International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

1,2,3,4Student, Department of Mechanical Engineering, Rajiv Gandhi College of Engineering Research and Technology, Chandrapur, Maharashtra, 442403

5Professor, Department of Mechanical Engineering, Rajiv Gandhi College of Engineering Research and Technology, Chandrapur, Maharashtra, 442403

***

Abstract In day to day life, vendors make an effort to push the hand trolley and walk together with the trolley miles away to sell products such as vegetables, goods, etc. To overcome the effort of pushing the trolley, we are adding gears to the trolley, which with the vendor will get a smooth ride and make the trolley pedal smoothly. The vendor can sell vegetables or other products under his supervision while driving. In other ordinary trolleys, people make modifications and attach the bicycle or bike in front of the trolley, and the driver has difficulties keeping the goods and products under watch while driving. The main objective of the project is to find an efficient and user friendly method of selling products using minimum effort from the user. Because of this project, we designed the trolley in such a way that the vendor keeps watch on their products and goods during transportation and selling, and help him save from theft of products and financial losses. This hand cart is advanced with modifications and attachments. While the cart is under drive or running, it will generate free electricity with the help of power generating mechanism. From that electricity, a vendor can also charge the battery and store electricity in it, and the vendor can use that electricity to light up the trolley at night.

Key Words: Handcart, Trolley, Steering, Renewable Energy, Supervision, Comfort.Theterm“Handcart”isoftenusedtorefertofour wheeledplatformcartsthatarepushedorpulledbyhand.In ancienttimescartswereoftenusedforjudicialpunishments, both to transport the condemned a public humiliation in itself.Inpresentdays,handcartsarewidelyusedinavariety of trades, such as delivering parcels, selling goods, selling vegetables, and hauling materials in both urban and rural areas. The current cart which is we have designed have a platformoverthreewheels andpushedbythepersonwho drivingitwiththehelpofsteeringwhichisattachedtofront wheel.

Themajordrawbackofprevioushandcartwhichis not been able to turned around a bend. This happened becausethewheelsofthehandcartarefixedonthefrontaxle. Asaresult,thehand cartcanbeturnedaroundabendonlyby physicallyliftingitbyitsrearwheelsandturningthewhole cartaboutthefrontwheels.Manuallyliftingthecartbecomes

extremelydifficultfortheperson Movingthecartneedsto provideenergyforpushingthecart,aswellastoliftthecart whileturningwiththebalancingtheloadonthefrontwheels. Thatbecomesmorechallenging.

Pushingthepreviouslyusedhand cartwasnotonly increases the efforts applied by the human who was operatingit.Duetoheavyloadandthereisnomechanism available to turn the handcart it needs too many effort to turnit.So,theloadcarryingcapacityofthecartisdirectly proportional to the human’s weight lifting capacity which they used to turn the hand cart. On the other hand, the previoushandcartsdonothaveanykindofsafetyequipment suchasbreaksandlighting.

Tofixthisissues,weneedthehandcartwhichwill push and turn easily with less effort. We have done some modificationsbyenablingsteeringmodeforreducinghuman effortsuchasweightliftingandpushingtheload.Wehave attacheda safetyfeatureby providing breakstohandcart. However,othertypeofhandcartsareworkingoroperating onpullingcriteria.Thescooterorbicycleisattachedinfront ofhandcart.Thistypeofhandcartiswidelyusednowadays fortransportingappliances,rawmaterials,andheavyloads. Usingthiskindofcartsarenotsuitableforsellingproducts andvegetables.Theuserofsuchkindofhandcartisunable tokeepeyeorspotontheirproductsorvegetable.

To avoid this kind of issue, we have linked or attached the bicycle at the rare side of handcart. This modification is very useful for the vendor who are selling vegetablesorotherveritiesofproductsoritems.Theitems willbeunderthesupervisionofthevendor.Apartfromthis, wehaveprovidedextraspacebeneaththehandcarttostore extra products or keep vegetable waste in that carriage spaceratherthanthrowvegetablesorotherwastesonthe road.

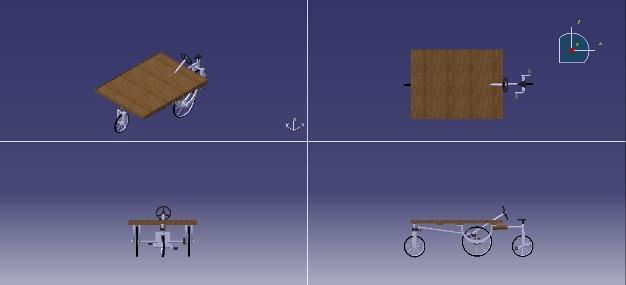

On the other hand, in this handcart, a power generatingmechanismisconnectedatthewheel.Thepower generatingmechanismisusedtogenerateelectricalenergy byconvertingrotatorymotionofthewheeltoelectricity.The generatedelectricitywillbeusedbyvendortogiveelectric power to the speakers or other applications as per convenience.Thevendercanstorethisgeneratedelectricity inthebattery.Thestoredelectricalenergy canbeusedby the vendor at night to lighting their handcart. This

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3922

Nayan Soni1 , Meghraj Gowardhan2 , Manish Sonkusare3 , Umesh Nannaware4 , Prof. Pravin D. Padole5International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

modificationhasmadethishandcartmoreadvanced.Asper thismodificationsandinnovationsitisdecidedtogivethe title to this project as “THE NEXT GENERATION HAND KART”.

For making farmers, goods sellers and vegetable vendor’slifecomfortableduringwork,wearetransforming the pushing handcart to riding handcart. This project will makethechangesindevelopmentfieldofengineeringand give benefits to farmers and sellers and retailers. The old mechanismofhandpushing trolleyorcartisveryhard to pushandwalkalongwiththetrolleytillthedestination.We are fabricating the next generation riding trolley. On this trolleythesellercankeepeyeontheproductsinfrontofhim andthusthechancesoftheftarereduced

From this project the vendors will get relief from walkingalongwithhandcartforsellingtheirproductsand theywillspottheproductsanditemsinfrontofthemwhile ridingthetrolleyandtheycanproducefreeelectricityfrom thepowergeneratingmechanismwhichismountedonthis hand cart. They will ride trolley with less effort and force andfromthattheywillgethealthbenefitstoo.

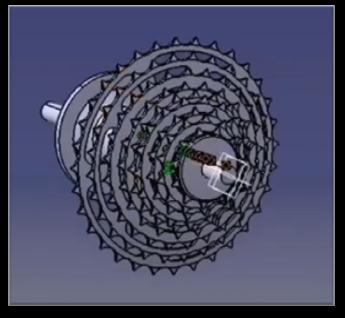

To give relief to the vendors from walking along togetherwiththetrolleyandkeepeyeontheirproductswe areintroducingthenextgenerationhandkartwhereweare connecting steering mechanism for front wheel to give turning movement to the trolley by using bevel gear mechanismandattachingbicyclegearstotherearwheelof thebicycle.Weareconnectingrearwheelofbicycletorear sideofthecartfortransmittingthepowertoridethetrolley with less efforts. The trolley we are making by using Ball bearings,Bevelgears,Connectingrod,trolleyframe,trolley wheel, Sprocket, Steering, pedals, seat, brakes, etc. The vendorwillgetamazingexperiencewhileridingandselling products.

We are connecting power generation mechanism to the cart which will generate the electricity whilecartisworkingorrunning.Thegeneratedelectricity will charge the battery and store the electricity in the battery. That stored electricity can used by the vendor at nighttolightingupthecartandotheruses.

This project is a successful attempt to modify a conventional & “Hand cart” The design and development approachinthisProjecthadmajorfocusontheissueslike

e ISSN: 2395 0056

p ISSN: 2395 0072

a)Providingasteeringmechanism. b)Provisionofseatalongwithpaddlingmechanism. c)Provisionofbraking.

Forfulfillingtheaboveobjective,adesigntakeninto considerationistheconventionalhandcartalongwithsome changes.Themajorchallengetoapplyasteeringmechanism to front two wheels, the front wheels are to be mounted independentlysothatasteeringmechanismcanbeprovided withalinkage.Theoperationofsteeringmechanismisnice and smooth with perfection of turning sensitivity. Handle providedisjustlikeahandleofbicyclehavingprovisionof hand brake and horn the paddling mechanism was also providedonrearwheelsofcart.However,itusesthefifth wheelduringpaddlingwhichmakestheoperationcomplex.

The seating position of driver is outside the cart trolley (i.e. some inches away from the rear wheels shaft) thatoffsetsthedriverweightfromrearaxlemakingthecart tilt. For overcoming this issue, a fifth wheel has been provided that makes the cart unnecessary heavy and creating more resistance during paddling. Though the steering mechanism is sensitive independent axle front wheelsgiveeffectivesteeringofhandcart.Someotherissues whicharenotaddressedintheexistingdesignare,

1) Security and Safety; needs more attention on those issues.

2) Hygiene;thecartisopenduringtheuse;thisleadsto unhygienicconditions.

3) Aesthetic consideration in design so that it looks smart.

4) Efficient paddling, the efforts taken during the paddlingaremoreandthereisunnecessaryincrease incostduetoprovisionoffifthwheel.

5) Ergonomics, which can make the use of cart more comfortableandeasier

Thesurveyhasbeenconductedduringthisproject;the majorrequirementofhawkerswaschangeofstorageunit sizeandshapei.e.tobemodular.

TheMarketsurveyshowsthattherequirementof storage space must be different for different purposes for examplethepani puristallneedswoodenplatformbecause steelgetcorrodedduetoacidicwaterofpani puriandtea stall needs steel platform because of use of stove. So, the storage platform must be detachable from main chassis easily and also easily attachable One should take this modular approach on priority during modification of the hand cart. During this project some on standardization of dimensions proposed which would be modified as per designrequirement.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008

2.1 Dissertation On Product Design Approach For Design And Development Of “Hand Cart” Submitted by Mr. Satish P. Lokhande

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

In this project, electrical energy is generated by meansofanon conventionalmethodjustbywalkingonthe footsteps. Non conventional system for energies are very muchrequiredatthistime.

Energygenerationusingfootstepshasrequiresno fuelinputtogenerateelectricity.Inthisproject,electricityis generatedjustwiththehelpofrackandpinionarrangement alongwithalternatorandchaindrivemechanism.

For its proper functioning such that it converts Forceintoelectricalenergy,themechanismconsistsofrack & pinion, chain drives, alternator and battery. We have discusseditsvariousalternateapplicationswithextension also.Thepowergenerationismuchworthybutithaslittle initialcosteffectivefactors.

Now,focusingonitsworkingprinciple,thisdeviceif embeddedinfootstepsofrailwayplatforms,citymalls,city footpaths e.t.c. & can convert the weight impact of people intoelectricalenergy.Whenapedestrianwillsteponthetop plate of this device, the plate will go down and this downward motion results in rotation of the shaft of the alternatorwhichproduceselectricalenergy.Afterremovalof force the top plate returns to its original position due to springs.

1) To create a four wheeled human powered load carryingcartassemblywithanintegratedsteering system.

2) Todevelopacartassemblythatavoidstheneedto beliftedfrombehindwhenturningaroundabend.

3) Toprovideacartassemblythatallowsheavyloads tobetransportedwithoutcausingstrainorinjuryto thepersonoperatingthecartwheneverturningthe cartovercurves.

4) To furnish a four wheeled, human powered load carryingcartassemblywithgoodmaneuverability andcontrolonuphillsurfacesandcurves.

5) To add a structurally simple and cost effective enhancementtothecurrenthand cartthatallowsit tobesteeredwithoutanyfurtherphysicaleffort.

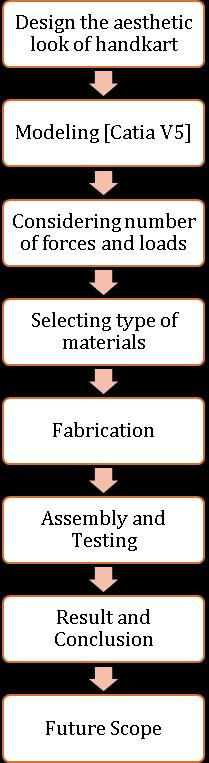

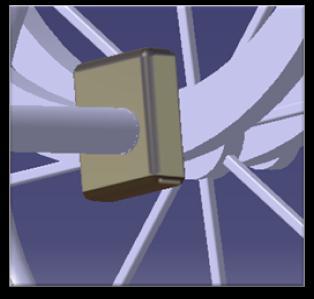

A methodology for pedalling, steering, and power generation mechanism of the Next Generation Handkart basedonmanpoweredwhichhasbeenfacilitatedtomoveis demonstrated.Thischapteralsodescribesmaterialselection basedontechnicalfactorsthatmadethematerialeligiblefor utilization.

Impact Factor value: 7.529

e ISSN: 2395 0056

p ISSN: 2395 0072

After doing research on the several material properties,themostfeasiblematerialisselectedfortheNext GenerationHandkart.Weinvestigatedforthecharacteristics whicharetakenintoaccount,whichincludingmachinability, durability,strength,weight,availability,andmaterialcost.A materialwithsufficientstrengthischosentoensurethatthe frameoftheNextGenerationHandkartdoesnotfailunder the strain exerted. Cast iron alloy has been used for this project.

The virtual model is created by using CATIA V5 modelling software to analyze the model. The dimensions are considered as per the physical model and a rough diagram of the Next Generation Handkart is drawn with designedhandcartpattern,theninCatiaV5.Withthehelpof workbench a cross section is drawn using basis tools like spine,mirror,line,circle,trimandafterthatbyusingtools likepad,chamfer,revolveandholetocreatea3Dmodel.

9001:2008

2.2 “FOOT STEP POWER GENERATION” Submitted by Sarat Kumar Sahoo, Shubham kumar, Pankaj Kumar Yadav and Rishav Kumar

Volume: 09 Issue: 04

Apr 2022

e

p

2395

2395 0072

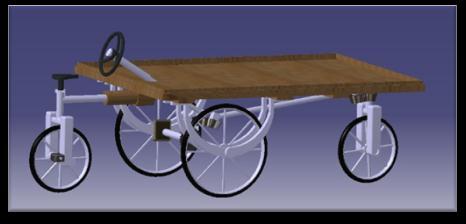

Thedesignofhandcartwasprimarilydividedintofollowing aspectofdesign;

1. KineticDesign

2. KinematicDesign

Followingarethedetailsofeachdesign.

The design of Kinetic is “of our relating to the motion of material bodies and the forces and energy associatedtherewith”.So,thekineticdesignmeansdesigning themotion,andcalculatingforces&energyrequiredtopull or push the cart taking into consideration the load on vehicle.Intheprojectfollowingarethecalculationsofthe wheel forces, rolling friction of bearing, the force used by driver(man).

Amancanpush227N[1]intheseatedpositionand251N [2]inthestandingpositionathismaxpotential.

Thestandardwheelsizeofhandcart[3]

Wheeldiameter= 70cm = 700mm = 0.7m

Radiusofwheel= 0.35m

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

M=Overallweight

1. Consideringliveloadoncart(200Kg)

2. Consideringweightofman(100Kg)

W = m × g

= 300 × 9.81

= 2943 N

H(height)=0.3m ……………{Assumed}

Fr = N × µ × b / √r2 b2

Where;

Fr RollingFriction

N Reactionattangent

µ CoefficientofFriction

b Surfaceincontact=0.03m

Fr =

Fr = 75.97 ~ 76 N

Hence,theforcerequiredtokeepthecartrollingis 76 N.

Thebearingissubjectedtopureradialload

RadialForce(Fr)= 1962N

N= 80rpm

Life(L)= 30000hrs

Shaftdiameter(d)= 15mm

Bearinglifemillionrevolution:

L10 = 60 N(L10) hr/106

= 144 million rev.

Dynamicsloadcarryingcapacity(C)

C = p(L10) ⅓ = 2943 (144) ⅓

C = 15425.68 ≈ 15426 N

HenceaswegotC= 15426 N

From Manufacturing Catalogue;

e ISSN: 2395 0056

p ISSN: 2395 0072

Bearing Designation : 6302.

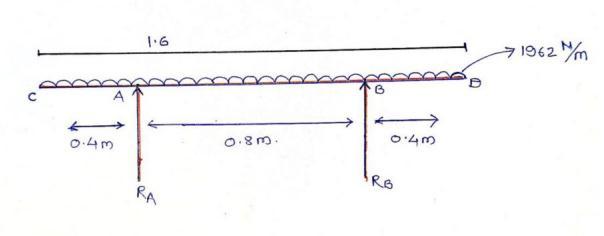

Itisassumedthatthe200kgloadisuniformlydistributed acrosstheentirehandcart.

Findingstressinducedinframeunderloading. AssumeframebeenunderUDL.

TofindthereactionatA&B

Assume∑Fy=0(↑+ve,↓ ve)

RA+RB 1962 1.6=0

RA+RB=3139.2N ∑M=0(⥀+ve,⥁ ve)

TakingmomentatpointA RB 0.8+(1.6 1962) 0.4=0

RB=1569.6N RA=3139 1569.6

RA=1569.6N

RA=RB=1569.6

SFatpointC=0

SFjustattheleftofpointA= 1962 0.4= 784.8N

SFatpointA= 784.8+1569.6 =784.8N

SFjustattheleftofpointB=784.8 1962 0.8 =784.8N

SFatpointD=784.8 1962 0.4 =0N

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

3926

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

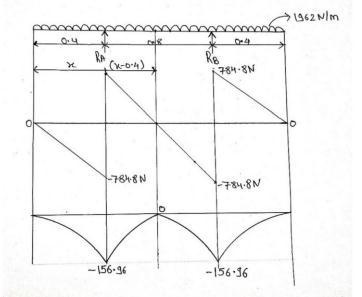

Tofindthepointofzeroshear;

= =

x = 0.8m

=(x 0.4)

6.2.2 BM CALCULATION

BMatthepointofzeroshear

Zeroshearisatx xsectionatx=0.8

BMatx x=RA (x 0.4) 1962 x =1569.6(0.8 0.4) 1962 =0

BMatx xatzeroshear=0

BMcalculationforotherpoints

BMatC=0(⥀+ve,⥁ ve)

BMatA= 1962 x

BMatA= 1962

Atx=0→BM=0

Atx=0→BM= 1962

BM= 156.96

BMatB=RAx(x2 0.4) 1962 x

Atx2 =0.4

BM= 156.96

Atx2 =0.8

BM=1596.6 (1.2 0.4) 1962

BM= 156.96

BMatD=0

e ISSN: 2395 0056

p ISSN: 2395 0072

FIG. 6.2: SF & BM DIAGRAM

Whenx=0.4;y=0 C2 = 115.104

M=1569.6 + +292.992 Putx=0.8 M=585.984

ForIofLsection; Thearea(A)=(h+b t) =(40+40 10) 10 =700mm2

Perimeter(P)=2b+2h =2 40+2 40 =160mm

Thedistance ofthecentroidfromtheleftedgeofthesection (xc),andfromthebottomedge(yc),canbe foundusingthe firstmomentsofareaofthetwolegs:

xc = ( (h2 +ht t2))

xc = 13.5714 mm

yc = ( (h2 +bt t2)) yc = 13.5714 mm

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

ThemomentsofinertiaIx0,Iy0 &Ix0y0oftheanglesection aroundthex0andy0axisare:

Ix0= (bt2 +h3 t3)

= 223.33 103 mm

Iy0= (ht2 +b3 t3) = 223.33 103 mm

Ix0y0= (b2 +h2 t2) = 77.5 103 mm

Ixy =Ix0y0 Axcyc

=(77.5 103) (700 13.5714 13.5714)

Ixy = - 5142.8 mm4

Y= = ………Esteel =200GPa

Y = 5.69 10 8 mm

Nowfromflexureformula, = → = 10 10 N/mm2

6.2.3 Bevel gear ratio

N1 =54

N2 =108

N1 :N2 =54:108 =1:2

Where,

N1 =Numberofteethondrivengear

N2 =Numberofteethondrivinggear

That is, if the driven gear is meshed to the driving gear installedonthefrontwheel.Ifthedrivengearcompletesone revolution, the driving gear rotates 180° within the revolution.

e ISSN: 2395 0056

p ISSN: 2395 0072

Toalleviatethehardshipofwalkingwithahandcart whilesomehowprovidingasafetyaspect,wemodifiedthe conventionalhandcarttomakethenecessaryimprovements. Thepowertransmissionisprovidedbytheunicycle,whichis mountedtotherearportionofthehandcart.Thesourceof powertransmissionisthepaddlemechanism,whichdrives the unicycle's wheel and generates pushing force for the handcart,allowingittomove.Abicyclegearisconnectedto offersevenspeedstothehandcart,toreducingtheamount ofeffortrequiredforpedalling.Theseven speedgearsystem willaidintheoperationofthehandcartoninclinesurfaces suchashillyareas.

Thesteeringmechanismisgiven toproviderelief fromweightliftingwhenmovingthehandcartontheturning andtoreducetrafficconditionsonthehighwaycausedby the handcart. The steering mechanism works similarly to thatofacar,usingbevelgearsandaconnectingrod.With the aid of the connecting rod, the bevel gears revolve in tandemwiththesteeringwheel.Asaconsequence,thefront wheel will get the turn moment needed to turn the next generationhandkartontheroad.

Thepowerproducingmechanismisnowpositioned paralleltothewheelasthefollowingchange.TheDCmotor houses the power generation mechanism. The sprocket is connected to the shaft of the DC motor. The sprocket is attached to the wheel, and when the handcart moves, the wheelrotates,causingtheshaftoftheDCmotortorevolve counter clockwise.Asaresult,theDCmotorwillfunctionas a power generator, producing electrical energy. The electricalenergywillbestoredinthebatteryforfuturefree electricityusage.

Thehandcartisequippedwithbrakesforoptimum safety.Thebrakesareattachedtothewheelofthehandcart, and when the brakes are applied, the rate of velocity decreasesuntilitreacheszero,atwhichpointthehandcart stops. The brake lockalso provided to keep the handcart stableormotionless.

Radium stickers are applied on the handcart's exterior surface for safety reasons. As a result, in a dark night scenario, the beams of light from other vehicles approachingthehandcartwillbeincidentonthesurfaceof the radium sticker, allowing it to glow. As a consequence, othervehicleswillseethehandcartinthedarknight,which willaidinsavingthehandcartfromanaccident.

Followingtheselectionofmaterialsthatarelightin weight,durable,andreadilyavailable,suchascastironalloy, teakwood,andsteelalloy.Severalmachiningprocessesare performed on the material. Clamps, steering wheels, supports, Bevel gear frames, and other elements are

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

Page3928

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

manufactured. In the fabrication, we do cutting, drilling, welding,millingandshapingoperations. Otheroperations onsupportsincludeagrooveforthebevelgearframeanda groveonthesupportplate.Bench wiseclampingisusedto preparetheclamps.Alathemachineisusedtopreparethe bevelgearframe.Followingthefabricationofallpieces,they areassembledintotheNextGenerationHandkartutilising cuttingandweldingoperations.

1. Vendors may sell their wares under their supervision.

2. Vendorswillberelievedofthehassleoftravelling withthehandcart.

3. Vendorswillberelievedoftheirheavypeddling.

4. Vendors can use brakes to slow down their handcarts.

5. Themerchantscanusethehandbraketokeeptheir handcartinplace.

6. Vendors can direct the handcart in the desired direction.

7. Thevenderswillreceivefreeelectricity.

8. Safetycriteriasuchasradiumstickers,brakes,and soonarefurnished.

1. The method for generating electrical power is dependentonthespeedofthehandcart.

2. Theeffortrequiredtopedalandthevelocityfactor are directlyproportional to the weight of the handcart.

3. Lubricationisnecessary.

4. Maintainancerequired.

TheNextGenerationHandkarthasbeensuccessfully designed,andithasthecapacitytocarryanaverageof200 Kg of load or items that can be sold under the vendor's supervision. This handcart is more efficient than a traditionalhandcart.Vendorswillberelievedoftheburden of trekking kilometres with a handcart to sell their stuff. Theycanturnthehandcartinthedesireddirectionwiththe helpofsteering.

Thebicyclegearisalsoinstalledormountedonthe rearwheeltomakethepedalmechanismsmoothandbatter. Thishandcartcanbedrivenwithlittleeffortbythevendor. This Next Generation Handkart includes built in safety measuressuchasbrakes,radiumstickers,ahorn,andbrake

e ISSN: 2395 0056

p ISSN: 2395 0072

lockfunctions.WiththeassistofaDCmotor,thishandcart may produce free electricity from the movement of the wheel.

Furthermore, if the pedalling mechanism fails, it maybepoweredbyabattery drivenelectricdrivecharged byasolarpanel.This"TheNextGenerationHandkart"will beupgradedintoanautonomoushand cartwithasafeanti thief system in the future. It will reduce the amount of manual work required and, most likely, popularise the design.Whennecessary,areversegearalsoprovided.

We expressourheartiestacknowledgement toall those who supported us and provided valuable guidance whilstcompletionofthisproject.Wewouldliketotakethis opportunitywithgreatpleasuretoexpressourdeepsenseof gratitudetowardsourguide Prof. Pravin D. Padole forhis valuable guidance and incessant encouragement and co operationextendedtousduringthisdissertationwork.We would like to say special thanks to our Hon. Head of MechanicalDepartment,Dr.PravinA.Potdukheandthein charge of workshop Shri. Thamke sir for giving us their valuabletime.

[1] Gavriel Salvendy; Handbook of Human Factors & Ergonomics;46Edition;©JohnWiley&Sons,Inc., 2012.

[2] Gnanvel Chokkalingam, Gopalalcrishnan T, Sivaganesan Selvaraju; Design & Fabrication of Pedal Powered Stair Climbing Trolley; DOI: 10.23883/ffrter.2018.4153.Afiwg;March 2018.

[3] Sun, Yun ; Effects of Load & Gradient on Musculoskeletal Loading During Dynamic Two WheeledCartPushing&Pulling;GraduateTheses, Dissertation & Problem Reports 4801; 2011. https://researchrespository.wvu.eduietd/4801.

[4] CCOHS: Pushing & Pulling Handcarts' https://www.ccohs.ca/

[5] https://www.quickcompany.in/patents/improved hand cart haath thela#documents

[6] Ergonomic&FeAnalysisofSmartHandCartW.S. Sheikh,B.B.Babre: http://iosrjen.org/Papers/Conf.ICMPIR 2019/Volume 10/10,%2048 50.pdf

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008

International

Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

Prof.PravinD.Padole,Guideofproject“The Next Generation Handkart” and Associate Professor of Department of Mechanical Engineering at Rajiv Gandhi College of Engineering Research and Technology, Chandrapur, Maharashtra They having 28 yearsofteachingexperience

Mr.NayanS.Soni,Projectleaderof“TheNext Generation Handkart”. He is currently pursuing final year of Bachelor of TechnologyintheMechanicalEngineeringat Rajiv Gandhi College of Engineering Research and Technology, Chandrapur, Maharashtra Aside from that, he is a researcher and innovator with enthusiasm and strong analytical skills he wishesto exploremore about cloud computing and relatedservicessuchasIBMCloudandAWS

Mr Meghraj Gowardhan, currently pursuing final year of Bachelor of Technology in the MechanicalEngineeringatRajivGandhiCollege of Engineering Research and Technology, Chandrapur, Maharashtra with the technical knowledge he eager to work in automobile industry.

Mr. Manish Sonkusare, currently pursuing final year of Bachelor of Technology in the Mechanical Engineering at Rajiv Gandhi College of Engineering Research and Technology,Chandrapur,Maharashtra Heis also detail oriented, precise, and has expertisedoingtechnicaldesigns

Mr. Umesh Nannaware, currently pursuing final year of Bachelor of Technology in the Mechanical Engineering at Rajiv Gandhi College of Engineering Research and Technology,Chandrapur,Maharashtra Apart from that He aims to obtain a deeper understanding of various automobile technologies by using his expertise and talents

e ISSN: 2395 0056

p ISSN: 2395 0072