International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

Abstract - Plastic is very hazardous in today’s world. This is the most dangerous problem that humanity faces nowadays. When it burned it releases toxic gases like furans, dioxins, and mercury. The plastic, which is lower than 75 m, causes serious issues for human beings as well as the ecosystem. This experiment was performed on the manufacturing of bricks using plastic waste. The brick is manufactured by the process of melting it with river sand at 110° 130°C. In this experiment, we have used different types of sand to plastic ratios. The different types of plastic percentages we used in this experiment were 30%, 35%, 40%, 45%, and50%, respectively, with the river sand. The tests that were performed on these bricks were compression tests, absorption tests, andother tests that were performed on normal bricks. These bricks are light in weight and economical in budget as we are using plastic waste.

Key Words: plastic waste, water absorption, compressive strength, hardness, efflorescence.

1. INTRODUCTION

Plastichasbeenmostusedthatplasticpollutionhasbecome one in every of the environmental problems of the planet and also to blame for the global climate change. The utilizationofplasticinourday to daylife,likepolyethene bags,foodpackets,disposalmaterials,etc.it'simpactedthe environment, our health and wellbeing. We’ve got all contributed to the present problem, and now it’s our responsibilitytofiguretowardsittocutbackandultimately End Plastic Pollution. The employment of plastic is additionally a serious issue everywhere the planet. Every day,thousandsofloadsofpollutantsarediscardedintothe air by natural events and human actions. Way more damaging are the substances discharged into the atmospherebyhumanactions.Mostplasticsarehighlyproof againstthenaturalprocessesofdegradation.Asaresult,it takesanextendedperiodofyourtimetodegradetheplastic. It’s resulted within the enormous presence of plastic pollutionwithintheenvironmentand,attheidenticaltime, affectedhumanhealthadversely.it'sestimatedthatplastic wasteconstitutesapproximately10%ofthefullmunicipal wasteworldwidewhich80%ofallplasticfoundwithinthe world’soceansoriginatesfromland basedsources.

1.1 Material Required For Manufacturing of Plastic Brick

PlasticwastesuchasPolyethene,Plasticbottles(Pet),Plastic with other composite materials, Engine oil, River sand (4.75mm)

2. SCOPE OF THIS EXPERIMENT

Togenerateplasticwasteinanefficientmannerandtouseit effectively.Toreducetheconsumptionofnaturalresources such as clay for the manufacturing of bricks. It takes less time for manufacturing as compared to normal brick. To producethe mostcost effective material andalsooffer an alternateoptiontothecustomer.Tominimizetheamountof plasticwastebeingrecycled.

3. MATERIALS & METHODOLOGY

3.1. Materials

3.1.1. Plastic waste

Plastic that is used afterwards and downcycled in the environmentbecomeswaste.

Fig-1 Plasticwaste

Plastic waste is the accumulation in the environment of synthetic plastic products to the point that they create problemsforwildlifeandtheirhabitatsaswellasforHuman populations.

An experimental study on the utilization of plastic waste for the manufacturing of bricksAnurag kumar1, Abhishek yadav2, Vimal kumar3, Faisal khan4, Ajit maurya5 1234Final year students, Civil engineering department, Institute of technology and management Gida Gorakhpur, Uttar Pradesh, India ***

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

Table 1 Compositionofplastic

Plastictype Amount

Lowdensitypolyethylene 23%

Highdensitypolyethylene 19%

Polypropylene 14%

Polyvinylchloride 6%

Polystyrene 9%

Polyethyleneterephthalate 10%

Others 19%

3.1.2 River sand

Thissandisnaturallyobtainedonthebanksideoftheriver. Riversandhasasmallamountofclay,silt,andotherorganic impuritiespresentinit.Itsgrainsizeisgenerallythatof4.75 mmcoarsefinesand.

Fig-2 Collectingofriversand

e ISSN: 2395 0056

p ISSN: 2395 0072

Fig 3 Collectionofplasticwaste

3.2 Methodology

3.2.1 Collection of materials

Inthisexperimentfirstly,wehavetocollecttheplasticwaste materialfromdifferentsitesinthewastearea

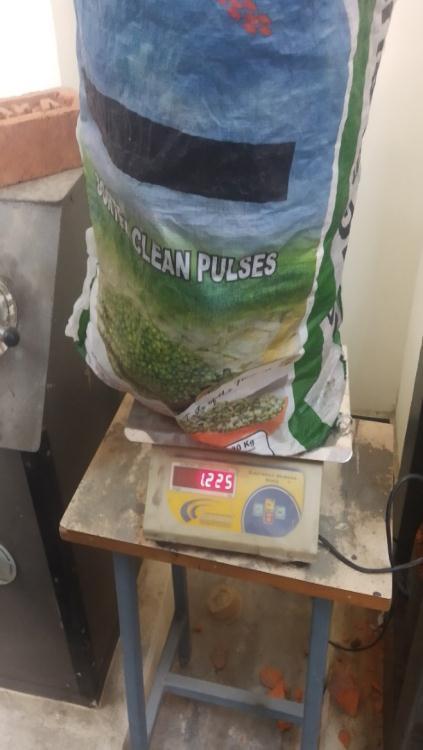

3.2.2 Batching

Thematerialthatwecollectedcontainssomeimpuritieslike soil,water,andotherwaste.Wehavetoseparateitfromthis kind of waste and keep it dry and weighted as per our requirements.

Fig 4 Weightedbatching

3.2.3 Melting

After collectionand batchingof material theplasticwaste weretobeputformeltingprocessat(1100 1300C)beinthe liquidformafterallthewasteplasticwerefullinliquidstate thenwehavetousethesandinitandinthemouldwehave touseengineoilsothatitnotstickitwiththemould.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3991

International

of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

Fig 5 Meltingofplasticwaste

4. RESULTS & DISCUSSION

4.1 Discussion

4.1.1 Qualities of good bricks

e ISSN: 2395 0056

p ISSN: 2395 0072

3.2.4 Moulding

Immediatelyafterthe mixingprocess,weshouldpourthe mixintothemould.Becauseimmediatelyaftermixing,the mixstartscoolingandithardens,thequickerthemixshould be poured into the mould and compacted. The size of the mould which we have used is 190mm X 90mm X 90mm, whichisthestandardmodularsizeofthebricks.

Fig 6 tampingofbrick

3.2.5 Curing

Because the bricks cool and harden at room temperature immediately after molding, no curing process is required. The brick itself leaves the mould after 30 minutes, and it automaticallycoolsdownafter1hourto1.5hours.

Fig 7 curingofplasticbrick

Thegoodbrickthatusedintheconstructionitpossessthese characteristic

4.1.1.1 Soundness

A good brick should give a clear, metallic sound when it strikewithanotherbrick

4.1.1.2 Hardness

Agoodbrickshouldbesohardthatourfingernailsshould notbeabletomakeanyimpactitssurfacewhenscratched.

4.1.1.3 Porosity

Agoodbrickshouldnotabsorbmorethan15percentofits dryweightofwaterwhenkeptimmersedfor24hours.

4.2 Results

4.2.1 Different composition with plastic wastes

SR.NO COMPOSITION (SAND:PLASTIC)

SAND PLASTIC WASTE

1. 3200gm of sample(70:30) 2240gm 960gm

2. 3200gm of sample(65:35) 2080gm 1120gm

3. 3200gm of sample(60:40) 1920gm 1280gm

4 3200gm of sample(55:45) 1760gm 1440gm

3200gm of sample(50:50) 1600gm 1600gm

3200gm of sample (45:65) 1440gm 1760gm

3200gm of sample (40:60) 1280gm 1920gm

3.

(50:50)

(45:55)

SAMPLE

(40:60)

SAMPLE

(45:65)

e ISSN: 2395

p

2395

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

5. CONCLUSION

Plasticbrickisfoundtobemorestrengthascompareto3rd classbrick Thesettingtimeofplasticislowifwecompareto normal brick Plastic waste is utilize in a good way Plastic waste brick is additionally accustomed reduce the environmental pollution It reduce the usage of clay in makingofbricksWaterabsorptionofplasticwastebrickis low as compared to normal brick Plastic brick give an alternateoptiontothepeopleWeconcludethattheplastic brickishelpfulforthedevelopmentindustryascompareto flyashand3rdclassclaybrick

6. REFERENCES

[1]DineshS;DineshA;andKirubhakaranK.,“Utilizationof WastePlasticinManufacturingofBricksandPaverBlocks” InternationalJournalofAppliedEngineeringResearch,Vol.2 (4).

[2]NitinLoyal;Manisha.“ConstructingstructuresusingEco bricks”, International Journal of Recent Trends in Engineering&Research,Vol.2(4).

[3]ManeethPD;PramodK;KishoreKumar;andShanmukha Shetty., “Utilization of Waste Plastic in Manufacturing of Plastic Soil Bricks” International Journal of Engineering Research&Technology,Vol.3

BIOGRAPHIES

ANURAG KUMAR

BachelorofTechnology,finalyear student, Dept. of Civil EngineeringInstituteofTechnology andManagementGida,Gorakhpur

ABHISHEK YADAV

BachelorofTechnology,finalyear student, Dept. of Civil EngineeringInstituteofTechnology andManagementGida,Gorakhpur

VIMAL KUMAR

BachelorofTechnology,finalyear student, Dept. of Civil EngineeringInstituteofTechnology andManagementGida,Gorakhpur

FAISAL AHAMAD KHAN

BachelorofTechnology,finalyear student, Dept. of Civil EngineeringInstituteofTechnology andManagementGida,Gorakhpur

e ISSN: 2395 0056

p ISSN: 2395 0072

AJIT MAUIRYA

BachelorofTechnology,finalyear student, Dept. of Civil EngineeringInstituteofTechnology andManagementGida,Gorakhpur