,McGraw Hill,13th Edition,NewDelhi.

[24] Punmia, BC, Ashok K Jain & Arun Kr Jain 2007, ‘Limit state design of reinforced concrete’, Lakshmi Publications,NewDelhi.

[25] Ricardo Perera & Javier Vique 2009, ‘Strut and tie modelling of reinforced concrete beams using genetic algorithms optimization’, Construction and Building Materials,vol.23,pp.2914 2925.

[26] RicardoPerera,DavidTarazona,AntonioRuiz&Andrés Martín 2014, ‘Application of artificial intelligence techniques to predict the performance of RC beams shearstrengthenedwithNSMFRProdsFormulationof designequations‘,ComputersandStructures,vol.66,pp. 162 173.

[27] Sankhadeep Chatterjee, Amira S Ashour, Sarbartha SarkarValentinaEBalas,SirshenduHore&NilanjanDey 2017, ‘Particle swarm optimization trained neural networkforstructuralfailurepredictionofmultistoried RC buildings’, Neural computing and applications, vol.28,pp.2005 2016.

e ISSN: 2395 0056

p ISSN: 2395 0072

[28] Se Woon Choi 2017, ‘Investigation on the seismic retrofit positions of FRP jackets for RC frames using multi objectiveoptimization’,Computersandstructures, vol.83,pp.34 44.

[29] Sinan Melih Nigdeli & Gebrail Bekdas 2017, ‘Optimal design of RC continuous beams considering unfavourable live load distributions’, KSCE Journal of CivilEngineering,vol.21,pp.1410 1416

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008