International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

e ISSN: 2395 0056

p ISSN: 2395 0072

Abstract Marble dust powder is a waste that causes environmental troubles because millions of tonnes of marble dust powder are generated per year. The aims of this paper are to utilize the marble dust powder by replacing cement with marble dust powder.Thishelpsin sustainable construction and also protects the environment.Marbledustpowderisgeneratedfromlime stone mines, Glass and Paper industries etc. In this experiment, marble dust was used as an admixture in concrete, It contributed to betterstrengthascompareto normal concrete (by replacing cement with marbledust powder in a limited amount). In this experimental study, preparation of concrete cube is done by replacing cement with marble dust powder at variouspercentages (0% ,5%, 10%, 20%, 30% & 40%) and study of the workability and compressive strength of concrete. It is done after seven days and twenty eight days.

Key Words: Marble dust powder (MDP), Compressive Strength, Workability , Cement.

Inthisproject,wehavestudyabouttheutilizationofa very fine grinding calcareous compound known as marbledustpowder,whichisproduceperyearinvery largeamountaswaste.Wehavestudiedtheutilization of marble dust as replacement for the pozzolanic material used in Portland pozzolanic cement. In this study, wehaveconcludedthat marble canbe a good enough replacement for pozzolanic material. This result in decrement in hazardous issues caused by carbon emission from the production of pozzolana cementandalsoconcludesthemanagementofwaste marbledustpowderproducedperyear.

After the mixing of marble dust powder in ordinary Portland cement, this reduced the increment of the concrete compressive strength and enhanced the

© 2022, IRJET

Impact Factor value: 7.529

bindingpropertiesofthecement. TheMarbledusthas highcalciumoxidecontentmorethan50%.Concrete (plastic concrete) is freshly mix material. It can be moulded into any shape. The water/cement ratio requiredbasedonconcreteworkabilityandconcrete workabilitydeterminedbyslumpvalue.

Inthisexperiment,prepared12concretecubeswitha size of for each and also prepared a sample by replacingcement with marble dustpowderatdifferentpercentages(0%,5%,10%, 20%, 30%, & 40%). Using the M25 mix design for determiningthecompressivestrengthandworkability of each sample. It is tested after 7 days and28 days. The increment of marble dust powder show the reduction of strengths concrete (with marble dust powder replacing 10% cement). It improved the prozzolanic reaction. Marble dust is a solid waste material. It can be used in concrete by replacing cementorfineaggregatewithlimitedamount.

In this experiment, replacing cement with marble powderwithvariouspercentages,alsodeterminesthe workabilityandcompressivestrengthofconcrete.

To compare results between normal concrete and various percentages of replacement cement with marbledustpowder.

Ordinary Portland cement is most common type of cement.Wegenerallyuseahighgradeofcementandit offers many advantages for making strong concrete. Portland cement consumption to a 10% to 20%

ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

reduction in cement consumption. As well as the physicalpropertiesdepictedbelow.

Table 1:Physicalpropertiesofcement

Physical properties of cement

Sr.no. Physicalproperties Testresult

1 Initialsettingtime 52min

2 Finalsettingtime 376min

3 Specificgravity 2.89

4 Standardconsistency 29%

Fineaggregateconsistingofnaturalsandfillsthevoid betweenaggregates.

It makes concrete more economical because fine aggregate is available in nature and provides the resistances against shrinkage and cracking. IS CODE 456:2000 recommends fine aggregate sizes ranging from4.75mmand0.15mm.itisgranularmaterial.

Table 2:Physicalpropertiesoffineaggregate

Physical properties of fine aggregate

Sr.no Properties Testresult

1 Waterabsorption 0.8%

2 Specificgravity 2.53

3 Bulkdensity 1.26(g/cc)

4 Finenessmodulus 4.039

e ISSN: 2395 0056

p ISSN: 2395 0072

Aggregate is an important constituentin concrete. It occupies 70 80% volume of concrete. The study of cementisincompleteunlesstheaggregatedepthand range are studied. Aggregate passing though 63mm sieveandretainedon4.75mmsievearecalledcoarse aggregate.

In this experiment, the size of aggregates was used. Ranging from 20mm and 10mm. cement is the only factorthatmakesastandardcompositioninconcrete. itisanatural,solidmaterial.Thestudyofaggregateis done under following: size, textures,specific gravity, soundness, sieve analysis, shape, strength, moisture contain.

Table -3:Physicalpropertiesofcoarseaggregate

Physical properties of coarse aggregate

Sr.no Properties Testresult

1 Waterabsorption 1%

2 Specificgravity 2.69

3 Bulkdensity 1.65(g/cc)

4 Finenessmodulus 4.13

TheamountwaterdependsonISCode456:2000,and theamountofwatercontainedcanalsobeadjustedby

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

Page3639

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022

slump value. The range of water required for M25 (1:1:2) is 21 to 27 liters with the weight of 563 kg cement,keepingwatercementratiobetween0.4to0.6. itisrequiredatnormalpressureandtemperature.Itis polarmolecule.

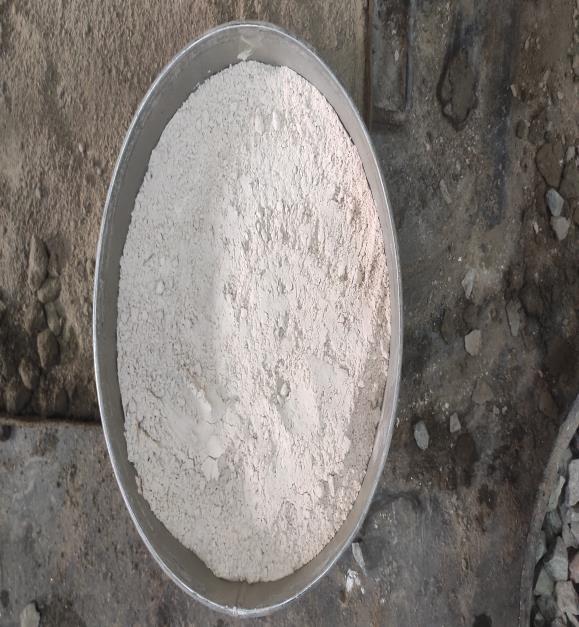

There is large amount of marble dust generated the during cutting of marble, extracting, polishing, processingandgrading.Itcanbeusedinvarioussector such as agriculture, construction, glass and paper industries.Thereplacementofcementwiththemarble dust powder make concrete more economical the chemicalcompositionofmarbledustpowderisgiven belowinthetable.

e ISSN: 2395 0056

p ISSN: 2395 0072

Fe2O3 9.40

MgO 1.52

In this experiment, we are using M25 (1:1:2) mix designasperISCODE456:2000.

Equipmentandcollectionofmaterialsuchasordinary Portlandcement,fineaggregate,coarseaggregateand marbledustpowder.

Batchingofmaterialbyweightandmixingofmaterial byhandmixing.

Asampleofconcreteispreparedinthisexperimentby replacing it with marble dust powder at different percentages(0%,5%,10%,20%,30%&40%).

Thesizeofthecubemouldusinginthisexperimentis

Cleanthecubemouldandapplyoilintheinnersurface. Placeconcreteintomouldinfourlayers,compacting eachlayerandfinallyprovidingasmoothsurface. After 24 hours, remove the concrete cube from the cubemould.

After7daysor28daysofcuring,theconcretecubeis removedfromwatertankfortesting.

Thestrengthofcubesisdeterminedbytestingafter7 daysand28daysbecausetheconcretecubegains99% strengthin28days.

Testing after 7 days and 28 days gave a quick idea aboutthequalityofconcrete.

There is large amount of marble dust generated the during cutting of marble, extracting, polishing, processing and grading. It can be used in various sectors such as agriculture, construction, glass and paperindustries.Thereplacementofcementwiththe marbledustpowdermakeconcretemoreeconomical thecompositionofmarbledustpowderisgivenbelow inthetable.

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

The factor affecting the workability of concrete.

Watercontent

Mixproportion

Sizeofaggregates

Shapeofaggregates

Surfacetextureofaggregates

Gradinofaggregate

Useofadmixture

Themostcommontestmethodistheslumptest.Itis usedtomeasuretheconsistencyofconcrete.Itisnot suitablemethodforverywetorverydryconcrete.

Themostcommontestmethodistheslumptest.Itis usedtomeasuretheconsistencyofconcrete.Itisnot suitablemethodforverywetorverydryconcrete.

Thecompressiontestisthemostcommontestbecause itiseasytoperform.Thegoaloftestingcompressive strengthofconcreteisensurethattheconcreteused on sitehasdevelopedthenecessarystrength.Testing of compressive strength plays important role in

Impact Factor value: 7.529

e ISSN: 2395 0056

p ISSN: 2395 0072

controlling and confirming the quality of concrete work.

In this experiment, determine compression strength after 7 days and 28 days because concrete gain strength65%in7daysand99%strengthin28days. Thepurposeoftestingcompressivestrengthbecauseit provideaquickideaaboutthequalityofconcrete.

Table -5:Compressionstestresult

%OF MDP 7 DAYS ((N/mm^2)) 28 DAYS ((N/mm^2))

9001:2008

conclusionof the experimentis

powderisagoodenoughwasteproduct

usedasareplacementforcement.

dust powder containing less then ten

or equal to ten percentages slightly

thecompressivestrengthoftheconcrete.

marbledustpowdercontainingmorethanten

and up to forty percentage slightly decreasesthecompressivestrengthoftheconcrete.

Replacement of cement with marble dust powder reducestheconsumptionofcementandhelpstoutilize themarbledustpowderinthemostefficientway.

During the experiment, we got the conclusion that when adding marble dust powder 5%or 10% by replacementofcement,itincreasesthesettingtime. Inthesecondmixture,afteradding20%andmorethan 20%ofmarbledustpowderbyreplacementofcement, then the amount of water required 50% less, and workabilityisnormal,butithasincreasedsettingtime ofconcrete.

[1] WWW.Scribd.com [2] WWW.Google.com [3] WWW.Researchnet.in [4] WWW.Wikipedia

[5] M.S.SHETTYBE,ME,FICI,FIIBE,FIE,MACCETechnical Advisor, MC Bauchemie (Ind) Pvt. Ltd. Principal TechnicalConsultant,GrasimIndustries,Ltd.Consultant toIMCCDelhiMetroCorporationFormerlySeniorProf. and Head of Department of Construction Engineering CollegeofMilitaryEngineering(CME),PuneMinistryof Defence

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

SANDEEP GUPTA, Bachelor of Technology , final year student, Dept. of CivilEngineeringInstituteof Technology and Management Gida, Gorakhpur

SARTHAK SRIVASTVA,

Bachelor of Technology , final year student, Dept. of CivilEngineeringInstituteof Technology and Management Gida, Gorakhpur

NAVEEN KUMAR, Bachelor of Technology , final year student, Dept. of CivilEngineeringInstituteof Technology and Management Gida, Gorakhpur

AMAN TRIPATHI, Bachelor of Technology , final year student, Dept. of CivilEngineeringInstituteof Technology and Management Gida, Gorakhpur

SHIVAM JAISWAL, Bachelor of Technology , final year student, Dept. of CivilEngineeringInstituteof Technology and Management Gida, Gorakhpur

e ISSN: 2395 0056

p ISSN: 2395 0072