International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

*** Abstract

China has a vast natural grassland, which is the cornerstone and guarantee of livestock development. However, in recent years, grassland degradation has become increasingly serious and the growth of forage grasses has been inhibited. Therefore, many improvement measures for degraded grasslands have been developed in China. One of the important tools for degraded grassland improvement is the arrow shovel submerged pine plow. As a key working component, the operational performance of the arrow shovel is closely related to the grassland soil characteristics. In this paper, the discrete element method is used to establish a four layer soil discrete element model by reasonably selecting the grassland soil parameters and setting the soil particle types to visually demonstrate the loosening process of the arrow shovel. The simulation shows that the surface layer of the arrow shovel is less disturbed during soil loosening, and the shallow loosening effect is good, which can effectively prevent the destruction of surface vegetation and is especially suitable for the improvement and restoration of dry grassland with shallow soil layer; the fluctuation of force on the arrow shovel is large, and the optimization of structural parameters is the key to improve the drag reduction effect of the arrow shovel.

Key words: arrow shovel, soil disturbance, discrete element method, grassland improvement

China has a vast land area with nearly 400 million hectares of natural grasslands, occupying 40% of the national land area, which is the largest terrestrial ecosystem in terms of area. At the same time, natural grasslands also provide adequate conditions for the development of animal husbandry in China and are a major guarantee for the development of animal husbandry[1].However,inrecentyears,duetonatural and human factors and other reasons, grasslands have been degraded to different degrees throughout the country[2 4].Grasslanddegradationdirectlyleadstoa significant decrease in forage production per unit area within the grassland and a decrease in forage quality, which affects the normal growth and development

needs of grasslands and seriously restricts the developmentoflivestockindustry[5].

Increasing the construction of degraded grassland improvement is conducive to protecting biodiversity and improving grassland productivity, which has significant ecological significance and economic benefits [6 7]. The arrow shovel submerged loosening plow produced by Versatile, Canada, cuts the forage or plant roots at the depth of plowing after entering the soil, breaks the slab layer of soil and grass roots, increases the permeability of the soil, and is conducive to the rejuvenation of theoriginal grassland vegetation [8]. To improve the adaptability of the arrow shovel submerged pine plow for different areas of grassland degradation and soil characteristics is an important step in promoting the application of this advanced

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

machine. As a key working part, the operational performance of arrow shovel is closely related to soil characteristics,anditisanimportantreferencevalueto carry out the simulation analysis of arrow shovel operation process and study the soil disturbance characteristics of arrow shovel to optimize the geometricparametersofarrowshovelandimprovethe operational performance of arrow shovel submerged pineplow.

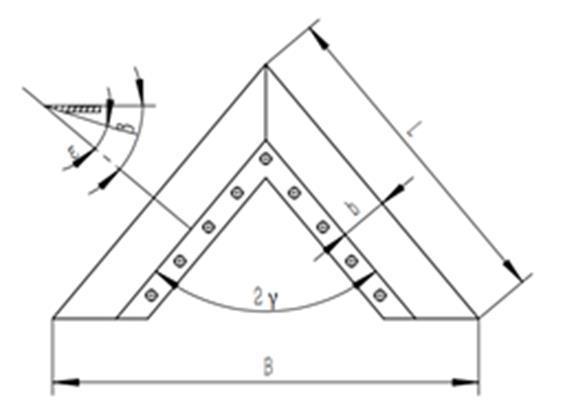

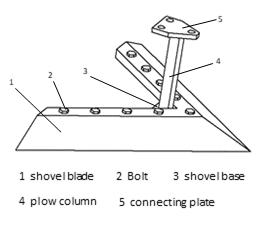

The structure of arrow shovel is composed of shovel blade, shovel base, plow column and connecting plate, etc.Theshovelbladeandshovelbaseareconnectedby a removable connection, which is convenient for sharpeningandreplacement.Inordertoensurethatthe simulationanalysisisthesameastherealsituation,the 3D drawing software is used to draw the 3D model of the arrow shovel according to the scale of 1:1. The structure of the arrow shovel is shown in Fig1, the structure of the arrow shovel blade is shown in Fig.2, andthemainparametersoftheshovelbladeareshown inTable1.

e ISSN: 2395 0056

p ISSN: 2395 0072

Fig.1 Arrowshapedshovel3Dmodel

Fig.2 Schematicdiagramofshovelbladestructureand parameters

Table 1 Mainparametersofarrowshovelblades

ParameterName Numerical size

openhornsofShovelwingsγ/° 40 Loosesoilcornerβ/° 30 GapCornerε/° 11.61

LengthofshovelbladeL/mm 522.16

Widthofshovelbladeb/mm 76.6 WorkingwidthB/mm 617.28

The grass soil model was created in the discrete element software and its basic dimensions were set to 1000mm*1000mm*400mm.wheretheparameters used in the grass soil discrete element model included materialparametersandcontactparameters. The material parameters include Poisson's ratio, density and shear modulus of the soil, and 65Mn [9]. Theshearmoduluscanbeobtainedbycalculatingitas G= �� 2(1+��)

However,duetotheparticipationofvariousplantroots inthesurfaceturf ofgrasslandsoil,theplantrootswill anchorandplatethesoillayerwitheachother,resulting in larger particle size and increased shear modulus of thesoillayer.Therefore,thesurfaceturfshearstrength reference experiment [10] was conducted to simulate the shear strength of grassland surface turf with the

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International

Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

shearmodulusofthesheepgrassroot soilcomplex. The contact parameters mainly include the recovery coefficient between soil soil and soil 65Mn, static friction coefficient and dynamic friction coefficient, whichcanbeobtainedthroughspecificexperiments[11] toensurethattheestablishedsoilmodelisthesameas the real situation. The specific parameters of the soil modelareshowninTable2.

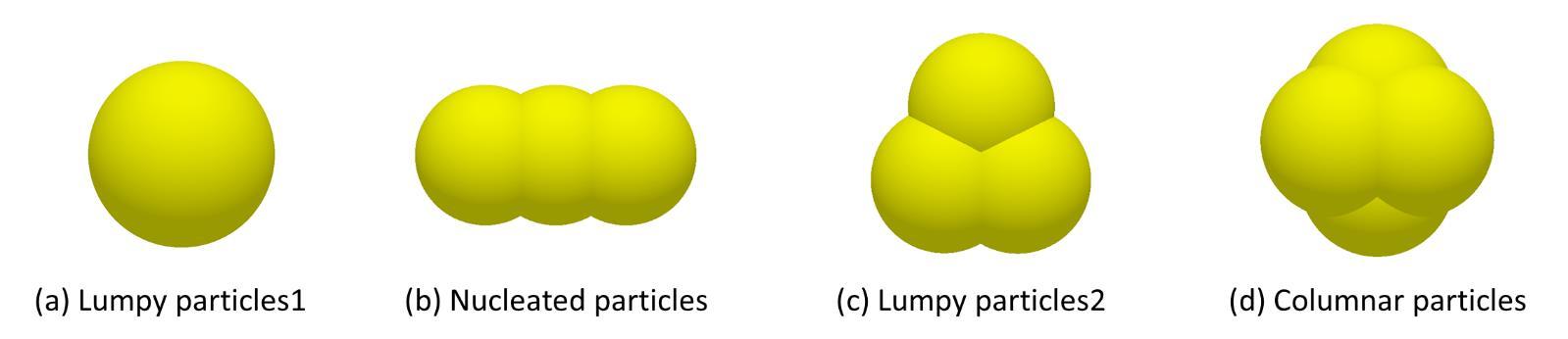

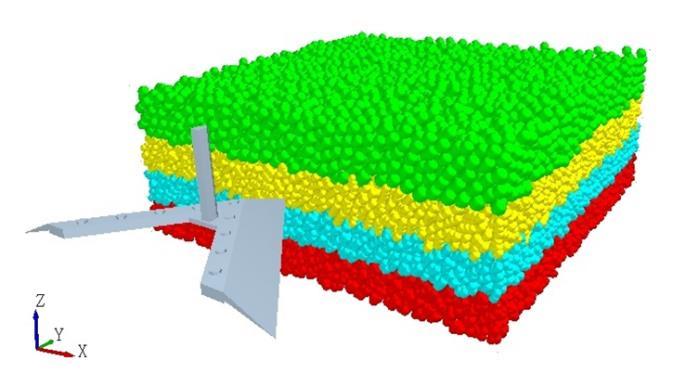

To facilitate the analysis of the movement state and disturbance behavior of the soil at different depths during the arrow shovel operation, the height of each soil layer was set to 100 mm. therefore, the soil in the soil tank was set to four soil layers, and the soil layers weredefinedasfourlayersfromtoptobottom:surface, shallow, medium, and deep. According to a large

e ISSN: 2395 0056

p ISSN: 2395 0072

number of studies, the basic structure of soil particles includes nuclei, columns, and blocks, and the four particle models are shownin Fig.3 [12]. Each soil layer is filled with four types of soil particles in turn. The types and numbers of soil particles are shown in Table 3.

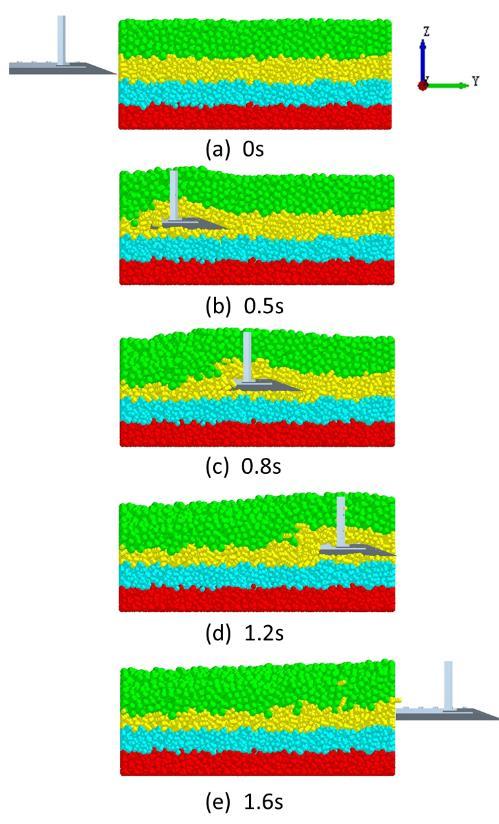

The 3D model of the arrow shovel was imported into the discrete element software. The plowing depth was setto200mm,thematerialofthearrowshovelwas65 Mn, and the speed of the arrow shovel was 0.83 m/s, whichwasinlinewiththeactualsituation.

The simulation setting time is 6s, and the discrete element model of deep soil is obtained after each soil grainiscast,asshowninFig.4.

ParameterName Numerical

sizeLoose shovel speed v/(m/s) 830

Loose soil depth h/mm 350 density of Soil particle (kg/m3 ) 1346

Poisson’s ratio of soil particles v1 0.4

Shear modulus of soil particles G1/Pa 1*106 Shear modulus of surface soil particles G2/Pa 4.1*106 Density of 65 Mn Steel (kg/m3 ) 7830

Poisson’s ratio of 65 Mn Steel v2 0.35 Shear modulus of 65 Mn Steel G3/Pa 7.27*1010

Coefficient of restitution between the soil and soil e1 0.2

Coefficient of rolling friction between the soil and soil e2 0.3 Coefficient of static friction between the soil and soil e3 0.4

Coefficient of restitution between the soil and 65 Mn Steel f1 0.3

Coefficient of rolling friction between the soil and 65 Mn Steel f2 0.4 Coefficient of static friction between the soil and 65 Mn Steel f3 0.5

Gravity acceleration G/(m/s2 ) 9.81

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

Table 3 Typesandquantitiesofdifferentsoilparticles

e ISSN: 2395 0056

p ISSN: 2395 0072

Soil layer Particle type Number of particles

Surface layer Lumpy particles1 15000

Shallow layer Nucleated particles 26000

Middlelayer Lumpy particles2 26000

Deeplayer Columnar particles 24000

Inordertounderstandindetailthedisturbancestateof the soil during the operation of the arrow shovel, the discrete element software was used to simulate the operation process of the arrow shovel, and the longitudinal section of the soil was intercepted to further understand the working mechanism of the arrowshovelonthegrass.AsshowninFigure5. The simulation analysis shows that 0 s arrow shovel starts to enter the soil, 0.5 s arrow shovel completely enters the soil, 0.8 s arrowshovel completelymoves in the soil, 1.2 s arrow shovel prepares to leave the soil model,and1.6sarrowshovelcompletelyleavesthesoil model.

Factor value:

AscanbeseenfromFig5,whenthearrowshovelstarts to enter the soil model, the surface and shallow soil particles are arched up, and the middle and deep soil

9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

particles are slightlydisplaced due to mutual extrusion between the particles. As the arrow shovel moves forward, some of the shallow soil particles move forward with the arrow shovel, and the surface soil basicallydoesnotmovewiththearrowshovel.Itcanbe seen that the surface layer is less disturbed when the arrow shovel is used to loosen the grass, which is conducivetokeepingthesurfacevegetationfrombeing destroyedinalargeareaandeffectivelypreventingsoil erosion.

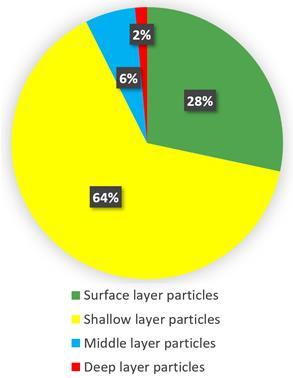

Soil disturbance efficiency is an important data to measure the effect of arrow shovel on soil operation [13],andsoildisturbanceefficiencycanbeexpressedas the percentage of the number of particles with kinematic velocity to the total number of particles in this category. After the arrow shovel completed the grass operation process, the distribution of the percentage of moving particles was derived in the discrete element software according to whether the particles had the motion speed or not, as shown in Figure6.

e ISSN: 2395 0056

p ISSN: 2395 0072

From Fig. 6, When the arrow shovel has finished loosening the soil, The number of particles with kinematic velocity as a percentage of the total number of particles in the layer was 28%, 64%, 6% and 2%, respectively in surface, shallow, medium and deep particles.It can be seen that the arrow shovel mainly disturbs the shallow soil particles when loosening soil, and the shallow soil is disturbed with maximum efficiency, while the medium and deep soil are disturbed with lower efficiency, indicating that the arrow shovel has good effect of shallow loosening, which is especially suitable for the improvement and restorationofdrygrasslandwithshallowsoillayer.

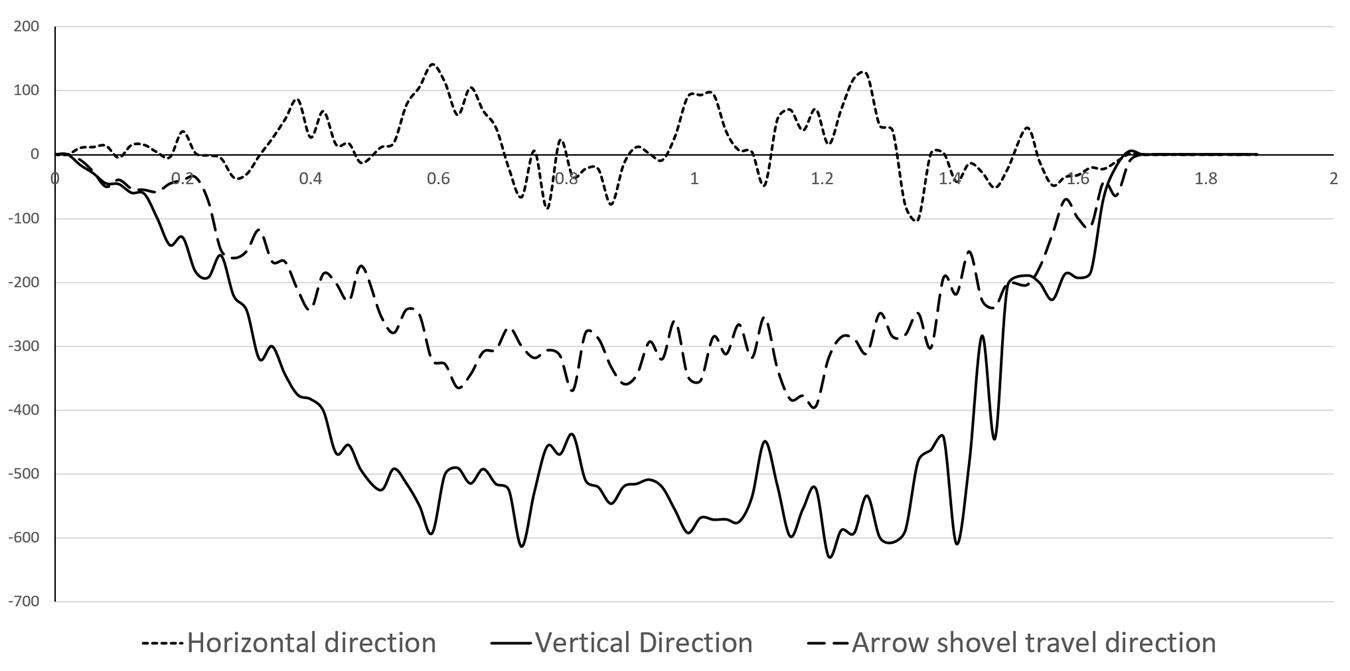

The resistance suffered by the arrow shovel in the working process is closely related to the energy consumption, and the working resistance of the arrow shovel is a measure of the quality of the arrow shovel, and the analysis of the force state of the arrow shovel can provide a basis for the structural optimization of the arrow shovel [14]. After the simulation, the forces onthearrowshovelinthehorizontaldirection,vertical direction and forward direction during the motion of the arrow shovel were derived by using discrete elementsoftware,asshowninFigure7.

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 05 | May 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

Fig.7 Theforceofthearrowshovelinthreedirections Fig.7showsthatwhenthearrowshovelentersthesoil, the force in the vertical direction and the travel direction increases due to the increasing contact area between the arrow shovel tip and the soil, while the forceinthehorizontaldirectionshowsanup and down trend and the force is small. In the process of traveling afterthearrowshovelcompletelyentersthesoilmodel, the force on the arrow shovel decreases because some soil particles are separated from the surface of the arrow shovel, while other soil particles are arched by thearrowshovel,resultinginanincreaseintheforce,at this time the force on the arrow shovel in the vertical direction and traveling direction fluctuates up and down, and the force in the vertical direction is greater than theforce in thetravelingdirection.Onlywhen the arrowshovelleavesthe soil, theforce will be gradually reduced.

Thesimulationresultsshowthattheforceonthearrow shovel and the contact between the arrow shovel and the particles are directly related. The projection size of thearrowshovelintheverticaldirectionandthetravel directiondeterminesthenumberofparticlesincontact withthearrowshovel,whichinturnaffectstheforceon the arrow shovel. The projection size is affected by the shovel blade width, shovel blade length, shovel blade tension angle and loosening angle, which in turn is

directlyrelatedtotheeaseofentryofthearrowshovel into the soil, which in turn affects the travel resistance ofthearrowshovel.

(1) Using discrete element software, the loosening processofthearrowshovelisdemonstratedvisuallyby reasonably selecting soil parameters and setting soil particle models. The simulation shows that the surface layer is less disturbed when the arrow shovel loosens soil, which is conducive to keeping the surface vegetation from being destroyed in a large area and effectivelypreventingsoilerosion.

(2) Discrete element simulation calculates that the disturbance efficiency of the arrow shovel on the surface,shallow,middle and deepsoilparticles is28%, 64%, 6% and 2% respectively, which indicates that the arrowshovelhasgoodeffectofshallowlooseningandis especiallysuitablefortheimprovementandrestoration ofdrygrasslandwithshallowsoillayer.

(3) The force analysis of arrow shovel shows that the resistance of arrow shovel is mainly the force of arrow shovel in the forward direction when it works. The resistance of the soil in front of the arrow shovel is closely related to the loosening angle, and the optimization of structural parameters is the key to

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

improve the resistance reduction effect of the arrow shovel.

WesincerelyexpressourgratitudetoProfessorCenfor hiscarefulteaching,whichhasplayedagreatroleinthe smooth progress of this research work, and also expressed our gratitude to the Inner Mongolia Autonomous Region Science and Technology Major Project (2020ZD0002) for its financial support for this work

[1] Editorial Department, Liu Y. 2016 National Grassland Monitoring Report. China animal industry,2017,8:18 35.(inChinese)

[2] Qi P Y. Causes of alpine grassland like grassland degradation and its analysis. NONGJIACANMOU, 2021,24:138 139.(inChinese)

[3] Zhou J, Qiao G H. Progress of research related to grassland degradation management. Agricultural Economy,2020,07:9 11.(inChinese)

[4]WangYZ,DaiLX,LiuXY,LiuG,WuGL.Discussion of the Grassland Situation and Approach of Ecological Restoration in China. Journal of GrasslandandForageScience,2007,05:29 32.

[5] Yan Q Z. Impact of grassland degradation on livestock farming and measures to cope with it. AnimalsBreedingandFeed,2020,12:163 164.

[6] Zhang J G. Effects of different improvement measures characteristics of community and soil of degradated grassland. Master dissertation. Inner Mongolia Autonomous Region: Inner Mongolia University,2017.

[7]ŽeljkoVaško,GordanaRokvić.Economicvaluationof grassland utilization improvement in the Western Balkans 2021. SHS Web of Conferences,2021,95, 01002.

[8] Yang S K, Su Z F. SICAO SHENGCHAN JIXIE YU SHEBEI.ChinaAgriculturalPress,2009.

[9] Hang C G. Soli disturbance behavior of subsoiling based on discrete element method. Master

dissertation. Shaanxi: Northwest A&F University, 2018.

[10]PanTH,DuF,WangY.Analysisofrootdistribution and shear enhancement resistance of slope protection plants in loess areas of northern Shaanxi. Research of Soil and Water Conservation,2020,03:357 363.

[11]XinZB,NiuZR,LiuXM,andYuanJ.StudyonSoil DisturbanceBehaviorofGloboidSubsoilingShovel Based on Discrete Element Method. International Workshop of Advanced Manufacturing and Automation,2018:684 693.

[12] Hang C G, Huang Y X, Zhu R X. Analysis of the movement behaviour of soil between subsoilers based on the discrete element method. Journal of Terramechanics,2017,74:35 43.

[13]ZhouJ,JiDD,LiLJ.StudyontheDragReductionof Sub soiling Shovel and Influence Factors of Tillage Resistance Based on LS DYNA. Journal of Agricultural Mechanization Research, 2019,4105: 157 162.(inChinese)

[14] Deng J Y. Simulation and experimental study of tillage resistance of deep loosening shovel based on discrete element method. Master dissertation. Heilongjiang Province: Heilongjiang Bayi AgriculturalReclamationUniversity,2015.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page7

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Wei Huijun, male, born in December 1997, from Jincheng City, Shanxi Province, master's degreestudent. Research interests: Introduction to intelligent equipment in agriculture and animal husbandry, agriculturalmachinerydesign. E mail:1535192639@qq.com

CenHaitang,borninOctober1967, from Zhuozhi County, Inner Mongolia Autonomous Region, doctor, professor, mechanical engineeringmaster'ssupervisor Researchinterests:digitaldesignof forage harvesting machinery, introduction to intelligent equipment in agriculture and animalhusbandry. E mail:1054949591@qq.com