International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

***

Abstract In the realm of bituminous materials research, self healing has become a hot topic. Interpenetration and bonding describe the healing mechanism, indicating that the cracking interface will vanish as a function of the time the cracking surfaces are brought into touch. The goal is to constructthepavementinsuchawaythatthefracturesmend themselves. Exhaustion and healing have been shown to be persistent issues throughout the life of a pavement. Deterioration of the road has a significant impact on its serviceability, riding quality, and safety. The flexible pavementsexperiencemajor cracksandpotholesduetoheavy loads. The minor cracks are not repairable due to very little crack width and there may be under surface cracks. In this research paper the heling techniques are analyzed and a comparative study is done. The healing techniques used are induction heating, nano technology, micro capsules, direct application of bacteria. In induction method, external temperature is provided for melting of asphalt and filling the cracks.Innanotechnologymethod,nanomaterialsareusedfor self healingprocess,whereasinmicrocapsulesmethod,micro capsules are embedded in the mix, and these capsules break when cracks appear, and heal the fracture. The direct application of bacterial based self healing technology is an effective method for healing the cracks in deteriorated pavement.Thistechniquewillmakethestreetself healedand increase its lifespan and serviceability.

Key Words: Self-healing techniques, induction heating, nanomaterials, micro capsules, bacteria, Bacillus Subtilis.

Constructionindustryplaysasignificantrolebyproviding variousstructuralmaterialsthatareusedinvarioustypesof infrastructures[1],[2].However,themajorissueprevailing inconstructionindustryisuseofsustainableconstruction practices[3].Theever increasinghighmaintenancecostsof various constructed infrastructures is the concern worldwide[4].Self healinghasemergedasahotissueinthe field of bituminous materials research [5]. The healing mechanism is defined by interpenetration and bonding, which shows that the cracking interface will vanish as a functionofthetimeandthecrackingsurfacesarebrought into contact [6]. Exhaustion and healing have been demonstrated to be ongoing difficulties throughout a pavement'sservicelife. Largecracksandpotholescan be foundinthepavementandotherstructuralelements[7],[8]. Major fractures can be repaired, but smaller cracks are

irreparable due to their modest crack width and location beneaththesurface[9].

Overloading,seepage,inadequateroadsurfacedrainage,lack ofsuitabledesign,badweatherconditions,andavarietyof other factors can cause cracks [10]. Because of the heavy loads,theflexibleasphaltsfacemajorfracturesandpotholes. Thereisafantasticapproachforrepairingpotholes,andin anyevent,becauseoftheheaps,theremaybelittlebreaches in the asphalt that cannot be repaired, resulting in major fissuresinthepavement[11].Minorbreaks,inanycase,are unrepairable due to the small break breadth and the possibilityofunder surfacebreaks[12].Fixingthesebreaks is extremely difficult because they aren't visible on the surface.Inthisapproach,mendingisoutofthequestion.Asa result,therearevariouswaysforrepairingasphaltdamages withouttheassistanceofothers[13].

Thefirstsitetrialofself healingconcreteatalargescalewas done in UK. It is first time that self healing concrete with micro capsules has been successfully scaled up and implementedon site.Forcomparison,self healingconcrete wasmadewiththehelpofNa2SiO3(waterglass)thatwere encapsulatedatmicrosizewasmadeonthesiteinholding wallpanelalongsideacontrolpanel.After35daysofcure, thewallsweremechanicallycracked,andthenitwasagain loaded and observed for self healing for 6 months for supervising permeability, fracture deepness, and microscopicfracturewidenessvalues.

Even though the inclusion of 8 percent microcapsules by cementvolumereducedmechanicalstrengthmarginally,the microcapsulewalldemonstratedenhancedcrackwidthand depthreduction,andpermeabilityrecovery,demonstrating thereal timeviabilityofhealingbasedonmicrocapsule.Van TittelboomandDeBelieinvestigatednumberofways,some of which try to improve the genuine process of automatic fracturehealing,whereasothersaimtochangeconcreteby insertingcapsuleswithappropriatehealingagents,allowing fracturestomendentirelyontheirownwhentheydevelop [14].Thesortsoftherapeutic agentsandcapsulesutilised are given special consideration. Furthermore, the various techniques have been assessed based on the trigger mechanism employed, with special focus devoted to the propertiesregainedasaresultofself healing.

Yoo et al. have reviewed that the potential of asphalt concrete to self heal was investigated using induction heating and quantified by differentiating the flexural strengthsofuntaintedandrecoveredsamples[15].Adding

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2015

Galgotia’s College of Engineering and Technology, Greater Noida, 201310, IndiaInternational Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

carbon nanomaterials, such as nanotubes made of carbon (CNTs) and nanofibers of graphite (GNFs), proved more successful than adding macro CFs in enhancing Marshall stability,indirecttensilestrength,anddynamicstability,as well as lowering porosity. This strategy, however, is not applicableeverywhere.Xueetal.havestudiedthatPU based polymer is the most promising self healing agent known, withexcellentflexibilityandacomparativelyquickercuring time,aswellasaself healingprocessthatdoesnotrequire water [16]. Stress concentration near the contact surface, separationofasolidself healingagent,insufficientblending, andearlyreactionallrequirefurtheradjustments[1].

Wiktor and Jonkers have reviewed that on crack healing measurementinanewbacteria basedself healingconcrete. Anew bio chemical self healingagenthasthepotential to improvethesustainabilityofconcretestructuresinhumid situations [17]. Vijay et al. have reviewed on self healing concrete which is prepared with the help of bacteria. The encapsulation method will produce superior success than directapplication,revealingthatbacteriacanenhancethe compressivestrengthandthedurabilityoftheconcrete[18]. Mansoori et al. have reviewed that, at 20oC, fractured asphaltmixtureswithcapsulesrestored52.9percentoftheir earliest strength, compared to 14.0 percent for cracked asphalt mixtures without capsules. Asphalt self healing capsules may be used securely on the road instead of amending its quality. The rigidity of capsules containing asphaltwasslightlylower,whichmaybereadilyremediedin thefuturebyreducingthecapsulesize[19].

Reddy et al. Stated that the involvement of bacteria into concretemaycauseittoself heal,loweringthestructure's maintenancecosts.Thecapabilityofconcretetoself healcan extendlifeofconstructions[20].Mullemetal.conducteda large scaleanalysisinBelgiumwiththehelpofSelf Healing Concrete. A healing agent based on bacteria was added to concretemixalongwiththeothercomponents.Fromthetest doneinlabitwasobservedthatthecracksatthebottomand wetanddrycyclesofthecrackhealingwerevisibleclosely [21]. On addition to that, the sealing efficiency of cracked sample which were soaked in water for 27 weeks, water permeabilitywasmeasuredfromthemeasuringdevices,that wasfoundtobeatleastequalto90%,havingthe efficiency ofatleast98.5%forthebiggestpartofthesample.

Kimar and Kumar stated that rejuvenation, induction heating, and Nano materials are all healing strategies for flexiblepavements.Self healingpavementshelptoreduce maintenancecostswhilealsoextendingthelifeofthesurface [22]. Nanomaterials such as Nano rubber, Nano clay, and Nanosilicacanbeusedtoimprovethehealingqualitiesof bitumen.Whenacrackemerges,thetinycapsulesareadded tothebituminousmix,andtheresinisejected.Steelfibresof various percentages and lengths have been used in pavementstoheatthebitumenwhenfracturesform.These arethemanymaterialstobeused,andthereisstilltimeto

figureoutthemostefficientmethodforcreatingself healing pavements [23]. Blaiszik et al. studied about Self Healing Polymers and Composites. Healing systems based on capsules,vascularbasedandintrinsichealingpolymersare three conceptual ways for self healing that have been demonstrated[24].

Self healing can be autogenous, meaning it proceeds its processofself healingwithoutanyhumaninterference,by utilizingexternalenergy[25].Despitethefactthatcapsule basedtechniquesarestraightforwardtointegrateintomany systems of polymer, this method is not used commonly. Vascularapproacheshavealotofpromiseformendinglarge volumesofinjuriesacrossavarietyofharmscenarios,but they're tough to integrate into existing material systems. Intrinsichealingtreatmentsarelovely,butthey'reonlygood forlittleinjuriesbecausetheyrequiredirectmaterialcontact torestore.Self healingpolymersshowabetterpathtorisk free, time honoured, defect surviving systems and constituentsin,transportation.Thisworkhasbeencarried outonself healingofpavementsusingbacteria.

Therearetwocategoriesofaggregates.Coarseaggregates andfineaggregatesarethetwokindsofaggregates.Coarse aggregatesarethosethatpassthroughasievewithasizeof up to 4.75 mm. Fine aggregates and stone crusher dusts wereobtainedfromanearbycrusher,withfractionspassing 4.75mmretainedonanISsieveof0.075mm.Thespecific gravity of which was discovered to be 2.78. Filler is aggregatethatpassesthrougha0.075mmISsieve.

Bitumenisatar likecombinationofhydrocarbonsgenerated naturallyorbydistillationfrompetroleumandusedforroad pavingandroofing.Bitumenisapetroleumliquidorsemi solid that is black and exceedingly viscous. This project employedVG30viscositygradebitumenasabinderinthe mixformulation.

ThebacteriaselectedforthisprocessisBacillusSubtllis.

Lookingforwardtowardsthepavementthathealitself,the techniquesthathelpinmakingself healingpavementsare: 1. InductionHeating 2. ByusingNano Materials

ByusingMicro Capsules

Bydirectapplicationofbacteria

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2016

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

The asphalt mix is combined with these fibres, and the pavementisplaceddown.Whenfracturesoccur,thefacetof the pavement is heated using induction heating, which allows the steel fibres to conduct heat and results the bitumen to glide and jam up the minor fissures. The exchanging current via the spiral triggers a changing electromagneticfield,whichinitiatestheinductionheating process [15]. When the conductive asphalt specimen is placed under the coil, the electromagnetic field causes currents to flow down the conductive loops that have emergedfromthesteelfibres.Thisstrategywasalsousedin the Netherlands, where test tracks were laid and the performancewassatisfactory,andmanynewhighwayswere built using this method. Steel fibres, Steel wool, Graphite, Carbon are the fibres that will be used in this process. Different writers tested with the fibres for percentages of twopart,fourparts,sixparts,andeightparts.

Theheatingtemperatureofasphaltforhealingisveryhigh nearlyabout85oC 100oC. Externalheatistobeprovided. Thereisnowaytokeeprecordsofthecracksformedinthe pavement. Induction heating types of equipment are complex,andadaptabilitytothepoor,difficulttoguarantee thequalityofwork in non uniformareas.Thedemerits in thismethodarethattheheatingtemperatureofasphaltfor healingisveryhighnearlyabout85oC 100oC.Externalheat is to be provided. There is no way to keep records of the cracksformedinthepavement.Inductionheatingtypesof equipment are complex, and adaptability to the poor, difficult to guarantee the quality of work in non uniform areas.

Thecostofinputsiscomparativelyhigh.

Nanotechnology entails research and development at the atomic,molecular,andmacromolecularlevels,withlength scales ranging from 1 to 100 nano meters, in order to provide a fundamental understanding of phenomena and materialsatthenanoscale,aswellasthecreationanduseof structures,devices,andsystemswithnovelpropertiesand functionsduetotheirsmalland/orintermediatesize[26]. Pavementmendinginvolvestheuseofnanomaterialssuch asnanosilica,nanoclay,nanorubber,NanoSiO2,TiO2,and others. Researchers have mostly worked with nano silica, nano rubber, and nano clay [27]. Bitumen was combined withnanosilicainvariousratios.Nanosilicaparticlesmay penetrate crevices and fill gaps due to their high surface energy.Nanosilicawillaidinthehealingofcracks[28].

Themechanicalparametersofthebitumenareimprovedby adding Nano silica, as is the bitumen's strength. The nano silica percentages used range from 2 to 10%. Nano silica reformedconcretehasahigherruttingresistanceandanti stripping property than traditional bituminous concrete.

Nanoclayandnanorubberwillalsobeemployedtoimprove thebituminousconcrete'shealingqualities[29].Nanoclay modifiedbitumencanimprovemechanicalqualitiessuchas indirect tensile strength, creep resistance, and fatigue resistance. When compared to ordinary bituminous concrete, the elasticity of nano clay modified bituminous concreteishigher,asaretherheologicalparameters.

Various Atomic Force Microscopy (AFM) techniques (i.e. tapping mode imaging, force spectroscopy, and nano indentation)aswellasX raydiffraction(XRD)experiments wereconductedonasphaltbindersmodifiedwithdifferent contentsofanano claymaterialtocharacterisethenanoand micro structure and mechanical behaviour of asphalt clay nano composites. The addition of nano clay modifiers to bitumenincreasedtheasphalt'sstiffness,whichimproved ruttingresistance.

Nanotechnology will benefit society in two ways: by improving the cost, durability, and efficiency of existing itemsandprocesses,andbygeneratingwhollynewproducts [30].Inparticular,thecharacteristicsofasphaltandasphalt mixtures. Nanotechnology has the various well known benefits. It improves the storage stability of polymer modifiedasphaltandimproveUVageingresistanceReduce the susceptibility to moisture under water, snow, and deicers. Improve the characteristics of low temperature asphaltmixes[31].Asphaltpavementsshouldbemademore durable.Conserveenergyandmoneysothatmaintenance requirements are reduced. While there are many possible concepts and uses for nanotechnology and pavement engineering,it'salsovitaltoberealisticandrecogniseand accept the field's current limitations and constraints. Environmental,health,andsafetyconsiderations,aswellas issueswithscalingnano effectsandprices,areamongthe concernsandobstacles[32].

Becausepavementsarebuiltinthenaturalenvironment,all materials (including nanomaterials) used in their constructionandmaintenancemustbecompatiblewiththe naturalenvironment,andtheirenvironmentalimpactmust be limited. As part of the examination of nanotechnology solutionsinengineering,thetechnicalandcost effectiveness of various technologies should be assessed. The problem withthismethodisthatitishazardoustohumanhealthand hasthepotentialforexposureanddeterminethehealthrisk of nanoparticles [33]. The majority of nanotechnology equipmentandmaterialscostalotofmoneyrightnow.This is due in part to the technology's novelty, but also to the equipment'scomplexity[34].

The capsules are mixed with the binder and filler, which facilitatesinthetreatmentofcracksaftertheyhaveformed, asthecapsules'energymayburstandreleasetheresinor binder,resultingincrackrepair[35].Theprimarygoalofa rejuvenatoristochangethepropertiesoftheasphaltmix,

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2017

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

lowering the stiffness of the oxidised asphalt binder and fluxing the binder, so extending the life of the pavement. These microcapsule shells are sufficiently reliable both thermally and mechanically. Reclaimed paxole1009, cycle paves, and ACF iterlene1000 are a few commercially convenient rejuvenating agents to endure the asphalt producing activity [36]. The oily rejuvenator is the most successful microcapsule shell to date, consisting of a prepolymer of melamine formaldehyde reformed by methanol and the resultant product. The advantageous microcapsule route for asphalt self healing enables the rejuvenation of old binder. In an asphalt mix, the optimal contentofmicrocapsulesinthebitumenshouldnotexceed 30%ofthetotalvolumeofthebitumen[19].

This is an experimental technique that will be extremely useful once it is implemented. Modulating the core/shell ratio,ontheotherhand,hasanimpactonandcontrolover the capsule's size. The microcapsule diameter should be 25m; lesser diameters, such as 10m or smaller, do not containenoughrejuvenatorandarethusunsuitableforself healing. Also, capsules larger than 30m are not employed since they facilitate the interface separation between microcapsulesand binders, resultingin theappearance of cracks[37].Asaresult,thecapsulesizeshouldbebetween 10 and 30 m, and the volume should be between 10 and 30%. The main problem of using the pavement mixture mixedwithmicrocapsulesisthatthesecapsuleactasvoids orhollowspaceswhichreducethestrengthofthepavement.

Thebacteriawhichisrichincalciumnutrientisaddedupin the concrete when the mixture is made. When the cracks occur in concrete calcium carbonate is precipitated from bacteriawhichsealsthecrack.Theadditionofbacteriainthe concrete will form a pervious layer when concrete gets fractured. The bacteria which can work in alkaline environmentischosenbecauseconcreteishighlyalkalinein nature [6]. The calcium carbonate precipitate formed by embeddingbacteriainconcretenotonlyfillsthecracksbut alsobindstheothercomponentsofthemixtureassandand aggregate. Thus, the calcite precipitation enhances the durabilityofconcrete.Bydirectapplicationofhealingagent inconcreteinLWAi.e.,lightweightaggregateandGNPi.e., graphitenanoplatelets,itisfoundthatGNPactsasthebetter exporter amalgam for bacteria and gives more promising resultsinhealingofcracks.

• Bacillus Subtilis bacteria + lightweight aggregate/graphitenanoplatelets=strengthoftheconcrete isincreased.

• BacillusAeriusbacteria+ricehuskashconcrete= thedurabilityofconcreteisincreased.

• BacillusMegateriumbacteriawhenusedinconcrete increasescompressivestrengthby24%.

• SporoscarcinaPasteuriibacteria+flyashconcrete= enhancestrengthanddurabilityofflyashconcrete

• Sporoscarcina Pasteurii bacteria + silica fume concrete= enhance strength and durability of silica fume concrete.

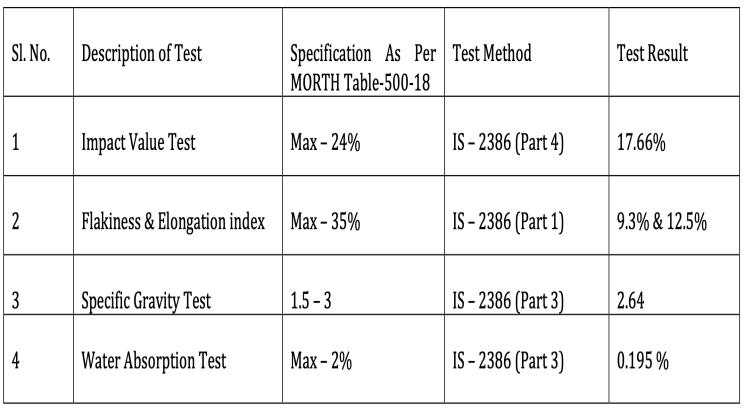

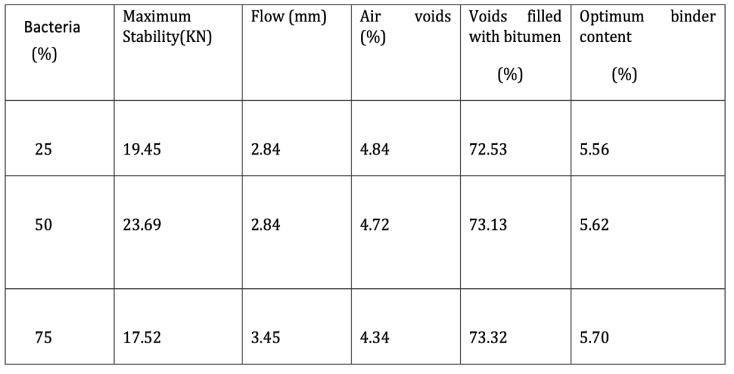

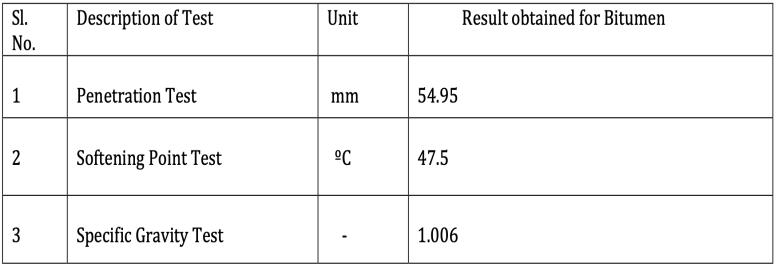

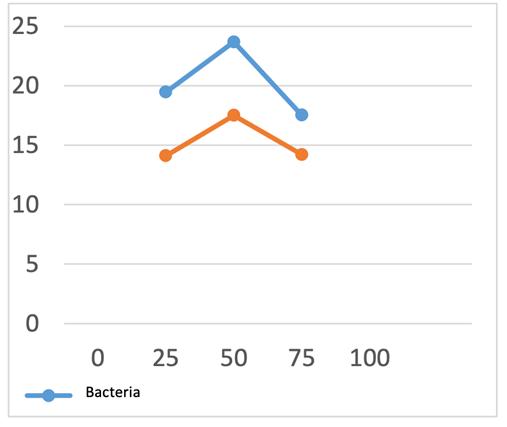

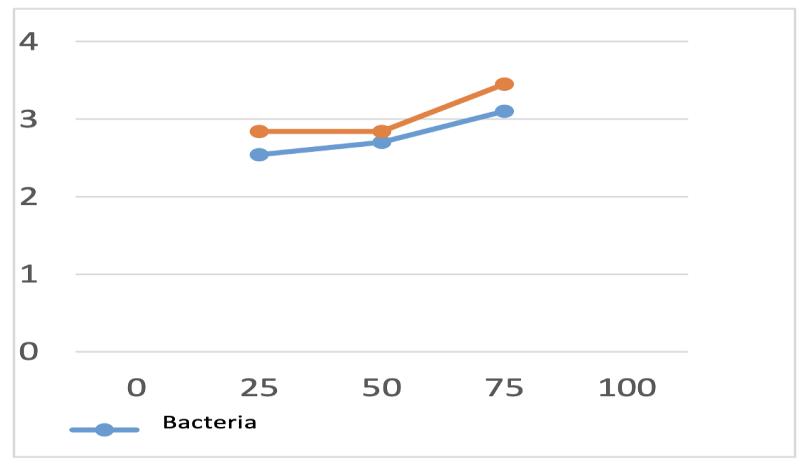

Theanalysisofthematerialusedforthepavementisvery essentialfactorbecauseitaffectscostefficiency,durability andsafetyoftransportationsystem.Thisanalysis helpsto provide the information about the characteristics of the pavement to determine its quality. Table 1 3 show the results of the studies carried out that have been further plottedinFigure1.

Table 1.Testonaggregate

Table 2. Testonbitumen

Table 3.MarshalStability

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

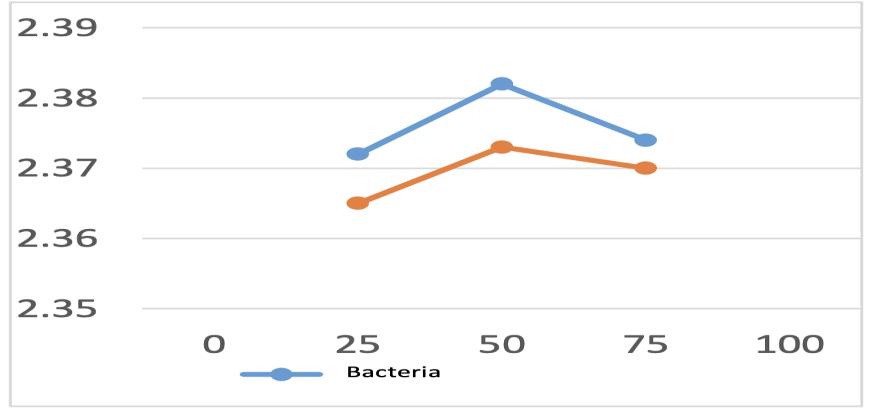

stabilitythantheothertwoslags.Soitisconcludedthat50% bacteriaisbetterforself healingpavementanditisfound thatbacteriahavelowerflowvalue,it’sbecausethebacteria hasporousanddensecharacteristics.

This research paper is focused on the various self healing techniques for the construction of pavement. There have beenavarietyoftechniques,butthisresearchpaperfocuses on the most efficient technique for making the pavement self heal. These methods are induction heating, nano technology i.e., using nanomaterials, microcapsule, and directapplicationofbacteria.

Figure 1.Comparisonofbulkdensitywithandwithout bacteria

Induction heating method requires external heat for self healing as it heals at high temperature which needs inductionheaters.Thecostinputmethodinthismethodis comparativelyhigh.Pavementmodifiedwithbitumendonot self heal properly under low temperature and the fatigue resistance lowers in modified bitumen. The problem with nanomaterialsisthatitishazardoustohumanhealthand hasthepotentialforexposureanddeterminethehealthrisk. The majority of nanotechnology equipment and materials costalotofmoneyrightnow.

Theadditionofmicrocapsulestothepavementmixreduces the strength of the pavement as microcapsules act as the void in the mix. Adding bacteria to the concrete mix improvesitscompressivestrength,durability,andstability. Accordingtothetestsperformedbyvariousresearchersitis foundthatthereplacementofhalftheamountofaggregate withbacteriagiveshigherstabilitytothepavement.Aftera comparative study of all the methods, it is found that the directapplicationofthebacteriamethodisfoundtobethe most promising method. The suggested technique used in the above explained data clarifies the roadmap for the researchersandenablesthemtoconductfurtherresearchin designingself healingpavements.

WearehighlythankfultoDepartmentofCivilEngineering, Galgotias College of Engineering and Technology for providingthehelpforthiswork.

Thegraphsareplottedfor25%,50%,75%replacementof aggregates with bacteria and compared with values of conventionalmix.Bycomparingtheabovegraphs,itisfound that 50% bacteria give the best result, because when compared 25% and 75%, 50% bacteria used has higher

[1] S.Rabab’ah,O.AlHattamleh,H.Aldeeky,andB.Abu Alfoul,“Effectofglassfiberonthepropertiesofexpansive soil and its utilization as subgrade reinforcement in pavementapplications,”CaseStud.Constr.Mater.,vol.14,p. e00485,Jun.2021,doi:10.1016/j.cscm.2020.e00485.

[2] A. Al Tabbaa et al., “Biomimetic cementitious constructionmaterialsfornext generationinfrastructure,” Proc.Inst.Civ.Eng. SmartInfrastruct.Constr.,vol.171,no. 2,pp.67 76,2018,doi:10.1680/jsmic.18.00005.

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2019

[3] R. Garg and R. Garg, “Performance evaluation of polypropylenefiberwastereinforcedconcreteinpresenceof silicafume,”Mater.Today,Proc.,vol.43,no.xxxx,pp.809 816,2020,doi:10.1016/j.matpr.2020.06.482.

[4] R. Garg, R. Garg, B. Chaudhary, and S. Mohd. Arif, “Strengthandmicrostructuralanalysisofnano silicabased cementcompositesinpresenceofsilicafume,”Mater.Today, Proc., vol. 46, no. xxxx, pp. 6753 6756, 2020, doi: 10.1016/j.matpr.2021.04.291.

[5] Z. Zhang, S. Qian, H. Liu, and V. C. Li, “Ductile concrete material with self healing capacity for jointless concretepavementuse,”Transp.Res.Rec.,vol.2640,no.1, pp.78 83,2017,doi:10.3141/2640 09.

[6] R.Garg,R.Garg,andN.O.Eddy,“Microbialinduced calciteprecipitationforself healingofconcrete:areview,”J. Sustain. Cem. Mater., vol. 0, no. 0, pp. 1 14, 2022, doi: 10.1080/21650373.2022.2054477.

[7] V. Kumar, S. Singla, and R. Garg, “Strength and microstructure correlation of binary cement blends in presenceofwastemarblepowder,”Mater.Today,Proc.,vol. 43, no. xxxx, pp. 857 862, 2020, doi: 10.1016/j.matpr.2020.07.073.

[8] R. Garg, R. Garg, and S. Singla, “Experimental Investigation of Electrochemical Corrosion and Chloride PenetrationofConcreteIncorporatingColloidalNanosilica andSilicaFume,”J.Electrochem.Sci.Technol.,vol.12,no.4, pp.440 452,2021,doi:10.33961/JECST.2020.01788.

[9] B.Li,G.Ke,andM.Zhou,“Influenceofmanufactured sandcharacteristicsonstrengthandabrasionresistanceof pavementcementconcrete,”Constr.Build.Mater.,vol.25,no. 10, pp. 3849 3853, 2011, doi: 10.1016/j.conbuildmat.2011.04.004.

[10] S. Dhiman, R. Garg, R. Garg, and S. Singla, “Experimental investigation on the strength of chipped rubber basedconcrete,”IOPConf.Ser.Mater.Sci.Eng.,vol. 961,no.1,2020,doi:10.1088/1757 899X/961/1/012002.

[11] U.M.MuthaiyanandS.Thirumalai,“Studiesonthe properties of pervious fly ash cement concrete as a pavementmaterial,”CogentEng.,vol.4,no.1,p.1318802, Jan.2017,doi:10.1080/23311916.2017.1318802.

[12] A.F.Cabalar,D.I.Hassan,andM.D.Abdulnafaa,“Use ofwaste ceramictilesfor roadpavement subgrade,”Road Mater.PavementDes.,vol.18,no.4,pp.882 896,2017,doi: 10.1080/14680629.2016.1194884.

[13] S.V.Bittencourt,M.daSilvaMagalhães,andM.E.da Nóbrega Tavares, “Mechanical behavior and water infiltration of pervious concrete incorporating recycled asphaltpavementaggregate,”CaseStud.Constr.Mater.,vol. 14,2021,doi:10.1016/j.cscm.2020.e00473.

[14] K. Van Tittelboom and N. De Belie, Self healing in cementitious materials a review, vol. 6, no. 6. 2013. doi: 10.3390/ma6062182.

[15] D.Y.Yoo,S.Kim,M.J.Kim,D.Kim,andH.O.Shin, “Self healing capability of asphalt concrete with carbon based materials,” J. Mater. Res. Technol., vol. 8, no. 1, pp. 827 839,2019,doi:10.1016/j.jmrt.2018.07.001.

[16] C.Xue,W.Li,J.Li,V.W.Y.Tam,andG.Ye,“Areview studyonencapsulation basedself healingforcementitious materials,”Struct.Concr.,vol.20,no.1,pp.198 212,2019, doi:https://doi.org/10.1002/suco.201800177.

[17] V. Wiktor and H. M. Jonkers, “Quantification of crack healinginnovelbacteria basedself healingconcrete,” Cem.Concr.Compos.,vol.33,no.7,pp.763 770,2011,doi: 10.1016/j.cemconcomp.2011.03.012.

[18] K.Vijay,M.Murmu,andS.V.Deo,“Bacteria based self healingconcrete Areview,”Constr.Build.Mater.,vol. 152, no. 1, pp. 1008 1014, 2017, doi: 10.1016/j.conbuildmat.2017.07.040.

[19] T. Al Mansoori, R. Micaelo, I. Artamendi, J. Norambuena Contreras, and A. Garcia, “Microcapsules for self healing of asphalt mixture without compromising mechanicalperformance,”Constr.Build.Mater.,vol.155,pp. 1091 1100,2017,doi:10.1016/j.conbuildmat.2017.08.137.

[20] C.ManvithKumarReddy,B.Ramesh,D.Macrin,and K. Reddy, “Influence of bacteria Bacillus subtilis and its effectsonflexuralstrengthofconcrete,”Mater.Today,Proc., vol. 33, no. August 2020, pp. 4206 4211, 2020, doi: 10.1016/j.matpr.2020.07.225.

[21] T.VanMullem,E.Gruyaert,R.Caspeele,andN.De Belie,“Firstlarge scaleapplicationwithself healingconcrete in belgium: Analysis of the laboratory control tests,” Materials (Basel)., vol. 13, no. 4, 2020, doi: 10.3390/ma13040997.

[22] P. G. Kimar and K. P. Kumar, “Self Healing TechniquesforSustainable Pavements AReview,”J.Rev. Sci.Eng.,pp.1 9,2021.

[23] RishavGarg,ManjeetBansal,andYogeshAggarwal, “Split Tensile Strength of Cement Mortar Incorporating MicroandNanoSilicaatEarlyAges,”Int.J.Eng.Res.,vol.V5, no.04,pp.16 19,2016,doi:10.17577/ijertv5is040078.

[24] B.J.Blaiszik,S.L.B.Kramer,S.C.Olugebefola,J.S. Moore,N.R.Sottos,andS.R.White,“Self healingpolymers and composites,” Annu. Rev. Mater. Res., vol. 40, pp. 179 211,2010,doi:10.1146/annurev matsci 070909 104532.

[25] M.N.Khan,S.Singla,R.Garg,andR.Garg,“Effectof Microsilica on Strength and Microstructure of the GGBS based Cement composites,” IOP Conf. Ser. Mater. Sci. Eng.,

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2020

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

vol. 961, no. 1, 2020, doi: 10.1088/1757 899X/961/1/012007.

[26] R.Garg,P.Rani,R.Garg,andN.O.Eddy,“Studyon potential applications and toxicity analysis of green synthesizednanoparticles,”TurkishJ.Chem.,vol.45,no.6, pp.1690 1706,2021,doi:10.3906/kim 2106 59.

[27] M.Kumar,M.Bansal,andR.Garg,“Anoverviewof beneficiary aspects of zinc oxide nanoparticles on performanceofcementcomposites,”Mater.Today,Proc.,vol. 43, no. xxxx, pp. 892 898, 2020, doi: 10.1016/j.matpr.2020.07.215.

[28] C.M.Kansal,S.Singla,andR.Garg,“EffectofSilica Fume&SteelSlagonNano silicabasedHigh Performance Concrete,” IOP Conf. Ser. Mater. Sci. Eng., vol. 961, no. 1, 2020,doi:10.1088/1757 899X/961/1/012012.

[29] S. A. Ghahari, E. Ghafari, and N. Lu, “Effect of ZnO nanoparticles on thermoelectric properties of cement compositeforwasteheatharvesting,”Constr.Build.Mater., vol. 146, pp. 755 763, 2017, doi: 10.1016/j.conbuildmat.2017.04.165.

[30] R. Garg, M. Kumari, M. Kumar, S. Dhiman, and R. Garg,“Greensynthesisofcalciumcarbonatenanoparticles usingwastefruitpeelextract,”Mater.Today,Proc.,vol.46, no. xxxx, pp. 6665 6668, 2020, doi: 10.1016/j.matpr.2021.04.124.

[31] B.O.BicaandJ.V.S.deMelo,“Concreteblocksnano modified with zinc oxide (ZnO) for photocatalytic paving: Performance comparison with titanium dioxide (TiO2),” Constr. Build. Mater., vol. 252, p. 119120, 2020, doi: 10.1016/j.conbuildmat.2020.119120.

[32] N.O.Eddy,R.Garg,R.Garg,A.O.Aikoye,andB.I.Ita, “Wastetoresourcerecovery:mesoporousadsorbentfrom orangepeelfortheremovaloftrypanbluedyefromaqueous solution,” Biomass Convers. Biorefinery, 2022, doi: 10.1007/s13399 022 02571 5.

[33] R. Garg, R. Garg, A. Thakur, and S. M. Arif, “Water remediationusingbiosorbentobtainedfromagriculturaland fruitwaste,”Mater.Today,Proc.,vol.46,no.xxxx,pp.6669 6672,2020,doi:10.1016/j.matpr.2021.04.132.

[34] D. Prasad Bhatta, S. Singla, and R. Garg, “Microstructural and strength parameters of Nano SiO2basedcementcomposites,”Mater.Today,Proc.,vol.46, no. xxxx, pp. 6743 6747, 2020, doi: 10.1016/j.matpr.2021.04.276.

[35] L.SouzaandA.Al Tabbaa,“Microfluidicfabrication of microcapsules tailored for self healing in cementitious materials,”Constr.Build.Mater.,vol.184,pp.713 722,2018, doi:10.1016/j.conbuildmat.2018.07.005.

[36] R. Davies et al., “Large scale application of self healingconcrete:Design,construction,andtesting,”Front. Mater., vol. 5, no. September, pp. 1 12, 2018, doi: 10.3389/fmats.2018.00051.

[37] J.Y.Wang,H.Soens,W.Verstraete,andN.DeBelie, “Self healingconcretebyuseofmicroencapsulatedbacterial spores,” Cem. Concr. Res., vol. 56, pp. 139 152, 2014, doi: 10.1016/j.cemconres.2013.11.009.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2021