International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

PARTIAL REPLACEMENT OF CEMENT WITH WOOD ASH AND ADDITION OF EXPANDED POLYSTYRENE BEADS AND COCONUT FIBRE IN CONCRET

Raghav Koushal1, Sourabh Lalotra2

1 PG Scholar, Sri Sai College of Engineering and Technology, Pathankot, India

2 Assistant Professor, Sri Sai College of Engineering and Technology, Pathankot, India

***

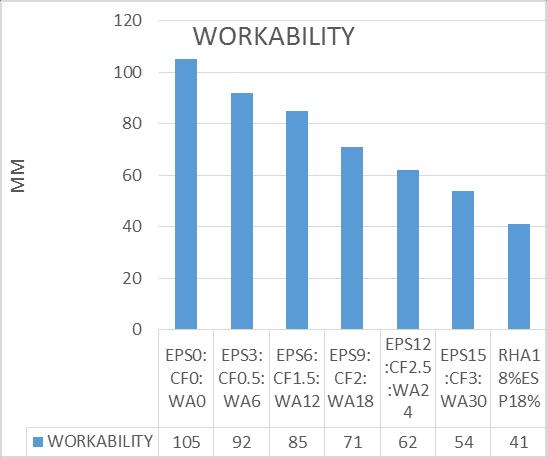

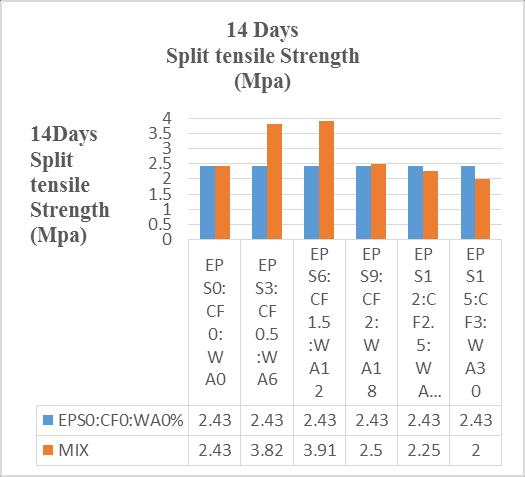

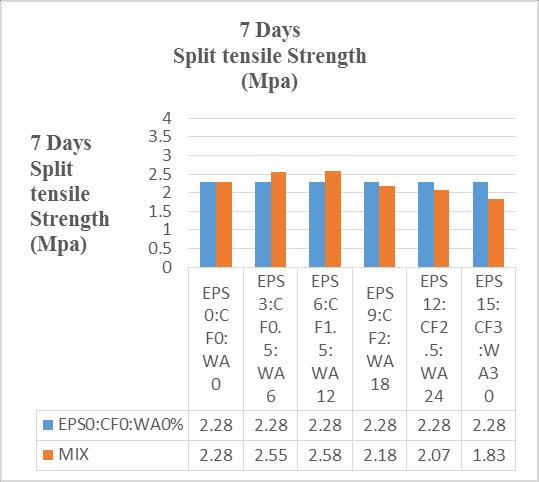

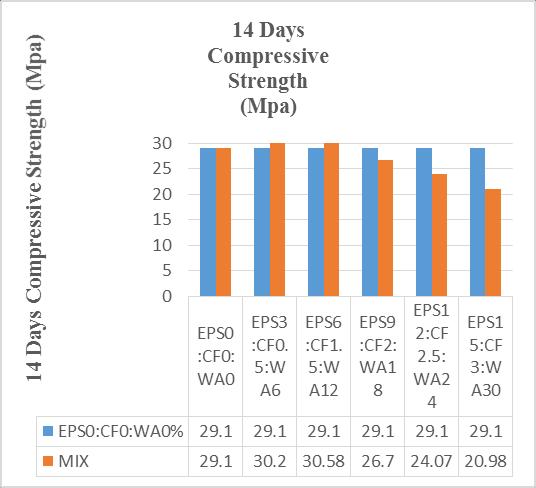

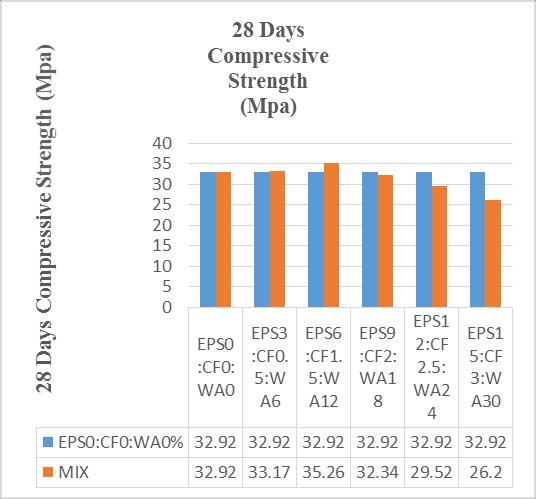

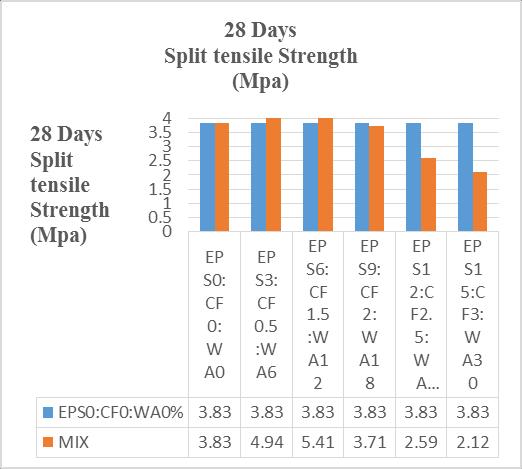

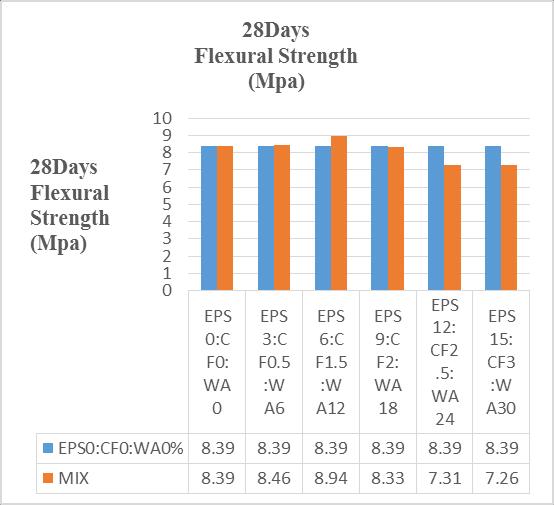

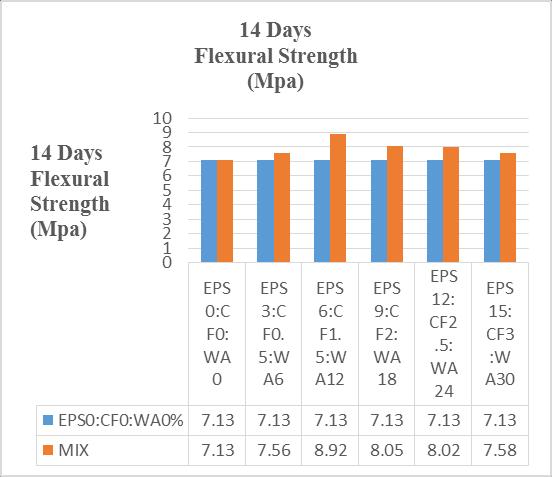

Abstract Withgrowingconstruction,thereisnoshortage oftallbuildingsandstructures.Butthereisonethingthatis gettingdepleted,thesearenaturalsourcessuchassandand aggregates. These material either require some alternate sourceorusingwastematerial.Thematerialneedtobesuch thatwhicharecausingharmtotheenvironmentoravailable in abundancies beads is one of the material which is non biodegradable and remains for longer time without any degradationordegradation.Also,coconutfiberisanatural source which is constantly getting produced. The use of thesematerialswillalsohelpinmakingconcretelightweight. Thewoodashcancontributetoreducingtheheatlossrateof buildingwasgiventheirrelativelylowthermalconductivity comparedtogypsumboard.Thisresearchexplainsaboutthe study methods for producing lightweight concrete by replacingWoodashwithcementadditionofEPSbeadsand fiber reinforced. The main objective of this study is to determine the workability, compressive strength, tensile strength and flexure strength of lightweight concrete prepared by using polystyrene beads, coconut fiber and woodashreplacewithcement.Thetestswillbeconducted tofindcompressivestrength,tensilestrengthandflexural strength. Based on the previous research work, a comparisonofstrengthpropertiesofWoodash,EPSbeads and fiber reinforced concrete is made with respect to conventionalconcrete.Differentspecimensofthematerial aretestedforstrength.Theresultshowthatworkabilityof concreteisfineandinrangeafteraddingepsbeads.Theflow gets controlled due to addition of coconut fiber. The workability of mixture reduces with more eps beads. The woodash,beadsandcoconutfiresaremixablewithother concrete aggregates. The strength parameters such as compression,tensionandflexurealsoincreases.Optimum value of strength in compression, split tensile and flexure came at EPS6:CF1.5:WA12 replacement of Wood ash with cement and addition of eps beads and coconut fiber. The strengthofconcreteincreasesuptotheEPS6:CF1.5:WA12 replacement,afterthatthereisdecreaseinthestrengthof theconcrete.Themaximumproportionofreplacementhas been found by conducting the following strength tests: Compressivestrengthtest,FlexuralstrengthtestandSplit TensileStrengthTest.

1. INTRODUCTION

The constant and ever going developmental activities in engineering and growing constructional activities have createdacontinuousdemandforbuildingmaterialswhich satisfyall thestringentrequirementsregarding the short term and long term performance of the structure. As the structuresoftomorrowbecometallerandmorecomplex,the materialsofconstructionareneedtobesuchthattheyfulfil therequirementcriteriaandstandardsofperformancethan thosethatareusednow.Thematerialaregettingdepletedso alternatematerialneedtobetestedsothattheyareaviable optionusedinconstruction.Thebuildingmaterialarenot goingtoincreaseasthenaturalmaterialsthatareusedfor constructionare reachinga saturationlevel.Itis required thatalternatematerialmustbeusedthatcanprovidesome benefitaswellasreducewastematerial.

1.1 LIGHT WEIGHT CONCRETE

Lightweight concrete is a good path in search of material whicharelowinweightascomparedtotheircontemporaries for alternative building materials in current construction application.Itgreatlyimprovesthetechnical,economicaland ecologicalaspectsoftheconstructionsector.Theuseoflight weightconcreteconsiderablyreducestheweightandloadon the structure. Compared to ordinary concrete it has many advantages such as lower thermal conductivity, lower density,fireresistanceandimproveddurabilityproperties. Being low in weight it greatly reduces dead load on the structurewhileprovidingbetterpropertiesinotheraspects. However, this type of concrete is associated with lower mechanicalpropertiesanditrequireshigherwaterduetothe porous natureof the lightweight concrete. But these voids canbecoveredbyusingcementpasteorcoveringtheoutside portion by pasting or plastering as it covers the inside portion. The use of these material can provide us the opportunitytomakefulluseofthesematerialforsustainable development.

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

1.2 EPS [EXPANDE POLYSTYRENE] IN CONCRETE

Expandedpolystyrene(EPS)appearasexcellentchoiceto producelightweightconcretesinceithaspropertieswhich areoftenrequiredinconcretesuchaslowdensity,moisture resistance,thermalresistance.Itisamaterialusuallyused forpackingofnumerousproductsforprotectionpurposes, insulation and impact absorbing nature. Mechanical robustness. It is present in various industrial fields and is mostoftenreleasedintonatureafteritsuse.However,being non biodegradable,itdoesnotdisappearbynaturalmeans and remains present in nature for many years. PS is chemicallyinertasitdoesnotreactinnormalatmospheric conditions. It is not poisonous in nature. It is also not a breeding ground for fungi and other bacteria. Since it is waste from packaging industry its use in making of lightweightconcretewillnotonlyreducecostbutalsoprove asaneffectivewayofwastedisposal.

1.3 COIR FIBRE IN CONCRETE

Coirfibrehasapplicationsinmanyfields.Oneoftheunusual or more recent application of it is in the concrete. Since, concreteisabrittlematerial.Itpossessesverylowresistance tocracking,lowtensilestrengthandductility.Whenstressis applied to the concrete, it develops crack due to various reasons such as shrinkage. Other factors also lead to the formationofcracks.Internalcracksarecausedinconcrete due to these reasons which propagates to the outer side causing external cracks in concrete which leads to brittle fractureinconcrete.Italsohaslowtensilestrengthwhich also leads to crack when subjected to tensile force, this opensupthecrack.Theinelasticdeformationinconcreteis causedbythesecracks.So,naturalfibreshavebeentriedas reinforcement in cement mixtures to produce low cost concretewhichcanbeused instructures.Coconutfibre is readilyavailableinnatureinplentywhichmakesitagood option to be used as reinforcement material. The use of coconutfibrewillalsoresultingeneratingrevenueforthe farmerswhocultivatecoconuttrees.

1.4 WOODASH

There are several minerals in wood ash, which can be extractedforfurtheruse.Abigingredientcalciumcarbonate, which is 25% or even 45% (depending on feedstock and burningcondition).Lessthan10percentispotashandless than 1 percent is phosphate; there are some elements of iron,manganese,zinc,copperandsomemetalparts.These numbers however, vary as combustion temperature is an importantelementforthedeterminationofwoodash.Many oftheseareintheformofoxides,mainly.Ifwemixtheashes towatertheinsolublesilicaandcalciumcarbonatewillsettle to bottom and sodium salt and soluble potassium will dissolve. We can then remove the water (containing the “goodstuff”)andthrowtheinsolubleingredients’away.To isolatesolublecarbonatesfromchlorides,wewillexploitthe solubilityofhotwater

2. LITERATURE REVIEW

e ISSN: 2395 0056

p ISSN: 2395 0072

V.Sai Uday,B.Ajitha(2017) conductedtheirexperiments toobtaintheeffectofcoconutfibersinconcretestructures. Theirexperimentdescribedtheadditioninpropertycaused byusingcoconutfiberintheconcrete.Theyfoundoutthat additionoffiberimprovesthestrengthofconcrete.Addition ofcoconutfiberimprovesthecompressivestrength,flexural strength and split tensile strength of concrete. The experimentwasconductedonhighstrengthconcretewith theadditionoffiberwith5mixproportions(1%,2%,3%,4%, and5%)bytheweightofcement.Thecompressivestrength and split tensile strength of cured concrete evaluated for 3days,7daysand28days.Thefibersusedintheirexperiment werecollectedfromlocaltemples.Thefiberswerepresoaked in water for 24 hours before use. The study found the optimum fiber content to be at 1 %( by the weight of the cement).This results show coconut fiber can be used in construction.

Batt and garg (2017) Woodashiscreatedaswastefrom combustioninboiler,inpulpandpapermills,steampower plantsandsomeothergeneratinginstallationsforthermal power. Wood is a renewable energy resource and an environmentalfriendlymaterial.Theincreaseddemandfor theuseofwastewoodforthepurposeofenergyproduction andthuscreationofmoreashwastefromwood.Theresearch focuses on wood ash incorporation in combination with ordinaryPortlandcementwhenusingitforvariousstructural works.Thedetailedstudyinsieveanalysis,consistency,and waterabsorption,settingtimeandslumptestsofwoodash producedimportantresulttoemphasizethedetailedstudy process.Uncontrolledsawdustburningtoformwoodashis usedasapartialcementsubstitute,andthereforechanging its physical and chemical properties in this way. Such properties are somewhat found the same as fly ash. The concretemixarereplacedwiththeamorphouswoodashas an admixture of cement having grain size less than 75 micronsinproportionsof5%,10%,15%,20%,25%and30% by weight of cement. In this Study, a research work is conducted for determining the change in workability or consistencyofconcrete.

Aman Mulla and Amol Shelake (2016) didtheirstudy tofindaconcretemixproportionwhichgavebetterresult thanBurntBrickincompressivestrengthanddensity.They studiedthepropertiessuchasdensity,compressivestrength and splitting tensile strength of lightweight Expanded Polystyrene(EPS)beadsconcrete.Thenitspropertieswere compared with M20 grade conventional concrete. Their conclusionswerethatEPSconcretegavegoodworkability. Thefinishingandcompactioncouldalsobedoneeasily.They alsofoundoutthatcompressivestrengthofEPSconcretewas lessthannormalconcrete.Theconcretemixhavelowdensity and it gives the strength more than burnt brick so the concretemixproportioncanbeusefulaslightweightconcrete brickinconstructionwork.Theconcretemixproportionare

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

also useful as precast concrete members with low density andmoreworkability.

Thomas Tamut, RajendraPrabhu,KattaVenkataramana, Subhash C Yaragal (2014)investigated variousthingswith theuseofEpsbeadsinconcrete.Theirexperimentwasbased onreplacementofcoarseaggregatesintheconcretemixwith theepsbeadsintheproportionof5%,10%,15%,20%,25%, 30%.The property of concrete such as compression and tension was compared with the normal concrete. The replacement they did was partial replacement of coarse aggregate. They found out that the property of concrete mixedwithepsbeadsdecreasewithadditioninpercentageof epsbeads.ThegradeofconcreteusedbythemwasM30.The workabilityofconcreteincreasedwithincreaseinpercentage ofepsbeads.Ontheotherhand,thecompressivestrengthof concrete decreased with addition of the eps beads. The tensilestrengthalsodecreasedwithincreaseintheamount oftheepsbeads

(Chouw et al.,2012) studied the viability of using coconut fiber ropesas verticalreinforcementinmortar free low cost housing in earth quake prone regions. The rope anchorageisachievedbyembeddingitinthefoundationand toptie beams.Thebondbetween therope and theconcrete plays an importantrole in thestability of thestructureand theropetensilestrengthisalsofoundtobefairlyhigh.The ropetensiongeneratedduetoearthquakeloadingshouldbe lessthanboththepulloutforceandtheropetensileloadto avoid the structurecollapse. The study concluded that the pull out energy increases with an increase in embedment length,ropediameter,cementandfibercontentinthematrix

Batt and garg (2017) Woodashiscreatedaswastefrom combustioninboiler,inpulpandpapermills,steampower plantsandsomeothergeneratinginstallationsforthermal power. Wood is a renewable energy resource and an environmentalfriendlymaterial.Theincreaseddemandfor theuseofwastewoodforthepurposeofenergyproduction andthuscreationofmoreashwastefromwood.Theresearch focuses on wood ash incorporation in combination with ordinaryPortlandcementwhenusingitforvariousstructural works.Thedetailedstudyinsieveanalysis,consistency,and waterabsorption,settingtimeandslumptestsofwoodash producedimportantresulttoemphasizethedetailedstudy process.Uncontrolledsawdustburningtoformwoodashis usedasapartialcementsubstitute,andthereforechanging its physical and chemical properties in this way. Such properties are somewhat found the same as fly ash. The concretemixarereplacedwiththeamorphouswoodashas an admixture of cement having grain size less than 75 micronsinproportionsof5%,10%,15%,20%,25%and30% by weight of cement. In this Study, a research work is conducted for determining the change in workability or consistencyofconcrete.

Factor value:

3. MATERIALS

e ISSN: 2395 0056

p ISSN: 2395 0072

CEMENT Inthisproject,oneofthebindingmaterialsis usedthatiscementandalsooneoftheimportantmaterials for building in today’s construction world. The Ambuja cement53gradeofordinaryPortlandcementbyIS:8112 1989isusedinthisproject.

3.1 FINE AGGREGATES Aggregatesconsistsoftwotypes, fine aggregates and coarse aggregates. Fine aggregates consistsofnaturalstoneorcrushedparticlespassingthrough 4.75mmsizesieve.Aggregateswhichaccountforone third percentageofthetotalvolumeofconcrete,aredividedinto twoseparatecategories fineandcoarse.Naturalgraveland sandaretypicallydugordredgedfromapit,river,lake,or seabed.Thecrushingofbigboulders,cobbles,quarryrock, and large size gravel also produces crushed aggregate. Aggregatesstronglyinfluenceconcrete'sfreshlymixedand hardened properties, mixture proportions and economy. Thereisalthoughalwaysavariationofaggregateproperties is expected, characteristics include durability, grading, particle shape and surface texture, abrasion and skid resistance, unit weights and voids, absorption and surface moisture.

3.2 COARSE AGGREGATES Theparticleswhichretainson the sieve and are larger than 4.75mm are referred to as coarse aggregates. For making a good mix of concrete aggregatesneedtobehard,cleanandstrongparticleswhich are free of coatings of clay or any absorbed chemical and other fine materials that could cause the deterioration of concrete.Coarseaggregatesareroundedorirregulargravel stones.Itconstitutethemajorityofcoarseaggregateusedin concrete with crushed stone making up most of the remainder.Coarseaggregatesshouldbecarefullyhandledto avoiddirtcontamination.Itshouldbecleananddry.

3.3 EPS [EXPANDE POLYSTYRENE]

PROPERTIES

COIR FIBRE

PROPERTY VALUES

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

4. Waterabsorption 160%

5. Density 480kg/m

6. Colour Brown

Table -2: Physical properties of coconut fibers

WOODASH COMPONENT MASS%

SiO231.8 31.8

Al2O3 28

28Fe2O3 2.34

CaO 10.53

NaO 6.5

K2O 10.38

MgO 9.32

P2O5 1.17

Lossofignition 27

Table 3: Chemical properties of wood ash

4. METHODOLOGY

CASTING In order to test compressive strength of concrete,concretespecimensofstandardcubicalmouldof size150*150*150mmwerecastedinelevendifferentbatches having different replacement percentage of Rice Husk Ash andESP.Thespecimenusedforthistestiscylindricalandits dimensionis150mmindiameterand300mminlength The testismadeonthebeamofsize700mm×150mm×150mm

4.1 CURING all the materials when mixed adequately to achievehomogeneousmixture.Aftermixingtheconcretewas checked for required slump and then filled into moulds of requiredtests.Themouldfilledwithconcretewascompacted by table vibrator to achieve proper compaction. Mould surfacewasfinishedwithtrowelanddateofcastingwithmix designationnumberismarkedonit.Theconcretespecimens were then removed from moulds after 24 hours and then placedincuringtanksforcuringprocessfor7,14and28days atnormalroomtemperature.

4.2 SLUMP CONE TEST Itcanbeusedinsiteaswellasinlab. This test is not applicable for very low and very high workabilityconcrete.Itconsistsofamouldthatisintheform offrustumhavingtopdiameterof10cm,bottomdiameterof 20cmandheightof30cm.Theconcretetobetestediffittedin the mould in four layers. The each is compacted 25 times withthehelpoftampingrod.Afterthemouldiscompletely filled it is lifted immediately in the vertically upward directionwhichcausestheconcretetosubside

e ISSN: 2395 0056

p ISSN: 2395 0072

Fig -1: SLUMP CONE TEST

4.3 COMPRESSIVE STRENGTH TEST

Thenfreshconcreteisfilledinmouldin4layersandafter fillingeachlayertampingshouldbedone35timesincaseof cube and 25 times in case of cylinder by using standard tamping rod. Once the mould is filled then leveled top surfaceofconcretewithtrowel.Afterthedaythemouldwill removedandspecimenaredroppedinthecuringtankunder standardtemperatureof27±2°c.After7,14and28daysin thisresearch

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

4.4 SPLIT TENSILE STRENGTH

The specimen used for this test is cylindrical and its dimensionis150mmindiameterand300mminlength.The instrumentusedforthistestingisuniversaltestingmachine. Thefreshconcreteispreparedinaccordingtotherequired gradesandrespectivemixproportion.Thefreshconcreteis filled in mould in layers and each layer is tamping with standardtampingrodwith25blowsforeachlayer.Afterthe

7.529

e ISSN: 2395 0056

p ISSN: 2395 0072

day the mould is removed and specimen is placed in the curing tank for 7,14 and 28 days in this research at the temperature27+2°c.Thendrawthelineonthespecimen

International

Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

Fig -7 SPLIT TENSILE STRENGTH 28 days

4.5 FLEXURAL STRENGTH TEST

Theconcreteispreparedatrequiredrateofmasselement the mould is filled with concrete in layers and blows 25 timeswithstandardtampingrod.Afterthedayorwecansay 24hoursthemouldisremovedandspecimenplacedinthe water tank for curing at a temperature of 27 + 2 C. Depending upon the requirement the test specimen is removedfromthewatertankandwipeitproperlyfor7,14 and28daysfortesting

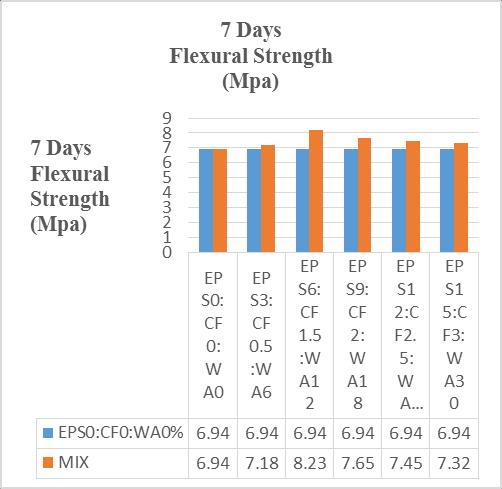

8 FLEXURAL STRENGTH 7 days

e ISSN: 2395 0056

p ISSN: 2395 0072

Fig 9 FLEXURAL STRENGTH 14 days

Fig 10 FLEXURAL STRENGTH 28 days

5. CONCLUSIONS

• 1. Workability results show that workability of concretedecreasesabitwithincreaseinWoodasheps beadsandfibers.Theworkabilityofmixturereduces with more eps beads. The Wood ash, beads and coconut fibres are mixable with other concrete aggregates.AlltheconcretecontainingWoodash,eps beadsandcoconutfibreshowgoodenoughworkability tobeeasilycompactedandfinished.

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

• Compressive strength result show that partially replacementofcementwithwoodashandadditionof coconutfibrethereisincreaseincompressivestrength. AfterEPS6:CF1.5:WA12volumereplacementthereis decrementofcompressivestrength.

• Themaximumcompressivestrengthisachievedat EPS6:CF1.5:WA12 Partially replacement of cement withwoodash,withAdditionofepsbeadsandcoconut fibre.

• The highest value of compressive strength was obtainedatEPS6:CF1.5:WA12%replacementwhichis 5.2Mpa.

• Thepartialreplacementofthepartiallyreplacement of cement with wood ash and addition of EPS and coconut fibre has shown +ve impact on split tensile strengthuptoEPS6:CF1.5:WA12%substitution.

• Thehighestvalueoftensilestrengthwasobtained atEPS6:CF1.5:WA12%replacementwhichis5.2Mpa.

• The flexure strength also showed maximum strengthwhenEPS6:CF1.5:WA12%isbeingreplaced by Partially replacement of cement with wood ash, withadditionofepsbeadsandcoconutfibre,increased thestrengthis6.18MPAat28th day.

• Theoptimumvalueofstrengthincompression,split tensile and flexure came at EPS6:CF1.5:WA12% replacementof WoodAshbycementandadditionof EPS,coconutfibre.

REFERENCES

1. V.Sai uday,B.A jitha “Concrete reinforced with coconutfibre”IJESCVolume7Issueno.4April2017

2. Aman Mulla,Amol Shelake,“lightweight expanded polystyrenebeadsconcrete”Internationaljournalof researchinadventtechnology(E ISSN:2321 9637) 19March2016

3. Thomas Tamut, Rajendra Prabhu et. al “Partial replacement of coarse aggregates by expanded polystyrene beads in concrete” IJERT Volume:03 Issue:02February2014

4. Majid Ali, Nawawi Chouw (2012),“Experimental investigations on coconut fibre rope tensile strength and pullout from coconut fibre reinforced concrete”, Construction and Building Materials,41,681 690

5. Hemant k. Sarje and Amol S. (2014), “ Study of performance of lightweight concrete”, International Journal of Latest Trends in

Impact Factor value: 7.529

e ISSN: 2395 0056

p ISSN: 2395 0072

Engineering and Technology, Volume 4, Issue 4,Page800 814.

6. Rapeti Muralidhar, E. T. Chakripani” Potential of WoodWasteAshasanAdditiveinFibreReinforced Concrete”(IJERT)ISSN:2278 0181Vol.4Issue12, December 2015

7. TEXT BOOK Shetty M. S., (2013), "Concrete Technology Theory and Practical", S.Chand Publishing.

8. IS456 2000,IndianStandard,PlainandReinforced Concrete codeofpractice.

9. IS 383 1970, Indian Standard Specification for CoarseandFineAggregatesfromNatural Sources forConcrete.

10. IS 10262 2009, Indian Standard Recommended GuidelinesforConcreteMixDesign