in India

(SCC)

many

are going in for SCC, the example being ‘The Signature Bridge’ on river Yamuna near New Delhi and the Bandra Worli sea link project,

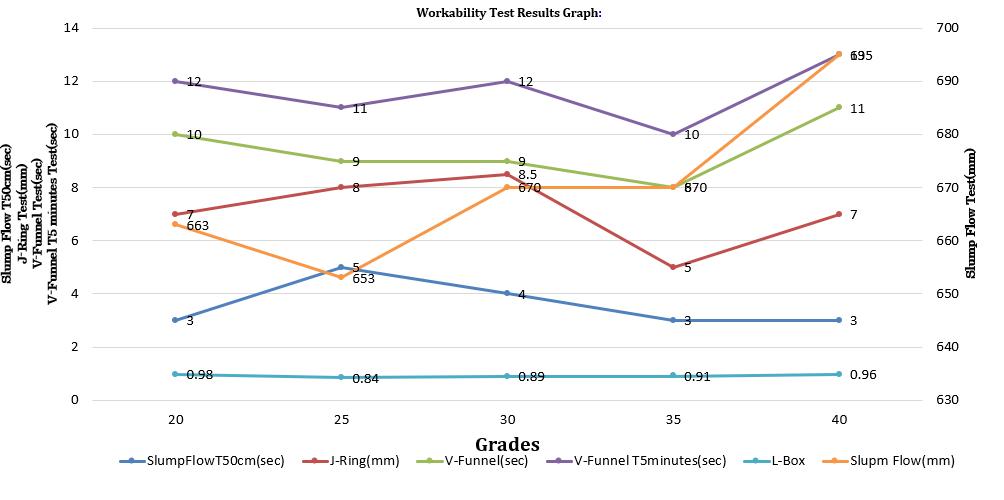

The Nan Su mix design is used for OPC concrete, but its application for Portland Slag Cement (PSC) concrete is not investigated as per the literature review. The present work proposes modificationto Nan Su mix designfor applicationto PSC concrete. The workability properties Slump Flow, J Ring, V Funnel and L Box values satisfy EFNARC Guidelines. Also establishes the use of Cooper Slag as mineral admixture to concrete.

Key Words: SCC,CopperSlag,PortlandSlagCement,Nan SuMixDesign, EFNARCGuidelines,SlumpFlowTest,J Ring Test,V FunnelTestandL BoxTest.

1.INTRODUCTION

TheuseofSelfCompactingConcrete(SCC)isincreasingday bydayinIndiaandmanyinfrastructureprojectsaregoingin forSCC,theexamplebeing‘TheSignatureBridge’onriver Yamuna near New Delhi and the Bandra Worli sea link project,Mumbai

TheworkabilitypropertiesofSCCcanbecharacterizedby thethreeproperties(EFNARC,2002):fillingability,passing ability and segregation resistance. Additional properties, such as robustness and consistence retention, are also important inapplications of SCC.Robustnessreferstothe abilityofSCCtoretainitsfreshpropertywhenthequantity andqualityofconstituentmaterialsandtheenvironmental conditionschange.Consistenceretentionreferstotheperiod ofdurationoffreshproperties

The Nan Su mix design application for Portland Slag Cement (PSC) concrete is not investigated as per the literaturereview.Inthepresentinvestigationmodificationis proposedforapplicationindesignofSCCwithPSC. Also,the use of industrial by product copper slag as mineral admixtureisstudied.

2.EXPERIMENTALINVESTIGATION

2.1Nan SuMixDesign

ThestepsusedinNan SuMixDesignaregivenbelow.

Step 1: Calculation of Coarse and Fine aggregate contents:

(2) Where, Wfa:contentoffineaggregatesinSCC(kg/m3), Wca :contentofcoarseaggregatesinSCC(kg/m3),

fa:unitvolumeweightoflooselypiledsaturatedsurface dryfineaggregatesinair(kg/m3),

ca:unitvolumeweightoflooselypiledsaturatedsurface drycoarseaggregatesinair(kg/m3),

PF:packingfactor,theratioofmassofaggregatesoftightly packedstateinSCCtothatoflooselypackedstateinair, :volumeratiooffineaggregates(sand)tototalaggregates, whichrangesfrom50%to57%.

Step 2: Calculation of Cement Content:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 04

Where, C=Cementcontent(kg/m3); f’

Apr 2022 www.irjet.net p ISSN: 2395 0072

=designedcompressivestrength(psi).

Step 3: Calculation of

Where, W

(kg/m

contentofmixingwatercontent

), =thewater/cementratiobyweight.

Step 4: Calculation of

by

DosageofSPusedW

=n%

W

(6) Where, n%=DosageofSPas1% Wc=Cementcontentinkg/m3 AmountofwaterinSPWwsp =(1 m%)W

(7) Where, m%=AmountofbindersanditssolidcontentofSPtakenas 50%

Step

Calculation

Where, w =densityofwater, G

=specificgravityofcoarseaggregates, G

=specificgravityoffineaggregates, Gc =specificgravityofCement, G

=specificgravityofwater, V

=aircontentinSCC(%). AsperNansuMixDesigntheformulaforcalculatingWPM is (9)

WhereA%=percentageofFlyAsh(Weightbasis) B%=percentageofGGBS(Weightbasis)

InthisdesignA%=100%,B%=0%

Butasperfollowingderivationthemodifiedformula (Eq. 9a)forcalculatingWPMisusedinthepresentinvestigation.

© 2022, IRJET

Factor value: 7.529

Where,GG,GFA, and canbeobtainedfromtests,A% andB%aregivenandVPF +VPG canbeobtainedfrom Eq.(8)

WF=A%×WPM (10)

WG=B%×WPM (11)

Mixingwatercontentrequiredforflyashpasteisobtained fromEq(12)

WWF= ×WF (12)

MixingwatercontentrequiredforGGBSpasteisobtained fromEq(13)

WWG= ×WG (13)

Step 6: Calculation of mixing water content needed in SCC:

mixing water content required by SCC is the total amountofwaterneededforcement,FAandGGBSinthemix. Therefore,itcanbecalculatedfromEq.(14)

Ww =Wwc +WWG +WWF Wwsp (14)

9001:2008

Journal

Page3534

International

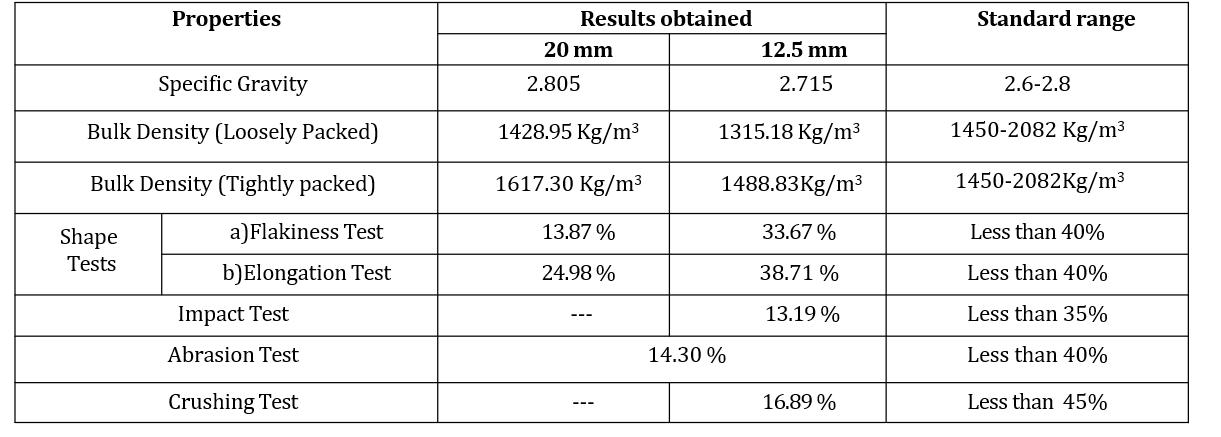

2.21MaterialProperties

The

Specific

Initial

Final

Bulk

Density

Packed)

Kg/m

Kg/m

1860Kg/m3

2097Kg/m3

(Zone 2) 2.90(Zone 2)

minutes

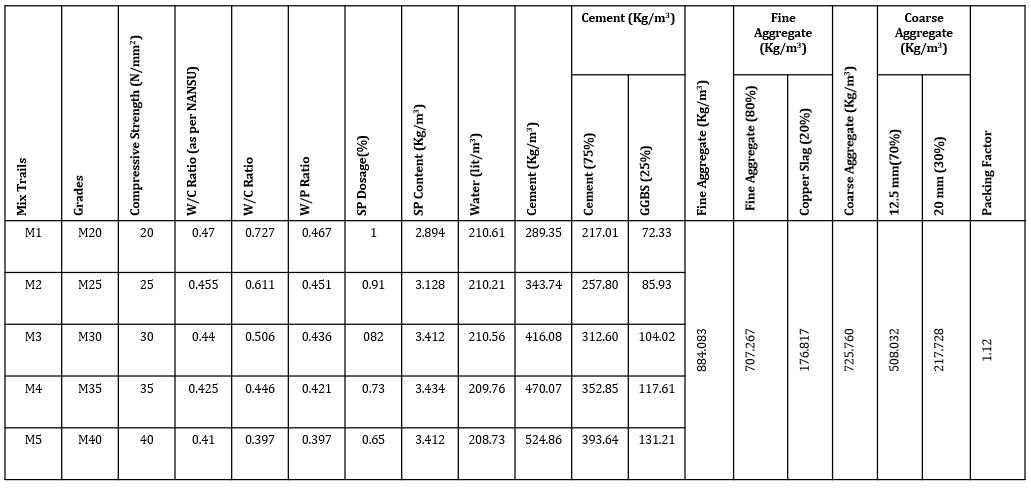

2.3.MixDesign

M20,M25,M30,M35,M40areconsidered

M20toM40mixesaredesignedasperthe above Nan Su mix design with proposed changes. Target meanstrengthasperIS10262:2019isusedforM20toM40 mixesinEq.4inplaceof f’c Thecementcontentcalculated fromEq.4isreplacedwith25%ofGGBS.Thefineaggregate

calculatedfromEq.1isreplacedwith20%ofcopper

BasedontrialmixesW/CratioandSPdosageisfixed satisfyingEFNARCguidelines.Themixproportionsforthe aboveSCCgradesareshowninTable5

Mix

Table

Grades

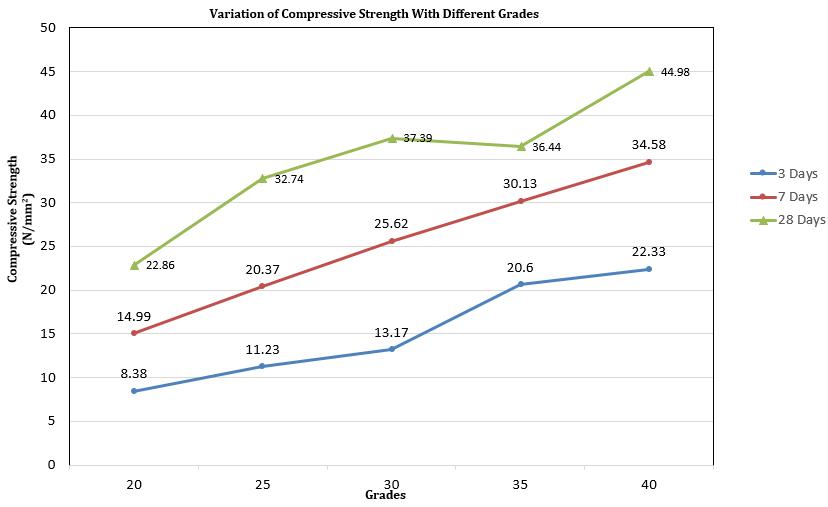

Strength (N/mm

3 Days 7 Days 28 Days

M1 M20 8.38 14.99 22.86

M2 M25 11.23 20.37 32.74

M3 M30 13.17 25.62 37.39

M4 M35 20.6 30.13 36.44

M40 22.33 34.58 44.98

The compressive strength obtained for all the grades is morethan fck ( fck =Characteristic compressivestrength of

for M20; fck =20 N/mm2). The compressive

obtainedforgradesM25&M30ismorethantarget

strength.

TheaboveresultsestablishtheuseofproposedEq.4forSCC

PSC. Copperslagcanbeusedasmineraladmixturefor partiallyreplacingfineaggregate.

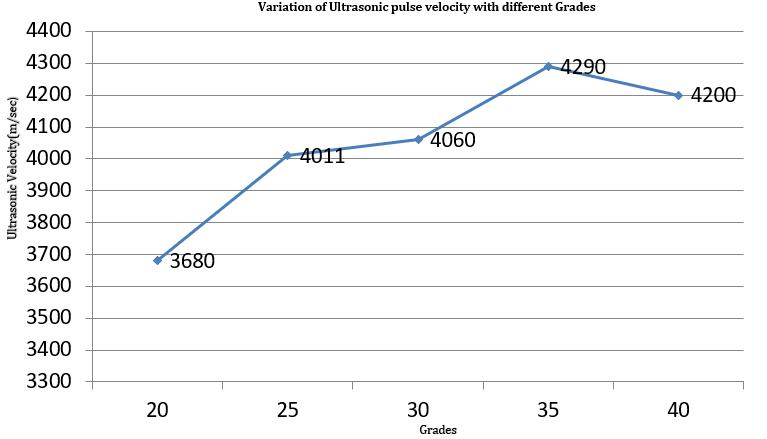

The

M1

4.CONCLUSIONS

1. Forallthegrades

is morethancharacteristic

2. ForM25

compressivestrength

M30

strength

morethanthetargetmeanstrength.

3. Thequalityofallthegradesofconcrete

goodbased onUltrasonicPulseVelocitytest.

4. AspertheresultsthemodificationproposedforNan Su mix design equation for the estimation of cement for PSCisacceptable.

5. Copper slag can be used as mineral admixture for partialreplacingfineaggregate.

REFERENCES

1. NanSu,Kung ChungHsuandHis WenChai(2001) proposed a ” Simple Mix Design Method for Self Compacting Concrete”JournalofCementConcrete Research , Vol. 31, No. 12, pp. 1799 1807., Dec. 2001.

2. Bhosale Mahesh Bhimarao, et.al(2020), “Replacement of Copper Slag with Fine Aggregate”, InternationalResearchJournalofEngineeringand Technology(IRJET),Vol.07,Issue.03,March2020, pp.4201 4204

3. Bhavani,C.KrishnamaRaju,S.TalhaZaid(2016), ” Effect on Mechanical Properties of M25 SCC with Variation of Class F Fly Ash & GGBS”.International Journal of ChemTech Research, Vol. 11, No. 07, 2018, pp. 70 77, DOI= http://dx.doi.org/10.20902/IJCTR.2018.110709

4. S.Dhiyaneshwaran,P.Ramanathan, I.BaskarandR. Venkatasubramani (2013), ”Study on Durability Characteristic of Self Compacting Concrete with Fly Ash”JordanJournalofCivilEngineering,vol.7,No.3, May2013,pp.342 353.

5. B. Chandraiah, C. Krishnama Raju, S. Talha Zaid, “VariationOfCompressive Strength AndSplit Tensile Strength Of M40 Self Compacting Concrete With Different Sizes Of Coarse Aggregate” , International Journal of Engineering Technology Science and Research (IJETSR), Vol. 4, Issue 8, August 2017, pp.279 285

6. G. Asif Hussain et.al(2020), “Properties of M60 High Performance Self Compacting Concrete by usingBlendsofDifferentSizesofCoarseAggregate”,

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net p ISSN: 2395 0072

National Virtutal Conference on Recent Trends in CivilEngineering 2020(RTCE’20),September2020 pp31 36,ISBN:978 81 942685 2 9.

7. S. Venkateswara Rao, M.V. Seshagiri Rao, P. Rathish (2010), ”Effect of Size of Aggregate and Fines on Standard and High Strength Self CompactingConcrete”, JournalofAppliedSciences Research,pp.433 442

8. N. Shanmuga Nathan, E.Ambrish, et.al, “Partial Replacement of Copper Slag as Fine Aggregate” , SSRG International Journal of Civil Engineering (SSRG IJCE),Vol.4,Issue3,March2017,pp.18 23. ISSN:2348 8352.

9. J. Vengadesh Marshall Raman, V. Murali Krishnan ”Partial Replacement of Cement with GGBS in Self Compacting Concrete for Sustainable Construction” , SSRG International Journal of Civil Engineering (SSRG IJCE) Vol.4,Issue3,March2017,pp.22 25

10. IS:2386(Part i,Part iii,Part iv) 1963, ”Methodsof TestforAggregateforConcrete”inBureauofIndian Standards.

11. IS:383 2016, ”SpecificationsforFineaggregateand Coarseaggregate”.

12. IS: 4031 1988, ”Methods of Test for Cement” in BureauofIndianStandards.

13. IS: 455:2015, ”Specifications for Portland Slag Cement”.

14. IS: 516 1959, ”Methods of Tests for Strength of Concrete”.

15. IS: 13311 (Part 1 and 2):1978, ”Non Destructive TestingofConcrete MethodsofTest”.

16. IS: 10262 2019, ”Concrete Mix Proportioning Guidelines”.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3539