International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

Revath B C1 , Tanmayee R2 , Prashanth C Veeru3, Nuthan B S4, Vishwas K Singh5, Gowtham B

1,2,3,4Students VVCE Mysore, Karnataka, India

5Asst. Professor, Dept. of Electronics and Communications, VVCE, Mysore, Karnataka India

6Asst.Professor,Dept.ofElectricalandElectronics,VVCE,Mysore,KarnatakaIndia ***

Abstract Electric vehicles powered by batteries are becoming increasingly popular around the world. Several causes are driving this trend, including the need to reduce air and noise pollution and reliance on fossil fuels. To have a better understanding of how batteries behave in various situations. It is vital to be aware of certain battery performance factors in certain circumstances. A battery management systemincludes a batteryfuelgauge,anoptimal chargingalgorithm, andcircuitryforcellandthermalbalance. It estimates essential states and parameters of the battery system, such as battery impedance, battery capacity, state of charge, state of health, power decline, and remaining useful life, using three non invasive measures from the battery: voltage, current, andtemperature. This paper reviews several papers publishedregardingEV chargingtypes, methods,BMS, state of charge.

Key Words: Electric Vehicles, Li ion Battery, Battery Management System, CAN Protocol, Open Charge Point Protocol,StateofCharge,BillingSystem,BatteryCapacity.

Electric mobility is becoming increasingly important in recentyearsasastrategytoreducethedependenceonfossil fuelsfortransportation.[1]Energyefficiencyisnowacore concern,propelledbyrisingconcernaboutclimatechange andrisingoilpricesincountriesthatrelyheavilyonforeign fossil fuels. According to research published by the International Energy Outlook, the transportation sector wouldraiseitsoilconsumptionshareintheworldmarketto 55percentby2030.[2]Cleanerandmoreenvironmentally friendly mobility will also contribute to decreasing CO2 emissionsintheatmosphereandhenceglobalwarming.[1] ElectricVehicles(EVs)andtheusageofRenewableEnergy Sources (RES) are the solutions for decarbonizing the transportation sector, and their use is unquestionably increasing.[5]Theglobalmarketforelectricvehicles(EVs)is nowasmallpercentageoftheentireautosector,butthisis likely to change quickly. EVs' worldwide market share increased from 8% in 2019 to 12% in 2020, according to BostonConsultingGroup,whichpredictsthatby2026,EVs wouldaccountformorethanhalfofalllightvehiclessold.[7] Now it is obvious that to support electric vehicles, the developmentofchargingstationsisveryessential.Oneofthe veryfirsttasksintheprocessistodesignchargingstations thatofferoptimal powerandthecomponentsthatgointo

them.[1]Oneofthemostcrucialobjectivesforaccelerating thegrowthofe mobilityistoenhanceelectricityproduction andmanagement.[1]

Whenever there is an electric power outlet available, the onboardbatterychargersenableEVownerstochargetheir vehicles. As a result, when compared to stand alone (off board) chargers, the cost of the infrastructure network is reduced, resulting in a better spread of charge spots and bettercoverage.Onboardtopologiesareclassifiedintotwo types based on their connection to the drivetrain: independentandcombined(integrated)circuittopologies. Thispaperisconcernedwithalltypesofonboardintegrated chargers. These chargers are divided into two major categories(isolatedandnon isolated)[17]

Theimplementationof‘ChargingStructureInfrastructure’is oneofthethreeprimaryaspectsresponsibleforboostingEV adoption.[1]

Themainfocuswillbeonmeasuringtheelectricalfeatures ofthebatteryinanelectric car,whichisa veryimportant factor in determining the driving distance available. If the remaining battery capacity level is not displayed by the driver,thedecisiononwhentorechargethebatterycanbe made. It is important to understand certain battery performance data in order to fully understand battery behaviourunderavarietyofconditions.[2]EVshavebeenin vogueforthepastfewyears,butlittleefforthasbeenmade tomakethecarbatterymoreefficient.Thereforeanin depth knowledge of Lithium ion batteries (Li ion) is essential during charging and discharging, as is the case with most electricvehicles.[5]

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

As electric vehicles (EVs) become more powerful in the transportationsector,itisimportantformanufacturersto haveacompleteunderstandingofthebestchargingstrategy. Dependingonit,itmayincreasebatterylifeandreducethe riskofenvironmentaldamage.[5]

Whilesafety,efficiency,andcomfortareallimportantfactors toconsiderwhenbuyingacar,thereisanotherimportant factortoconsiderwhenpurchasingaPlug inHybridElectric Vehicle(PHEV)orBatteryElectricVehicle(BEV):charging time. While recharging the Internal Burning Engine (ICE) takes only a few minutes, recharging the main battery in PHEVsandBEVstakeslonger.[3]

Basically,chargingcanbeACorDC.ThebatteryrequiresDC charging,so,forACcharging,aswitchisrequiredbetween thechargingsocketandthebattery,whiletheDCcharging motorisconnecteddirectlytoaDCthatcanbepluggedinto the battery. Various ‘levels’ are related to the amount of energythatcanbedelivered,andthis,too,isrelatedtothe sourceofenergy.Higherquality,morepoweravailableand chargingtimeshorter.Anotherbigdifferenceiswherethe chargeris.InDCcharging,thechargerisoutsidethecarand all repair power (integration and repair) is performed outside the car. DC charging usually has very high power ratings and is used for most commercial/public charging stations, such as those located on the premises of gas stationsornearahighway.[3]

Theoperatorsofmostofthechargingstationsnowoperate on the basis of selling the transferred power, without the slightestincentiveforthedrivertoremovethevehicleafter it has been fully charged. Users of charging stations are looking for ways to improve their efficiency without interferingwithcustomerinformation.Theintroductionof time based costs, based on parking lessons, may help to increasetheefficiencyofthechargingstationcapacity.Even though payments are known to influence the choice of billing,littleisknownabouthowthefeesaffectthedecision tomovethecaronceitisfullycharged.[6]Pricestrategies appear to have an impact on charging, depending on the numberofindicators.Ifthecostvarieswidelyenough,the choice of charging station may be affected. However, estimates of the effect of price strategies, especially time basedstrategies,arelacking.[6]

Ourmaingoalhereistounderstandtheoperatingcycleand charge of Li ion batteries, to design an effective way to determine the State of Charge (SoC) of Li ion batteries accurately, and to design a Level 1 onboard intelligent charging system and ultimately provide an automatic paymentsystemtocalculateprices.

Level 1 charging is relatively inexpensive as it uses a standard230 voltoutlet,whichallowsEVownerstocharge their electric vehicles almost anywhere. This charging method is very time consuming and is often used as a

2022, IRJET

e ISSN: 2395 0056

p ISSN: 2395 0072

backuporotheremergencychargingmethod.Inmulti unit dwellings (MUDs), such as apartment buildings or townhouses,andinotherbusinesses.Pricelevel1maybea possibleoption.MostLevel1charginginMUDareasisdone usingtheexisting230 Voutletsintheparkinglotorprivate homeowners'garages.TheLevel1chargingpoweroutput varies greatly but is usually between 12 and 16 amps of unchangedpoweramps.[8]

Kadlag Sunildatta Somnatha, Mukesh Kumar Gupata [2] discuss different types of chargers and charging methods with different topologies along with their advantages and disadvantages.Italsogivesusinsightintotheconstructionof battery charging systems and efficiency of EVs. It explains differentcategoriesofac dcanddc dcconverterstopologies suchasunidirectional,bidirectionalalongwithnon isolated andisolatedtopologieswhichcanbeusedforconstructingan onboard charger circuit for EVs. The role of battery management system in EVs and the functions of BMS is discussed such as Data acquisition, State estimation, Charge/Discharge control, cell balancing, thermal managementandsafetyprotection.

Xu Xiao, He Molin, Paraskevi Kourtza, Adam Collin, Gareth Harrison, Sasa Djokic, Jan Meyer, Sascha Müller and FriedemannMöller[9]discusstypicalcircuittopologiesand controlalgorithmsforanonboardunidirectionalsingle phase electric vehicle charger and provide a simple yet detailed component basedmodel.Thepresentedmethodologycanbe usedformodelinganonboardlevel1chargerforEV.Thefull circuitoftheEVBC(ElectricVehicleBatteryCharger)model consistsofasupplysystem,EMIfilter,DBR,Boostconverter, DC DCfull bridgeFconverter,a PFC(PowerFactorControl) control,PWM(PulseWidthModulation)control,andbattery which together form front end and backend of the circuit. Boostconverterwithinductorcurrentkeptinacontinuous conductionmodeformsthea PFCofthecircuitpresented.A high frequencytransformerisusedforgalvanicisolation.The batteryischargedistwomodeswhichiscontrolledbythe back end DC DC circuit: Constant current and constant voltage mode. The battery is charged up to 80% 90% in constantcurrentmodebykeepingthecurrentinconstantat thereferencevalue.Thenitisswitchedtoconstantvoltage mode.Thefunctionalityofeachblockisexplainedindetail withitscharacteristics,advantagesanddisadvantages.The importance of active PFC control, the control circuit is discussedalongwithcomprehensivecircuitdiagramswith appropriate equations. The accuracy of the results is validatedagainstactualEVBCsforidealvoltagesupplyand distortedvoltagesupplywaveformsandarepresentedwith relevantgraphs.

Morris Brenna, Federica Foiadelli, Carola Leone1, Michela Longo [10] discusses an overview of different EV battery chargersbasedonpowerlevels,directionofpowerflowand

Impact Factor value: 7.529

9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

charging control strategy. It includes inductive and conductive charging methods along with their advantages anddisadvantages.Thecharacteristicsoflevel1,level2and level3chargersaretabled.Theneedofvehicle to gridpower flow(bidirectional)isexplainedwithitscontributiontothe powergrid.Atwo stageonboardchargingsystemconsistsof AD DC stage and DC DC stage. AC to DC stage can be constructedusinghalf bridge,full bridgeormultileveldiode bridge and an PFC converter. Resonant power converters with LLC configuration are used in the second stage. A suitablechargingmethodforLi ionbatteriesusedinEVsis discussed which includes the constant current constant voltagemethod.Thebatteryischargedinitiallyinconstant current mode until a certain value of voltage know cut off voltageisreachedandthenitcontinuescharginginconstant voltage mode until thecurrent decreasesto 3 5%of rated current. A graph representing current vs time is plotted which represents current and voltage throughout the charging process. An alternative method for faster, better batterycharginglifeandsafetyisalsoexplainedknownasthe Five Stepchargingpattern.

MingyueZhangandXiaobinFan[11],describeintheirreview paperthatoneoftheelectriccar'shurdleshasbeenbattery technology. Whether in theory or in reality, battery managementresearchiscritical,particularlyforestimating thebatterystateofcharge.Thebattery,infact,hasa wide range of time varying and non linear features that are exceedinglysophisticated.Asaresult,preciselydetermining the level of charge is difficult. We chose this paper as it examinesanumberoftypicalpatentsandpapersrelatingto methods for estimating the state of charge of an electric vehiclebattery.

In this paper, the estimating techniques were divided into three groups based on their theoretical and experimental characteristics:Conventionalmethodsbasedonbatterytests, Current methods based on control theory, and Alternative approachesbasedonnovelconcepts,withaspecificfocuson controltheoryalgorithms.

Electric vehicle battery management is critical for vehicle safety,prolongingbatterylife,loweringcosts,andincreasing driving range. In a real car, a typical Battery Management System(BMS)ismadeupofanumberofsensors,actuators, controllers,andcommunicationlines.Abatterymanagement system'slevelofchargeisanalogoustoatraditionalpetrol car'sfuelmetre

Hariprasadwithhisstudents[12]explainsthat,inElectric Vehicles, battery management systems (BMS) are used to monitor and control the charging and discharging of rechargeablebatteries,makingtheoperationmoreefficient. Thebatterymanagementsystemkeepsthebatterysafeand dependable while increasing senility without causing damage.ThispaperdiscussesthebasicstructureofaBattery Managementsystemanditsfunctionalitieslikeanalysisofthe

e ISSN: 2395 0056

p ISSN: 2395 0072

condition of charge, health, and longevity, as well as the maximum capacity of a battery. Different monitoring techniques are employed to maintain the status of the battery,includingvoltage,current,andambienttemperature. Different analog/digital sensors with microcontrollers are utilized for monitoring purposes. As the batteries used in electric vehicles should not be overcharged or excessively drained,thebatterymanagementsystem(BMS)isacritical systeminelectricvehicles.Ifthishappens,thebatterywillbe damaged, the temperaturewill rise, the battery's life span will be reduced, and the people who are using it will be affected.It'salsoutilizedtoextendtherangeofavehicleby efficientlyutilizingtheenergystoredinit.

This paper also helps us understand that Lithium ion batteriesareveryreactive,light,andhavethehighenergy. Lithium ion batteries charge and discharge much more quicklythantraditionalbatteries.

To avoid a cascade of chemical reactions, a rise in temperature,cellventing,andfire,lithium ioncellsshould notbedrivenbeyondtheirsafeoperatingvoltagerange.Asa result, a battery management system (BMS) is employed, which allows the battery to run within its safe operating range.

Forthefollowingreasons,abatterymanagementsystemis required.

1.Maintainbatterysafetyandreliability.

2.ChargingStatusandBatteryLife.

3.Controllingbillingstatus

4.Controltheoperatingtemperatureandbalancethecells

5.Managingrenewableenergy

BalakumarBalasingam,MostafaAhmedandKrishnaPattipati [13]havestudiedandmentionedthechallengesfacedinthe variousSoCmeasurementtechniquesandthesolutionstothe problemsfacedintheirpaper.

Basedonvoltagedata,theOCV SOCmodelmaybeusedto predict the SOC. However, since the battery must rest for severalhoursbeforeOCVcanbemeasured,itisnotpossible to monitor OCV in real time during battery operation. A measure of OCV may be derived when the battery is functioningbyestimatingthevoltageacrossthebatteryECM (electricalequivalentcircuitmodel).

ThisneedsthecalculationoftheECMcharacteristicsaswell. AfterestimatingtheOCV,theSOCmaybecalculatedusingthe OCV SOCcharacterizationparameters.

Davide Andrea [14], one of the leading experts in Li ion BatteryManagementtechnologyinhispapermentionswhya suitableBatteryManagementSystemisabsolutelynecessary

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

Page3965

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

for the CCCV mode of Battery charging in High Voltage Batteries.

Why BMS is absolutely necessary for CCCV mode of Battery charging in High Voltage Batteries

For small batteries, a CCCV (Constant Current, Constant Voltage)modeofchargingisoptimal.Thebatteryischarged atConstantCurrentatfirst.Whenthebatteryisnearlyfull, the charger's Constant Voltage setting kicks in, and the current begins to decrease exponentially as the battery receivesalastcharge.Inatinybattery,thechargervoltageis distributedquiteevenlyacrossthecells.

When charging a vehicle battery, for example, a Constant Voltageof13.5Visgiventothe12Vbattery,givingeachof the6cellsaround2.25V.

Ifonecellismorechargedthantheothers,itsvoltagewillbe somewhatgreater,detractingfromthevoltageoftheothers. Therefore, with a high voltage battery with several cells connectedinseries,theoverallpackvoltageismorelikelyto beunevenlydistributedacrossthecells.Abatterymadeupof ten LiFePO4 cells connected in series (with a maximum voltageof3.6V)mayhaveatotalvoltageof36V.However, it'simpossibletosaywhethersomecellsareat5Vandothers are at 3.2 V. Li Ion cells do not deal well with the overcharging problem; once charged, they can't take any more current until the remaining cells in the series have received their requiredcharge. Because their voltage rises quickly after being charged, it's quite easy to overcharge them.

When charging high voltage Li Ion packs, a BMS (Battery Management System) is required. The BMS will not just inform you if a cell's voltage is too high. When correctly connectedtothecharger,theBMSwillcutoffthechargeras soonasanycellreachesitsmaximumchargedvoltage.Agood BMSwillalsowithdrawchargefromthehighestchargedcell untilitsvoltagefallslowenoughforthechargertoturnback onandchargetheremainingcells.Aftermanycycles,allof the cells will be at the same voltage and fully charged, indicatingthatthepackisbalanced.

ThebatterychargeriscrucialinthedevelopmentoftheEV. Thechargerforthebatteryshouldbeefficientandreliable, with a high power density and low cost of low power consumption,aswellaslowvolumeandweight.EVchargers arerequiredtoensurethatutilitycurrentsaredrawnwithas littledistortionaspossibletominimizepowerqualityeffects whilemaintainingahigh powerfactortoprovidethemost realpoweravailablefromtheutilityoutlet.[19]

e ISSN: 2395 0056

p ISSN: 2395 0072

© 2022, IRJET | Impact Factor value: 7.529

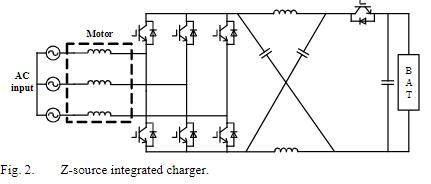

As shown in Figure 1, this section only integrates a conventional DC/DC converter as part of the onboard charger.Byaddingafewcomponents,aDC/DCconvertercan be used as a new converter. In some integrated chargers, convertersalsoactasrectifiers.

The reference proposes a single stage integrated charger capable of achieving V2G while minimizing the second harmoniccurrentripple.However,gird sidefilterinductors are still needed. When the charging power increases, the inductance increases. The size and weight of the inductor increase, requiring more space. As a result, the concept of incorporatingmotorwindingsintochargerswasraised.

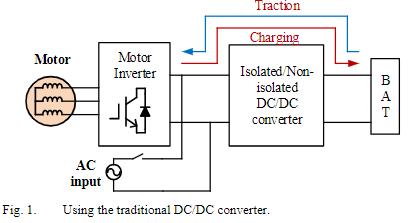

F.Z.PengproposesaZ sourcenetwork.TheZ source network,whichisabi directionalconverter,canalsobeused as a boost function in EVs. Benefits are mentioned. The reference suggests a modified Z source integrated EV charger. A voltage boost is possible in only one phase. In addition, the Z source includes a split charger for battery charging. A method of controlling the Z source integrated charger is proposed. As shown in Figure 2, no additional componentsareneededtochargethebattery.[18]

It is generally accepted that widespread EV adoption can haveseriousconsequencesforthedistributiongrid,including distribution transformer overheating, voltage fluctuations,

ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

andharmonicdistortion.Tocopewiththeabovedifficulties, inthelongrun,thegridwillneedfurtherupgrades.Itwillbe necessarytobuildinfrastructure.Itisrecommendedtouse pricingmethods.Therearetwoofthem.Therearetwotypes ofchargingstrategies:integratedandintegratedstrategies. WhenEVsarehigh,itisnaturaltoadoptacoherentstrategy. OwnerswillchargetheEVbatteryassoonastheyarriveat home or charge the car randomly from the home's power outlet.Chargesthatarenotintegratedincreasethelocalload. Whendemandincreases,pricesriserapidly.Asaresult,there ismorepowerconsumption.Damageiscausedbyoverload distributiontransformersandwires.Thechargingtacticsthat are integrated are the answer to eliminating the consequencesofhighEVpenetrationgridsbyoptimizingthe charging schedule and the length of time it takes to charge.[20]

NayanandChandrasekhar[15]aimtocreateaCANprotocol for communication between a battery charger and a BMS (battery management system). This enables the battery chargertointeractwiththebatterymanagementsystemand make choices without the need for human intervention, protecting the battery from damage. The Controller Area Network,orCAN,isamulti masterhalf duplexprotocolthat allows for real time control of up to 1 Mbps. The battery managementsystemusestheCANnetworktocommunicate withthebatterychargerandinstructittotakeappropriate actionifthecurrent,voltage,ortemperaturedataexceedsthe thresholdlimit.Thechargeralsogivesinformationaboutthe battery management system such as current supply, the temperatureofthecharger,etc.ThearchitectureoftheCAN moduleconsistsofamessagecontroller,aprotocolkernel, andaCANtransceiver.

TheCANprotocolusedforcommunicationmakesthewhole system more reliable and accurate as no data loss was observedduringthestudy.

Studieshaveshownthatinsomeseveresituations,suchasa suddensurgeinvoltageandcurrentorover temperature,the charger shuts off immediately, which helps prevent any damagetothelithium ionbattery.Thiscanonlybeachieved if the protocol is more reliable and supports faster communicationspeeds.

Pruthvi, Niladri, Phaneendra and Sai [16], in their paper, describethatthegoalofOCPP(OpenChargePointProtocol) istoprovideatrulyinteroperableEVchargingbase,onethat is flexible and easy to use for both EV drivers and system administrators. Clients can use the OCPP to integrate chargingstationsfromavarietyofmerchantsintoasingleIT back endarchitecture.

e ISSN: 2395 0056

p ISSN: 2395 0072

There are 16 Functional Blocks in total, each with one or moreusecases.Onlyafewofthesearerequiredtosetupa simpleChargingStation.Someoftheseusecasesare

1) Booting, Configuration, and Resetting a Charging Station

2) Authorization options

3) Transaction mechanism

4) Availability

5) Sending transaction related Meter values

Although it is estimated that electric vehicles will become themainmeansoftransportationinthefutureduetotheir environmentalbenefits,theproportionofEVsisnowlowin Australiaandaroundtheworld.Themainreasonforthisis thelongchargingperiodandthewaitingtime(7 8hours)for the automobile to fully charge. Although home and public chargersarebecomingincreasinglycommon,chargingtime cannotbeeasilyreducedduetothepowerratinglimitations oftheconnection.

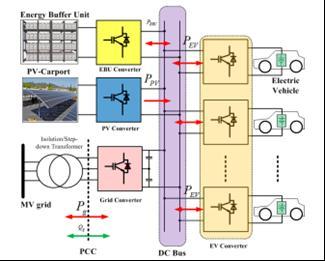

The only viable answer is to build fast charging stations (FCS),whichcanfunctionjustlikeagasstationandallowthe EV to charge within half an hour after its reduction. However, widespread adoption of FCS is challenging as it also requires distribution grid updates. In addition, FCS technology, codes, and standards are in their infancy, requiring significant investment to build the system. Renewable Energy Resources and Energy Buffer Units (EBUs) are commonly associated with FCS to reduce the effectsofFCSonthegrid.

Fig.3 shows the future of FCS for public charges. Solar PV energyandEBUareusedtoreducegridproblemsduetothe fast chargingpulsepower.

Thegrid,EVbattery,andenergybufferunitcanallexchange energy.Duringregularoperation,ifnecessary,EVbatteries canbechargedbysolarPVduringthedaywiththehelpof EBUorotherparkedEV.EVbatteriescanbechargedfrom the grid at night using an EBU or other parked EV. If necessary, EVs can also assist the grid during peak load demand.Thegridwillneverbecomeunstableasaresultof highEVchargingpulsepower.

Recently,rooftopresidentialPVsystemshavebecomemore popularinAustralia,ashavinganEVchargedathomeusing PV solar energy is considered environmentally friendly. Fromthispointofview,theconceptofcombiningtwopower conditioning systems in one system is established. This reduces investment costs and reduces the need for high power equipment while improving the stability of the system.[20]

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

Fig.3. TheinfrastructureofafutureEVfast chargingstation.

[1]RohanPal,SureshChavhan,SanjeevikumarPadmanaban, Sayed Sayeed Ahmad, Baseem Khan “A Comprehensive AnalysisofElectricVehicleChargingStationInfrastructure inanUrbanArea”

[2] Kadlag Sunildatta Somnath, Mukesh Kumar Gupata “Review Paper on Electric Vehicle Charging and Battery Management System” Proceedings of International ConferenceonCommunicationandInformationProcessing (ICCIP) 2019, Published: July 2019 doi http://dx.doi.org/10.2139/ssrn.3416669

[3] AVNET Electric vehicle (EV) onboard chargers 22/10/2021 https://www.avnet.com/wps/portal/abacus/solutions/mar kets/automotive andtransportation/automotive/power train and ev hc phev systems/ev onboard chargers/

[4]NicolòDaina,ArunaSivakumar,JohnW.Polak“Electric vehicle charging choices: Modelling and implications for smart charging services” Published: August 2017 doi: https://doi.org/10.1016/j.trc.2017.05.006

[5]EmmanouilD.Kostopoulos,GeorgeC.Spyropoulos,John K.Kaldellis “Real worldstudyfortheoptimalchargingof electric vehicles” Published: November 2020 doi: https://doi.org/10.1016/j.egyr.2019.12.008

[6] Rick Wolbertus and Bas Gerzon “Improving Electric Vehicle Charging Station Efficiency through Pricing” Published: 03 September 2018 doi: https://doi.org/10.1155/2018/4831951

[7]APTIV “BEV,PHEVorHEV:TheDifferencesAffectthe Architecture” 23/10/2021

e ISSN: 2395 0056

p ISSN: 2395 0072

https://www.aptiv.com/en/insights/article/bev phev or hev the differences affect the architecture

[8]CALeVIP “ElectricVehicleCharging101” 23/10/2021 https://calevip.org/electric vehicle charging 101

[9] Xu Xiao, He Molin, Paraskevi Kourtza, Adam Collin, Gareth Harrison and Sasa Djokic “Component Based ModellingofEVBatteryChargers”Publishedin:2015IEEE Eindhoven PowerTech Publisher: IEEE DOI: 10.1109/PTC.2015.7232690

[10]MorrisBrenna,FedericaFoiadelli,CarolaLeone,Michela Longo“ElectricVehiclesCharging TechnologyReviewand Optimal Size Estimation” Published: 02 October 2020 Journal of Electrical Engineering & Technology DOI https://doi.org/10.1007/s42835 020 00547 x

[11]MingyueZhangandXiaobinFan.“ReviewontheStateof Charge Estimation Methods for Electric Vehicle Battery” World Electric Vehicle Journal MDPI Published: 11 March 2020,doi:10.3390/wevj11010023.

[12] A. Hariprasad, I. Priyanka, R. Sandeep, V. Ravi & O. Shekar.“BatteryManagementSysteminElectricVehicles” InternationalJournalofEngineeringResearch&Technology (IJERT) Vol.9 Issue 05, May 2020, doi: 10.17577/IJERTV9IS050458

[13] Balakumar Balasingam , Mostafa Ahmed and Krishna Pattipati. “Battery Management Systems Challenges and SomeSolutions”Energies MDPI Published:2June2020, doi:10.3390/en13112825

[14] Davide Andrea. “CCCV Chargers: A False Sense of Security” Creative Commons Attribution Share Alike 3.0 Unported License 19 September 2008, doi: http://liionbms.com/php/wp_cccv_charging.php

[15]NayanKhulbeandChandrashekharChoudhary.“CAN Based Protocol Implementation Between Battery Charger And Battery Management System For Electric Vehicles” Pantnagar Journal of Research Vol. 17 (2), May August 2019,doi:http://www.gbpuat.res.in/uploads/archive/Vol.17 (2).9.pdf

[16]ThotaVenkataPruthvi,NiladriDutta,PhaneendraBabu Bobba&BSaiVasudeva.“ImplementationofOCPPProtocol forElectricVehicleApplications”ES3WebofConferences January2019,doi:10.1051/e3sconf/20198701008

[17]NadimSakr,DanielSadarnac,AlianGascher“AReview of onboard integrated chargers for electric vehicles” 16th European Conference on Power Electronics and Applications August2014,doi:10.1109/EPE.2014.6910865

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3968

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

[18] Tuopu Na, Xue Yuan, Jiaqi Tang, Qianfan Zhang”A Reviewofonboardintegratedchargerforelectricvehicles and A New Solution“ 10th International Symposium on Power Electronics for Distributed Generation Systems (PEDG) June2019,doi:10.1109/PEDG.2019.8807565

[19] Murat Yilmaz, Philip T. Krein “Review of Charging Power Levels and Infrastructure for Plug In Electric and Hybrid Vehicles” 2012 IEEE International Electric Vehicle Conference March2012doi:10.1109/IEVC.2012.6183208

[20] Viet T. Tran, Danny Sutanto, Kashem M. Muttaq “The State of The Art of Battery Charging Infrastructure for Electrical Vehicles: Topologies, Power Control Strategies, and Future Trend” 2017 Australasian Universities Power Engineering Conference (AUPEC) Nov 2017,doi: 10.1109/AUPEC.2017.8282421

Impact Factor value: 7.529

e ISSN: 2395 0056

p ISSN: 2395 0072