International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

1

Abstract: This research has been done to find out the maximum percentage of Alccofine as partial cement ReplacementandCopperSlagaspartialreplacementoffine aggregate.Theconstructionindustriesareinthesearchto find alternative products that can reduce the cost of construction.Demandforcementhasbeengrowingevery day. In this Research, different Alccofine concretes were developed by replacing 0 18% of Alccofine for cement as practicalalternativeinplaceofotherhydraulicmaterials.By using it as an replacing material in form of Alccofine and copperslaginconventionalconcretewithgradeM50,asitis normallyusedinconstructionsites.Copperslagisoneofthe waste materials which can be a promising future in the constructionindustryasapartialorfullsubstituteofeither cementoraggregatesjustbecauseofitsphysicalsimilarity to the fine aggregates. For each ton of copper production, about2.2tonsofcopperslag.Thisslagiscurrentlyusedfor many purposes like landfilling, construction of abrasive tools, roofing granules, cutting tools, and railroad ballast material,whicharenotveryhigh value addedapplications. TheCopperSlagisreplacedwithsandinthepercentageof 0%to66%.ResultshowsthattheAlccofineandcopperslag replaced with Cement show positive results. Workability reduceswithincreasing%ageofAlccofineandcopperslag. Themaximumproportionofreplacementhasbeenfoundby conducting the following strength tests: Compressive strength test, Flexural strength test and Split Tensile StrengthTest

Keywords: ALCCOFINE, Copper Slag, Compressive Strength,SplitTensileStrength,FlexuralStrength

Concreteisthegraduallyuseddevelopmentmaterialinthis planet. Globally its consumption is approximately two tonnesperyear.Itisthebackboneofeverycountryforits development work. The quality being used here may experience diverse revolution ozen egg yolk to Europe, Japan,andothercountries.Itrangesfrom60to100N/mm2. This type of concrete can resist high loads that normal strengthconcretecannot.Themainapplicationsthatarein situ concrete construction in columns are multi storey

***

buildings,offshorestructures,bridgeshavinglongerspan& highway structures. Higher strength could be attained by makingoptimumusebyfundamentalingredientsthatadds upthematerialrequired.Moreover,theselectionofthegood quality materials, water cement ratio, gen admixtures are requiredforthedevelopmentofHSC.ACIhasdefinedHPCin which a high quality concrete is made by appropriate materialsacc.tomixdesign;properlymixed,transportedat site, placed and compacted and cured so that it gives outstandingperformancevizconventionalconcrete.

Theoptimumuseofindustrialwasteorsecondarymaterial hasstrengthentheproductionofcementandconcreteinthe constructionfield.Therearenumberofnewbyproductsand waste materials are generated by various industries on a largescale.CSalsodemonstratespozzolanic.Theutilization of CS substitution as cement replacement in concrete, for instance,ordinaryPortlandcementsubstitutioninconcrete, or the dual benefit of eliminating the cost of disposal, and loweringthecostoftheconcrete

Alccofineisanewgeneration’smuchawaitedmaterialwhich is much finer then most of other materials used in constructionworkthatareusedinourcountry.Ithasrare propertytoimprove&maintaintheperformanceofconcrete inallstagesrangesfromfreshtohardenedone.Itcouldbe used as practical alternative in place of other hydraulic materials.Itismainlymanufacturedinsomekindofspecial conditionswiththehelpofsomespecialequipmentthatare usedtomanufacturethedesiredsizeofparticledistribution thatisitsrarestproperty.Alccofine1203andAlccofine1101 is of 2 different kinds which has different property from other respectively. GGBS is a non metallic creation comprising basically of aluminates and silicates & other bases

PJ. PATEL. et al, 2013 Did the detail study on compressive & flexural Strength of High Performance

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net p ISSN: 2395 0072

Concreteincludingalccofineaswellasflyashalso.Trialof comp.strengthwasdoneforalmost90daysasuppermost comp.strengthachievedwas78.58N/mm2formix,whichis morethanaimedstrength.Gainingupto7dayswasexcellent in every proportions, b/w 7 days to 28 days as gaining of strengthiscomparativelyless,butb/w28daysto56days gainingofstrengthmorebecauseoffly,ash.Slumpcameout tobeextrathen150mmforeach&everymixtures.

In August 2014, Praeen Nayak S. et, al. comparedthe concretepropertywhicharein hardenedstage madewith mixtureofS.F.&alccofine&stagingidealtechniquewasused forcomparablestudy.Thestudywhichdonestatesthatthe compressive&flexuralstrengthofalccoofinemixturewith concretewasfarbetterthenmicro silicamix.Effectivenessof micro silica mixture turned out to be merely higher to alccoofine.

Al-Jabri, K.S., Abdullah, H., Al-Saidy and Ramzi Taha (2011) hasdonetheirresearchstudyontheEffectofcopper slagasafineaggregateonthepropertiesofcementmortars andconcreteandobservedmorethan70%improvementin thecompressivestrengthofmortarswith50%copperslag substitution in comparison with the control mixture and observed almost5%increaseintheconcretedensity,when copper slag was used as a sand replacement, whereas the workability increased substantially with an increase in copperslagcontentandfinallycomeintotheconclusionsthat thecopperslagintherangeof40 50%,canreplacesandin concretemixtures.

Deval Soni et, al. (2013) performed&lookoutonHPC (HighPerformanceConcrete),developedbycombinationof alccofine&flyashinidealproportion.Thestudycametoend thatthemixingof8%alccofine&16%flyashwasdiscovered outtobeanidealproportionofH.P.C.Alccofinewasfoundto havebetterpresentationaswellasworkabilitywhencollate toothersupplementarycementitiousmaterialssuchasmicro silica,GGBFSetc.

3.1 CEMENT OPCisthemostordinarytypeofcementis generallyusedaroundtheworldasperbasicingredientsof concrete, mortar and mostly no specially grout. It is a fine powderproducedbyheatingmaterialstoformclinker.After grindingtheclinker,wewouldaddsomesmallamountsof remainingpartsofingredientsItcomestodifferentgradesof cement,the53GradeOPCCementprovidesfrequentlyhigher strength compared to others. As per the Bureau of Indian Standards(BIS),thegradeno.ofacementhighlightsthemin. compressive strength that cement is expected to attained within 28 days. For 53 Grade OPC Cement, the min. compressivestrengthachievedbythecementattheendof the28thdayshouldn’tbelessthan53MPaor530kg/cm2. The color of OPC is grey color and by eliminating ferrous oxideduringmanufacturingprocessofcementwewouldget

value:

whitecementalso.OrdinaryPortlandcement(OPC)ofgrade 43ofbrandUltraTechwillbeusedforallconcretemixes.

3.2 FINE AGGREGATES Naturalsandisbeingusedhere as fine aggregate. Source of natural aggregates was local villagenearbytothesiteoftesting.Todeterminethezoneof sand,Sieveanalysiswillbedoneasperrecommendedinthe IScode.Tofindthepropertiesofnatural sandlikespecific gravity,finenessmoduluswerealsocarriedout.

3.3 COARSE AGGREGATES Theparticleswhichretains onthesieveandarelargerthan4.75mmarereferredtoas coarseaggregates.Crushedaggregates,angularinshapeare utilizedhere in experimental work.Coarseaggregate &its gradingisbeingdonehereasaccordinglygiveninIS:383 1970.Aggregateofsize10mmareused.Thewaterabsorbing &SpecificgravityofaggregateisalsocarriedoutasacctoIS 2386(PART 3) 1963. 3.4 COPPER SLAG

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net p ISSN: 2395 0072

checked for required slump and then filled into moulds of requiredtests.Themouldfilledwithconcretewascompacted by table vibrator to achieve proper compaction. Mould surfacewasfinishedwithtrowelanddateofcastingwithmix designationnumberismarkedonit.Theconcretespecimens were then removed from moulds after 24 hours and then placedincuringtanksforcuringprocessfor7and28daysat normalroomtemperature

4.3 SLUMP CONE TEST Itcanbeusedinsiteaswellasinlab. This test is not applicable for very low and very high workabilityconcrete.Itconsistsofamouldthatisintheform offrustumhavingtopdiameterof10cm,bottomdiameterof 20cmandheightof30cm.Theconcretetobetestediffittedin the mould in four layers. The each is compacted 25 times withthehelpoftampingrod.Afterthemouldiscompletely filled it is lifted immediately in the vertically upward directionwhichcausestheconcretetosubside

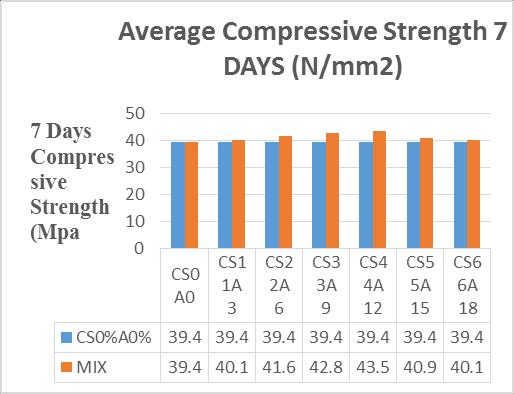

Fig 2: COMPRESSIVE STRENGTH TEST 7 days

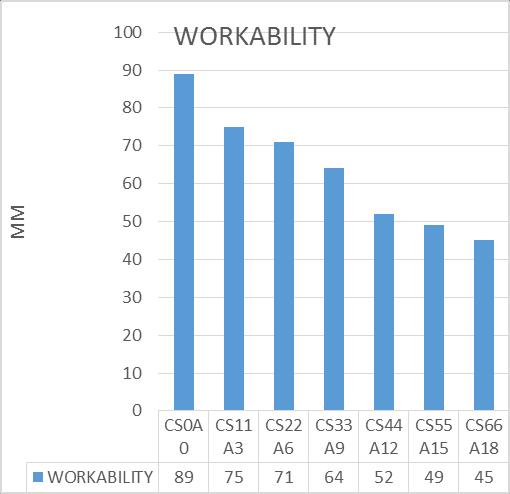

Fig 1: SLUMP CONE TEST

Thenfreshconcreteisfilledinmouldin4layersandafter fillingeachlayertampingshouldbedone35timesincaseof cube and 25 times in case of cylinder by using standard tamping rod. Once the mould is filled then leveled top surfaceofconcretewithtrowel.Afterthedaythemouldwill removedandspecimenaredroppedinthecuringtankunder standardtemperatureof27±2°c.After7and28daysinthis research.

The specimen used for this test is cylindrical and its dimensionis150mmindiameterand300mminlength.The instrumentusedforthistestingisuniversaltestingmachine. Thefreshconcreteispreparedinaccordingtotherequired gradesandrespectivemixproportion.Thefreshconcreteis filled in mould in layers and each layer is tamping with standardtampingrodwith25blowsforeachlayer.Afterthe day the mould is removed and specimen is placed in the curing tank for 7 and 28 days in this research at the temperature27+2°c.Thendrawthelineonthespecimen

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

removedfromthewatertankandwipeitproperlyfor7and 28daysfortesting.

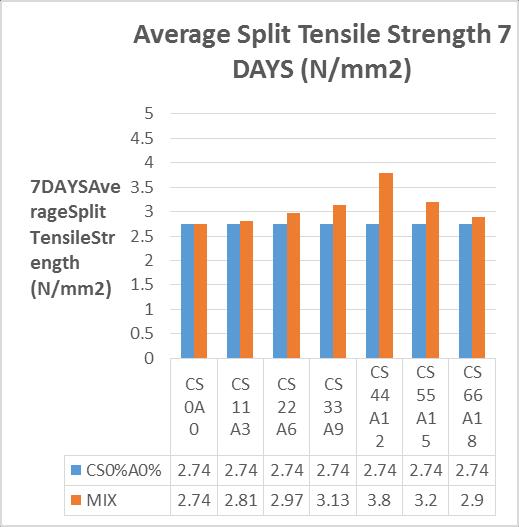

Fig -5 SPLIT TENSILE STRENGTH 7 days

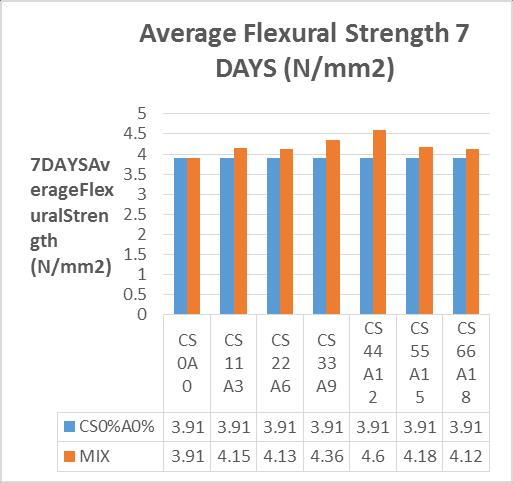

Fig 8 FLEXURAL STRENGTH 7 days

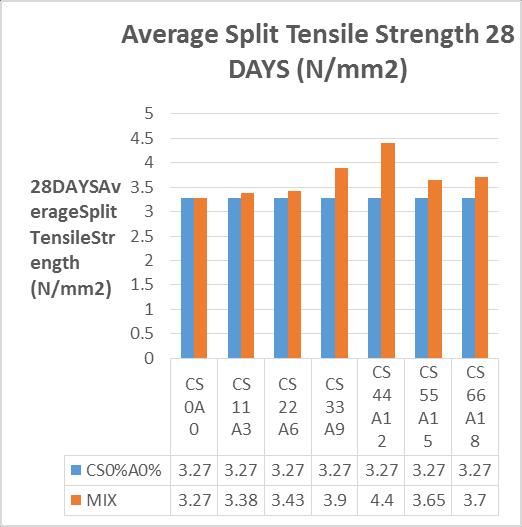

Fig 6 SPLIT TENSILE STRENGTH 28 days

Theconcreteispreparedatrequiredrateofmasselement the mould is filled with concrete in layers and blows 25 timeswithstandardtampingrod.Afterthedayorwecansay 24hoursthemouldisremovedandspecimenplacedinthe water tank for curing at a temperature of 27 + 2 C. Depending upon the requirement the test specimen is

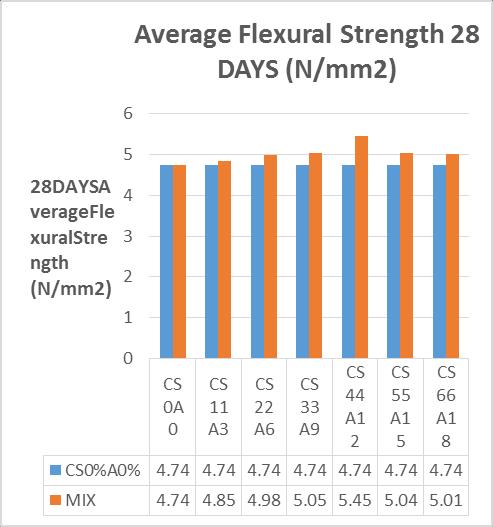

Fig 9 FLEXURAL STRENGTH 28 days

TheoutcomeofworkabilitybySlumptestmethod concludedthatworkabilityreduceswithincreasing %ageofAlccofineBypartialreplacementofcement andcopperslagbyfineaggregates.Thismaybedue

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net p ISSN: 2395 0072

towaterdemandraiseswithraising%ageAlccofine andcopperslag.

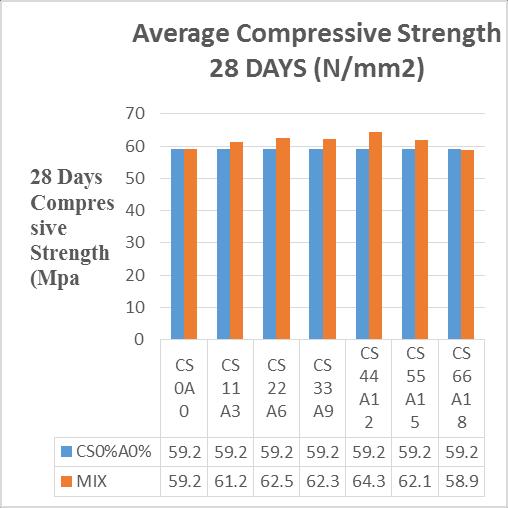

The Compressive strength results show that Alccofine By partial replacement of cement and copperslagbyfineaggregates,thereisincreasein compressive strength but aggregates in higher volume decreases strength. After Alccofine and copperslagvolumeadditionandreplacingCement, thereisdecrementofcompressivestrength.

cement with wood ash for M30 Grade Concrete, 2019IJSRST/Volume6/Issue3

3) Al JabriK.S.,TahaR.A.,Al HashmiA.andAl Harthy A.S.“Effectofcopperslagandcementby passdust addition on mechanical properties of concrete”, Construction and building materials, Vol. 20, pp. 322 331,2006.

The excellent substitution % age of Railway concretesleepersandEggshellpowderintermsof strengthandeconomyisCS44%A12%.Thevalueof Compressive strength obtained at optimum percentage substitution is 64.30MPA which is 8.61%higherthannormalMix.

4) BipraGorai, Jana R. K. and Premchand, “Characteristics and utilisation of copper slag a review”, Resources, Conservation and Recycling, Vol.39,No.4,pp.299 313,2002.

5) Saurabh Gupta, Dr. Sanjay Sharma, Er. Devinder Sharma3 “A review alccofine a supplementary cementitiousmaterial,IJMMTERVol.3

The split tensile strength and flexural strength or modulusofruptureshownsamenatureasthatof compressivestrengthortoughnessstrength

The use of Alccofine and copper slag in civil engineering works will reduce environmental pollution,upgradequalityofconcrete,andreduce itscostofproduction.

6) Saurav,AshokKumarGupta,“Experimentalstudyof strengthrelationshipofconcretecubeandconcrete cylinderusingultrafineslagAlccofine”International Journal of Scientific & Engineering Research, Volume5,Issue5,May 2014102ISSN2229 5518

ThepartialreplacementoftheAlccofineBypartial replacement of cement and copper slag by fine aggregates has shown +ve impact on split tensile strengthuptoCS44%A12%substitution.

7) SiddharthPUpadhyayProf.M.A.Jamnu“Effecton compressivestrengthofhighperformanceconcrete incorporatingalccofineandflyash”ISSN,Volume2 Issue2

8) Yatin Patel, Dr. B.K. Shah, „Study on durability of high performance Concrete with alccofine and fly ash,(1998).IJSRDVol.1Issue(2013)

Thehighestvalueoftensilestrengthwasobtained atCS44%A12%replacementwhichis4.40Mpa.

The flexure strength also showed maximum strength when CS44%A12%is being replaced by Alccofine By partial replacement of cement and copper slag by fine aggregates, increased the strength is 5.45MPA at 28th day. Both help in increasingstrengthatlowvolumereplacement

9) IS456 2000,IndianStandard,PlainandReinforced Concrete codeofpractice.

10) IS 10262 2009, Indian Standard Recommended GuidelinesforConcreteMixDesign.

The excellent of favourable substitution % age of Alccofineandcopperslagintermsofstrengthat28 daysandeconomyisCS44%A12%.

1) KarunKumar,N.Priyanka,Experimentalstudyon propertiesofstrengthanddurabilityofconcreteby partialreplacementoffineaggregateswithcopper slag and cement with wood ash, International JournalofProfessionalEngineeringstudies,Volume VIII/ISSUE4/May2017

2) Syed Saad Ali et al, An experimental study on properties of strength of concrete by partial replacementoffineaggregateswithcopperslagand

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified