International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

1DR. JANARTHANAN M Assistant Professor Level II, Department of Textile Technology, Bannari Amman Institute of Technology, Sathyamanagalam, Erode, Tamil Nadu, India.

2,3,4students, Department of Textile Technology, Bannari Amman Institute of Technology, Sathyamanagalam, Erode, Tamil Nadu, India. ***

zbstract: Thegarmentindustryisconstantlyworkingtoenhanceproductionandgarmentqualityinordertocompetein such a crowded market. The productivity of the clothing industry determines its long term viability and profitability. A variety of procedures are carried out at various locations during the garment manufacturing process. Because of the operators to obtain the desired results, all of these activities must be coordinated, scheduled, and completed on time, productivity. In industries, many practises and procedures are used to increase production. Almost every garment companyusestimestudyasoneofthemosteffectivetoolsforoptimisingoutputrate.Thisarticleexaminestheproduction processofshirt.whichwehaveinvestigatedthetimespentoneachphaseoftheprocess.

Introduction:

This is a study conducted at spreading section in shirt factory where we have come up with a solution to an issue that many companies experience. If necessary and suitable action is taken against this particular point, any garment house's quality and output will undoubtedly increase while saving time. It is feasible to increase productivity while minimising waste by employing methods relating to time saving, capacity, and production analysis. Two crucial characteristics have been considered. The possibility of a standard approach for each activity and the time commitment. To record the real individual capacity of each worker and process line, a time study was conducted. For measuring the timesandratesofworkingintheelements,work measurementtechniqueswereused. hefindingsofwork measurement are used to analyse the data and determine the time required to complete a job at a specified level of performance. The first work measuring technique was time study, which derived from Taylor's work. The goals of this project are to determinetheaveragetimeittakestocompleteeachgarmentmanufacturingprocess,examinethegapbetweenactualand basictimeforeachgarmentmanufacturingprocess,andmakerecommendationsforincreasingproductionratebasedon the analysis. Time study is a branch of engineering in which the productivity of a manufacturing process is examined to determinewhereimprovementsmightbemade.Atimestudyelucidatestheoptimalapproachtoperformsomethinginthe production process. Time study explains on assembling process about the most effective way to follow through with something,thetimeexpectedtofinishresponsibility,andthemethodforestimatingcreationrates.Thepresentclientsall over the world request item at the most ideal cost.

Three laying tables was selected for this study plain, checks/ stripes and women’s wear. At the time of study industry has maximum order of these type of fabrics. these types of fabrics in that three tables are more focused on improvingtheproductivityofthelayingtables.Also,itispossibletostudythelayingprocessthroughtheentirestudy.

Tounderstandtheprocess,sequenceaprocessstudyisdonemanuallyandtoidentifythebottlenecksatimestudyisdone manuallywiththehelpofstopwatch.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p-ISSN: 2395-0072

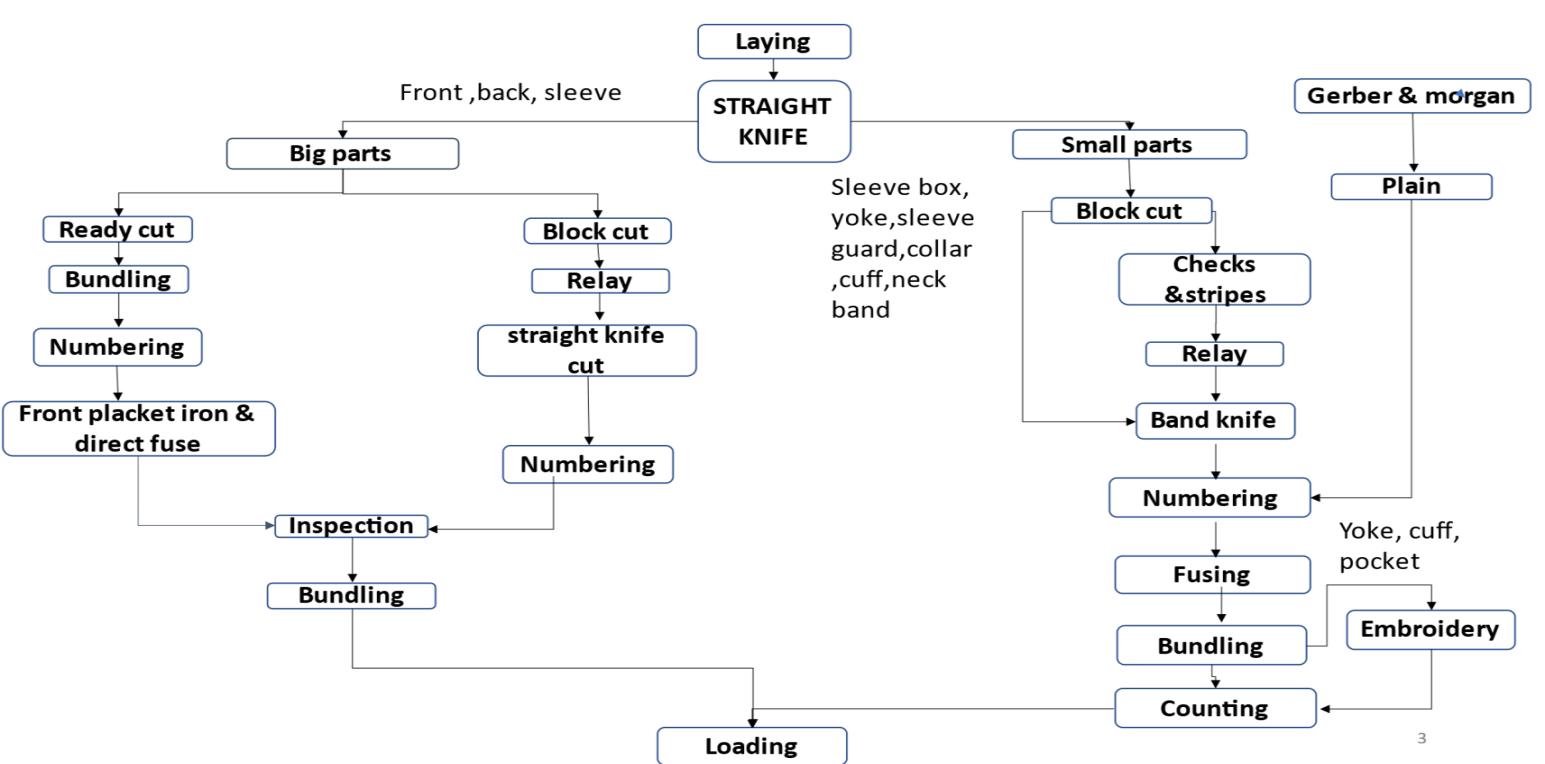

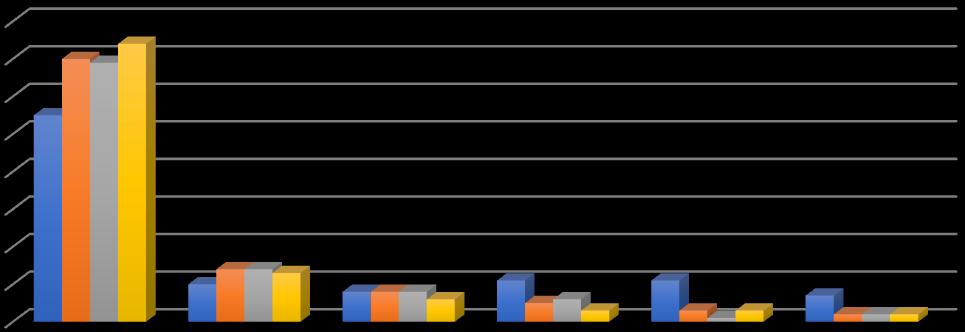

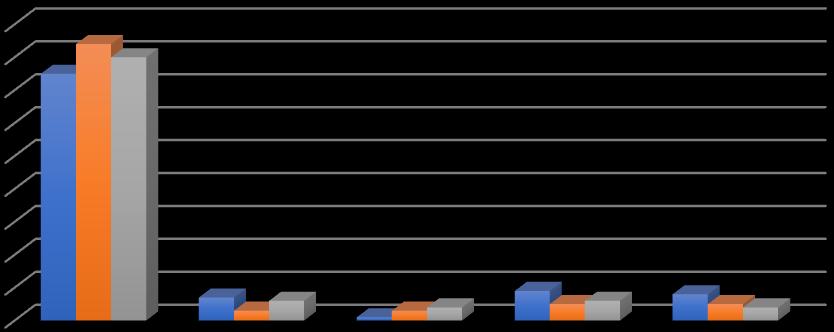

Following figure1 elaborates the processing sequence of operations involved in cutting section manufacturing and There are many cycles included however here we considered some particular activity which was required to have been controlledinordertoabbreviatethetimeframe.Thesecyclesshouldbefinishedindeterminedtimeyetwhenreallyitwas noticedtheoutcomeshowedthatthereisextratimeincludedwhichisprojectedtobediminished.

Fig1

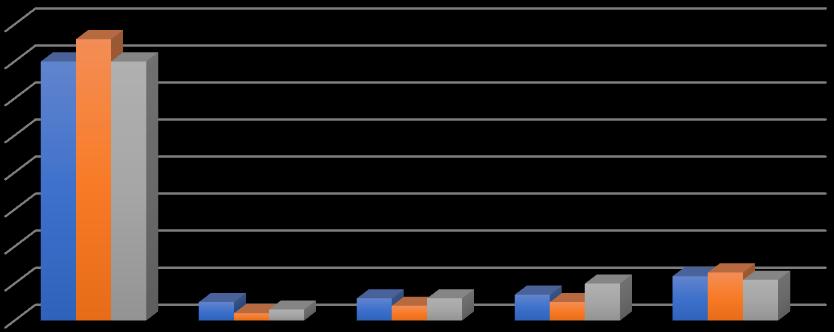

Spreading(Laying) process isfirst material flowstartprocessincutting section andmaterial is movedconsequently. So, this study was started with three different types of fabric in spreading (laying) tables. So the time study was taken for thosetableswiththehelpofstopwatch.Fromthetimestudyitisidentifiedthatthereisabout30%to40%ofrequirednon value added action and non value added action and remaining is about value added actions, spreading. The following graphshowsthedetaileddataofthevalueaddedandrequirednonvalueaddedandnonvalueaddedactionspercentagein thespreadingtable

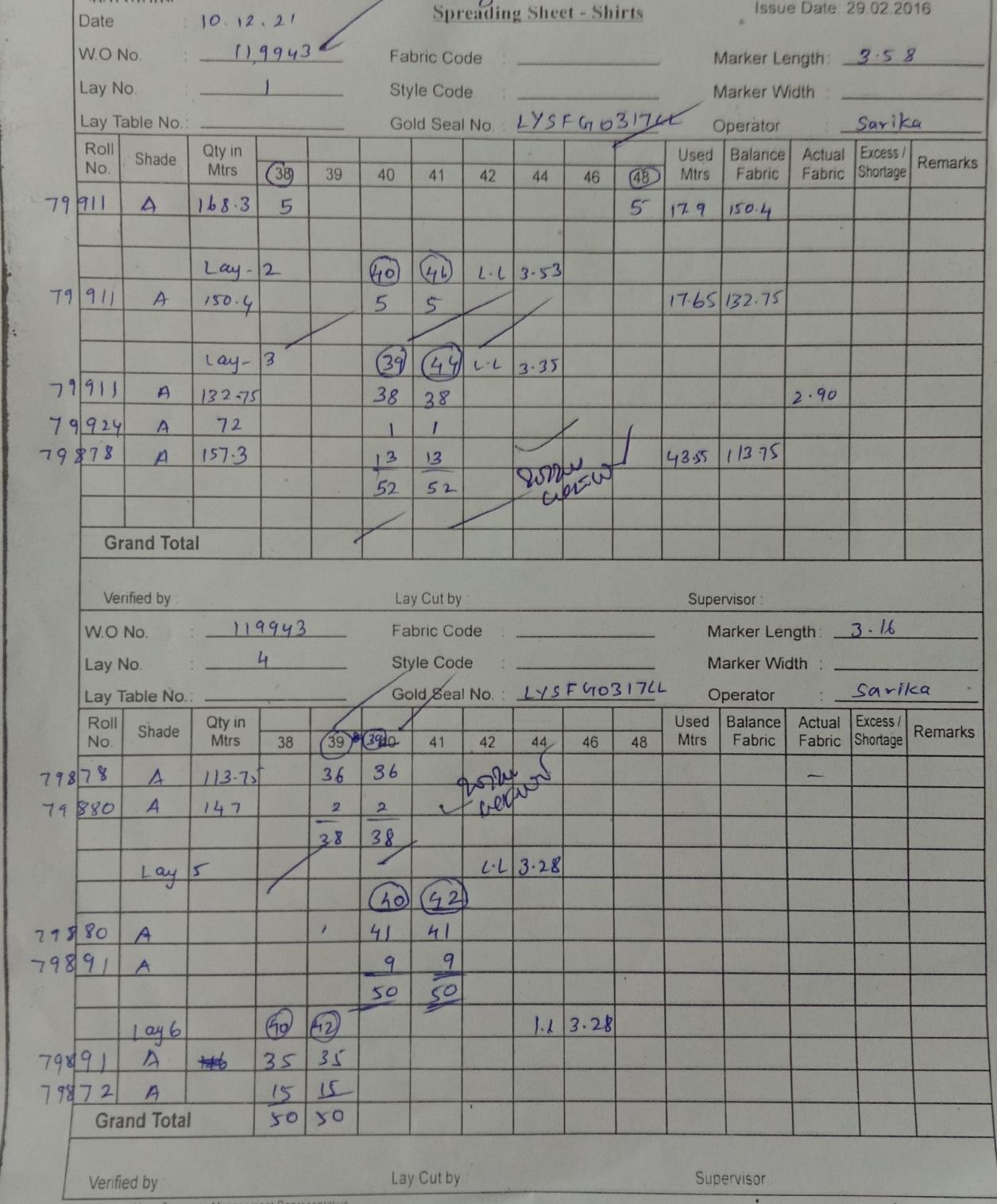

Fromthetimestudyitisidentifiedthatlaysheetentryseemstobeamostimportantrequirednonvalueaddedactivityso theeliminationofthatshouldbecarriedoutfirst.

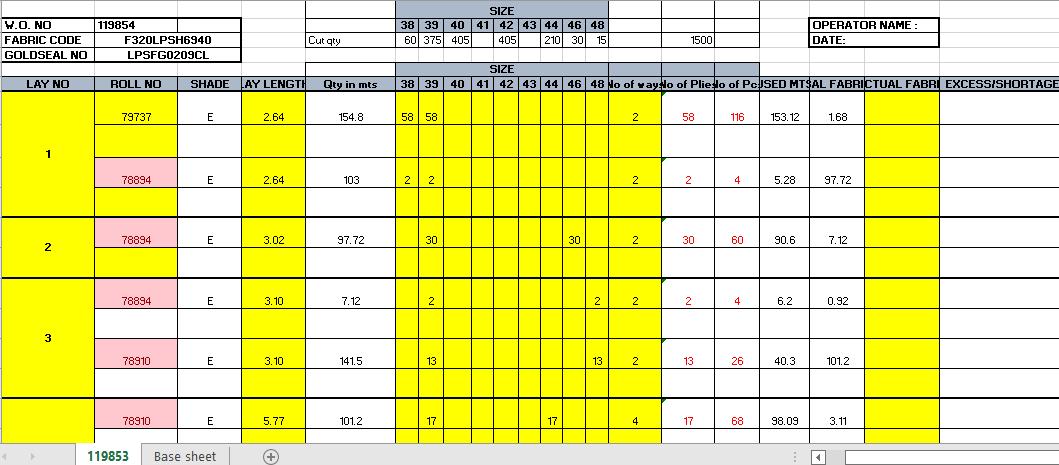

Itisamanualwritingwhichcontainsinformationaboutproductionorderwhichincludes,workordernumber,fabriccode, stylecode,goldsealnumber,markerlengthandwidth,layno,numberofplies,shadegroup,usedfabricrollno,usedroll meter,laywise,sizewise,balancefabric,endbitsgeneratedinutilizedroll.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Laysheet(Manualentry)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

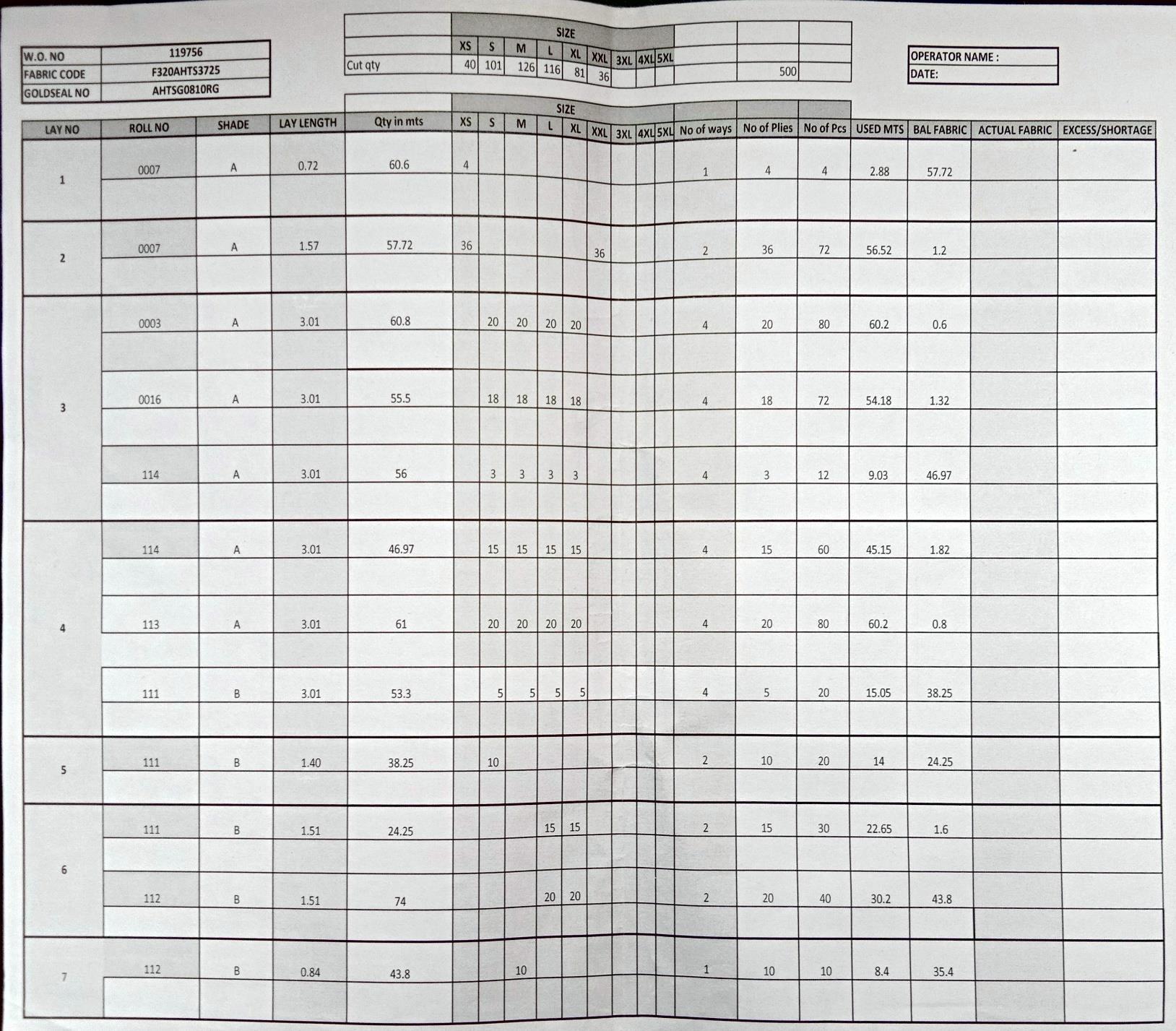

Intheindustrytheyhavecutplaninthatthenumberoflaysandnumberofpliesdetailsaretheresowiththehelpofcut plan we design a new type of lay sheet using excel VLOOKUP in that all the manual entry can be calculated before the operation that can be taken as print out and can be given to the operators and use it for other purposes. That is predeterminedlaysheet Pre determinedlaysheetwhichcontainsalltherequireddetailssimilartothemanualentrylay sheet

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

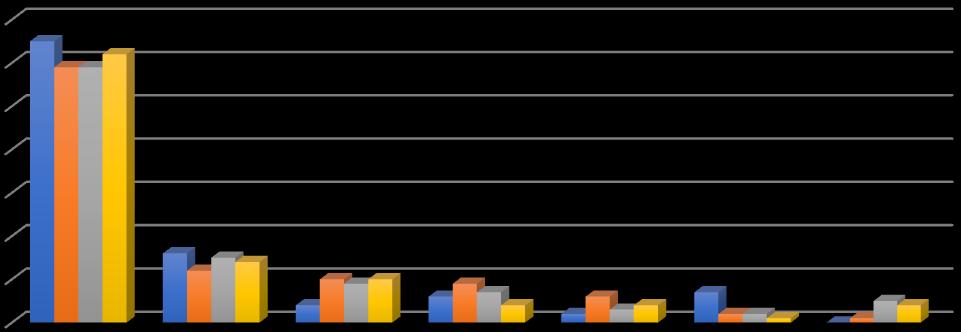

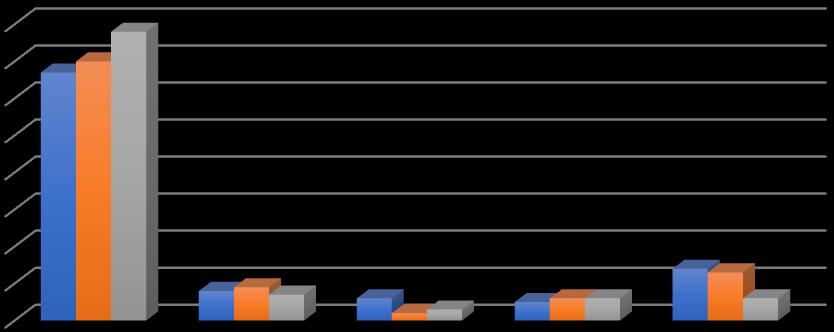

RESULT:

Afterimplementation,theproductionnumbershaveincreaseddaybyday.

CONCLUSION: Henceaftertheimplementationofpredeterminedlaysheet,thespreadingpercentageofthecuttingsectionhas risenfrom64%to75%byourprojectthespreadingpercentageincreasedupto11%thanbefore.

Khatun, Murshida. Application of Industrial Engineering Technique for Better Productivity in Garments Production,InternationalJournalofScience,EnvironmentandTechnology,Vol.2,No6,2013,1361 1369. Price, John WH., Industrial Engineering: Important for Management in Australia, Fourth International ConferenceonEngineeringManagement,1994:Preprints.InstitutionofEngineers,Australia,1994.

Haque Ahasanul, Lead time management in the garment sector of Bangladesh: an avenues for survival and growth,EuropeanJournalofScientificResearch,Vol.33(4)2009,617 629.

Kader Shahidul, and Maeen Md Khairul Akter, Analysis of the factors affecting the lead time for export of readymade apparels from Bangladesh; proposals for strategic reduction of lead time, European Scientific Journal,Vol.10,No.33,2014,268 283,

Basak Avizit, Supply Chain Management in Garments Industry, Global Journal of Management and Business Research,Vol.14(11),2015,23 28

Khanna: Work study,

and motionstudy,DhanpatRaiand