International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 |May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 |May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

1M. Tech Structural Engineering, Department of Civil Engineering, Gayatri Vidya Parishad College for Degree and P.G Courses(A), Rushikonda, Visakhapatnam, A.P, India.

2Assistant Professor, Department of Civil Engineering, Gayatri Vidya Parishad College for Degree and P.G Courses(A), Rushikonda, Visakhapatnam, A.P, India.

***

Abstract - This study summarizes the literature reviews of several papers that were exposed to blast loading with various sorts of materials. It discusses the technique taken by the many authors and materials chosen for testing, as well as the behaviour of that material during blast loading. As a result, we may learn about the many materials that can withstand blast loading as well as the behaviour of various materials during blast loading. so that we can determine the best materials to withstand blast action and build structures using those materials, as well as determine the strength and resistance of those materials under blast loading in future analytical studies utilizing ANSYS software

Key Words: Blast Effect, Finite Element Method, ANSYS

Due to the sheer increasing number of terrorist attacks and unintentional explosions, the design of structures for blast resistance is becoming increasingly importantinconstruction,asstructuresfailcatastrophically asaresultofblastaction.Asaresult,thestudyofbuildings subjected to blast loads is becoming more popular and attractingmore.

Theblasteffectisapotentiallyhazardouseventin whichabuildingfailscatastrophicallyasaresultofintense heatradiation.Themainpurposeoftheresearchistouse thesoftwareANSYStoassessthebehaviourofmulti story buildingsbyemployingdifferentheat resistantmaterialsto resistblastaction.Stimulationofthebehaviourofstructural components with different thermal resistant materials by finiteelementmethodusingANSYSsoftwarewithdifferent temperaturechangescanshedsomelightontheavailable reinforcingmaterialsthatarebestsuitabletoresistsudden blasphemy.Itprovidesaconceptforconstructingblast proof buildings as well as information on various heat resistant materialsandtheirbehaviourunderdifferenttemperatures, and the best material to endure high temperatures by analyzing material properties with ANSYS software. High Securitystructuresthatareunderthreatfromanexplosion canbebuiltusingtheseprinciples,providingsecuritytothe structures

Impact Factor value: 7.529

Stimulation of the behaviour of structural components with different thermal resistant materials by finiteelementmethodusingANSYSsoftwarewithdifferent temperaturechangescanshedsomelightontheavailable reinforcingmaterialsthatarebestsuitabletoresistsudden blasphemy

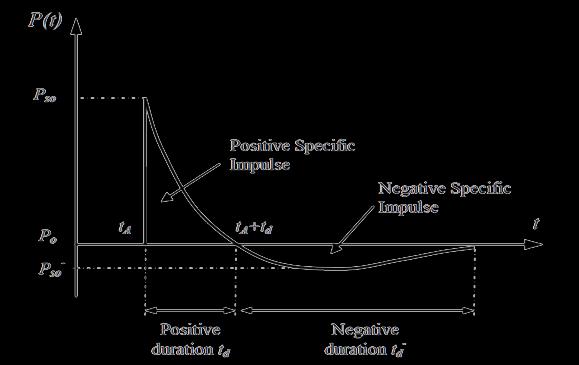

When heavy explosives are detonated, considerable pressureisgenerated,whichpropagatestothesurrounding regionandformsa powerful shock waveknownasa blast wave.Fromambientpressuretopeakincidentpressure,the velocityofthisblastwaveincreasesfast.Figure1depictsan idealizedblastwavebasedonpressureversustimehistoryat the structural fixed point from the site of detonation. [1] Yusofetal.(2014)

Detonationtakesplaceattimet=0.AftertimetA,the blastwavearrivesatthepointandpressureinstantaneously increasesfromambientpressure,P0topeakoverpressure,Pso causedbythedetonation.AttimetA+td,thepressurereturns toambientpressure,Powhichisapositivephase,isoverand followedbyanegativephase,Pso

9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 |May 2022 www.irjet.net

Magnusson&Hallgren(2004)studiedthereinforced highstrengthconcretebeamssubjectedtoairblastloading [2] A total of 49 reinforced concrete beams were tested, includinghighstrengthconcrete(HSC)and,forcomparison, normalstrengthconcrete(NSC).Inashocktube,38beams wereexposedtoairblastloading,whiletheremainingeleven beamswereexaminedstaticallyforreference.Concretewith nominalcompressivecubestrengthsof40,100,140,150,and 200MPawasutilized,andafewbeamsadditionallyhadsteel fibres.Beamswithtwoconcretelayersofvaryingstrength werealsotested.Inflexure,allbeamsexposedtostaticstress failed. Shear failure was seen in beams without fibres and withhighreinforcementratiosduringdynamictesting.The incorporationofsteelfibresinthematrixwasshowntoboost theshearstrengthandductilityofthebeams.Accordingto thefindingsofthisstudy,beamssubjectedtoairblastloading haveahigherloadcapacitythanequivalentbeamssubjected tostaticloading.

Ngoetal.(2007)studiedthebehaviourofultra high strength prestressed concrete panels subjected to blast loading [3]. This report describes the findings of an experimentalstudyontheblastresistanceofconcretepanels formed of ultrahigh strength concrete UHSC material in Woomera,SouthAustralia,inMay2004.Fortestingconcrete panel targets against blast loading, a unique concrete supportingstructurewasconstructed.Four2m1mpanels with varying thicknesses and reinforcing features were evaluatedat30and40mstandoffdistancesundera6tTNT equivalentexplosion.Blastpressuresandpaneldeflections wereamongthedataacquiredfromeachspecimen.Thetest resultswerestudiedinordertodeterminetheperformance ofUHSCandnormal strengthconcreteNSCpanels.Reactive Powder Concrete (RPC) is a UHSC material composed of cement,sand,silicafume,silicaflour,steelfibres,admixture, and water with strengths of up to 200 MPa. RPC has the potentialtobeaverygoodmaterialforblastresistance.The 75 mm thickUHSCpanelwasmoderatelydamaged,butthe 100 mm thickNSCpanelwasshattered.

Tabatabaeietal.(2013)entitledexperimentaland numericalanalysesoflongfibrereinforcedconcretepanels exposed to blast loading [4] The insertion of long carbon fibresintotypicalreinforcedconcreteisrecommendedasa solutiontoincreasetheconcrete'sblastspallingresistance.A series of experiments were carried out to assess the blast resistance of panels made of standard reinforced concrete (RC)withlongcarbonfibre reinforcedconcrete(LCFRC).As controlspecimens,conventionalreinforcedconcretepanels wereexamined.Foreachpanel,pressuresensorsdetected both the free field incident pressure and the reflected pressure.Furthermore,anLS DYNAfiniteelementmodelwas developed to simulate both a control panel and an LCFRC panel in order to see if the models could anticipate the observeddamage.TheLCFRCpanelsallhadlessmaterialloss

e ISSN: 2395 0056

p ISSN: 2395 0072

andsurfacedegradationthanthecontrolpanels.TheLCFRC panelsallhadlessmateriallossandsurfacedegradationthan thecontrolpanels.Theuseoflongcarbonfibresconsiderably boostedtheblastresistanceoftheconcreteandreducedthe degreeofcrackingassociatedwiththeconcretepanels.

Xuetal.(2016)studiedthebehaviourofultra high performancefibre reinforcedconcretecolumnssubjectedto blast loading [5]. UHPFRC is a cement based composite material that is reinforced with reactive powder and steel fibres.Itisdistinguishedbyitshighstrength,ductility,and toughness,andthesepropertiesenableittohavesignificant potential in protective engineering against extreme loads such as impact or explosion. A series of field experiments were carried out in the current study to investigate the behaviour of UHPFRC columns subjected to blast loading. Four0.2m0.2m2.5mUHPFRCcolumnsweretestedunder various planned explosions, but all at a 1.5 m standoff distance.Toanalyzetheirbehaviourunderidenticalstress circumstances,fourhighstrengthreinforcedconcrete(HSRC) columnswiththesamesizeandreinforcementasUHPFRC columns were subjected to blast tests. Three significant damagemodesweredetected,includingflexural,shear,and concrete spalling failure mechanisms. Post blast fracture patterns, permanent deflections, and varying levels of damage observations revealed that UHPFRC columns outperformed HSRC columns in blast loading resistance. Ultra HighPerformanceFiberReinforcedConcrete(UHPFRC) specimenscanefficientlywithstandtheoverpressuresand shock waves caused by high explosives, minimizing the maximum and residual displacements of columns when subjectedtosimilarblastloadsandsignificantlyimproving blast resistantcapacity.

Ngo&Mendis(2017)studiedblastandblasteffects on structures [6] Major disasters caused by gas chemical explosionsresultinhighdynamicloadsonmanybuildings thatarebiggerthantheinitialdesignloads.Becauseofthe threatposedbysuchintenseloadingconditions,effortshave beenmadeoverthelastthreedecadestodeveloptechniques of structural analysis and design that can withstand blast loads.Thestudyanddesignofstructuressubjectedtoblast loadsneedathoroughunderstandingofblastphenomenaas well as the dynamic response of diverse structural components. Blast loading impacts on structural elements can cause both local and global reactions associated with variousfailurescenarios.Thekindofstructuralreactionis determined primarily by the loading rate, the target's orientation about the direction of blast wave propagation, and the boundary conditions. Flexure, direct shear, or punchedsheararethemostcommonfailuretypesassociated with blast stress. Local responses are characterized by localizedbleachingandspallingandareprimarilycausedby theclose inimpactsofexplosions,whereasglobalresponses arefrequentlyshownasaflexuralfailure.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 |May 2022 www.irjet.net

Lan et al. (2018) studied on blast response of continuous densitygradedcellularmaterialbasedonthe3D Voronoi model [7]. The one dimensional blast response of continuous density graded cellular rods was theoretically and statistically explored. The blast response of density gradedcellularrodswaspredictedusingananalyticalmodel basedontherigid plastichardening(R PH)model.Anovel modelbasedonthe3DVoronoiapproachwasusedforfinite element(FE)analysis.TheFEfindingscorrespondwellwith theanalyticalexpectations.Undervariedblastloads,theblast response and energy absorption of cellular rods with the same mass but varying density distributions were investigated.Cellularmaterialswithhighenergyabsorption and low impulse transmission are appealing as blast resistance structures. However, modifying the density distributioncannotaccomplishhighenergyabsorptionand lowimpulsetransmissionatthesametime.Theinitialblast pressureandthecharacteristicdurationoftheexponentially decreasing blast loading improve the energy absorption capacity. When utilized as a blast protective device, the capacityofcellularmaterialtoabsorbenergywhilemanaging the loading sent to the protected structure makes it appealing. A positive density gradient, on the other hand, accomplishes the most energy absorption and transmits a relativelyhighimpulsetotheprotectedstructure,whereasa negativeonetransmitsarelativelylowimpulsebutachieves thelowestenergyabsorption.

Masekoetal.(2018)studiedthecharacterizationof ceramicreinforcedtitaniummatrixcompositesfabricatedby spark plasma sintering for anti ballistic applications [8] Spark Plasma Sintering (SPS) is a powerful process for producing Ti ZrB2 binary composites at low sintering temperatures. The approach adopted in this study was efficientinproducingadispersionstrengtheningeffectonthe composites,asallofthecompositesimprovedinhardnessas aresultofthedispersionoftheceramicparticlesthroughout thematrixmaterial.TiBwaseasilysynthesizedthroughthe in situ interaction of Ti and B species, resulting in strong interfacial bonding between the Ti matrix and the TiB reinforcing phase. The strong interfacial connections between the titanium matrix and the boride based reinforcements will improve titanium's anti ballistic characteristics.

Jahamietal.(2019)studiedtheefficiencyofusing CFRPasastrengtheningtechniqueforreinforcedconcrete beams subjected to blast loading [9]. The performance of reinforcedconcretebeamsmadeofcarbonfibrereinforced polymer (CFRP) when subjected to blast loading is investigated in this research. The experimental data, includingdamageanddeflection,weregatheredfromaprior inquiry and numerical analysis was carried out using ABAQUSsoftware.Inaddition,thesingledegreeoffreedom (SDOF)modelwasemployedtosupplementtheresultsofthe numericalanalysis.Followingthestrongconnectionbetween the experimental and numerical results, a further

e ISSN: 2395 0056

p ISSN: 2395 0072

examination of reinforced concrete beams enhanced with carbon fibre reinforced polymer was done (CFRP). It was discoveredthatusingCFRPimprovedloadcapacity,energy absorption,andreducedcentraldeflection.Furthermore,Iso Damagecurvesweregeneratedforeachbeam,allowingdam age to be forecast. When reinforced concrete beams were exposed to blastloads,theuse ofCarbonFiberReinforced Concrete (CFRP) decreased the level of damage. The mid span deflection increased as the number of CFRP layers increased.Themid spandeflectionofbeamswithfourlayers ofCFRPis30%lessthanthatofabeamwithnoCFRP.Using morethantwolayers,ontheotherhand,doesnotresultina further decrease in deflection. In the presence of CFRP, a reinforcedconcretebeammaywithstandlargerblastloads. WhencomparedtoabeamwithoutCFRP,strengtheningthe beamwithfourlayersofCFRPcanraisetheTNTquantityby 50%togeneratethesamedamage.

Badiger et al. (2021) studied the seismic performance of hybrid and non hybrid fibre reinforced concrete basedbeam columnjoints[10].Experimentationis commonly used to investigate individual component components and concrete strength under varied stress circumstances. These structural components are also analyzed using finite element analysis. The use ofFEA has been the favoured approach for studying the behaviour of concrete since it is faster and less expensive than the experimental method. Because of the development of advanced numerical analysis techniques such as the finite element method (FEM), it is now possible to describe the complicatedbehaviourofreinforcedconcretebeamsusing FiniteElementmodelling.Thefiniteelementapproachisa numerical analytical method that separates a structural elementintosmallercomponentsandthensimulatesstatic loading situations to assess concrete response. The non linear analysis is a method that stimulates the exact behaviourofthematerialtoassessstrengthintheinelastic range and to find the possibility of the high load carrying capacityofthecomponentsthroughredistribution,tensile, andshearstrength.

Themechanicalratiooftensilereinforcement(ωs) wasdeterminedtothebeamsaccordingtotheequation[2] Magnusson&Hallgren(2004) whereAsistheareaoftensilereinforcement,banddarethe widthsandtheeffectivedepthofthebeamrespectively,fsy

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 |May 2022 www.irjet.net

the yield strength of the rebars and fcc is the compressive cylinderstrengthofconcrete.

To express the fundamental explosive input or chargeweightW,asamassofTNTequivalent.Theoutcomes are then shown as a function of the dimensional distance parameter (scaled distance). [6] Ngo & Mendis (2017)[9] Jahamietal.(2019)

e ISSN: 2395 0056

p ISSN: 2395 0072

Theairbehindtheshockfrontistravellingoutward at a lesser velocity as the blast wave propagates into the atmosphere.Thevelocityoftheairparticles,andhencethe wind pressure, is determined by the blast wave's peak overpressure.The dynamic pressure qr,isconnected with thelatervelocityoftheair.Thegreatestvalueqr,isgivenby [6]Ngo&Mendis(2017)

Where:

Ristheactualeffectivedistancefromtheexplosion. Wisgenerallyexpressedinkilograms.

ZisScaleddistance.

Estimations of peak overpressure due to spherical blast

based so scaled distance were introduced by Brode(1955)as:[6]Ngo&Mendis(2017)

If the blast wave reaches an impediment perpendiculartoitspropagationpath,reflectionraisesthe overpressuretoamaximumreflectedpressurePras[6] Ngo &Mendis(2017)

Newmark and Hansen (1961) proposed a relationshiptodeterminethemaximumblastoverpressure, Pso,inbars,forahighexplosivechargedetonatesnearthe groundsurfaceasfollows:[6]Ngo&Mendis(2017)

Mays and Smith (1995) and TM5 1300 provide a comprehensive explanation and detailed tables for forecastingblastpressuresandblastdurations(1990).Table 1 shows some sample numerical values of peak reflected overpressure.[6]Ngo&Mendis(2017)

W R 100kg TNT 500kg TNT 1000Kg TNT 2000kg TNT

1m 165.8 354.5 464.5 602.9 2.5m 34.2 89.4 130.8 188.4 5m 6.65 24.8 39.5 60.19

10m 0.85 4.25 8.15 14.7 15m 0.27 1.25 2.53 5.01 20m 0.14 0.54 1.06 2.13 25m 0.09 0.29 0.55 1.08 30m 0.06 0.19 0.33 0.63

Mills(1987)introducesanotherequationforpeak overpressure in kPa, in where W is the equivalent charge weightinkilogramsofTNTandZisthescaleddistance.[6] Ngo&Mendis(2017)

2022, IRJET

Impact Factor value: 7.529

Table:1PeakreflectedoverpressuresPr(inMPa)with differentW Rcombinations

Reflectedoverpressuremaybemodelledfordesignreasons by an analogous triangular pulse with maximum peak pressurePr andperiodtd,yieldingthereflectedimpulseir. [6]Ngo&Mendis(2017)

ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 |May 2022 www.irjet.net

Duration td is related directly to the time taken for the overpressuretobedissipated.Overpressurecausedbywave reflectiondecreaseswhenthedisturbancepropagatestothe obstacle's edges at a velocity proportional to the speed of sound (Us) in the compressed and heated air behind the wavefront.UsingStorepresentthegreatestdistancefrom an edge (for example, the lesser of the height or half the breadthof a standard building),theextra pressuredue to reflectionisassumedtodecreasefromPr Psotozerointime 3S/Us. Conservatively, the Us may be defined as the usual speed of sound, which is around 340 m/s, and the extra impulse to the structure can be calculated using the assumptionoflineardecline.

Peakpressuresatthefourcharacteristicspotsofthe beamareusedtocomputethepeakequivalentuniformblast load. [11]Liuetal.(2018)

Thecorrespondingblastloadimpulseissettobethe centreblastloadimpulse.[11]Liuetal.(2018)

We can conclude from the literature reviews of variouspapersstudiedbydifferentauthorsthatultra high strength prestressed concrete, ultra high strength fibre reinforcedconcrete,longcarbonfibrereinforcedconcrete, reactive power concrete, and Ti ZrB2..., etc., have higher blast resistance than conventional reinforcement. These results will be used in subsequent research, using these materials in the studies of a multi story structure with differenttemperaturechangesforblastloadingusingANSYS software.

[1] Yusof MA, Army M, Lumpur K, et al. “Simulation Of ReinforcedConcreteBlastWallSubjectedToAir Blast Loading(3dConcreteWall)”, Journal of Asian Scientific Research, Volume 4, Issue 49, 2014 Pg:522 533. http://www.aessweb.com/journals/5003

e ISSN: 2395 0056

p ISSN: 2395 0072

[2] Magnusson J, Hallgren M. “Reinforced high strength concretebeamssubjectedtoairblastloading. Structures and Materials”,Volume15,2004,Pg:53 62.

[3] Ngo T, Mendis P, Krauthammer T. “Behavior of Ultrahigh Strength Prestressed Concrete Panels Subjected to Blast Loading.” Journal of Structural Engineering,Volume133,Issue11,2007,Pg:1582 1590. Doi:10.1061/(ASCE)0733 9445(2007)133:11(1582)

[4] Tabatabaei ZS, Volz JS, Baird J, Gliha BP, Keener DI. “Experimental and numerical analyses of long carbon fibre reinforced concrete panels exposed to blast loading.” International Journal of Impact Engineering, Volume 57, 2013, Pg:70 80. doi: 10.1016/j.ijimpeng.2013.01.006

[5] Xu J, Wu C, Xiang H, et al. “Behaviour of ultra high performance fibre reinforced concrete columns subjected to blast loading.” Engineering Structures, Volume 118, 2016, Pg:97 107. doi: 10.1016/j.engstruct.2016.03.048

[6] T.Ngo,P.MendisAG&JR.“BlastaandBlastEffectson Structures An Overview.” Procedia Engineering, Volume 199, 2017, Pg:2519 2524. doi: 10.1016/j.proeng.2017.09.432

[7] LanXke,FengSshan,HuangQ,ZhouT.“Blastresponse ofcontinuous densitygradedcellularmaterialbasedon the3DVoronoimodel.” Defense Technology,Volume14, Issue5,2018,Pg:433 440.doi:10.1016/j.dt.2018.06.003

[8] MasekoSW,PopoolaAPI,FayomiOSI.“Characterization of ceramic reinforced titanium matrix composites fabricated by spark plasma sintering for anti ballistic applications.” Defense Technology,Volume14,Issue5, 2018,Pg:408 411.doi:10.1016/j.dt.2018.04.013

[9] Jahami A, Temsah Y, Khatib. “The efficiency of using CFRP as a strengthening technique for reinforced concretebeamssubjectedtoblastloading.” International Journal of Advanced Structural Engineering,Volume11 Issue 4, 2019, Pg:411 420. doi:10.1007/s40091 019 00242 w

[10] BadigerNS,MalipatilKM,DasP,ChoudhuryS.“Seismic performanceofhybridandnon hybridfibre reinforced concrete based beam column joint.” Civil and Environment Research,Volume9,Issue8,2021,Pg:88 95.doi:10.13189/cea.2021.090625.

[11] Liu Y, Yan J bo, Huang F lei. “Behavior of reinforced concretebeamsandcolumnssubjectedtoblastloading”. Defense Technology,Volume14,Issue5,2018,Pg:550 559.doi:10.1016/j.dt.2018.07.026

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 |May 2022 www.irjet.net

M.N.R.Divya

M.TechStructuralEngineering, DepartmentofCivilEngineering, GayatriVidyaParishadCollegefor DegreeandP.GCourses(A), Rushikonda,Visakhapatnam,A.P, India.

P.SeshaRatnam

AssistantProfessor, DepartmentOfCivilEngineering, GayatriVidyaParishadCollegefor DegreeandP.GCourses(A), Rushikonda,Visakhapatnam,A.P, India

e ISSN: 2395 0056

p ISSN: 2395 0072