International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

INVESTIGATION REPORT ON PRELIMINARY TESTS ON FAILURE OF STRUCTURE AND MONITORING

RAYALA CHENNA RAO1 , J. SASHI KANTH2

1PG Student, Department of Civil Engineering, Nova College of Engineering and Technology, Affiliated to JNTU Kakinada, Vegavaram, Jangareddygudem, West Godavari (District), A.P 534447.

2Guide, Assistant Professor & Head of Department of Civil Engineering, Nova College of Engineering and Technology, Affiliated to JNTU Kakinada, Vegavaram, Jangareddygudem, West Godavari (District), A.P 534447

Abstract In this Research, various details for structural failures like Faulty Design, Inferior quality of materials, Poor Workmanship, Weathering conditions, Naturalcalamitiesetc., have been discussed. It is also discussed about the various methods of doing the repair woks that is remedial measures. To know better about the nature of concrete elements, ten (10) concrete beamswithnominalreinforcement have been cast. All the beams were subjected to loading test in Loading Frame at Nova Engineering College, Jangareddygudem, Eluru (District), Andhra Pradesh, India Three beams were kept as control specimens. Allthe beams were first tested up to initial crack condition. The control specimens were tested up to ultimatefailure.Thevaluesofload and deflections were obtained and tabulated. The repair materials used are GPRF of 225 GSM, 300 GSM, 400 GSM, Jute Fiber and Steel Jacket. After curing they were tested up to failure. The values of Load and Deflections were noted. Load Cells are used for noting down the Deflections. Fromthe values obtained it was noted that, out of all the methods applied Steel Jacketing is found to be the most effective and also most economical. So that method is recommended for the concrete repairing work.

Wall atChina,TheWhiteHouseetc.,Thefailuresofbuildings arebroadlydividedintotwotypes.Structuralfailuresandthe other is nonstructural failures. Structural failure affects the structures in a noticeable way and also the life of the occupants.Structural failuremeansthefailureofaconcrete construction to fulfill the purpose for which it was constructed. Nonstructural failures includes defects in brickwork,defectsinplasterwork,defectsinplumbingwork, and defects in electrical work etc., which do not affect the safety of structure to a greatextentingrandmanner.The pastoffailureofstructureshappeningfromveryoldentime from300A.D.andlaststilldate.Figure1.1showsthestrong of a tall structure into twoportionsinaverticalmannerat OogueatSiberia.

1. INTRODUCTION

In early days man used to live in huts which were constructed with the materials availablein abundance in nature.Theycouldbuildtheirhutsinsafeplaces whichwere notaffectedbynaturalcalamities byexperience.Ifanything happened like failure they could repairthem withtheleast cost materials available in nature. But due to increase in population and the invention of new building materials, it becomes important to know about structural failures in a building and remedial measures to be done. Failures in engineering construction are caused by deterioration of various building materials with age due to various causes. Awarenessaboutvariousagenciescausing deteriorationis essential to understand the problem and to find out the solution. All Civilconstructionsaresubjectedtofailuresin oneorotherwayataparticulartimeexceptsomeimportant monumentslikeTheTajMahal,TheKutubMinar,The Great

IRJET

Impact Factor value: 7.529

1.1 Types of Failure and the Reason for Failure

General structural failures are Cracks, Damping, Leakageand Spalling etc. and these show weakness of buildings.Thereasonforthesefailuresmaybe

1. Inferiorqualityofmaterials

2. Poorworkmanship

9001:2008

Engineering

Volume: 09 Issue: 05 | May

METHODOLOGY

2.1 Objectives

Theobjectivesofthethesisare

Tofindthefailuremode(developmentofcrack) onthebeamwhenitreachedthecrackingloadand ultimateload.

Tocarryout different Rehabilitation Methods.

Toidentifythebestmethodofrehabilitationin aspectofstrengthanddeflection.

2.2 Specimen Preparation

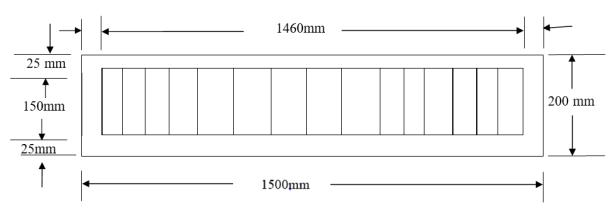

Thebeamsizeis150mmX200mmwithspanof1500mm.The grade of concrete is M25 and steel is Fe415 TMT bars. The beam has beencastbyusingOPC 43grade cement withthe water cement ratio of 0.4. For Tension and compression Reinforcement two numbers of 12mm diarod areprovided, 8mmdiarodisprovided as shearreinforcementat 100mm c/c distance.Shearreinforcementisprovidedwithtwolegs, withaleglengthof35mm.Forbeamspecimentypicalcross section drawing of beam is shown in Figure 3.2 with the details of its size and reinforcement details and its longitudinalsectioninFigure3.3.

12mm Rod Compression zone

Reinforcement

Technology (IRJET)

e ISSN: 2395 0056

p ISSN: 2395 0072

2.2 Testing

The beams of eighteen numbers were casted. After curing theyweretestedwiththeLoadingFrame.Threebeamswere keptascontrolspecimensandtestedforUltimateLoadand thecorrespondingDeflectionwasnoted.Theaveragevalue is calculated. Similarly other beamsweregroupedintofive groupseachcontainingthreebeams.Allthebeamsarefirst testeduptoinitialcrackcondition.Tothecrackedbeamsfive methods of retrofitting or rehabilitation wasdone. The Rehabilitation methods consisted of Wrapping Technique using GFRP of 225GSM,400 GSM, 300 CSM and Jute Fiber and Steel Jacketing was done for them. Then the repaired beamsweretesteduptoultimatefailures.Tocrosscheckthe experimentalwork,theoreticalcalculationisdoneforcontrol SpecimeninLimitStateDesignMethodbytheclauseswhich is stated under IS 456 2000 code and compared with the ultimateloadwhichwasobtainedfromtheexperimentaltest. With the testing results comparison of Ultimate Load CarryingCapacity and Deflections atthatLoadweredone for all the five methods of Retrofitting with the Control Specimen.Fromtheresulttheconclusionwasarrived.

3. PRELIMINARY TESTS

As this thesis mainly concentrates on study of structural failures, mainly cracks, it hasbeen decided to cast beams which are main component of any construction. So the materialsused for casting should be tested for their properties. Then the beams are casted. As preliminaryworkallbasematerialsaretestedfornecessary properties like specific gravity, water absorption, sieve analysis, initial setting time final setting time for cement, cubetestforconcreteandcementaredoneasperprescribed IScodes.Forthisproject,20mm Sizeaggregateisused as Coarseaggregateand naturalsand isusedasfineaggregate. And the size of aggregate both fine and coarse is within limitsasstatedinIS 383

Cement used for this specimen is OPC 43 grade conformingto IS 8112 1969 Itistestedaccordingto IS:460 1962 andtheresultsweresummarizedasfollows:

Fineness Modules of cement = 3%

Specific Gravity of cement = 2.46

Consistency ofCement = 35%

Initialsettingtime = 30Min.IS:4031(Part6)

Finalsettingtime = 600Min.

3.1 Test Results for Fine Aggregate

FineAggregateusedforthisspecimenistestedaccordingto IS:2386(Part 3) -1963 andtheresultsweresummarizedas follows:

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

SpecificGravity ofFineAggregateis = 2.55

WaterAbsorptionofFineAggregateis= 1.23 %

Percentage of Fineness modulus is 5.349 (Zone III) (IS: 2386 (Part 1) 1963)

3.2 Test Results for Coarse Aggregate

Specific Gravity 20mm Aggregate = 2.887

GradationofAggregate= 5.28%

WaterAbsorption = 1%

FlakinessIndex = 14.26%

ElongationIndex = 24.36%

Impact value of Aggregate = 11.41% IS: 2386(Part 4) 1963

3.3 Strength Test on Concrete

For checking the concrete strength with the design mix, cubes are casted and tested forcompressionstrengthand Tensilestrength.

Compressive Strength of ConcreteCube = 27.8N/ mm2 Tensilestrength of Concrete = 2.56N/mm 2(10% of fc k) Flexuralstrengthof concrete = 31.6N/ mm2

e ISSN: 2395 0056

p ISSN: 2395 0072

mats can be torn by using hand; these mats are used in specific region to increase the strength of the area.

Fig 2: Chopped StrandMat

3.5 Jute Fiber

JuteFiberisoneofthe easily availablematerialsinIndia. Themanufacturingprocessofthejutefiberismucheasyand itisthedoneasahomemadebusiness in many ofthesmall villages in India. When jute fiber is compared with the glass fiber in the aspect of the cost it ismuch cheaper material. But in the aspect of the strength jute will not perform as much as glass fiber, still jute is used for rehabilitationworkbecauseofitsavailabilityandlowcost of thematerial.

3.4 Chopped Strand Mat

Chopped StrandMatis alsoshortly knownasCSM. It will havechopped glass fiberwhich is 3 to 4 inches in length and the fiber runs in multi directions. Usually chopped strandfiber mat is compatible only with the resin like polyester and vinyl ester. Epoxy resin will not have compatibilitywiththechoppedstrandmat.Choppedstrand

4. PRELIMINARY TESTS

Thebeamsizeis150mmX200mmwithspanof1500mm. ThegradeofconcreteisM25andsteelisFe415TMTbars. ThebeamhasbeencastbyusingOPC43gradecementwith thewater cementratioof0.4.ForTensionandcompression Reinforcement two numbers of 12mm dia. rod are provided,8mmdia.rodisprovidedasshearreinforcement

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page169

Fig 1: CompressionTest on Cube Fig 3: JuteFiber5. EXPERIMENTAL WORK

Duringtheexperimentalworkitwasobservedthatwhen the beam reaches the cracking load the initial cracks are formed. After formation of initial cracks, continous applyingof theload,theinitialcrackhasbeendevelopedinto broaderanddeepercrack,whichmakesthebeamincapable tocarryloads,thusultimateloadisattainedbythebeam.Asa flexural member, due to deflection crack is formed at the middle1/3portionofthebeam.This beamisdesigned asan under reinforced beam so that the failure of the concrete takesplacefirstbytheformationofcrack.Thiskindofbeam is safe, because we can getwarningofstressinbeamby the crack appearance. If the beam is reinforced as over reinforcedbeam steel will fail first due to failure of steel, concrete will fail immediately, therefore we can’tget any kindofwarningfromthebeammember

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

6. CONCLUSIONS

The problem of structural failure has been taken with intention of providing remedial methods to solve the problem.Thoughtherearesomany structural failures like cracks, leakage, dampness, spalling and others, the thesis dealtwithcracksinbeams.Beams are the mostimportant partofanystructure.Withthedetailedstudyandsurveyof literature related to structural failures and retrofitting methods,practicalworkto be done was decided. Before castingbeamsthebase materialswere selected andtheir properties were tested confirmed with IS Codes. Totally Eighteen beams were casted and tested. The report was presented.

For the control specimens the mean cracking loadis65.33kN.Themeandeflectionis14.1mm.

For the beam rehabilitated by GFRP 225 GSM the average ultimate load taken by thebeam is 72kN. So the load bearing capacity is increased by 10%.Thedeflectionis15.37mmwhichisincreased by9.7%.

ForthebeamrehabilitatedbyGFRP400GSM the averageultimateload takenby thebeamis85.67kN. Theloadbearingcapacityisincreasedby31%.The deflectionis16.73mmwhichisincreasedby18%.

ForthebeamrehabilitatedbyGFRP300GSM the average ultimate load taken by the beam is 71kN. The load bearing capacity is increased by 9% . The deflection is 13.27mm which is more than 0.83mm whencomparedwithcontrolspecimen.

For the beam rehabilitated by Jute Fiber the averageultimateloadtakenbythebeamis68.33kN. Theloadbearingcapacityisincreasedby5%.Butthe deflectionis12.43mmwhichislessthan 14%when comparedwithcontrolspecimen.

ForthebeamrehabilitatedbytheSteelJacketing methodthemeanvalueofUltimateloadis111kN.The ultimateloadcarryingcapacityisincreasedby70% andthedeflectionis11.9mmwhichisalsodecreased by16%.

REFERENCES

[1] Abd Elhamed.M.K,“Retrofitting and Strengthening of Reinforcement Concrete Damaged Beams using Jacketing of Steel Wire Mesh with Steel Plates” International Journal of Engineering Research & Technology,Volume 04,Issue 04,PP596 604,April 2015.

Impact Factor value:

e ISSN: 2395 0056

p ISSN: 2395 0072

[2] Abo Alanwar,M.MandElbatal,S.A,“ASmartReinforced Steel Wire Mesh U Shape Jacketing Technique in Strengthening and Retrofitting RC Beams”, International Journal of Engineering Research & Technology, Volume 04, Issue 12, PP 46 55,December 2015.

[3] Alfred M Freudenthal “Safety and the Probability of StructuralFailure”ProceedingsofAmericanSocietyof CivilEngineers,Volume80,Issue8,pp:1 46,1954.

[4] AnutagK.Jain,Prof.D.S.Padole,“EnhancementofRupture StrengthusingCarbonFiberPolymerandE GlassFiber”, International Journal for Scientific Research & Development, ISSN(Online), pp:2321 0613,Volume 4, Issue 03,2016.

[5] Ayyanar J, Shanmugavalli.B, “Experimental Study in Flexural Behaviour of RCC Beams, Using Natural Fiber Wrapping”, International Journal of Engineering Science and Computing, Volume 06, Issue 05,PP5252 5258,2016.

[6] Bank.L.CandGentry,T.R,“CompositeforConstruction Structural Design with FRP Materials”, John Wiley & Sons,Inc.(2006).

[7] BerylShanthapriya.A,Sakthieswaran.N,“Optimization of GFRP Confinement in RC Columns using Shape Modification Technology”, International Journal of EngineeringResearch&Technology,Volumn 04,Issue 08,PP705 713,Aug 2015.

[8] Drs Brian Falzon and Emile Greenhalgh and Victoria Bloodworth“Mechanismsandmodelingofstringerde bonding in post buckled carbon fibre composite stiffenedpanels”Ethos,imperialcollegeLondon,2008

[9] Brown,M.D.,Bayrak,O.andJirsa,J.O.“DesignforShear BasedonLoadingConditions” ACIStructural Journal Volume103,Issue4,pp:541 550,2006.

[10] YS Chung, C Meyer, M Shinozuka, “ Modeling of ConcreteDamage” Structural Journal86(3)259 271, 1989

[11] Cui,C.andSheiek,S.A.“ExperimentalStudyofNormal and High Strength Concrete Confined with Fibre Reinforced Polymers” , Journal of Composite for Construction,ASCE,pp553 561,2010.

[12] DarioCoronelli,KamyabZandiHanjari,KarinLundgran “Severely corroded RC with cover cracking” publishedintheJournalofStructuralEngineering139 (2)221 232,Apr2012.

[13] David Aveiga and Marcelo L.Ribeiro,“A Delamilation Propagation Model for Fiber Reinforced Laminated Composite Materials”, Hindawi, Mathematical

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

ProblemsinEngineering,ArticleID1861268,9pages, 2018.

[14] DipeshK.Rathod,Prof.TarakP.Vora,“ToStudytheEffect of Different Strengthening Patterns Using GFRP on ShearCapacityoftheBeam”,International Journal of Engineering Research & Technology, Volume 02, Issue 06,PP156 161,June 2013.

[15] Li, H., Dong, S., El Tawil, S., Kamat, V “Relative displacement sensing Techniques for post event structural damage assessment review”American SocietyofCivilEngineersSeptember2012.

[16] Elsevier. Bank.L.C and Gentry,T.R “Composite for Construction Structural Design with FRP Materials”,JohnWiley&Sons,Inc.January2006.

IRJET | Impact Factor value: 7.529 | ISO 9001:2008

e ISSN: 2395 0056

p ISSN: 2395 0072