International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

e ISSN:2395 0056

p ISSN:2395 0072

WASTE AND RECYCLED MATERIAL IN CONCRETE TECHNOLOGY

B.tech, Department of Civil Engineering, Medicaps University, Indore, M.P, INDIA

B.tech, Department of Civil Engineering, Medicaps University, Indore, M.P, INDIA

B.tech, Department of Civil Engineering, Medicaps University, Indore, M.P, INDIA (Ast. Professor, Department of Civil Engineering, Medicaps University, Indore, M.P, INDIA)

***

ABSTRACT

India is an industrializing nation on the rise. Every day, the population grows, and this trend will continue. These two contribute significantly to the development of numerous types of solid waste, the majority of which is discarded in an indiscriminate manner. These actions have a harmful impact on the ecosystem and the health of several animals. Furthermore, many researchers have made attempts to guarantee that part of these wastes are recycled and used in the creation of different alternative materials as a way of sustainable technology in order to maintain the environment. Among numerous alternate building materials. They are also cost effective and quite handy. This research looks at several recycled waste materials that may be used in buildings. Some recycled waste material or risers, fly ash, and concrete recycling, include their advantages and problems in India. Concrete use per person in the world exceeds 1000 kg. Demand is likely to rise in the future. Concrete is the most abundant man made substance in terms of volume. Waste is also accumulating on a daily basis. These recycled materials have been acknowledged internationally owing to the unique qualities that make them acceptable for use in the building sector. These reuse also investigate the limitations associated with the adaption of these resources as alternative building materials. However, it is widely understood that the reuse of waste materials in the building sector has a low environmental effect and that their research would have a significant economic benefit.

1. Introduction

The supply of social infrastructures such as roads, buildings, and bridges is an important aspect of India's future growth that must be maintained. Sustainable development necessitates addressing daily needs without jeopardizing the country's future. Adequate safeguards should be put in place in this manner to assure the availability of materials for future growth. Waste products such as fly ash, risers, and destroyed concretehavebeenahazardforthewell beingofspecies in recent years. In several regions, these materials have been examined, and various studies have looked into

employing them as an alternative. The pace of garbage creation is growing all across the globe. As a growing nation, India creates 62 million tonnes of trash every year, with the figure expected to rise to 165 million tonnes by 2030. Solid waste is classified into industrial, agricultural, and home waste. The majority of these waste items, such as fly ash, rises, and destroyed concrete, are quite valuable and recyclable. Materials producedvia differenttechniques ofchangingdiscarded materials into new ones are referred to as recycled materials. Today, recycled materials are accessible for highway buildings all around the globe. Most of these materials are easily accessible in the form of trash and were in use at the time. Underutilized resources, of which zero to seventy percent are recyclable. Some of them, which are biodegradable, include compounds that are detrimental to the environment, whereas the vast majority are not. This has become a serious worry for everyone, and it is in line with the second trend of identifying possible resources from created solid waste. Some researchers devised methods for recycling these materials, which are widely accessible and suitable for highway building. This idea was considered in light of thefactthatmostroads,particularlyinIndia,areinpoor condition and the cost of standard building materials is too expensive. Aside from the high expense, widespread usage of recycled materials has become a possibility. Building utilizing both new and recycled materials is a sustainable technique. Concrete, formed from Portland cement, water, admixtures, and aggregates, is the most abundant of all man made materials. Historically, if new compounds were developed or waste material was gatheredinindustries,theywereusedasacomponentof concrete. Examples include fly ash rises and destroyed concrete, among others. The universal desire to save resourcesand the environment will placea strongfocus ontheuseofwastematerialsandbyproducts.Theyhave several remarkable technical qualities that make them acceptable for use in pavement construction, and their use will encourage waste reduction, a cleaner environment, cost reduction, and construction work, as wellasasalternativeconstructionmaterials

Pranshul Jain, Deepak Dubey, Vishal Singh, Ashwin Parihar

International

Volume: 09 Issue: 04

2. Literature Review

2.1 Fly ash

2.1.1 Introduction

Apr

Engineering

Technology (IRJET)

e ISSN:2395 0056

p ISSN:2395 0072

Worryingly, the draught notice also grants power stationsa10 yearextensiontograduallyusetheirlegacy ash. Giving extra ten years for legacy ash and just extending thedeadline wouldonlymakematters worse.

TheuseofflyashinPortlandcementconcrete(PCC)and the pavement has several advantages and enhances concrete performance in both the fresh and hardened states. The addition of fly ash to concrete increases the workability of flexible concrete as well as the strength anddurabilityofhardenedconcrete.Theusageofflyash is also cost efficient. The quantity of Portland cement usedinconcretemaybeloweredwhenflyashisadded.

2.1.2 Challenges of fly ash in India

Though fly ash breach incidents have become more common in recent years, the deadline for legacy ash utilization is being considered for an extension by another ten years in the government's latest draught notification, yet another fly ash breach incident was reported from the Chhattisgarh district of Korba. The breachhappenedattheNTPCKorbaPowerPlantandthe ACB India Power Plant, causing outrage among those living nearby. NTPC Korba is a decommissioned plant with a capacity of 2,600 megawatts (MW). Its five units were put into service between 1983 and 1989. Despite being an elderly plant, it has a plant load factor of more than 95%. The facility, which is almost at full capacity, generates massive volumes of ash but is unable to adequately use it. Its average ash usage over the last decade has stayed at 40%, resulting in a massive build up in its ash ponds. Several major ash dyke breaches havebeenreportedinthelasttwoyearsfromtheNorth Chennai Power Station in Tamil Nadu, the Sasan power plant, NTPC Vindhyachal and Essar Power Plant in Madhya Pradesh, NTPC Talcher in Odisha, the Bokaro Power Plant in Jharkhand, and the Khaparkheda and Koradi Power Plants in Maharashtra. In a few instances, asuddenashdelugeofsurroundingvillageshasresulted in the loss of life. These accidents occurred despite the fact that several power plants have reported increased fly ash use percentages to the Central Electricity Authority in recent years. With such instances on the increase,thegroundrealityofash managementlooksto be very different and bleak. A significant let down Despite similar events, the Union Ministry of Environment,Forests,andClimateChangeissuedafresh draught fly ash notice this year, pushing the date even further. The notion of a 3 5 year compliance cycle is introducedinthisdraughtnoticeinordertoaccomplish the aim of 100% fly ash usage by the conclusion of the cycle.

The legacy ash issue arose only as a result of numerous facilitiesfailing tocomplywithearlier noticesyearafter year and failing to handle their ash. Even in terms of fulfilling the 2015 emission standards, the industry failedpoorly.Insteadoftakingharshactionagainstnon compliant facilities in the past, the deadline to fulfill emission regulations has simply been extended every time. Extending deadlines year after year sets a bad precedent.Plantswillcontinuetopolluteandwillrefuse tocomplywiththelegislation

2.1.3 Benefits Of Fly Ash

In general, fly ash helps new concrete by lowering the amount of water required for mixing and enhancing the paste flow behavior. The following are the advantages a result:

Improved workability spherical shaped fly ash particlesserveassmallballbearingsinsidetheconcrete mix, giving lubrication. This similar impact enhances concrete pumpability by lowering frictional losses during the pumping process and improving flatwork finishability.Reducedwaterconsumption Theuseoffly ash for cement decreases the water requirement for a givenslump.Waterconsumptionisdecreasedbyaround 10% when fly ash is added at roughly 20% of the total cementitious. Higher fly ash levels result in greater water savings. Drying shrinkage/cracking is unaffected bydecreasingwaterdemand.Incertaincases,flyashhas beenshowntominimizedryingshrinkage.

Reduced heat of hydration By replacing cement with the same quantity of fly ash, the heat of hydration of concrete may be reduced. This decrease in hydration heat does not jeopardize long term strength improvement or durability. Heat rise concerns in bulk concreteinstallationsarelessenedduetothelowerheat ofhydration.

Theinteractionof flyashwithaccessiblelimeandalkali in concrete produces extra cementitious compounds, whichisoneofthekeyadvantagesofhardenedconcrete. The pozzolanic interaction of fly ash with lime to create extracalciumsilicatehydrate(C S H)binderisshownby thefollowingequations:

(hydration)

Cement Reaction: C3S +H C S H + CaOH Pozzolanic Reaction:CaOH+SC S HPozzolanicReaction:CaOH+S C S H

silicaderivedfromashcomponent

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

Improved durability The reduction in free lime and the accompanying rise in cementitious compounds, together with the reduction in permeability, improves the durability of concrete. This has various advantages: Resistance to ASR has improved. Fly ash interacts with accessible alkali in concrete, making it less available to react with particular silica minerals in aggregates. Resistancetosulphateassaulthasbeenimproved.Three events are induced by fly ash that increase sulphate resistance: Because fly ash eats free lime, it is no longer accessible to react with sulfate. The decreased permeability prevents sulfate from penetrating the concrete. The availability of reactive aluminates is reduced when cement is replaced. Corrosion resistance hasbeenimproved.

Workability- Fly ash is utilized in PCC to reduce costs and increase performance. Fly ash is often utilized to replace 15% to 30% of the Portland cement, with even higher percentages used for mass concrete pours. For thecementremoved,anequalorlargerweightofflyash is supplied. Fly ash to Portland cement substitution ratiosarecommonly1:1to1.5:1.Amixdesignshouldbe testedwithdifferentratiosofflyash.Foreachcondition, time versus strength curves may be plotted. To satisfy specification criteria, curves for different replacement ratios are created, and the best replacement % ratio is chosen. Using the given building materials, a mix design should be created. It is advised that the performance of the fly ash concrete being evaluated contains local components.

2.2 Rice Husk

2.2.1 Introduction

As an alternative to cement, rice husk ash is utilised in concrete building. The notion of employing rice husk arose as a result of the growing incidence of environmental degradation and the consideration of the sustainability element. Around the globe, about 100 million tonnes of rice paddy manufacturing by products areobtained.Theyhavealowbulkdensityrangingfrom 90to150kg/m3.Thisleadsinahigherdryvolumevalue.

2.2.2 Challenges by Rice Husk-

EVERYYEAR,atthestartofthewinterseason,Delhiand the surrounding regions suffer an air pollution issue causedbytheburningofricestubbleandstrawinDelhi, Haryana, Punjab, and the National Capital Region. The impoverished farmers, who are responsible for these states' development, are blamed for pollution by governmentsandcourts.

The issue has existed for a long time, however the severityofthepollutionwaslower.Whenwinterarrives, the northern region's atmosphere becomes frigid and

e ISSN:2395 0056

p ISSN:2395 0072

thick. The chilly air above stops the smoke from rising. Asa consequence,it lingers intheatmosphereuntil it is blownawaybythewind.Theissuehasbecomeworsein recentyearsastheamount ofricegrowninthesestates has risen. Farmers burn the root stubbles and straw on the spot since there is no financial incentive to gather anddisposeofit.Becausecattledonotingestricestraw, there is little market for it in the northern area. The collection of these byproducts is costly, and farmers are unwilling to invest time and money in it. There is also a limited amount of time remaining after the rice harvest topreparethegroundforwheatplanting.Asaresult,the farmerhasdiscoveredthatburningitinplaceisthebest option.AlthoughallstatesinIndiaproducerice,theland is not often utilized for producing a subsequent crop immediately,whichispeculiartothenorthernarea.Asa consequence, the field leftovers, or stubbles, degrade before the following planting season. Furthermore, unlikethecattleinHaryanaandPunjab,cattleandother ruminant animals in the rest of the nation consume rice straw. Cow dung cakes prepared during the summer months are used as fuel by inhabitants in the northern region. When these cakes are burned, they emit a thick smoke that contributes to the issue of air pollution. Pollution from automobiles and power plants exacerbates Delhi's and the neighboring regions' pollution problems. The issue will not be remedied simply by making the burning of rice straws illegal. So yet, governments have done little to alleviate the situation. Almost 80% of irrigated land in these three states now follows a rice wheat cycle, and the area has continually expanded. As a consequence, the amount of rice residue has grown. Rice yields an equal quantity of grain, straw, and stubble. These two states alone generate over 15 million tonnes of paddy, as well as an equivalentquantityofstrawandrootstubble. It'snotas if there aren't any answers to the situation. Farmers, both large and small, are unwilling to invest money on trash collection and disposal. They believe that burning in place is the best answer. Harvesting is now mechanical,andthemachinesleaveasignificantamount of the straw uncut. Stubble is a tough substance that doesn't breakdown quickly. Straw is not eaten by cattle inPunjabandHaryana,andthelargematerialisdifficult to transport. The crisis spurred creativity, and distilleries started utilising rice husk as a fuel, resulting in a remunerative price for rice mills for a previously problematic byproduct. This removed the mountains of rice husk that had accumulated surrounding the mills. Initially, rice mills gave it out for free, but as demand grew,theystartedchargingforthehusk.Today,owingto innovation in boiler systems, the rice husk issue has been significantly decreased, as has the smoke output duringcombustion.Whysingleoutthefarmers?Instead, with a little technology and money, this issue can be solved. Putting the burden of proof on the farmers and penalizingthemisunjust.Iffurthertechnologyisneeded

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

to build on what has been proposed, all of the northern states have strong agricultural, veterinary, and engineering colleges. These organizations should be enlistedtohelpfixthesituation.

2.2.3 Benefits of rice husk-

When used as a partial replacement for cement, rice husk ash has high reactivity. These are prevalent in places with considerable rice cultivation. The appropriatelypreparedricehuskasheswerediscovered to be active inside the cement mix. As a result, the utilizationandpracticaluseofricehuskashforconcrete makingarecritical.

Properties of concrete with rice husk

When rice husk ash is mixed with concrete, it becomes an environmentally acceptable additional cementitious ingredient.

Thefollowingpropertiesoftheconcretearealteredwith theadditionofricehusk:

When rice husk ash is mixed with concrete, it becomes an environmentally acceptable additional cementitious ingredient.

Theinclusionofricehuskchangesthefollowingqualities oftheconcrete:

The hydration heat is minimized. This aids in drying shrinkage and increases the durability of the concrete mix.

The permeability of a concrete building is reduced. This will aid in the penetration of chloride ions, preventing theconcretestructurefromdisintegrating.Resistanceto chloride and sulfate assault has increased significantly. More hydration products are produced when the rice husk ashes in the concrete react with the calcium hydroxide. The intake of calcium hydroxide reduces the reactivityofchemicalsintheenvironment.

2.2.4 Application of rice husk ash

Ricehuskashisagreensupplementalmaterialwithuses ranging from small to big. It is suitable for waterproofing. It is also used as an additive in concrete to make it resistant to chemical penetration. The following are the primary uses of rice husk ash in construction:

High performance Concrete Insulator

Concretethatiseco friendly

e ISSN:2395 0056

p ISSN:2395 0072

Floorsinbathrooms

Factoryfloorsinindustrialsettings

Thefoundationisbeingconcreted.

Poolsforswimming

Waterproofingandrestoration

2.3 RECYCLED/DEMOLISHED CONCRETE

2.3.1 INTRODUCTION

Manyconstructionprojectsbeginwiththedestructionof concrete foundations, sidewalks, driveways, and other concretebuildings,whichmayleaveacontractordealing with a large number of heavy, thick debris. Concrete, fortunately, can be recycled and reused in a variety of ways.Typically(butnotalways),theprocedureinvolves crushing or pulverizing concrete debris near the demolition or construction site. The optimal procedure is frequently determined by the size and form of the concretechunkstoberecycled.

Reusing concrete may help you save money on construction while also helping the environment. Recycled concrete not only keeps waste out of landfills, but it also substitutes resources like gravel that would otherwisehavetobeminedandtransportedforuse.

CHALLENGES

India recycles just one percent of its construction and demolition (C&D) waste, a new report released by the Delhi based non profit, Centre for Science and Environment(CSE)onAugust25,2020,hasshown.

The country generates an estimated 150 million tonnes of C&D waste every year, according to the Building Material Promotion Council. But the official recycling capacity is a meager 6,500 tonnes per day just about one percent. What's more, unofficial estimates of the total waste generated in the country put the figure at three fivetimesmorethantheofficialestimate.

Even the Swachh Bharat Mission has recognized the need for C&D waste management. Ranking points for C&D waste management for Swachh Survekshan 2021 have been doubled to 100 points, divided equally between management infrastructure and waste processing efficiency. Cities will need to have a C&D waste collection system in place; notified charges for C&Dservicesandsegregationofwasteinfivestreams.

Under waste processing efficiency criteria, ranking points will be awarded based on the percentage of collectedwastethatisprocessedandreused.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

Page3744

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

2.3.2 Benefits of concrete recycling

Recycling concrete reduces building waste, extends the lifeoflandfills,andsavesbuildersmoneyondisposal or tipping costs. It also saves money on shipping since concretecantypicallyberecyclednearthedemolitionor building site. If a builder is pursuing LEED Green Building certification, using recycled concrete can earn them points. In certain cases, new job possibilities emerge as a result of a recycling activity that would not haveexistedotherwise.

2.3.3 How Concrete Is Recycled

Industrial crushing equipment with jaws and massive impactorsisusedtorecycleconcrete.Aftertheconcrete has been broken up, it is frequently sent through a secondary impactor before being screened to remove dirt and particles and separate the big and small aggregate. To separate certain materials from crushed concrete, additional procedures and equipment such as waterflotation,separators,andmagnetsmaybeutilised. Pulverizing the concrete is an alternate approach, but it is not always the ideal solution since it makes the separation process more difficult and may leave more pollutionfromsmallerby products

2.3.4 Uses for Old Concrete

Manyofthesameapplicationsasnewmaterials,suchas gravel, paving materials, and aggregates, may be made fromrecycledconcrete.

•Permeable pavement for sidewalks, driveways, and other outdoor hard surfaces: Carefully set broken concrete forms a solid, porous traffic surface through which rainwater may flow. This strategy decreases the quantity of runoff water that must be handled by storm sewer systems while also aiding in groundwater replenishment.

•Rubblizationisatechniquethatcreatesafoundationfor fresh asphalt pavement. Old concrete pavement may be broken up and reused as a foundation layer for asphalt pavement.

•Bed foundation material for trenches containing underground utility lines: To aid drainage, utility trenches are oven covered with gravel, and crushed concreteisagood,low costsubstituteforgravel.

•Aggregate for new concrete mixing: Crushed concrete can substitute for some of the virgin (new) aggregate usedinready mixconcrete.

•Controlling streambank erosion: bigger chunks of crushed concrete put along susceptible stream banks or gulliesmayaidinerosionmanagement.

© 2022,

e ISSN:2395 0056

p ISSN:2395 0072

•Landscapingmulch:Whenproperlycrushedandsorted, ground concrete may be utilised as a ground cover or mulch in lieu of river rock or other gravels broken in placeandusedasabaselayerforasphaltpavementlaid overit.

•Fill for wire gabions: Crushed gravel filled wire cages (gabions) may be used to create ornamental and useful privacyscreenwallsorretainingwalls.

•Material for constructing new marine reef habitats: big slabs of concrete properly placed offshore may serve as thefoundationforcoraltoconstructnewreefs.

SN. Model Type Seismic Zone Displacement

1 Model A 4 10.044mm

2 Model B 4 11.335mm

3 Model C 4 10.248mm

4 Model D 4 11.364mm

5 Model E 4 12.16mm

6 Model F 4 10.99mm

7 Model G 4 11.29mm

8 Model H 4 13.20mm

9 Model I 4 9.2mm

3. Methodology Materials and methods Materials Cement

Portland cement CEM I 52.5 N is used in all mixtures. It has been tested in comparison with the ES 4756 1/2013.Itpresentsthephysicalandchemicalfeaturesof cementitiousmaterials.

Aggregate

Thefineaggregatewhichiscleanandroundedisusedin this experiment is natural siliceous sand with, bulk unit weight of 1680 kg m 3, a particular specific gravity of 2.67, and a fineness modulus of 2.85. The coarse aggregatewaslocalsquashedlimestone(dolomite)with aspecificgravityof2.70,bulkunitweightof1700 kg m 3 andithasamaximumnominal sizeof13 mm,according to ES 1109/2008. The ratio of 1:2 is ideal between the fineandcoarseaggregate.

Impact Factor value:

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

RHA

It is formed by burning husk under a high temperature. TheresultantashwaspassedthroughaBritishStandard (BS)withasievesizeof75 micrometerstoremovelarge particles. The produced RHA has grey in color. Energy dispersive X ray (EDX) composition analysis and transmission electron microscopy (TEM) analyses were applied to the produced RHA. By EDX test it has been observed that ash contains 96.2% silicon dioxide (SiO2) and 0.47% calcium oxide (CaO). By the results, it has been shown that EDX is a more reactive material comparedtocementandFA.Thechemicalcompositions ofRHAinthistestarethesameas thoseofAlkalimetal. 15and52 μmisavariessizesofparticles.

FA

Itisproducedindustriallywithcoal firedpowerstations byproducts; the FA utilized in the current test is fall underclass ‘F’ in accordance with the requirements of ASTM C618 19. The chemical composition of FA is determinedviaX rayfluorescence.

Superplasticizer (high rang water reducing admixtures)

A high performance superplasticizer is used to increase the workability of theconcretemixturewhichisformed by the admixture of the aqueous solution of modified polycarboxylate basis (Viscocrete 5930). Viscocrete 5930 complies with ASTM C494/C494M 17, with a specificgravityof1.11.Tobalancethereducedwaterthe dosage should be approximately 3.2% and cementitious contents of 450 and 550 kg m3 increase the workability ofthemixture.

Water

The ratio (w/c) was set to 0.58 for water to cementitious material mixtures with 350 kg m 3 cementitious content. However, it is reduced to 0.25 to improve the compressive strength of concrete mixtures withcementitiouscontentsof450and550 kg m 3

•Mixture proportions

Inthisresearch,21mixesarecreatedandclassifiedinto three groups. Each group has seven different combinations. There are three cement contents: 350, 450, and 550 kg m3 for groups one, two, and three. The mixesineachgroupwerecategorisedasfollows:control mixture,threemixturescontaining10,20,and30%RHA, and three mixtures containing 10%, 20%, and 30% FA. Thefineaggregates to coarseaggregatesratiowaskept constant at 1:2. The mixes were created using 0.55 w/c and350kgm3ofcementitiousingredients.Toincrease

e ISSN:2395 0056

p ISSN:2395 0072

the compressive strength of the concrete, the w/c was lowered to 0.25 for groups two and three. To compensate for the lower water content, superplasticizer was added to the concrete with 3% cementitiouscontentingroupstwoandthree.

Thefollowingaretheexperimentalmixingsteps:Forthe first minute, the fine and coarse particles were mixed together. The cementitious components were then added, and the mixture was agitated for 3 minutes. In relation to the superplasticizer addition, water was addedtothemixtureduringthemixingphase.Following that,themixingprocedurewasextendedfor3minutes.

•Test procedure

Slump values (ASTM C143/C143M 15a) and air content values (ASTM C231/C231M 17a) were used to assess the consistency of new concretes. Concrete compressive strength wasmeasuredoncube shapedspecimens(150 mm) at 3, 7, 28, 60, and 90 d (BS 1881 116). The splittingtensiletestwasperformedoncylindersamples (150 300 mm) at 28 days (ASTM C496/C496M 17). The flexural strength test (ASTM C78/C78M 18) was done after 28 days. The flexural strength test was performed on prism specimens (100 100 500 mm). The average values of the three specimens were recorded for each testing age and all strengths. To test the modulus of elasticity at 28 days (ASTM C469/C469M 14), cylinder forms (150 300 mm) were manufactured. Pulling steel bar from cylinder samples was used to test the bond strength. To evaluate the depth of water penetration in concrete, permeability was tested at 28 days on specimens with a diameter of 150 mm and a length of 150mm

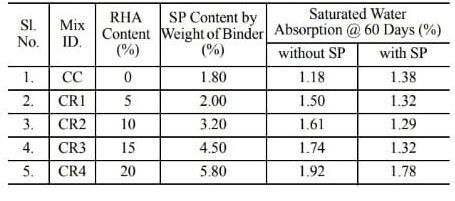

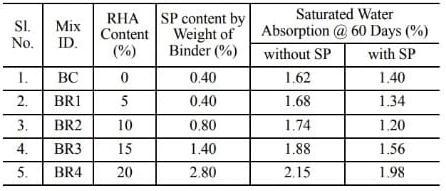

Saturated Water Absorption and Porosity

The water absorption and porosity values for various mixturesofconcreteweredeterminedon100mm×100 mm ×100 mm size cubes as per ASTM C 642. The specimens were taken out of the curing tank at 60 days to record the water saturated weight (Ws). The drying was carried out in an oven at a temperature of 105oc. The drying process was continued until the difference betweentwosuccessivemeasuresbecomessmall. Oven driedspecimenswereweighedaftertheywerecooledto roomtemperature(Wd).

Usingtheseweights,SaturatedWaterAbsorption(SWA) wascalculatedbytheequation:

SWA=[(Ws−Wd)/Wd]×100(1)where,

Ws:Weightofspecimeninthefullysaturatedcondition

Wd:Weightofoven driedspecimen

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

The porosity obtained from the absorption test is designatedaseffectiveporosity.

Itisdeterminedbyusingthefollowingformula,Effective porosity=(Volume of voids)/(Bulk volume of the specimen)

The volume of voids was obtained from the volume of waterabsorbed byan oven dryspecimenorthevolume of water lost on oven drying of a water saturated specimen at 105oC to constant mass. The volume of the specimen is given by the difference in mass of the specimeninairanditsmassundersubmergedcondition inwater.

4. RESULTS AND DISCUSSION

FLY ASH

Fortestingflyashcompressivewecastconcretecubesof size150150150mmandprismsizeof100100500mm withminimalwater.Wereplaceflyashwithcement30% 40%50%forM20M25andM30gradesofconcrete. For the study the durability of fly ash replaced concrete. A replacement of fly ash 30% to 40%50% was chosen for this study to find the effect of fly ash on compressive strengthandflexuralstrengthofconcrete.

RICE HUSK

Weconductacompressivestrengthtestonricehuskash. we take 150 150 150 cube specimens for each grade of concrete and tested them under compressive load at various ages. we test all the specimens after wiping out the surface moisture. For each mix combination, we use different tests for different ages i.e 7,14,28,56 days with the help of a compression testing machine. The compressivestrengthwascalculatedasperIS 516.

•compressivestrength

It varies with respect to the percentage of replacement of RHA and no. Of days of curing. we observe that for both M30 and M60 grades of concrete there is a reduction in compressive strength at early ages with increasing RHA content in the mix proportions of concrete. The required strength could not be achieved after 90 days for 15% and 20% of replacement of

e ISSN:2395 0056

p ISSN:2395 0072

cement by RHA. But with the addition of SNF based plasticizers, the compressive strength of M30 concrete improves5%to10%cementreplacementbyRHA.

5.CONCLUSION FLYASH.

Theuseofflyashreducesenvironmentalpollution.Ithas a high percentage of unutilized concrete by use of this material many problems can be handled and it is also veryeconomical.

RICEHUSK

Rice Husk is an organic and fibrous material. It absorbs more water and after the addition of plasticizer, it improves the workability property of concrete. Compressive strength increased by 6% and 10% of replacement of rice husk are 4% and 5% at 28 days respectivelyforM10grade concrete. Weknowthathow harmfulisricehusksolidwasteforcountryso,itisgood we can use rice husk ash in construction and also can improvethestrengthofstructure.

6. REFERENCES

Abu Lebdeh, T., S. Hamoush, W. Heard and B. Zornig, 2010a. Effect of matrix strength on pullout behavior of steel fiber reinforced very high strength concrete composites. Constr. Build. Mater. J., 25: 39 46. DOI: 10.1016/j.conbuildmat.2010.06.059

Abu Lebdeh, T., S. Hamoush and B. Zornig, 2010b. Rate Effect on pullout behavior of steel fibers embedded in very high strength concrete. Am. J. Eng. Applied Sci., 3: 454 463.DOI:10.3844/ajeassp.2010.454.463

Awwad, M.T. and L. Shbeeb, 2007. The use of polyethyleneinhotasphaltmixtures.Am.J.Eng.Applied Sci.,4:390 396.DOI:10.3844/ajassp.2007.390.396

Begum, R.A., S.K. Satari and J.J. Pereira, 2010. Waste generation and recycling: Comparison of conventional and industrialized building systems. Am. J. Environ. Sci., 6:383 388.DOI:10.3844/ajessp.2010.383.388

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3747

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

CalRecycle, 2006. Asphalt roofing shingles recycling: Introduction. The California Department of Resources RecyclingandRecovery.

Ellie, H., I. Fini, L. Al Qadi, T. Abu Lebdeh and J.F. Masson, 2011. Use of surface energy to evaluate adhesionofbituminouscracksealantstoaggregates.Am. J. Eng. Applied Sci., 4: 244 251. DOI: 10.3844/ajeassp.2011.244.251

Emery, J.J., 1981. Potential uses for kiln dusts. Proceedings of the Symposium on Mineral Fillers, OntarioResearchFoundation,(MFORF’81),Toronto.

FHWA, 2004. Transportation Applications of Recycled Concrete Aggregate. 1st Edn., Federal Highway Administration,Washington,DC.,pp:38.

Fini, E. and T. Abu Lebdeh, 2011. Bonding property of bituminous crack sealants in the presence of water. Am. J. Eng. Applied Sci., 4: 124 129. DOI: 10.3844/ajeassp.2011.124.129

Hamoush, S., T. Abu Lebdeh, M. Picornell and S. Amer, 2011. Development of sustainable engineered stone cladding for toughness, durability and energy conservation. Constr. Build. Mater., 25: 4006 4016. DOI: 10.1016/j.conbuildmat.2011.04.035

Hassim, S.J.M.S.A., 2009. The contractor perception towers industrialized building system risk in construction projects in Malaysia. Am. J. Applied Sci., 6: 937 942.DOI:10.3844/ajassp.2009.937.942

e ISSN:2395 0056

p ISSN:2395 0072