International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

1234Student, Dept. of Mechanical Engineering, PCCOE, Maharashtra, India ***

Abstract - Robotics has influenced all modern day infrastructuresanddevelopments,andiscrucialtofinditsway throughtraditionalagriculturalpracticesthatarestillmostly done by manpower and human interference. Pesticides being chemical agents, if sprayed excessively on agricultural/organic matter may highly influence its health, and also cause soil degradation to a very high extent leading to degradation of farm fertility, as most of the farmers being unawareofthedamages thatsuchexcessiveinsecticidesprays can cause to land and plant health. Thus, our prime motive is to develop a robot governed by Artificial Intelligence and Machine Learning algorithm dedicating itself to spray pesticidesonlywhere itisessential,by incorporatingmachine vision. Thus, analyzing plants, monitoring their health status, and spraying pesticides if and only if plant is prone to infestation or attack.

Key Words: ArtificialIntelligence,Automation,Robotics, Embedded Electronics, Actuators, Raspberry Pi, Machine Vision

Infarms,thefarmersneedtospraypesticidesandhaveto stayupinthesunandspendalotoftime.Sincetheycannot lookateachplantseparately,theytendtospraypesticideon alltheplants,whichalsowastesthepesticidesbecausesome plantsmightnotneeditanditdamagesthesoil.Incaseof larger field, the labour costs also increase. Therefore, to minimisetheseissueswehavedesignedourproject.

TodevelopanddesignanAIMLoperatedpesticidesprayer whichcanidentifyhealthyandunhealthyleaveswithhelpof artificial intelligence and machine learning model to help reduceexcesswastageofinsecticidesandhelpreducelabor andtimecostsoffarmersalongwithkeepingthesoilfertility atoptimallevel.

Ourprimeobjectivetocreatearobotwhichcanautomatically detecttheleaveswhichareundertheattackofinsectsand requiresprayingofpesticidessothatfurtherdamagecanbe prevented.Itisofprimeimportancetofacilitateautomation inthefieldofagriculture,thusboostingaccuracy,efficiency andtoachieveautomationinpracticesthatcanbetiringand cumbersometohumanworkers.

Themethodologyoptedforourprojectisbyfirstlystudying research papers and doing a thorough background verification regarding the need, scope and history of the project.Initiallyaconceptualdesigndepictingthephysical structureandlookalongwiththemechanismsandworking ofourmodelaredeveloped.Thedesignofthestructurefor variousloadingconditionswereanalysed.ThegoverningAI modelsarefirstdecided,finalised,programmedandtested forerrors.Thenthemodelarefurthertrainedbyproviding samplephotosanddatasetstofacilitateproperdevelopment oftheneuralnetworkandlateronthecircuitsaredesigned andsimulatedusingProteus8professionalsoftwareandthe materialsareselectedaccordingtothedesignspecifications towhichourprojectconformswith.

Intheirpaper[1]talkabouthowpesticidesimpact human health and environment. How they affect aquatic ecosystem.Thispaperalsotalksaboutthedifferentwaysof ecological effects, detection methods of pesticides, degradationofpesticidesinwater,soilandtheirprocessof metabolism.Typesofvariouspesticidesandtheirchemical structures are differentiated. The methods of pesticides extractions and detection were given special focus. This paper talks about the impacts of their consumption by motheronthenew born Consistentusageofthesechemicals notonlydegradetheproductivityofsoilbutalsothemultiple lives by interfering the food chain. To provide a proper impactfulsolutiontothisproblemwedesignedourproject. [1]

Thispaperoffersclearandconceptualideaaboutthe Methodology. Thisparticularpapermainlyfocusesonearly identification of plant disease by monitoring the plants. It talksabout1]Identification2]capturingandcomparing3] decision making. Our project revolves around these three mainpoints.Theplantsarefirstidentified.Thenthroughthe sensorsorscanners,variousimagesaretakenandsenttothe processor.Aftertakingtheimagesasinput,theimagesare compared. If the picture is found contaminated, then the sprayercomesintotheframetospray.[2]

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3970

Onkar Kasture1, B Shivakumar2, Aham Warikoo3, Shweta Nangare4International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

Module usedhere is Raspberry PI, which is called single board computer. Being a fast processor with low powerconsumptionmakesitbeneficiarytouse.Inaddition toit,itishighlyreliablewithcompactness.Hereby,weare using python, which is object oriented programming language.ThispapertalksaboutHDMIcable,RaspberryPI zero,OpenSourceComputerVision,Camerainbrief.Image processingtechniquesdetectplantdiseases.Adigitalcamera capturestheimagesoftheplant,whichisfurtherinterfaced withtheraspberrypiboard.[3]

Thevariouscomponentsandelectronicparts,which are required for smooth functioning of the AI model, integratedwiththemachinevisionsystemi.e.cameramodule interfaced with pi is obtained from researching various papersandgettinginsightsfromthispaper.[4]

This paper talks about existing system and advancementincropsprayingandvariousmethodologiesof spraying.ThatinvolvesFixedNozzleSpacing,OptimalSpray CoverageandOneTarget OneShoot(OTOS).Themoreuseof pesticidecandegradesoilandthishappenssincefarmersuse manual labor work since they are unskilled. They used a movablesprayinggadgetastrialinstrumenttoexecuteone targetoneshootsprayingstrategy,asitismoreefficientthan otherones.Selectionofnozzleplaysvitalroleindesignasit decides the amount of spray and fertility of soil. This was amount sprayingmechanism.

Inroboticmechanism,thispapermentionsthat,the plan of case o for the robot was started. Initial test is for planningacase,whichwouldcarryaheapofuntil2 5Kgs. Ironis utilizedatfirstasthemetalofskeleton.Yet,case is weighingaround1Kg.Soforavoidingthestumblingloadof thegadget,ironwasnotpreferredasthemetalofskeleton; toughaluminiumisusedinmostpieceofthesuspensionand ironhasusedjustincertainareasasa fragilemetalrather thanaluminium.[5]

The robot is a 4 wheeled vehicle operated by DC motors coupledwiththewheels.Thetotalloadactingonthewheels wouldbe3kg,witheachwheeltakingaloadof0.75kgor750 grams. Thus by taking into consideration, the total load of 750 grams acting on the motors, the force acting on each motorwouldapproximatelybe14.715Newton.Therefore, fromdesigncalculations,thenetTorqueactingduetothis force is 2.943 Nm. Thus, from above criteria and design calculations,standard12VDCmotor,8500rpmisselected.

Bodyoftherobotsupportsaverticalarmwithahorizontal arm coupled to it at one end with the rear end of the

Impact Factor value: 7.529

e ISSN: 2395 0056

p ISSN: 2395 0072

horizontal arm(housing thecamera unit and the spraying end)heldabovetheplantunderinspectionatthetopofthe plant.Inaddition,thebodysupportsastoragetank(1L)to storeliquidpesticideandamini liquidpump(6VDC,0.35A, 5W, 60ml/min discharge) to pump pesticide from tank to nozzleviahosepipe.

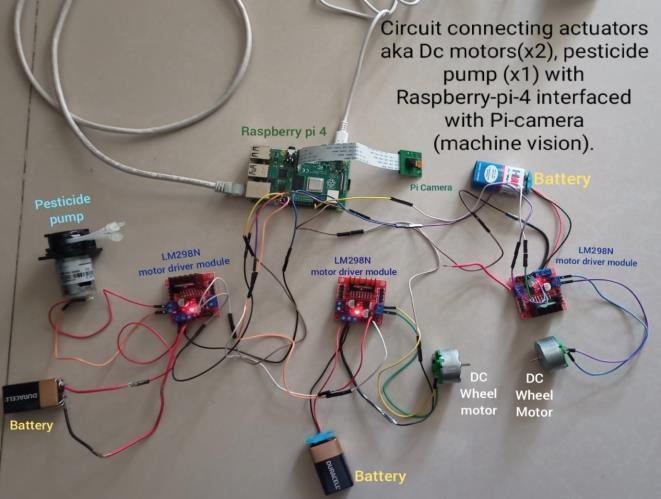

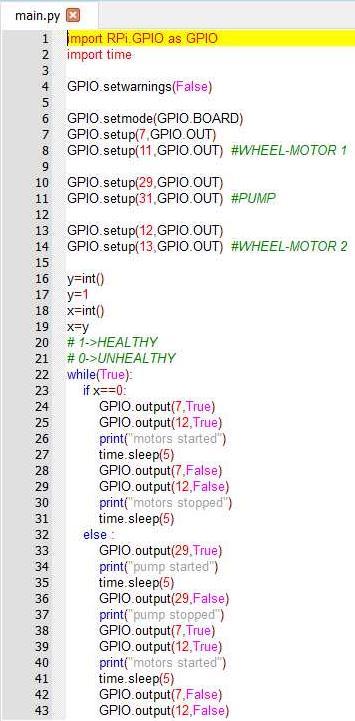

TheactuatorsliketheDC motorsandLiquid pesticidepump are all controlled by interfacing them with Raspberry Pi 4 model BSBC(SingleBoardComputer)whichistriggeredto respond in first hand by the input received from camera module(machinevision).Photoscapturedbythe“Machine Vision System”, after being processed by the well trained neural network model inside the Raspberry Pi 4 micro controller, will decide whether to energize the pesticide pumpornot,basedonplanthealthsituation.

Ifplantisfoundhealthy,therobotwillsimplymoveontothe nextplantforanalysis,butiffoundinfestedbypests,thenthe

Pi is set to actuate the pesticide pump and pesticide is sprayedontotheinfestedzonevianozzle.

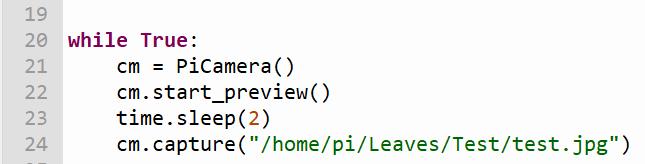

Communication starts from the Camera module of the raspberrypi.Themachinevisionsystemofourmodel will firstcaptureimagesoftheplantunderinspectionbyclicking its pictures andstoring it inthe pi memory allocated toit. Thisimagesstoredinthepidirectorywillbeaccessedbyour AIprogram.

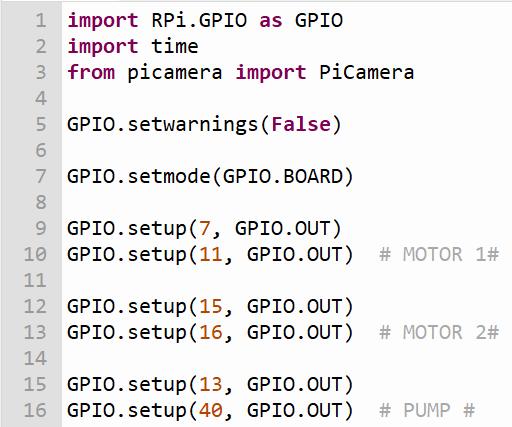

All the essential actuators are controlled by the response receivedfromtheprocessedoutputofAIalgorithm.Basedon thecategoryunderwhichtheimagesarecapturedbythePI CameraoftheraspberrypiSBCbyclassificationmodel.The raspberrypiisprogrammedtofurtheractuatecorresponding actuatorsinthesystem.Themaincontrollingoftheactuators in our system like the DC Motors and the DC pumps are mainlycontrolledbyLM298H bridgemotordrivermodule.It hastheabilitytocontroltwoMotorsatatimeithastwoinput sectionsandtwooutputsectionsandrequiresanadditional DCvoltagesupplyforamplificationofvoltagetoactuateour actuators.Weareusinga14.8V2200mahLi Ionbatteryto power our motor driver module to achieve an overall reductioninsystemweight.

The DC motors and the DC Pesticide pump are interfaced withLM298NMotorcontrollermoduleandthecontrollers arefurtherinterfacedwithRaspberryPi.TheRaspberryPiis theninterfacedwiththecameramoduletogetinputpictures of plants to be analyzed. Thus, the flow of the process is startingfromthecameramoduletoraspberrypiandfrom raspberry pi to the motor controllers and from the motor controllers to the motors and the pumps. These processes keep on repeating itself iteration after iteration until the entire row of the agricultural farmland is completely analyzedbytheAIalgorithm.

9001:2008

International

Volume: 09 Issue: 04 | Apr

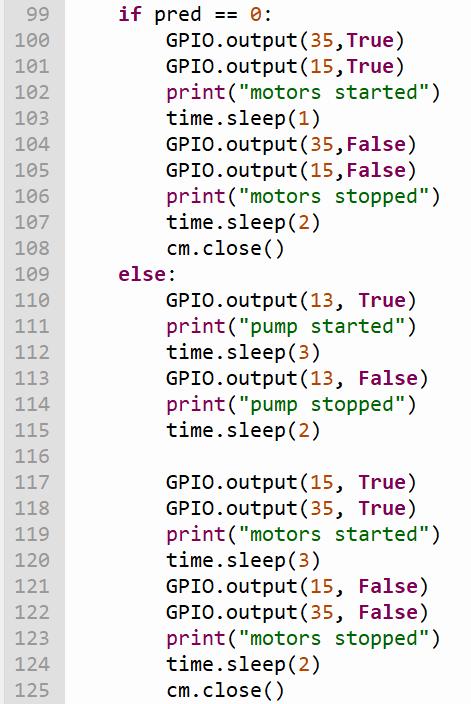

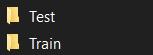

Basedonthelogicconfirmedtotheaboveliteraturewewill set the pin numbers corresponding to the motors and the pump correspondingly as high or low thus controlling the on/offtimingasperthefieldrequirements.

Now the decision making whether the plants are to be sprayedwithpesticidesbyactivatingthepumportosimply moveontothenextplantbyactivatingthemotorisdoneby usinganif elselogicalstatement.Aftertheanalysisdoneby the AI algorithm, if the predicting variable corresponds to logic1thentheleavesareconsideredtobeunhealthyandthe pump is activated corresponding to the if else logical statement.Else,thepredictingvariablecorrespondstologic 0,thenthemotorsareactivatedandtherobotmovestothe nextplantforfurtheranalysis.

Technology (IRJET)

e ISSN: 2395 0056

p ISSN: 2395 0072

Fig-6

International

Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

Back

e ISSN: 2395 0056

p ISSN: 2395 0072

ArtificialIntelligenceisdefinedasuseofneuralnetworksto train a computer to think like a human brain. While the conceptissimpleonsurface,theactualapplicationismuch more nuanced. We are actually using a form of artificial intelligenceandnottheexactterm.WeareusingMachine Learning, which is defined as training a model through continuousfeedingofdatasetsuchthatthemodelisableto understandthepatternsanddifferencesandisthenableto perform them autonomously. What this means is that we providethemodel (code)withknowndatasetimagesand known labels. The model then understands the difference betweenthevariouslabelsanddevelopsalogic.Thislogicis then used to perform the process at much faster rate and autonomously.

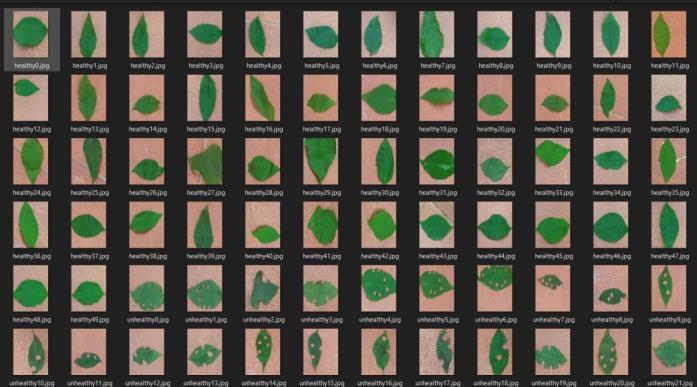

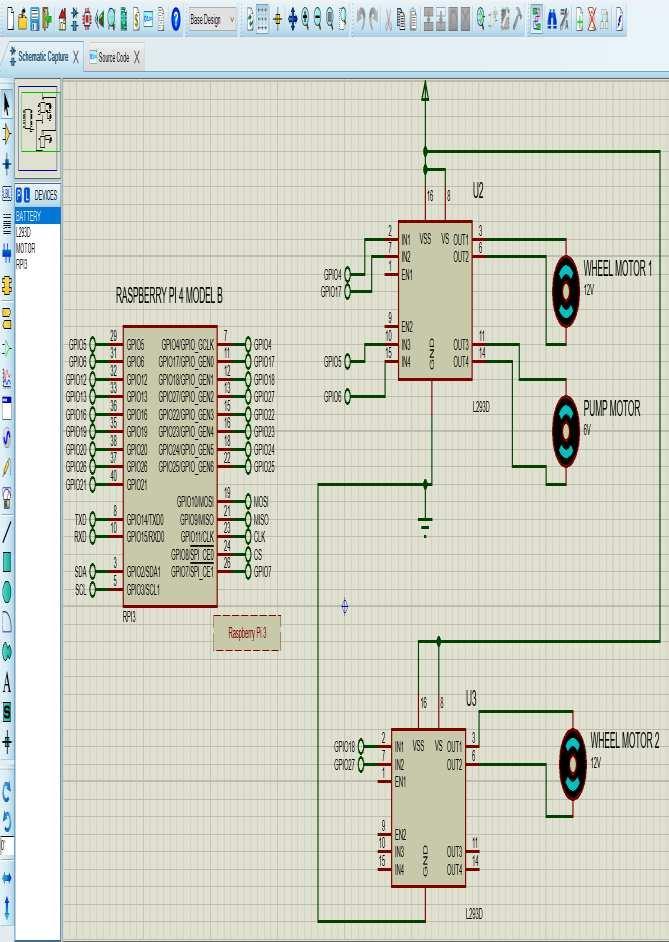

Herewehavetwofoldersinourmaindatasetfolder, testandtrain.Thetrainfolderincludesalltheknownimages alongwiththeirlabels;forexample,thenamesoftheimages containtheinformationregardingwhethertheleaveinthe imageishealthyorunhealthy.The model thendevelopsa pattern of similarities between two same categories and differencebetweentwodifferentcategories.Thatmeansthe model will learn to identify which leave is considered healthy and why and how it connects with other healthy leaves. Same with unhealthy leaves, it will learn why unhealthy leave is unhealthy and it will understand the differencebetweenhealthyandunhealthyleaves.

Proteus

Simulation

Thisprocessingtakesalotoftimeandcomputationalpower, doing this locally is generally faster but then you need to haveapowerfulgraphics processingunit,whicharequite expensive.

9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

Ifthemachineusedforthistrainingofmodelisslow and weak in terms of computational power, then it might takedaysorevenweeksfortheprocesstofinish.

To solve this issue, we are using Google Collab Platform, which is a free platform provided by Google for developersandstudentswhichisusedfordoingtheheavy processing.WeusedGPUbasedworkbooksandthemodel wastrainedthere,ittookaround6hoursforthetrainingto completesincethedatasetwasalsoneededtobeuploaded togoogleservers.

IRJET

e ISSN: 2395 0056

p ISSN: 2395 0072

Impact Factor value: 7.529

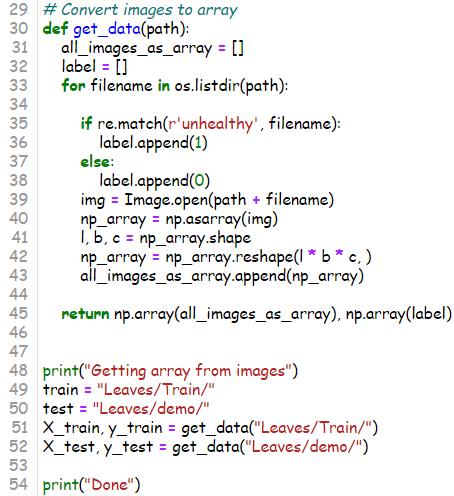

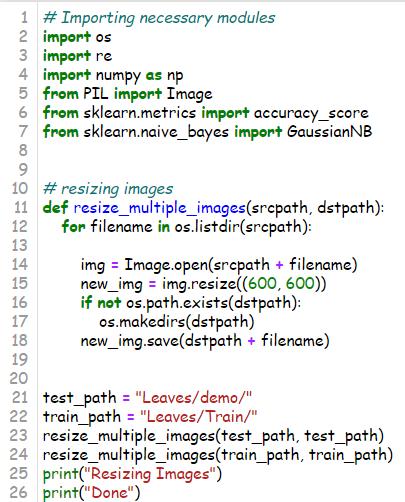

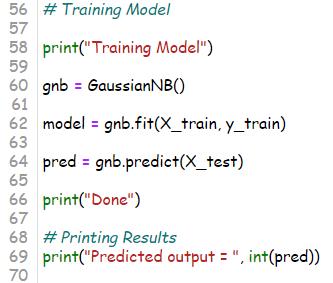

Herewehavethecompletecodeusedforthemodel andmachinelearning.Thecodeiswell captionedfor easy understandingofwhataparticularblockofcodedoesand whatfunctionitserves.

Followingarethestepsinvolvedinthecode:

1. Importingnecessarymodules:Hereweincludeall themodulesandlibrarieswewillneedthroughout the code, these modules are downloaded and compliedinternallywheneveritrunsonasystemso nomanualoverlookisrequired.

2. Resizingimages:Sincetheresolutionofourcamera outputimagesis1920x1080,itwilltakealongtime to training using that high resolution while the improvementinaccuracywillbemarginal.

Hence,weresizetheimagesto600x600sothatitis easierfortheGPUtoprocessthem.

3. Convertingimagestoarray:Thecomputerdoesnot understand what an image is and how it looks; hence,itisnecessaryforustospecifytheimagesin alanguagethecomputercanunderstand.Hence,we convert the images into an array (matrix) which includes colour values of all the 600 pixels in the images.

4. Training the model: This is where the magic happens, the array is fed to the code, which then understands the similarities and differences betweenthepixelcolorvaluesanddevelopsalogic aroundthat.

5. Results: The logic developed above is then tested with the images from test folder whose data is unknown to the code but known to the accuracy

ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

testingcodeblock.Theoutputofthemodelisthen matchedwiththeknown/expectedoutputandthe accuracyiscalculated.

In our code, we found the average accuracy to be around85%,whichisenoughforourusage.

Theobjectiveofthisresearchwork wastodevelopa low costagriculturalrobottosprayfertilizersandpesticidesin agriculturefieldsaswellasforgeneralcropmonitoring.The prototypesystemisafour wheeledrobotthatconsistsofa mobilebase,asprayingmechanismandacameraforcrop healthandgrowthmonitoring.Testsconductedontherobot showedthatitcouldperformasrequiredunderreal world usagescenarios.Whiletheproductivityoftherobotinterms ofcropcoverageisslightlylowerthanahumanworker,the laborcostsavingsaffordedbytherobotismuchgreaterasit functions completely in an autonomous mode and only requirestheoperator’scontroltoplacetherobotatthestart ofthecroppath.Furthermore,therobottargetsandsprays theliquidfertilizerandpesticideonlyontheplantsandnot inthespacesbetweenindividualplants,as opposedtothe humanworkerswithknapsacksprayerthatfloodtheentire crop path with liquid fertilizer and pesticide. Thus, the systemisabletonotonlyreducethelaborrequirementsand costs, but also result in greater resource savings and reduction of the contamination in underground water sourcesduetoleechingprocess.

Wewishtoexpressourdeepsenseofgratitudeandhonour towardsourrespectedguideMrs.J.P.Waghforherinspiring guidance and constant encouragement. Her committed devotion,dedicationandencouragementwithfullfaithonus were like a lamp in our path that keeps us constant throughoutprojectwork.

SpecialthankstoProf.IshanSathoneforhisguidanceand supportatvariousstagesduringthecourseofour project completion.Wealsoexpressourhonourandgratitudetoour Head of Mechanical Department Dr. P. A. Deshmukh for consistentencouragementforcompletingourprojectwork successfully.

WearealsothankfultoourrespectedPrincipalDr.GovindN. Kulkarni.WearethankfultoallTeachingandNon Teaching staff member of the institute and our classmate who had madeusenthusiasticfortheprojectwork.

[1] Pesticidespollution:Classifications,humanhealth impact, extraction and treatment techniques Mohamed.A.Hassaan,Ahmed.El.Nemr

e ISSN: 2395 0056

p ISSN: 2395 0072

[2] Development of Smart Pesticide Spraying Robot PvrChaitanya,DileepKotte,A.Srinath,K.B.Kalyan

[3] Plant Pathology Detection and Control Using Raspberry Pi T. Thamil Azhagi. K. Swetha , M. Shravani&A.T.Madhavi

[4] Pesticide Spraying Agricultural Robot Arjun Prakash,BharathiG.,ManasaandGayathri

[5] LeafDiseaseDiagnosisandPesticideSprayingUsing Agricultural Robot (AGROBOT) G.R. Gayathiri, Dr.M.G.Sumithra

[6] AgriculturalRobot Apesticidesprayingdevice P. RajeshKanna,R.Vikram

[7] DesignandOperationofAgricultureBasedPesticide SprayingRobot AmrutaSulakhe,M.N.Karanjkar

[8] Smart Pesticide Spraying Robot Punit Kanse, KaustubhMasekar,ChetanPokale,ProfV.N.Patil.