International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Assistant Professor, Department of Civil Engineering, Guru Nanak Institute of Technology, Nagpur, Maharashtra, India1

UG Students, Department of Civil Engineering, Guru Nanak Institute of Technology, Nagpur, Maharashtra, India2,3,4,5,6 ***

Abstract Minimization of waste in the development business is a significant theme in the development the executive’s field. Development organizations' advantage from diminished squander age by lower statement expenses and lower buying expenses of virgin materials. Presently a day's development squander the board is an overall issue that concerns not just the on location development the executives yet in addition the practical advancement course of development industry. The measurement of development squander volume, at the task stage, is fundamental for the structure experts to appropriately plan and control the removal. A definite model is laid out to assess the on location volume of development squander for new structure project. Thesepaperpresentsasurveyondifferentresearchworkdone in the space of minimization all out development squander.

Key Words: Construction Waste Management, Disposal, Recycle,MinimizationinWaste

Past examination into the reasons for squander in developmentprojectsdemonstratethatwastecanemergeat any phase of the development interaction from initiation, directlythroughtheplan,developmentalso,activityofthe assembledoffice.Squanderinthedevelopmentbusinesshas been thesubject of a few exploration projectsall overthe planetlately.Itisregularlyrecognizedthatanexceptionally elevated degree of waste exists in development. Since developmentaffectsnumerousdifferentbusinessesthrough both buying inputs and giving the items to any remaining ventures,killingorlesseningsquanderinthedevelopment business could yield extraordinary expense investment fundstothegeneralpublic.

Natural:Highmeasureofdevelopmentsquanderproduced during development movement which is hostile to the climate.Financially:Constructionsquanderpromptsadverse consequencetocostoftaskwastecanbecharacterized as "any shortcoming that outcomes in the utilization of hardware,materials,workorcapitalinbiggeramountsthan those considered depending on the situation in the development of a structure". Waste can be named unavoidable waste (or normal waste), in which the speculation essential for its decrease is higher than the

economycreated,andavoidablewaste,inwhichtheexpense ofwasteishigherthantheexpensetoforestallit,Thelevelof unavoidablewastereliesupontheinnovativeimprovement leveloftheorganization,Thewastecanlikewisebeordered byitssource;specificallythestageinwhichtheunderlying driversofwastehappens.Wastemightresultfromthecycles goingbeforedevelopment,forexample,materialsproducing, plan, materials supply and arranging, as well as the development.

Researchshowsawidevarietyinwastagepacesofbetween 5% 27% of absolute materials bought for development projectsinIndia.Theongoingliberalworldwidemonetary requestmakesitmovingforIndianstructurebusinessesto stay serious around the world. The business should along these lines endeavor to convey significant items and administrations at the base conceivable expense for their clientstostayinthebusiness.

Toaccomplishleastexpenseindevelopment,thestructure businessshouldseethevalueinthedistinctionamongwaste and worth and how to dispense with squander in the activities which are completed. The inquiry currently emergesregardingwhetherexpertsinthestructurebusiness knowabouthowmuchmaterialssquanderproducednearby.

Thestudyaimstoadvanceknowledgeonconstructionsite waste minimization through the application of better Practices

Tohelpachievetheaim,thefollowingobjectiveswereset;

1.Toidentifythesourcesandcausesofmaterialswasteon buildingconstructionsitesandtoprovideacompendiumon waste arising from storage and handling of high waste generating building materials used in the construction industry.

2 Toassesstheviewsofconstructionprofessionalsonthe levelofcontributionofsomewasteminimizationmeasures

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

to waste reduction, and the level of practice of such measuresintheconstructionindustry.

3 To propose a framework that has the potential of minimizing materials waste through the implementation waterreducingprinciples.

Thestudyseekstohavepositiveimplicationsonthebuilding constructionindustry.Amongthemare:

1. Theresultswillenablebuildingorganizationstoimprove construction quality and efficiency through the implementation of the measures suggested to remove potential barriers to the implementation of lean construction.

2. Minimizing materials waste would improve project performance and enhance value for individual customers, andhaveapositiveimpactonthenationaleconomy.

Followingarethebriefliteraturereviewofpreviousresearch, Saheed O (2017) In the building destinations there is a giganticmeasureofdevelopmentsquander.Forthissituation projecttheboardoughttobeexercises,includingtheplan, materialsproject,andthedevelopmentperiodsoftheProject conveyancesuchsortofstudyrequired.Thisstudyincludes actualcapacityandstrategicmeanstolimitthewastecreated by development exercises and furthermore include philosophyofinformativeendlesslyresearchreviewsinits systemic structure to grasp the peculiarity of the point of viewofthebusinessofthedevelopmentbusiness.Lowwaste administration, low waste stockpiling the board, viable material conveyance the executives, squander wastage quantityandsoforth.

S. E. Sapuay (2016) Constructionindustryismajorsource ofproducingwaste.Tomaintaintheenvironmentbydispose of construction solid waste from their working area Demolition waste is a major waste in some construction industry.Contractoristheresponsiblepersontomanagethe constructionwasteinsite.Thispapermainlyfocusedonthe issues of construction wastes encountered in projects and howthesewastecanbereusedintheworksite.Underthis study an ecological solid waste management has been improved.

GhanimA.Bekr (2014) Thisstudyfindoutthecausesand magnitudeofwastageofmaterialsonconstructionsitesin Jordan. He had prepared a questionnaire form it includes questionsaboutthecausesofwastagegeneratedinsitesand theestimatedpercentagesofwastageoftenmostimportant materials used on construction sites. A pilot survey was conductedinthestudy.

R. B. Surve (2013) Thestudyaimstoknowingthesources and causes of construction waste occurrence. The waste generated on construction site has been found to resultin financiallossesi.e.thecostoftransportinganddisposingof site waste and material storage cost. In this research the studyofconstructionwastegenerationatdifferenttypesof constructionsiteslikecommercial,residentialandindustrial sites was done and the data regarding waste generation sourcesandaveragewastegenerationwasdone.Alsointhis project route optimization for selected sites is carried out usingGISapplication.

Mahesh D. Meghani (2011) InConstruction,4 M(Material, Manpower, Money, Machine) assume a significant part. Materialwastehasbeenperceivedasaprincipalsquander createdinthedevelopmentbusiness.Theinformationtobe gathered from 5 structuredestinations situated in various areainIndia.Inlodgingprojectbuildingmaterialsrepresent 60 to 70% of the task cost. The capacity of waste administrationisgreatestuseofassets(Material)andlessen thegeneraltaskcost.

Inthisreview,interviews,organizedpollandsitevisitswere utilized Study of information from past examination is utilizedinthesocialaffairofinformation.

The meetings were adjusted to gather definite data about respondents‟ encountersand impressionsabout materials wastage.Itwastoousedtogatherfundamentaldatatohelp inorganizing,thesitevisitsincludedperceptionswherewe lookedtofigureouthowmaterialswereputawayanddealt with and furthermore to give a summary on high waste producing building materials utilized in the development industry.

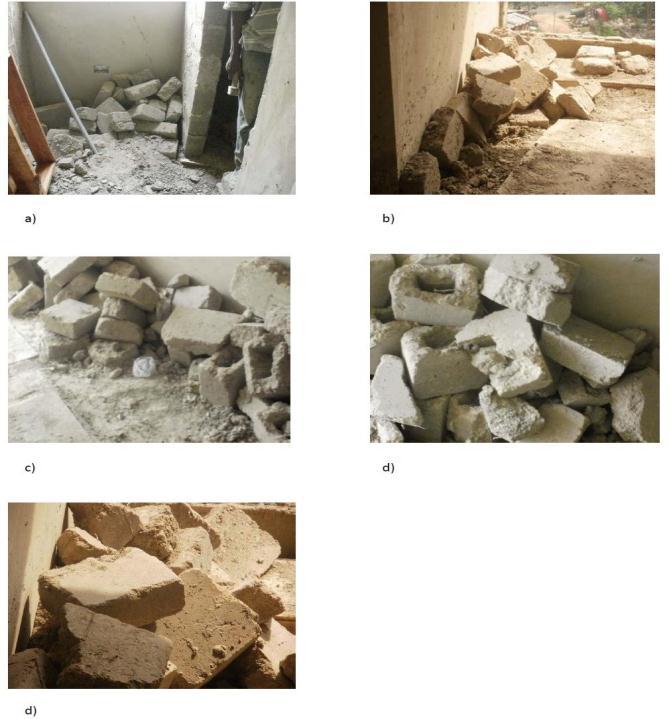

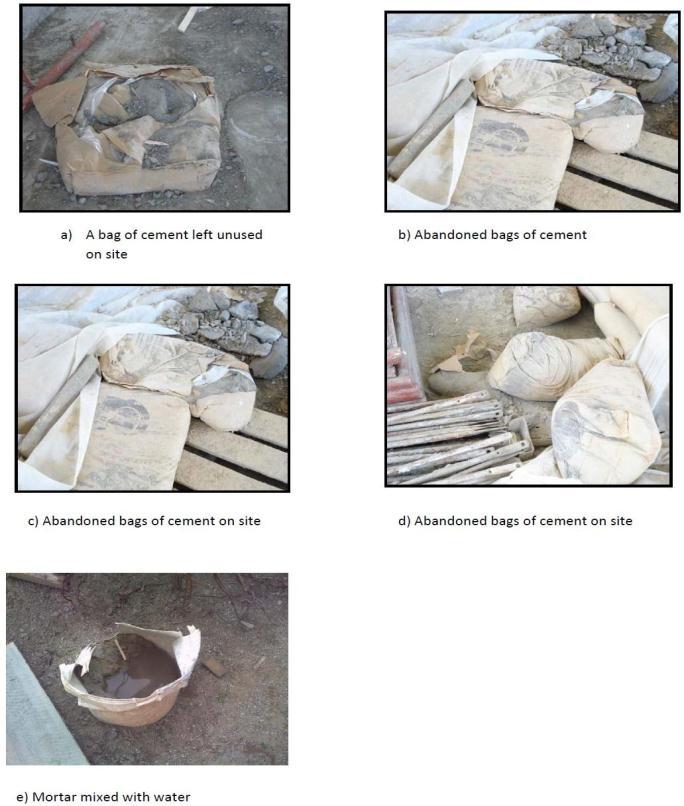

We invested energy in building locales and noticed the streamexercisesofMaterialsOnlydealingwithandcapacity wereconsideredonthegroundsthatfromthepollreview, theventureadministratorsverifiedthewaythatmaterials capacityanddealingwitharethesignificantsourcesofwaste onbuildinglocales.Thepollstudyuncoveredthatthefour high waste producing building materials are lumber, concrete,concrete/mortarandsquares.Photosweretakento reporthowthesematerialswereputawayandtakencareof onlocation.

Inthisreview,interviews,organizedpollandsitevisitswere utilized Study of information from past examination is utilized inthesocialaffairofinformation.Themeetingswere adjusted to gather itemized data about respondents‟ encountersandimpressionsaboutmaterialswastage.Itwas likewiseusedtogatherprimerdatatohelpinorganizing,the sitevisitsincludedperceptionswherewelookedtofigureout how materials were put away and taken care of and

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

furthermoretogiveanabridgmentonhighwasteproducing buildingmaterialsutilizedinthedevelopmentbusiness.We investedenergyinbuildinglocalesandnoticedthestream exercisesofmaterialsOnlydealingwithandcapacitywere considered on the grounds that from the poll review, the venturechiefsconfirmedthewaythatmaterialscapacityand taking care of are the significant wellsprings of waste on buildingdestinations.Thepolloverviewuncoveredthatthe four high waste producing building materials are lumber, concrete,concrete/mortarandsquares.Photosweretakento recordhowthesematerialswereputawayanddealtwithon location.

The review relied upon both essential and auxiliary information.Essentialinformationwascomprisedofdirect information gathered by the up and comer using surveys, meetings and site visits (perception). The optional wellspringsofinformationweregottenutilizingsignificantA tonofstudieshavebeenembracedconcerningthewastageof materialsonbuildinglocales.Aportionofthematerialsthat are squandered on the building locales incorporate steel support,concrete,structurework,blocks,concrete,mortar, tiles,andline,aggregate.

Agreatdealofstudieshavebeenembracedconcerningthe wastageofmaterialsonbuildingdestinations.Aportionof the materials that are squandered on the building locales incorporatesteelsupport,concrete,structurework,blocks, concrete,mortar,tiles,pipe,aggregate.

Steel reinforcement bars are normal materials utilized in building Controlling the utilization of steel support in building destinations is moderately troublesome on the groundsthatitisunwieldytodealwithbecauseofitsweight and shape , The primary drivers of wastage of steel are becauseofcutting,harmsduringcapacityandrusting.The reasonsoflikelymisuseofsteelsupportareharmtowork and bars, misfortune in mud and abundance utilization of tyingwire.

Therearetwosortsofblendedconcrete,substantialprepared blended (premixed endlessly substantial site blended, Concrete is the most broadly utilized material both for foundation and superstructure of structures. The wastage chiefly results from the crisscross between the amount of cementrequestedandthatexpectedonaccountofprepared blendedsubstantialstockpile.Theprojectworkermaynot havethefoggiestideaaboutthespecificamountduetoflaw arranging,promptingover requesting.Substantialsquanders likewiseresultfromprojectdelaysandpointlesswastetaking care of cycles. By and large, 3 5% of the material was squandered and the greater part of it was lost through inordinatematerialrequesting,brokenstructureworkand re tryingbecauseofunfortunatesubstantialsituationquality. Thestructureworkerforhiremaynothavethefoggiestidea aboutthefundamentalamountduetoflawedplanning.This prompts over requesting and stuffing of the method for transportandstructurework.Assumingthestructureworkis stuffed,skimmingbecomesessential,i.e.,eveningoutofthe substantialfilledthestructurework.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Breaking down the misuse of concrete is somewhat perplexingbecauseofthewaythatthismaterialisutilizedas a part of mortar and cast set up concrete in a few distinct cycles,forexample,blockwork,putting,andfloortirade.By contrastthisisamoderatelycostlymaterialthathaselevated degreesofwaste.

ineffectively performing destinations, mixes of materials squandercausesareconnectedwiththemisuseofblocksand blocks.Atafewdestinations,thereareissuesconnectedwith the conveyance of materials, for example, the absence of controlinhowmuchblocksorblocksreallyconveyedandthe harmofblock

Fig 3. Wasted cement/mortar on construction site

In certain pieces of the Country , Sand and mortar are typically conveyed in trucks, thus there might be extra misfortunes connected with the absence of control in the conveyance activity and the essential taking care of it requests.

Anorganizationshavebegunutilizingpressedpreparedto utilizemortarblend,whichwill ingeneralkillasignificant number of the issues connected with conveyance control, taking care of, and transportation. Albeit insufficient informationareaccessible,therearesignsthatsuchchanges havediminishedthemisuseofmortar,incontrastwiththe conventionalstrategyfordeliveringmortarnearby.

Blocksandblocksarethemostwell knownwallingmaterials, the primary driver of block and block squander is cutting. Unloadedsupplymightexpandwastageofbrokenharmin lightofthedelicateideaofthematerials.Unusedblocksleft nearby may wind up in the garbage skip at last. In most

Materialscontrolremembersthoseexercisesthatguarantee materials accessibility for the expected amount, at the appropriatetime,consideringthebasepracticalexpenseto fulfillcreationneedsandcorporategoals.Materialscontrol exercisesincorporatedecidingmaterialsneeds,orderingthe buyorcreationofpartsinlightofmakeorpurchasefinancial aspects,recordkeeping,demandingforcreationandstatus detailingtechniques.

Controlofthematerialsutilizednearbystartsatthetimethe projectworkerisgivenoverthesite.Allmaterialsconveyed tositeshouldbecontrastedandthepertinentnorms.Other thanthegeneralmisuseofmaterialsonlocation,thereisa greatdealofharm,andthisisfrequentlybecauseofabsence of appropriate oversight. Obligation regarding materials controlshouldstartwiththeindividualtakingcareofthem. Numerousforemenandmanagersseetheirprimarycapacity asthatofmaterialsprovidertothegatheringtheyareliable for,subsequently,disregardingmaterialstakingcareof.On the off chance that a materials regulator is delegated to

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

expectmaterialsprerequisiteandconveysupplies,exchanges foremen will have sufficient opportunity to appropriately takecareoftheirbusiness.Sitetheexecutivesiseventually liableformaterialsuseanddealingwith.Bethatasitmay, materials might be kept nearby over lengthy or brief timeframeuntiltheyarerequired

The Environmental Protection Agency sees squander minimization as; a strategy that decreases the volume or harmfulness of a waste that requires removal. From a functional perspective, a technique decreases the sum it includes any technique, interaction or movement which dodges,killsordiminishessquanderatitssourceorpermits reuseorreusingofthewaste.

Movingtowardssquanderminimizationexpectsthatthefirm concedes toexpanding the extent of non squander leaving exercises.Squanderminimizationisaboutsoundjudgment and a difference in demeanor, as opposed to new advancements. The principal phase of an entire waste administrationplanissquanderminimization.Obviouslythe most ideal choice is for squander not to be made by any means.Minimizationincludeslookingovertheprogressionof materialsintoas well as outofa site,andevaluating what steps could be utilized to lessen the quality and scope of material disposed of, the course of waste minimization comprises of two essential tasks: source decrease and reusing.Sourcedecreaseisgenerallyalluringtostayaway from squander age, while reusing is helpful to moderate assetsandtokeepmaterialsfromenteringthewastestream

Thestructurebusinessisutilizingalotofassets,howeveron theoffchancethattheexistencepatternofthematerialon locationisfirmlyinspected,it is for the most partrealized thatthereisasomewhathugepieceofthematerialsbeing squandered in light of unfortunate material control on buildingdestinations.

The potential for limiting development and destruction squanderisextensive.Downtoearthsquanderminimization systems require a definite comprehension of what causes development squander, inspected squander minimization techniques and the general meaning of development squandersourcesutilizingoverview.

Source decrease is characterized as any action that diminishesorkillstheageofwasteatthesource,normally inside an interaction. It is most noteworthy on the developmentsquandertheexecutive'sprogressivesystem;it hasthebestnaturaleffectbecauseoftheactivityhavingan immediateoutcome.Manyplanandplaceofworkpractices can essentially decrease waste and cost of materials on a

development projectwhile requiring justslightchangesof standardmethodology.

Workers for hire can apply source decrease nearby, by requesting materials in differing lengths to meet development project conditions, as opposed to requesting singlelengthsofmaterialsCarefulcoordinationofthebuying of materials can likewise diminish squander in the developmentcycle.

Reusing is regularly characterized as a course of isolating recyclable materials from non recyclable materials and providing them to a hauler or business so they can be handled to make new. Purchasing building materials with reusedcontentfostersabusinessopportunityforthewaste materialonereusesfromtheplaceofwork.

3.3.4

Developmentanddestructionprojectspresentoneofakind difficultiesinthespaceofwasteminimization.Sinceeachtask isunique,producingitsownoneofakindmixofsquanders, theprojectworkershouldbeadaptableandimaginativein tracking down ways of decreasing, reuse, or reuse the differentsortsofsquanders.

Overseeingdevelopmentanddestructionwastecancomprise amassiveexpenseforthebusiness.Afewsquandersrequire cautiousandmaybecostlytakingcareofstrategiesduringthe developmentinteraction.Anorganizationcansubsequently help in various ways from decreasing how much waste it needs to discard. The thought of waste minimization can producebenefitslikemonetaryandecologicaladvantages

1. Forestallingsitesquanderfromenteringthepublicwaste streamanddivertingpossiblewastefromlandfillstoreuse andreusingapplications.

2. AdecreaseinC&Dsquandertransportationandremoval costs.

3. Diminished material acquisition costs because of decreased site wastage and the utilization of on location auxiliarymaterials.

4. Assurance of the project workers (currently tight) net revenue.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Perfectfirst time quality Achieve zero defects, revealing and solvingproblemsatthesource

Waste minimization Eliminating all non value adding activitiesandmaximizingtheuseof resources

Continuous improvement Reductionofcosts,increasequalityand productivity

Pullprocessing Productspulledfromtheconsumerend, i.e.notpushedfromthe productionend

Flexibility Theproductionofdifferentmixesand/ orgreaterdiversityofproducts, withoutcompromisingefficiency

Relationships Building and maintaining long term relationshipswithsuppliers

Table 1. Key Manufacturing Principles Employed to Reduce Waste

Therehasbeenexpandingstraintoconcoctprocessesthat lessenwastageontheplaceofworkandguaranteetheyield of natural structures. This request is an aftereffect of elements for example, a need to diminish the expense of development,aneedtoexhibitecologicalobligationanda needtoagreewithseverenearbywasteregulationandgoals. Improvingbuildingsitesquandertheexecutivescanaddto the general improvement of the presentation of the development business. It will likewise present to us a bit nearertoaccomplishingmanageabilityindevelopment.

[1] Abhijith H., Sreejith M.H., Jacob P.A., Aiswarya S., “Minimizing Construction Wastes by Efficient Site Practices”. International Journal of Education and AppliedResearch,ISSN:2348 0033(Online),ISSN 2249 4944(Print),2014.

[2] Anagal V., Nagarkar G., Atnurkar K., Patel A., “Construction and Demolition Waste Management A CaseStudyofPune”,NationalSeminar Roorkee,Paper No.A 18,2012.

[3] Anantha R.V., Lokeshwari M.” Management of Construction and Demolition Waste”, Journal of EnvironmentalResearchandDevelopment,Vol. 5No. 1, July September2010.

[4] Jain M.” Economic Aspects of Construction Waste Materials In Terms of Cost Savings A Case of Indian ConstructionIndustry”,InternationalJournalofScientific and Research Publications, Volume 2, Issue 10, ISSN: 2250 3153,2012.

[5] Ajayi,S.O.Oyedele,L.O.,Bilal,M.,Akinade,O.O.,Alaka,A.H andOwolabi,H.A.(2017).Criticalmanagementpractices influencingon sitewasteminimizationinconstruction projects.WasteManagement59:330 339.

[6] Mr. R. B. Surve, Dr. S. S. Kulkarni(2013) “Construction wastereduction Acasestudy”InternationalJournalof EngineeringResearch&Technology(IJERT),Vol.2

[7] SaheedO(2017)“Optimisingmaterialprocurementfor construction waste minimization: An exploration ofsuccess factors” Sustainable Materials and Technologies1 28.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal