International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume:09Issue:05|May2022 www.irjet.net p ISSN:2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume:09Issue:05|May2022 www.irjet.net p ISSN:2395 0072

1Professor, Department of Civil Engineering, Rajarambapu Institute of Technology, Rajaramnagar, India 2,3,4,5,6 Diploma Student, Department of Civil Engineering, Rajarambapu Institute of Technology, Rajaramnagar, India ***

Abstract The amount of Steel slag consumed annually has been growing progressively in utilization.Consequently, slagwasteusagehasbecome one among the main challenges in recent times. The management and usage of slag waste is speedily growing because it may be a valuable resource of industries and its terribly unsafe substances and with low usage rate. The employment of slag waste materials may be a partial answer to environmental and ecological issues, because the use of plastic waste can reduce the mixture value and provides a good strength for the structures. It'll reduces the lowland value and it is energy saving. This study has chosen steel slag waste, to analyse its potential use as slag mixture in concrete application. The waste plastic was utilized in concrete with partial replacement of 21%, 23% and 25% by volume of standard coarse aggregate. The tests were conducted on block prepared with course aggregate, fine aggregate, steel slag, M sand, and cement to their property i.e. compressive strength. 3 varieties of concrete specimens each type 3 blocks, for comparison purpose, were ready. All the concrete specimens were tested for its completely different mechanical properties after a curing period of 7 days. Moreover, it's complete that the utilization of steel slag in concrete provides some benefits like reduction within the use of standard mixture, disposal of wastes, prevention of environmental pollution, and energy saving.

Key Words: Steel slag, fine and coarse aggregate, partialreplacement.

Thewastesfromtheindustriesarethemajorproblem in present condition. The recycling of all waste using recycling unit is economically facing many problems. The main objectives of this study is the partial replacement of Steel slag from the industrials to find the strength of concrete. The main objectives of this study is the partial replacement of Steel slag from the industrials to find the strength of concrete. Highquality slag concrete, which

possess standard shape, sharp edges, smooth surfaces, high durability, and great strength, can be used for temporarystructuralconstructionsuchasroadsprepared duringconstructionwork,parkingtiles,etc.

Steelslagareusedinconcretemixwithdifferentratios.In this process to reducing constructional cost, reducing the environmental pollution and some of the general disposal methodsarereduced.

• Todevelopanalternativebuildingmaterial.

• To determine the compressive strength of concretecontainingslagaggregate.

• To analyses the cost of concrete block using steel aggregate.

• Mix Design and casting methodology may be furtherimprovedandstudiedforfuture.

• Suitable admixture increasing the compressive strengthmaybestudied.

• High quality steel slag concrete, which possess standard shape, sharp edges, smooth surfaces, high durability, and great strength, can be used for temporary structural construction such as roads prepared during construction work, parkingtiles,etc.

• Low quality blocks or poorly mixed blocks are used as aggregate for foundation concrete and road metal works. This is because they can break easilyandnotsuitableforconstructionpurpose.

Theadvantagesofusingslaginaconcretemixare as follows: enhancing the compressive strength of

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume:09Issue:05|May2022 www.irjet.net p ISSN:2395 0072

concrete due to the tendency of slow increase in compressive strength; increasing the ratio between flexibility and compressive strength of concrete; reducing the variation of compressive strength of concrete.

A disadvantage of slag is its greater weight compared to natural rock, and this has an impact on logisticsandtransportcosts.

• High quality slag blocks, which possess standard shape, sharp edges, smooth surfaces, high durability, are often used for permanentstructuralconstruction.

• The Concrete Blocks are employed in many small Landscape Projects. as an example, in Outdoor Seating, Decorative Screen, Outdoor Bar,FlowerBed,manyOutdoorFurniture.

Steel slag can normally be obtained from slag processors who collect the slag from steel making facilities. Slag processors may handle a variety of materials such as steel slag, ladle slag, pit slag, and used refractory material to recover steel metallic. These materials must be source separated, and well defined handling practices must be in place to avoid contamination of the steelslagaggregate.Theslagprocessormustalso be aware of the general aggregate requirements oftheenduser.

Manufactured Sand (M Sand) is sand made from exhaustinggranitestonebycrushing.Thecrushedsand is of cube like form with grounded edges. It is then washed and ranked with consistency to be used as a substitute of river sand as a construction material. Factory made sand is an alternate for river sand, because of quick growing industry, the demand for sand has raise hugely, causing deficiency of appropriate river sand in most part of the globe.

Coarse aggregates are irregular broken stone or naturally occurring rounded gravel used for preparing concrete.Materialsthatarelargetoberetainedon4.7mm sieve size are referred to as coarse aggregates, and its maximumsizewillbeupto63mm.Theymustbewashed well before using in concrete. Aggregate is one amongst theforemostvitalpartcomponentsoftheconcrete.Coarse Aggregates offers volume to the Concrete. Coarse aggregates are used in every Construction projects which includes the development of roads, Buildings, Railway Tracksetc.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume:09Issue:05|May2022 www.irjet.net p ISSN:2395 0072

Cement is a binder, a substance used for constructionthatsets,hardens,andadherestoalternative materialstobindthemtogether. Cementisrarelyusedon its own, however rather to bind sand and gravel (aggregate) along, Cement mixed with fine mixture produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material existing and is behind only water because the planet'smostconsumedresource

The water used for experiments was potable water Fresh portable water free from organic matter and oilisemployedinmixingthepreparationofplasticbricks. Waterinrequiredquantitiesweremeasuredbygraduated jarandaddedtothequarrydustandM sandmix.Therest of the material for preparation of concrete was taken by weighbatching.ThepHvalueshouldn'tbelessthan7.

The material of M20 grade ratio 1:1.5:3 was brought and stored to an approximate temperature of 27 ±3degreeCelsius.Alsoourwasteproducti.e.wasteplastic was brought. Water cement ratio for M20 grade of concrete we used is 0.42 for maintaining workability of concrete.

i. Mixratiofor21%replacementofsteelslag

Table1:Ratiofor21%replacement

S.No. Material Weight(g)

1. Cement 1500

2. M Sand 2250

3. CourseAggregate 3555

4. SteelSlag 945

ii. MixRatiofor23%replacementofsteelslag

Table2:Ratiofor23%replacement

S.No. Material Weight(g)

1. Cement 1500

2. M Sand 2250

3. CourseAggregate 3465

4. SteelSlag 1035

iii. MixRatiofor25%replacementofsteelslag

Table3:Ratiofor25%replacement

S.No. Material Weight (g)

1. Cement 1500

2. M Sand 2250

3. CourseAggregate 3375

4. SteelSlag 1125

Handmixing:Theprocessiscompletedontherectangular pan until a uniform mix is obtained. Cement must be uniformlymixedwithatrowelsoasthereexistnolumps.

Dry mixing of fine aggregates and cement, additionofcoarseaggregateandsteelslagwiththecorrect proportion, addition of m sand and quarry, addition of calculatedwaterinbatchtillconsistencyisachieved.

The casting mould was chosen made of cast iron andwasrubbedwithoiloninnersideforeasyremovalof cubes. The specimen was casted in 3 layers (5cm each) and properly compacted in order to prevent honeycombingformation.

Fig. 6. Casting of Specimen

Compacting was done through tamping bar, minimum 35 strokes was exhausted in all parts of a cube for correct compacting. This tamping bar has the dimensionofdiameter16mmandlengthof0.6m.

The cube test for Compressive strength can be doneon7days.Insomecases,thestrengthofgreaterages is required which is performed from 13 to 52 weeks. But wetookcubeteston7thdayaftercuring.

Itisnecessarytohaveaminimumof3specimens for testing from different batches. The mean of compressive strength achieved by this specimen is employedtodetermineactualstrengthofthebatch.

1) Placethe preparedconcrete mix in thesteel cube mouldforcasting.

2) Once it sets, after 24 hours remove the concrete cubefromthemould.

3) Thenspecimenwaskeptinwaterfor7days.

4) Ensured that concrete specimen was well dried beforeplacingitontheCTM.

5) Testing specimens was placed in the space betweenbearingsurfaces.

Fig. 7. Specimen placed on CTM

6) Care must have been taken to prevent the existence of any loose material or gritted on the metalplatesofmachineorspecimenblocked

7) The concrete cubes were placed on bearing plate and aligned properly with the center of thrust in thetestingmachineplates

Fig. 8. Aligned specimen on CTM

Fig. 9. Failure/breakdown of specimen

8) The loading must be applied axially on specimen withoutanyshock.

9) Due to the constant application of load, the specimen started cracking at a point and final breakdown of the specimenbeennoted.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume:09Issue:05|May2022 www.irjet.net p ISSN:2395 0072

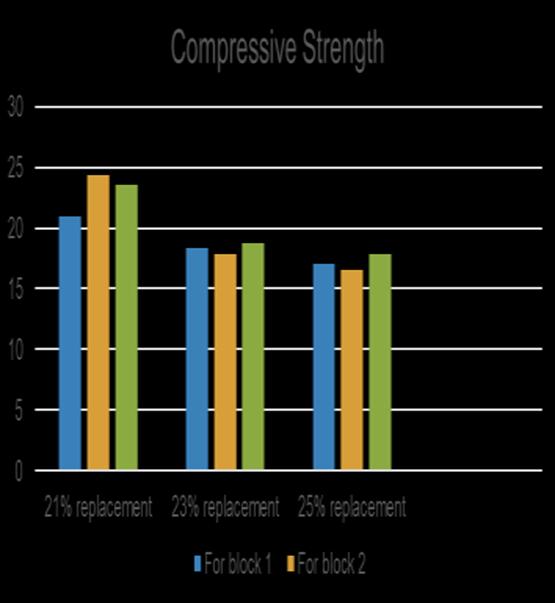

A.CalculationTable after 7days

1)For21%replacementofSteelSlag

Table4:Calculationfor21%replacement

Details For block 1 For block 2 For block 3

Testresult (load) 48000Kg 56000Kg 54000Kg Compressive strength 20.92 N/mm2 24.41 N/mm2 23.54 N/mm2

Calculation:

i.CompressiveStrengthofConcreteforblock1 =Loadcarriedbyblock/Topsurfacearea =(48000x9.81)/150x150 =20.92N/mm²

ii.CompressiveStrengthofConcreteforblock2 =Loadcarriedbyblock/Topsurfacearea =(56000x9.81)/150x150 =11.37N/mm²

iii.CompressiveStrengthofConcreteforblock3 =Loadcarriedbyblock/Topsurfacearea =(54000x9.81)/150x150 =23.54N/mm2

AverageCompressiveStrengthofConcreteforblocks =20.92+24.41+23.54/3 =22.95N/mm2

2)For23%replacementofSteelslag

Table5:Calculationfor23%replacement

Details For block 1 For block 2 For block 3

Test result (load) 42000Kg 41000Kg 43000Kg

Compressive strength 18.31N/mm2 17.87N/mm2 18.74N/mm2

Calculation:

i.CompressiveStrengthofConcreteforblock1 =Loadcarriedbyblock/Topsurfacearea =42000x9.81/150x150 =18.31N/mm²

ii.CompressiveStrengthofConcreteforblock2 . =Loadcarriedbyblock/Topsurfacearea =41000x9.81/150x150 =17.87N/mm²

iii.CompressiveStrengthofConcreteforblock3 =Loadcarriedbyblock/Topsurfacearea =(43000x9.81)/150x150 =18.74N/mm2

AverageCompressiveStrengthofConcreteforblocks =18.31+17.87+18.74/3 =18.30N/mm2

3)For25%replacementofSteelslag

Table6:Calculationfor25%replacement

Details For block 1 For block 2 For block 3

Test result (load) 39000Kg 38000Kg 41000Kg Compressive strength 17.04N/mm2 16.56N/mm2 17.87N/mm2

Calculation:

i.CompressiveStrengthofConcreteforblock1 =Loadcarriedbyblock/Topsurfacearea =39000x9.81/150x150 =17.04N/mm2

ii. Compressive Strength of Concrete for block 2

=Loadcarriedbyblock/Topsurfacearea =38000x9.81/150x150 =16.56N/mm²

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

iii. Compressivestrengthofconcreteforblock3

=Loadcarriedbyblock/Topsurfacearea

=(41000x9.81)/150x150 =17.87N/mm2

AverageCompressiveStrengthofConcreteforblocks =17.04+16.56+17.87/3 =17.15N/mm2

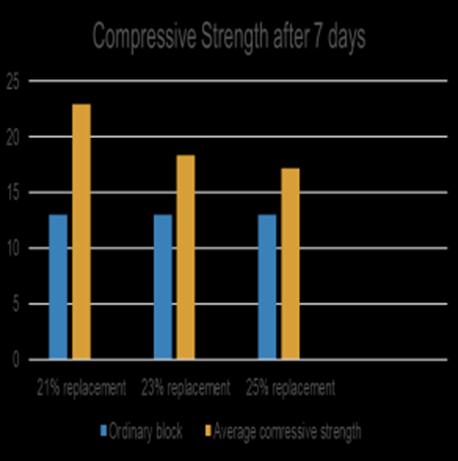

1. Average compressive strength for 21% replacement of steelslagafter7days=22.95N/mm2

2. Average compressive strength for 23% replacement of steelslagafter7days=18.30N/mm2

3. Average compressive strength for 25% replacement of steelslagafter7days=17.15N/mm2

Cost comparison for ordinary concrete and steel slag concrete(1m3 volume):

Table No. 7 Cost comparison

Sr. No. Details Cost (Rs)

1 Ordinaryconcrete 4695

2 21% replacement of steel slag aggregate 4630

3 23% replacement of steel slag aggregate 4625

4 25% replacement of steel slag aggregate 4619

Fig. 10. Strength of blocks

In this research, compressive strength has been investigatedforvarioustypesofconcretecontaining21%, 23%and25%ofsteel slagaggregatebyvolumeofcourse aggregate.

The following conclusions can be drawn based on the abovereport:

• The compressive strength of concrete containing different proportion of steel slag was different however the compressive strength at 21% volume of course aggregate provided higher strength that allowed it to be utilizedinstructuralapplication.

• Steel slag are often used to replace a number of the aggregatesinaconcretemixture.

• Cost of concrete containing steel slag is less as compare to ordinary concrete, so economy can be achieved as well as strength. So concrete containing steel slag is beneficial instrengthandcost.

Fig. 11. Comparison between ordinary concrete block Strength and slag containing concrete blocks.

•Mainly,alltheaboveareconcludedthatthesteelslagare utilized in concrete mix with completely different ratios. During this method to reducing constructional cost, reducing the environmental pollution and some of the finaldisposalwaysarereduced.

Volume:09Issue:05|May2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2478

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume:09Issue:05|May2022 www.irjet.net p ISSN:2395 0072

1. https://www.sciencedirect.com/science/arti cle/pii/S0304389406002421P.

2. Suman and B. S. C. Kumar, “Investigation on PartialReplacementofCoarseAggregatewith PlasticWasteinConcrete,”

3. https://www.sciencedirect.com/science/arti cle/pii/S0959652619314647S.

4. Vanitha, V. Natrajan, and M. Praba, “Utilisation of Waste Plastics as a Partial ReplacementofCoarseAggregateinConcrete Blocks 3, Indian Journal of Science and Technology,Vol8(12),June2015.

5. https://www.sciencedirect.com/science/arti cle/pii/S0950061815306814

6. https://www.sciencedirect.com/science/arti cle/pii/S0375674205000919

7. https://link.springer.com/article/10.1007/s1 1771 009 0128 x

8. https://www.sciencedirect.com/science/arti cle/pii/S0950061821005432

9. https://www.hindawi.com/journals/ace/201 8/14260

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal