International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1

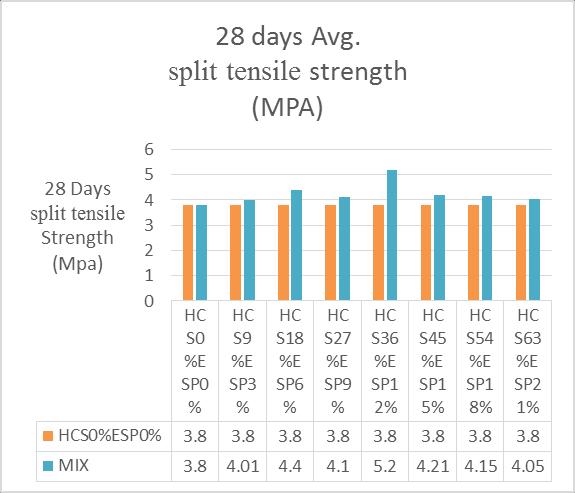

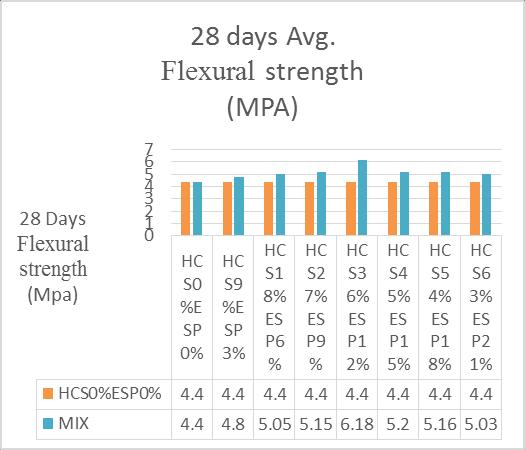

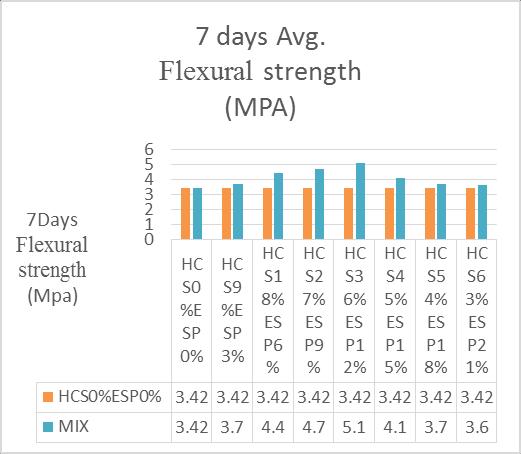

Abstract: In recent years the construction industry throughout the world has supports initiatives to improve sustainabilitybyincreasingtheuseofrecycledaggregatesin concrete production. This is mainly because of the consumption of quality primary aggregates and some quarters, greater awareness of environmental protection. The industrial waste contains many inorganic and toxic substances far away the acceptable limit which cause an impactontheenvironment.Scarcityoftheconst.materials usedthenaturalresourceslikesandaggregatesandstone aggregate.Thepartialreplacementofaggregatesisneedfor the future generation of concrete structures for the environment supportable. The depletion of the natural resourcesgetsexhausted.Wehavethinkoverthealternate replacement of the materials. In present work the partial replacementoftheEggshellpowderwiththeCementand the coarse aggregates is partially replaced by the high performancerecycledconcretesleepers.Optimumvalueof strength in compression, split tensile and flexure came at HCS36%ESP12%replacementoftheEggshellpowderwith theCementandthecoarseaggregatesispartiallyreplaced by the high performance recycled concrete sleepers. The workability of mixture increases and after that there is decreaseintheworkabilityoftheconcretewhenweincrease thepercentageofESP.Aseriesofexperimentwerecarried out to measure the compressive strength, split tensile strengthandflexural strengthoftheconcrete. The results showedthatthecompressivestrength,splittensilestrength andflexuralstrengthincreaseswiththeaddingofthehigh performanceconcretesleepersandEggshellpowder.

Keywords: EPS (egg shell powder), HCS (High performance recycled concrete sleepers), workability, compressive strength, Split Tensile strength, Flexural strength.

AccordingtoEuropeanUnionstatisticsfrom2012onwards, constructionhadbecometheindustrialsectorproducingthe highestamountsofwaste.Forlast20yrs,thecognizanceof govt.andpublicinstitutions oftheimportanceof recycled Const.andDemolitionWaste(C&DW)hasincreased.Forall evolvenewstandardsanddirectiveframeworkstocutback, theC&DWdisposalinlandfills,therecyclingratiosarestill

insufficient, particularly in southern European countries. The on site recycling of demolition materials is the most competentprocessofreducedlandfillandnaturalaggregates intake, as well as reducing transportation costs and detrimentalenvironmentalaffect.Severaltypesofrecycled aggregates could be received from C&DW. The ascendant constitution of concrete particles in RCA avert the higher sulphatecontents&lowerdensitieswhichnormallycaused by the presence of gypsum and masonry particles. Nonetheless, most properties of the RCA are poorer than these of natural aggregates, particularly the properties of water absorption, porosity and crushing value due to old mortar attached to the aggregates. If we talk about egg production then India comes at the fifth position with an annual rate of egg production amounts at 1.61 million tonnes. Both poultry and egg processing units have come predominantly in India. Andhra Pradesh stands at the top among all eggshell producers in India. The maximum egg productioninAndhraPradeshaccountsforonethirdofthe country’sdailyproductionof5.5croresoftheState’stotal production, nearby districts accounted for 3 crore eggs a day,HyderabadatoneandhalfcroreandTelanganadistrict produced40lakh.Hyderabadisthecitywiththemaximum numberofpoultriesandhatcheriesinAndhraPradesh.The stateischeeringupthelargeplayersinthepoultryandmeat sector to achieve an annual growth rate of 6% in egg production,10%inBroilerproduction,and2.5%inmeat production for the next 20 years. India exports eggs, egg powder, albumin powder, and frozen egg yolk to Europe, Japan,andothercountries.

Natural river sand is incorporated as fine aggregate. Aggregatetestresultsgivesspecificgravitywithvalueof2.60 andabsorptionratiowithavalueof0.95%.Thesizeofthe riversandiswelldispensedthemidpointofthelowerand upper limit of the gradation test requirement in Korea standards. Crushed granite is used as natural coarse aggregate(NA)withthespecificgravityof2.72andthewater absorptionratioof0.37.Thematerialpropertiesofnatural aggregates.Theconcretesmixturestestedanteriortosleeper production,inordertocheckthattheymeettheneedsofthe Spanishrailwaytechnicalspecification.Allconcretemixtures

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2904

Atul Sharma1, Sourabh Lalotra2 PG Scholar, Sri Sai College of Engineering and Technology, Pathankot, India 2 Assistant Professor, Sri Sai College of Engineering and Technology, Pathankot, India ***International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net p ISSN: 2395 0072

wasproducedinSpanishprecastconcreteplant.Thenatural aggregate concrete were that already used in HPC for the productionofprestressedconcretesleepers,accordinglyto theFuller’sdosagemethod.Inordertocontroltheconcrete output,therecycledaggregateswerenearlysaturated,at80 90%oftheirwaterabsorptioncapacity.

IfwetalkabouteggproductionthenIndiacomesatthefifth positionwithanannualrateofeggproductionamountsat 1.61milliontonnes.Bothpoultryandeggprocessingunits havecomepredominantlyinIndia.AndhraPradeshstandsat thetopamongalleggshellproducersinIndia.Themaximum eggproductioninAndhraPradeshaccountsforonethirdof the country’s daily production of 5.5 crores of the State’s totalproduction,nearbydistrictsaccountedfor3croreeggs a day, Hyderabad at one and half crore and Telangana district produced 40 lakh. Hyderabad is the city with the maximum number of poultries and hatcheries in Andhra Pradesh. The state is cheering up the large players in the poultryandmeatsectortoachieveanannualgrowthrateof 6%ineggproduction,10%inBroilerproduction,and2.5% inmeatproductionforthenext20years.Indiaexportseggs, eggpowder,albuminpowder,andfrozeneggyolktoEurope, Japan,andothercountries.Tamilnaduisatthenumberone positionintheeggproductionfollowedbyAndhraPradesh whichisatsecondpositioninIndia.TamilNadu,withashare ofaround20percentwithabouttwothousandcroreeggs produced in the state each year. Maharashtra, Haryana, Punjab, and West Bengal are other leading egg producing statesinIndiabuteachhasashareoflessthan10percentof the total egg produced in India. The Namakkal district in Tamil Nadu is India's egg export hub and accounts for around90%ofIndia'stotaleggexports.

S. K. Singh P. C. Sharma (2012) Thispapershowsthe experimentalresultsofrecycledcoarseaggregateconcrete& resultsaredifferentiatewiththenaturalcrushedaggregate concrete. The fine aggregate used in concrete, i.e. recycled and received is hundred percent natural. For both type of concretei.e.M 20andM 25,watercementratio,max.sizeof aggregateandmixedportionarekeptconstant.Theevolution ofcompressivestrengthofrecycledaggregateconcreteatthe ageof1,,3,7,14,28,56,and90days;theevolutionoftensile& flexuralstrengthattheageof1,3,7,,14andstaticmodulusof elasticityattheage of28days arelook into it. The results showed the compressive, tensile and flexural strengths of recycledaggregateareaverage85%to95%ofthenatural aggregateconcrete.Thestrengthparametersarelookintofor recycledaggregateconcreteandfoundtobegoodagreement withBISspecifications.

aggregate to met durabilityand strength requirements for different apps. Aggregate strength, gradation, absorption, specificgravity,shapeandtexturesaresomeofthephysical& mechanical characteristics that bring to the strength and durabilityofconcrete.Therefore,theexperimentalprogram thedevelopmentofphysicalandmechanicalpropertiesofthe recycled aggregate over a period of 6 months. In adding, concrete properties it produced fine & coarse recycled aggregatewasassess.Severalconcretemixeswereprepared with 100 % recycled aggregates and the results was compared to control mix. SEM w start to study the microstructure of selected mixes. The results showed the concrete with received strength and durability can be producedifhigherpackingdensityisachieved.

AndrewGonzalez(2016) A analysis of the structural behavior of prestressed concrete sleepers make with high performance concrete, and high performance recycled aggregate concrete(HPRAC) is present in this study. Two types of HPRAC, sleepers tested, using 50 and 100% of recycled concrete aggregate (RCA) is replaced of coarse naturalaggregates.TheRCAworkedintheresearch,sourced from crushing refuse HPC sleepers. The aim of study is to ascertain through analysis the HPRAC sleepers behaviour satisfied the European min. requirements of std. for prestressed concrete sleepers and compares there experimentalbehaviourswiththatoftheHPCsleepers.The threetypesofprestressedconcretesleepersweresubjected tostaticloadtestsatrail seatandcentresection(positive andnegativeload.Inthecentresectiontestsacomparatively study b/w the experimental results and the values of four assessmentmethodsofcrowningcapacitycarriedout.

Amarnath Yerramala Et.Al., (2014) studied the Properties of concrete with eggshell powder as cement replacement, and showed the Compressive strength was higherthancontrolconcretefor5%ESPreplacementat7 and28daysofcuringages.Splittensilestrengthconcreteup to10%withESPreplacement

DohShuIngAndChinSiewChooEtAl.,(2014) carried outaninvestigationoneggshellpowderaspotentialadditive to concrete, showed aninclusion of eggshell powder in concretehasimprovedthecompressivestrengthofconcrete andwithadditionof10%eggshellpowderinM25Gradeof concrete

SyedSaadAli,et.al2019: Inthisstudy,testwasdoneon concretewithpartialreplacementofcementwithESPinthe proportionof(0 20%)andfineaggregatewithCopperscum (0 20%). Slump cone value for the copper slag and ESP increases with increasing in the percentage of ESP and copperslagsotheconcretewasnotworkable.Thevalueof theCompactionfactortestaboutcopperslagandeggshell powder decreases with increase in the percentage of both copper slag and ESP in the concrete. The compressive strength of concrete is find out to be optimum at 10% replacementofcopperslagandeggshellpowderandisthe

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net p ISSN: 2395 0072

optimumvalueafter7dayscuringand28dayscuring.The splittensilestrengthofconcreteisfindouttobeoptimumat 15%replacementofcopperslagandeggshellpowderfor28 days curing in M30 grade concrete and maximum at 10% replacementofcopperslagandeggshellpowderfor28days curing.So,thereplacementof10%to20%ofcopperslagand eggshellpowderisusefulforbetterstrengthvaluesinM30 gradeofconcrete.

3.1 CEMENT OPCisthemostordinarytypeofcementis generallyusedaroundtheworldasperbasicingredientsof concrete, mortar and mostly no specially grout. It is a fine powderproducedbyheatingmaterialstoformclinker.After grindingtheclinker,wewouldaddsomesmallamountsof remainingpartsofingredientsItcomestodifferentgradesof cement,the53GradeOPCCementprovidesfrequentlyhigher strength compared to others. As per the Bureau of Indian Standards(BIS),thegradeno.ofacementhighlightsthemin. compressive strength that cement is expected to attained within 28 days. For 53 Grade OPC Cement, the min. compressivestrengthachievedbythecementattheendof the28thdayshouldn’tbelessthan53MPaor530kg/cm2.

3.2FINEAGGREGATES Aggregatesconsistsoftwotypes, fine aggregates and coarse aggregates. Fine aggregates consistsofnaturalstoneorcrushedparticlespassingthrough 4.75mmsizesieve.Aggregateswhichaccountforone third percentageofthetotalvolumeofconcrete,aredividedinto twoseparatecategories fineandcoarse.Naturalgraveland sandaretypicallydugordredgedfromapit,river,lake,or seabed.Thecrushingofbigboulders,cobbles,quarryrock, and large size gravel also produces crushed aggregate. Aggregatesstronglyinfluenceconcrete'sfreshlymixedand hardened properties, mixture proportions and economy. Thereisalthoughalwaysavariationofaggregateproperties is expected, characteristics include durability, grading, particle shape and surface texture, abrasion and skid resistance, unit weights and voids, absorption and surface moisture.

3.3 COARSE AGGREGATES Theparticleswhichretainson the sieve and are larger than 4.75mm are referred to as coarse aggregates. For making a good mix of concrete aggregatesneedtobehard,cleanandstrongparticleswhich are free of coatings of clay or any absorbed chemical and other fine materials that could cause the deterioration of concrete.Coarseaggregatesareroundedorirregulargravel stones.Itconstitutethemajorityofcoarseaggregateusedin concrete with crushed stone making up most of the remainder.Coarseaggregatesshouldbecarefullyhandledto avoiddirtcontamination.Itshouldbecleananddry.

S.NO. PROPERTIES VALUES

1. Specificgravity 0.011 2. Bulkdensity 6.86kg/m3 3. Particlesize(spherical) 4 8mmdia

Table 1: Properties of epsbeads

3.5 HIGH PERFORMANCE RECYCLED AGGREGATES

SpecificGravity 2.48 AbsorptionCoefficient 4.53 LAAbrasionCoefficient 32.2

Table 2: Physical properties of HPRC

4.1 CASTING In order to test compressive strength of concrete,concretespecimensofstandardcubicalmouldof size150*150*150mmwerecastedinelevendifferentbatches having different replacement percentage of Rice Husk Ash andESP.Thespecimenusedforthistestiscylindricalandits dimensionis150mmindiameterand300mminlength.The testismadeonthebeamofsize700mm×150mm×150mm.

4.2 CURING all the materials when mixed adequately to achievehomogeneousmixture.Aftermixingtheconcretewas checked for required slump and then filled into moulds of requiredtests.Themouldfilledwithconcretewascompacted by table vibrator to achieve proper compaction. Mould surfacewasfinishedwithtrowelanddateofcastingwithmix designationnumberismarkedonit.Theconcretespecimens were then removed from moulds after 24 hours and then placedincuringtanksforcuringprocessfor7and28daysat normalroomtemperature.

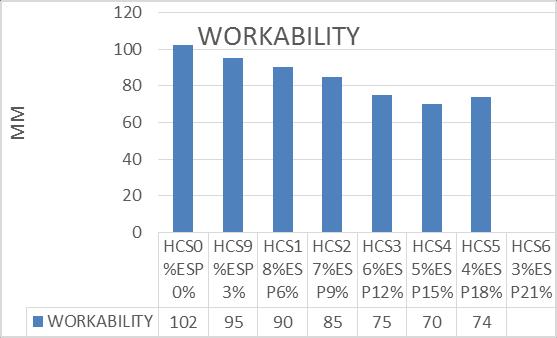

4.3SLUMPCONETEST Itcanbeusedinsiteaswellasinlab. This test is not applicable for very low and very high workabilityconcrete.Itconsistsofamouldthatisintheform offrustumhavingtopdiameterof10cm,bottomdiameterof 20cmandheightof30cm.Theconcretetobetestediffittedin the mould in four layers. The each is compacted 25 times withthehelpoftampingrod.Afterthemouldiscompletely filled it is lifted immediately in the vertically upward directionwhichcausestheconcretetosubside

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net p ISSN: 2395 0072

Fig-1: SLUMP CONE TEST

Thenfreshconcreteisfilledinmouldin4layersandafter fillingeachlayertampingshouldbedone35timesincaseof cube and 25 times in case of cylinder by using standard tamping rod. Once the mould is filled then leveled top surfaceofconcretewithtrowel.Afterthedaythemouldwill removedandspecimenaredroppedinthecuringtankunder standardtemperatureof27±2°c.After7and28daysinthis research

4.5

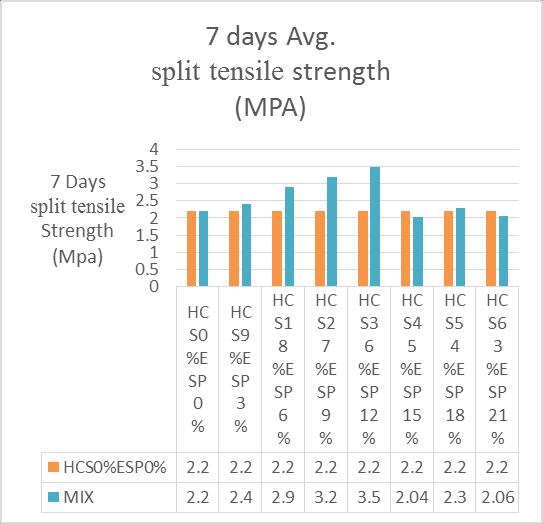

The specimen used for this test is cylindrical and its dimensionis150mmindiameterand300mminlength.The instrumentusedforthistestingisuniversaltestingmachine. Thefreshconcreteispreparedinaccordingtotherequired gradesandrespectivemixproportion.Thefreshconcreteis filled in mould in layers and each layer is tamping with standardtampingrodwith25blowsforeachlayer.Afterthe day the mould is removed and specimen is placed in the curing tank for 7 and 28 days in this research at the temperature27+2°c.Thendrawthelineonthespecimen

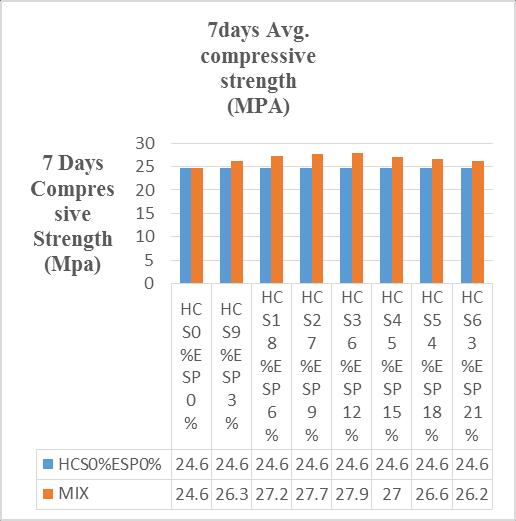

Fig 1: COMPRESSIVE STRENGTH TEST 7days

Fig 3 SPLIT TENSILE STRENGTH 7 days

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net p ISSN: 2395 0072

Theconcreteispreparedatrequiredrateofmasselement the mould is filled with concrete in layers and blows 25 timeswithstandardtampingrod.Afterthedayorwecansay 24hoursthemouldisremovedandspecimenplacedinthe water tank for curing at a temperature of 27 + 2 C. depending upon the requirement the test specimen is removedfromthewatertankandwipeitproperlyfor7and 28daysfortesting.

Fig -6 FLEXURAL STRENGTH 28 days

TheoutcomeofworkabilitybySlumptestmethod concludedthatworkabilityreduceswithincreasing % age of Railway concrete sleepers and Egg shell powder.Thismaybe dueto waterdemandraises withraising%ageofESP.

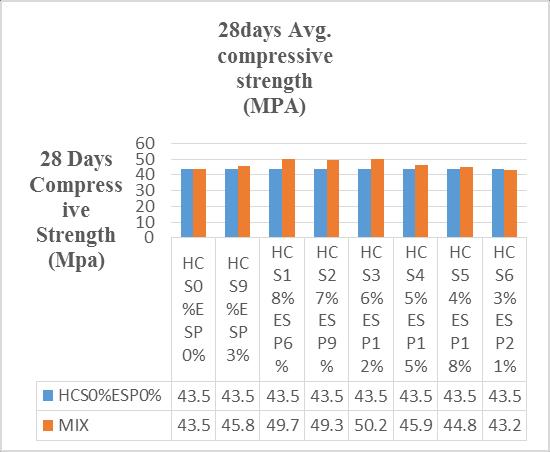

The Compressive strength results show that by partial replacement of the Egg shell powder with the Cement and the coarse aggregates is partially replacedbythehighperformancerecycledconcrete sleepers,thereisincreaseincompressivestrength butaggregatesinhighervolumedecreasesstrength. After Railway concrete sleepers and Egg shell powder volume addition and replacing Cement, thereisdecrementofcompressivestrength.

The excellent substitution % age of Railway concretesleepersandEggshellpowderintermsof strength and economy is HCS36%ESP12%. The valueofcompactionstrengthobtainedatoptimum percentage substitution is 50.20MPA which is 15.4023%higherthannormalMix.

The split tensile strength and flexural strength or modulusofruptureshownsamenatureasthatof compressivestrengthortoughnessstrength

TheuseofRailwayconcretesleepersandEggshell powder in civil engineering works will reduce environmental pollution, upgrade quality of concrete,andreduceitscostofproduction.

The partial replacement of the Egg shell powder with the Cement and the coarse aggregates is

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net p ISSN: 2395 0072

partiallyreplacedbythehighperformancerecycled concrete sleepers has shown +ve impact on split tensilestrengthuptoHCS36%ESP12%substitution.

Thehighestvalueoftensilestrengthwasobtained atHCS36%ESP12%replacementwhichis5.2Mpa.

Research Online A Peer Reviewed International Journal Articlesavailableon Vol.3.,Issue.4.,2015 (July Aug)

The flexure strength also showed maximum strengthwhenHCS36%ESP12%isbeingreplaced bypartialreplacementoftheEggshellpowderwith the Cement and the coarse aggregates is partially replacedbythehighperformancerecycledconcrete sleepers,increasedthestrengthis6.18MPAat28th day.Bothhelpinincreasingstrengthatlowvolume replacement

7) M.Bharathet.al(2018) ExperimentalInvestigation onMechanical&DurabilityofConcreteContaining fly ashandESPin:InternationalResearchJournalof Volume:05Issue:03,Mar 2018

8) Anzar Hamid Mir (2015) Improved Concrete Properties Using ESP as substitution for Natural Sand in: International Journal of Engineering Research and Development in Volume 11, Issue 03:(March2015),PP.46 52.

The excellent of favourable substitution % age of RailwayconcretesleepersandEggshellpowderin terms of strength at 28 days and economy is HCS36%ESP12%.

1) S.kSingh,P.CSharma,Useofrecycledaggregatesin concrete.2012,NBM&InfraConstruction& EquipmentMagazine.

2) Amit kumar Raval,Dr.Inderjit n.patel,Dr.jayesh kumarPitroda.Effectivereplacementofcementfor establishing sustainable concrete,Interantional journal of engineering trends and technology(IJETT) volume4issue6 june2013

3) Francisco Carrion, Mechanical and Physical Properties of Polyester Polymer Concrete UsingRecycledAggregatesfromConcreteSleepers, ScientificWorldJournal, 2014; 2014: 526346.Published online 2014 Aug 27. doi: 10.1155/2014/526346

4) Sheriff Yehia,Kareem helal,Anaam Abu Sharakh,Amani Zaher(2015),Strength and durability evaluation of recycled aggregate concrete, International Journal of Concrete Structures and Materials volume 9, pages219 239(2015).

5) MdDaniyal,ShakeelAhmad(2015), Applicationof werete ceramic tile aggregates in concrete, International Journal of Innovative Research in Science,EngineeringandTechnology(AnISO3297: 2007 Certified Organization) Vol. 4, Issue 12, December2015.

6) P.K.ROY,DEVANSHJAIN,VIJAYMESHRAM(2015) USE OF ELECTRONIC WERETE AS A PARTIAL REPLACEMENT OF COARSE AGGREGATE IN CONCRETE , International Journal of Engineering

9) TEXT BOOK Shetty M. S., (2013), "Concrete Technology Theory and Practical", S.Chand Publishing.

10) IS456 2000,IndianStandard,PlainandReinforced Concrete codeofpractice.

11) IS 383 1970, Indian Standard Specification for CoarseandFineAggregatesfromNatural Sources forConcrete.

12) IS 10262 2009, Indian Standard Recommended GuidelinesforConcreteMixDesign

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |