International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

1M.Tech Scholar, School of Engineering & Technology, MUIT Lucknow, U.P., India

2Assistant Professor, School of Engineering & Technology, MUIT Lucknow, U.P., India gotopreetiagarwal@gmail.com

***

Abstract - Rice companies are under pressure to find a method for disposing of "rice husk ash", which is rapidly accumulating. It is critical to increase the amount of green concrete produced by rice husk ash. it can be added to concrete to improve its energy efficiency and other sturdiness properties. As a result, we can employ rice husk ash in pervious concrete as a partial cement substitute. As a result, the study's purpose is to track pervious concrete behaviour while altering rice husk ash within concrete proportions. According to test results, compressive energy achieved as much as 10% as an alternative to cement with rice husk ash can be most effective without altering the properties of sparkling as well as cured concrete.

Key Words: RiceHuskAsh,CompressiveStrength,Flexural Strength,Eco Friendly,PerviousConcrete,IndustrialWaste, LowCost,O.P.C.Cement,RiceHuskAsh.

One of a kindandpowerfulalternativefordecreasingrunoff andreplenishingfloorwaterfrompavedareas.Traditional concreteismorecapableofuprootinghurricanewaterthan perviousconcrete.Inordertocompensateforthelackofa retention pond, swales, and hurricane water control measures,itispresentlyrechargingfloorwater.Itislikewise putoffluxurioushurricanewaterdetentionvaultsaswellas piping systems. Thus lessen creation expenses, protection troublesaswellaspreservationcost.Wastecontrolhassle has already end up intense with inside world. Hassle is compounded via way of means of unexpectedly growing quantity’sofbusinesswastesofacomplicatednatureaswell ascomposition.Energyperformsavitalpositionwithinside increaseofrisingnations.Intheenvironmentofpoornon renewableresourceavailabilityelectricitysourcescoupled with necessity’s of huge portions of electricity for constructingsubstanceslikecement,significanceofusageof businesswastecannotbeunderestimated.Asaresult,the fundamentalpurposesubstancesincreaseaggregateshareas well as compressive and flexural electricity. Within 2010 Indiaproducesroundonehundredtwentymillionheapsof ricepaddy,givinground24millionheapsofricehuskaswell assixmillionheapsof"ricehuskash".Authorsdiscovered that incorporating silica fume and superplasticizer into pervious concrete improves its strength significantly. By usingsmallerparts,thestrengthofporousconcretecanbe

improved[1].Addingsmallvolumesofsuperplasticizerto silicafume containingmixturesimprovedbothpermeability and compressive strength of pervious concrete [2]. Permeability of pervious concrete isdetermined by water cementratio,aggregateshape,andsize[3].Foralltypesof aggregates,pervasiveconcretemixesgeneratedwithsmaller aggregatesizesresultedinimprovedcompressivestrength. Permeabilityandcompressivestrengthofperviousconcrete areaffectedbyparticlesizesaswellastheA/Cratio They employedanA/Cratioof6:1,8:1,and10:1.Whencompared toA/Cratiosof8:1and10:1,theydiscoveredthata6:1A/C ratiogeneratedthehighestcompressivestrength.Mixtures withahigherA/Cratio,suchas8:1or10:1,areregardedto be appropriate for pavements with low compressive strengthbuthighpermeability.Theyconcludedthatcoarse aggregatewithasmallerparticlesizeshouldhaveahigher compressivestrengthandpermeablyrate[4].

RiceHuskAsh(R.H.A.)disposingofit,ithasthepotentialto become an environmental disaster in resource rich countries. The cultivation of rice paddy is linked to the productionofricehuskandricebran,whichareessentially two byproducts. The outer shell that protects the R.C.E. kernel is termed as the husk, often known as hulls. About 220 kilograms (22 percent) of husk is produced for every 1000kgofpaddymilled.Themajorityofricehuskisusedas afuelinpaddyprocessingboilers.Whenthehuskisburned with bolers, about 55 kg (or 25%) of R.H.A. is generated. Chart1depictsricehuskashcollectedbyGuruMetachem Pvt.Ltd.,Ahmedabad,fromR.C.E.fields.Table1represents the chemical properties of RHA. Table 2 represents the physicalpropertiesofRHA.

Dibyendu Mani1 , Dr. Preeti Agarwal2

oxide(Al2O

0.0 2.5%

oxide(Fe2O3) 0.0 1.5%

Calciumoxide(CaO) 0.0 1.0%

(c) 2.0 4.0%

oxide(Na2O) 0.0 1.0%

Potassiumoxide(K2O) 0.0 3.0%

Table-2:PhysicalpropertiesofRHA

and Technology (IRJET)

e ISSN: 2395 0056

p ISSN: 2395 0072

1. Silicondioxide(SiO2) 2177%

Aluminumoxide(Al2O3) 259%

Sulphurtrioxide(SO3) 241%

Calciumoxide(CaO) 5702%

Magnesiumoxide(MgO) 271%

Ferricoxide(Fe2O3) 65%

Aggregate makes up majority of volume of concrete, indicatingthatitisoneofmostsignificantcomponents.They giveconcretebody,reduceshrinkage,aswellassavemoney. withinthisstudy,twosizesofaggregatewereused.Toreach neededrange,coarsematerialutilisedwithininvestigation wassieved.Table5listsaggregate'sphysicalcharacteristics. Thefollowingaretwosizesavailable:

a. Aggregatethatpasses20mmfilter100percentof time as well as is retained 100 percent of time on 10 mm sieve.

b. Foreachconcretemix,useaggregatethatpassesa 10 mm screen 100% of time as well as measures 100*100*500mmratioof0.30 0.35 0.40.

Afteraround24hours,specimensweredemoulded,as well as water curing was maintained until corresponding specimensweretestedforcompressiveaswellasflexural strengthafter7,14,aswellas28days.

Sr. No. Property Aggregate 20 mm 10 mm

1. FinenessModulus 7.52 3.19

2. SpecificGravity 2.75 2.65

3. WaterAbsorption 1.82 1.30

Becauseitfacilitatesinthechemicalinteractionbetween cement and water, water is an important component of concrete. Water quantity and quality must be carefully evaluated because they both contribute to the strength of cementgel.

Table6showsRHA adjustedmixproportion.Table7shows pervious concrete design mix utilising RHA. aggregate compositionofdesignmixis1500kg/m3,witha Cement: Aggregateratioof1:4maintained.

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

Table 6:Mixproportionsofricehuskash

Mix Aggregate content Cement content W/C ratio Cementitious material

Mix0.30 1500kg/m3 375 kg/m3 0.30 0%RHA

RMix1 10%RHA

RMix2 20%RHA

Mix0.35 1500kg/m3 375 kg/m3 0.35 0%RHA

RMix1 10%RHA

RMix2 20%RHA

Mix0.40 1500kg/m3 375 kg/m3 0.40 0%RHA

RMix1 10%RHA

RMix2 20%RHA

Table 7:Mixdesignhavingricehusk

Concrete Design Mix Proportions(kg/m3)

Mix W/C rati o

Quantity Requirements Cemen t (kg) Rice Hus k Ash (kg)

Aggregat e 10 mm (kg)

Aggregat e 20 mm (kg)

Wate r (Liter )

Mix0.3 0 0.30 375.00 00.0 0 750.00 750.00 112.5 0

R Mix 1 337.50 37.5 0 750.00 750.00

R Mix 2 300.00 75.0 0 750.00 750.00

Mix0.3 5 0.35 375.00 00.0 0 750.00 750.00 131.2 5

R Mix 1 337.50 37.5 0 750.00 750.00

R Mix 2 300.00 75.0 0 750.00 750.00

Mix0.4 0.40 375.00 00.0 0 750.00 750.00 150.0 0

R Mix 1 337.50 37.5 0 750.00 750.00

R Mix 2 300.00 75.0 0 750.00 750.00

e ISSN: 2395 0056

p ISSN: 2395 0072

Concretetestingisfirststepwithindeterminingwhether R.H.A.maybeusedthesameascementsubstitute.Cement, water, coarse aggregate, as well as R.H.A. make up perviousconcrete.R.H.A.isusedtoreplacebetween10% as well as 20% of cement within pervious concrete. For eachconcretemix,a150*150*150mmmouldwithwitha w/c ratio of 0.30, 0.35, a partial substitution of cement, 0.40, 0.50 as well as 0.40. On size mould, three beam sampleswerecast.

For each concrete mix, dimensions are 100*100*500 mm, withpartialcementsubstitutionatw/cratiosof0.30,0.35, aswellas0.40.Followingaround24hours,specimensbede molded, as well as water curative maintained until corresponding specimens were tested for compressive as wellasflexuralstrengthafter7,14,aswellas28days.

Usingcubesamples,compressionstrengthtestswere done on a compression testing equipment. average strength values provided within this research were determinedbytestingthreesampleseachbatch.Oneach concrete mix, comparative experiments were conducted for 0.30, 0.35, as well as 0.40 W/C ratios of partial substitutioncementedR.H.A.at10%aswellas20%.

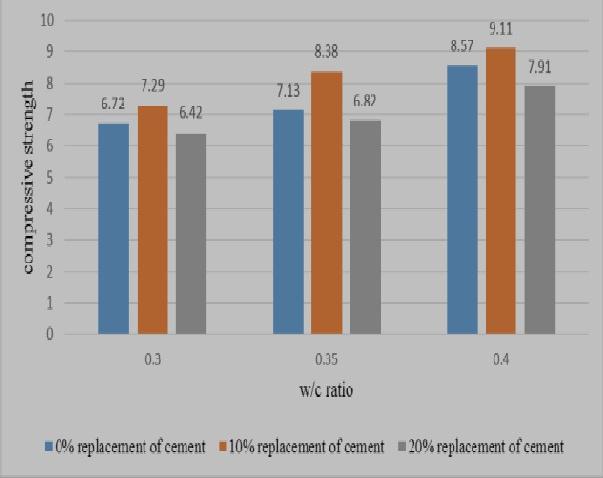

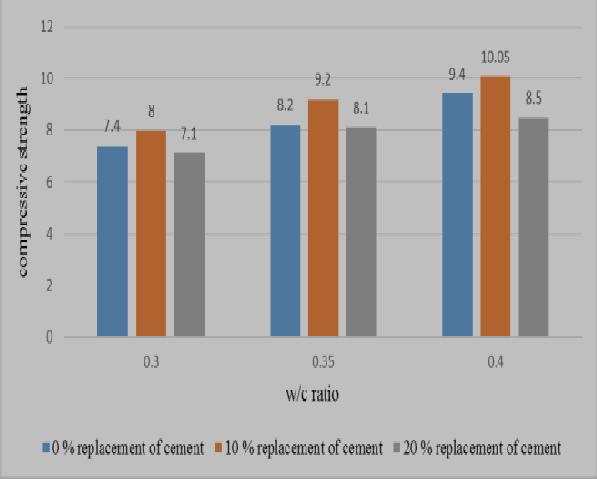

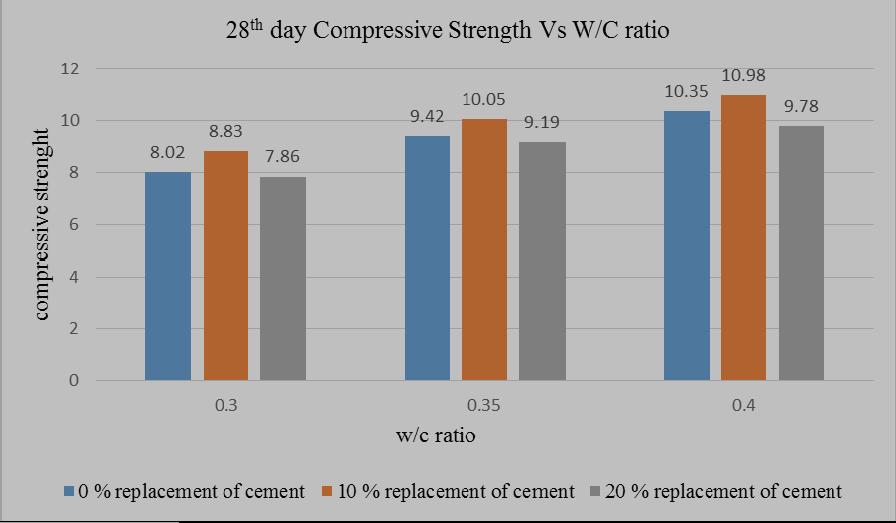

The pervous concrete compressive strength is described within Table 8. Table as well as Charts 2, 3, as well as 4 demonstrateexperimentaloutcomes.

Concrete Mix W/C ratio % Replacement of Cement

Average Compressive Strength (N/mm2)

7 Days 14 Days 28 Days

Mix0.30 0.30 0 6.72 7.40 8.02

RMix1 10 7.29 8.00 8.83

RMix2 20 6.42 7.10 7.86

Mix0.35 0.35 0 7.13 8.20 9.42

RMix1 10 8.38 9.20 10.05

RMix2 20 6.82 8.10 9.19

Mix0.4 0.40 0 8.57 9.40 10.35

RMix1 10 9.11 10.05 10.98

RMix2 20 7.91 8.50 9.78

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

Chart-2: 7th daycompressivestrengthvsW/cratio

Chart 3: 14th daycompressivestrengthvsW/cratio

Chart-4: 28th daycompressivestrengthvsW/cratio

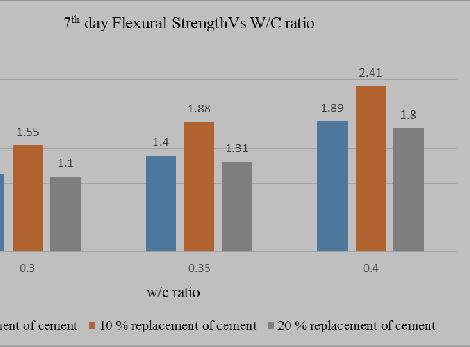

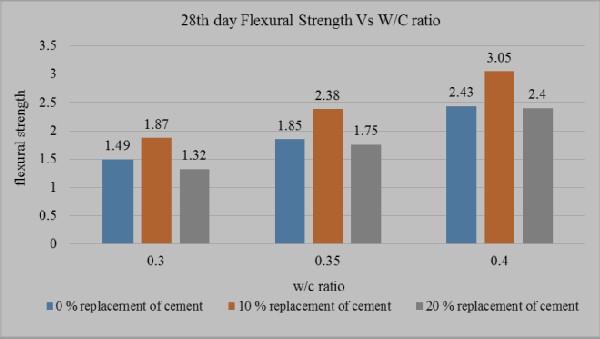

Usingbeamsamples,Onaflexuraltestingtable,flexural strength tests were performed equipment. average strength values provided within this research were determinedbytestingthreesampleseachbatch.Flexural tests were performed on each concrete mix using 0.30, 0.35, as well as 0.40 W/C ratios of partial cement substitution with R.H.A. at 10% as well as 20%, respectively. pervious concrete flexural strength is

©

e ISSN: 2395 0056

p ISSN: 2395 0072

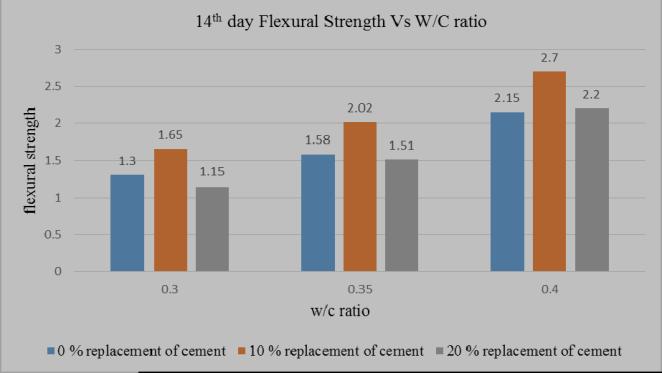

describedwithinTable9.Table9aswellascharts5,6,as wellas7demonstrateexperimentaloutcomes.

Concrete Mix W/C ratio % Replacement of Cement

Average Flexural Strength (N/mm2)

7 Days 14 Days 28 Days

Mix0.30 0.30 0 1.14 1.30 1.49

RMix1 10 1.55 1.65 1.87

RMix2 20 1.10 1.15 1.32

Mix0.35 0.35 0 1.40 1.58 1.85

RMix1 10 1.88 2.02 2.38

RMix2 20 1.31 1.55 1.75

Mix0.4 0.40 0 1.89 2.15 2.43

RMix1 10 2.41 2.70 3.05

RMix2 20 1.80 2.20 2.40

IRJET | Impact Factor value: 7.529

ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

Chart-7: 28th dayflexuralstrengthvsW/cratio

Observationsmadeexaminationsintoaswellasflexural strengths of concrete. W/C ratio of pervious concrete increases,resultingwithinincreasedcompressiveaswellas flexuralstrength.WhenCementissubstitutedwithRHA,the compressivestrengthofporousconcreteincreasesbyupto 10%, after which it begins to decline. It is a feasible alternativeapproachforsafeR.H.A.disposal.

[1]. J. Yang and G. Jiang (2003), “Experimental study on propertiesofperviousconcretepavementmaterials”. CementandConcreteResearch,vol.33,pp.381 386. doi:https://doi.org/10.1016/S0008 8846(02)00966

3

[2]. C.LianandY.Zhuge(2010),“Optimummixdesignof enhanced permeable concrete An experimental investigation”. Construction and Building Materials, vol. 24, , pp. 2664 2671. doi: https://doi.org/10.1016/j.conbuildmat.2010.04.057

[3]. A.K.JainandJ.S.Chouhan(2011),“Effectofshapeof aggregateoncompressivestrengthandpermeability propertiesofperviousconcrete”.InternationalJournal ofAdvancedEngineeringResearchandStudies,vol.1, pp.120 126.

[4]. S. O. Ajamu, A. A. Jimoh and J. R. Oluremi (2012),“Evaluation of Structural Performance of Pervious Concrete in Construction”, International JournalofEngineeringandTechnology,Vol.2,pp.829 836.

[5]. IS:12269 1987 OrdinaryPortlandCement,43Grade Specification.

[6]. IS:516 1959 TestMethodsforStrengthofConcrete.

Impact Factor value: 7.529

e ISSN: 2395 0056

p ISSN: 2395 0072

9001:2008