Design and analysis of composite leaf spring for TATA 407 truck

Abstract - Leaf spring is one of the fundamental components and it gives a brilliant suspension. Shocks and struts are critical for riding safety. Their function is to maintain the tyres on the street via way of means of controlling spring and suspension moves and through keeping a vertical load at the tyres. The primary purpose of the suspension machinery is to damp the vibrations because of street irregularities. It additionally helps to permit fast cornering without intense rolling. It performs a important function in automobile handling mainly in rolling, braking. The better the suspension is mounted, the better the CG of the vehicle shifts from the floor which in turn results into growth in tendency of rolling. The suspension system accounts to 15 20 % of unsprung weight of the automobile. Unsprung weight is the load that is not supported through the suspension which incorporates wheel axles, wheel bearings, wheel hubs, tires, and a part of the load of driveshafts, springs, shock absorbers, and suspension links. There are one of a kind varieties of suspension system, however in this research, leaf springs are being studied.

Key Words: Suspension, Leaf Spring, Automobile, Vibration, Riding Safety.

1. INTRODUCTION

Thesprings,shockabsorbers,andconnectorsthatconnect thevehicletothewheelarereferredtoasthe"suspension system.". The suspension system's primary function is to dampen vibrations caused by road irregularities. It also serves as a support weight, allowing for quick cornering without excessive rolling. It's important for car control, especiallywhenitcomestorollingandbraking.Thehigher the suspension, the further the car's centre of gravity is shifted away from the ground, increasing the chances of rolling.Thesuspensionsystemaccountsfor15 20%ofthe vehicle's unsprung weight. Wheel axles, wheel bearings, wheel hubs, tyres, and a percentage of the weight of driveshafts,springs,shockabsorbers,andsuspensionlinks areallexamplesofunsprungweightthatisnotsupportedby the suspension. Suspension systems come in a variety of shapesandsizes,butleafspringsarethefocusofthisstudy.

1.1 Methodology

ReverseEngineering.

Designofleafspringusingcalculation.

Designof3Dmodelofleafspringbyusingsolidworks.

Static analysis of leaf spring for various composite materialsbyusingANSYSsoftware.

Comparisonofresults.

1.2 Theory of leaf spring

Engineering materials constructed from two or more constituentmaterialsthatremainseparateanddistinctona macroscopic level while creating a single component are known as composite materials. The two categories of component materials are matrix and reinforcement. The matrix materials' principal tasks are to transfer stresses between reinforcing elements and to protect them from mechanicaland/orenvironmentaldegradation,whereasthe presence of fibers/particles in a composite increases mechanicalqualitiessuchasstrength,stiffness,andsoon. Bypreservingtheirrelativelocations,thematrixmaterial surroundsandsupportsthereinforcementorfibreelements. The mechanical and physical features of the reinforcing materialimprovethematrixquality.

1.3 Principle of leaf spring

A leaf spring is commonly used for the suspension in vehicles.Thesuspensionofleafspringisthattheareawhich needstofocustoenhancethesuspensionsofthevehiclefor comfort ride. The suspension spring is one among the potentialitemsforweightreductioninautomobilesbecause it accounts for 10% to 20% of unsprung weight. it's well knownthatspringsaredesignedtoabsorbshocks.therefore, the strain energy of the material becomes a significant consider designing the springs. The introduction of compositematerialwillmakeitpossibletoreducetheload oftheleafspringwithoutreductioninloadcarryingcapacity andstiffness.Sincethecompositematerialencompassesa high strength to weight ratio and has more elastic strain energy storage capacity as compared with steel. The relationshipofspecificstrainenergyisoftenexpressedas:U =σ2/2Ρe

Itcanbeobservedthatmaterialhavinglowerdensityand modulushaveagreaterspecificstrainenergycapacity.Thus, composite material offers high strength and light weight. TheleafspringofaTata"Model 407"motorvehicleisused in this study for further analysis. By reducing vertical vibrations,hits,andbumpscausedbyroadirregularities,the suspension quality can be enhanced, resulting in a more comfortable ride. The vehicle industry is introducing a

International

Volume: 09

of Engineering and Technology

varietyofcarsthatarenewlydevelopedandupdatedwith sophisticated and composite materials to provide a more comfortable ride, lower weight, and superior mechanical qualities.

1.4 Comparison with metals

• Compositesarelong lasting.

• Composites are lighter in weight and can resist highertemperaturesthanmetals.

• Compositeshaveahighelasticitymodulus.

2. Experimental setup

The data of TATA 407 truck is taken. Total weight of the vehicleis4450Kg.

Lengthoftheleafspring=1428.8mm.

Factorofsafety=2.5. Elasticity=207000MPa.

The force is the product of weight of the vehicle and the accelerationduetogravity

F=4450×9.81=43665.5N

Sincethevehicleis4 wheelertheonefourthoftheforcecan besustainedbysingleleafspring.

43665.5÷4=10913.62N

Theleafspringactsasasimplysupportedbeamso,theforce ononeendofleafspringcanbecalculatedas

2F=10913.62

Therefore,theforceis5456.81N.

2L=1428.8

L=714.4mm

Therearetwoequationstocalculatethethickness(t)and width(b)ofleafspring.

i. σ(stress)=3FL/bh3

ii. δ(deflection)=3FL/Ebh3

Byre arrangingandputtingthevaluesofforceandlength, thevaluesofbandtare80mmand16mmrespectively.

Thevaluesofmaximumstressandmaximumdeflectioncan becalculatedbyputtingthevaluesofb,t,F,LandEinthe abovetwoequations.

Thus, the values of the maximum stress and maximum deflectionare571.04N/mm2and87.99mm.

Tocalculatethecamberofleafspring, C/L=0.089

Therefore,thecambervalueis127.16mm.

2395

2395

3. Results and discussion

3.1 Load Vs Deformation

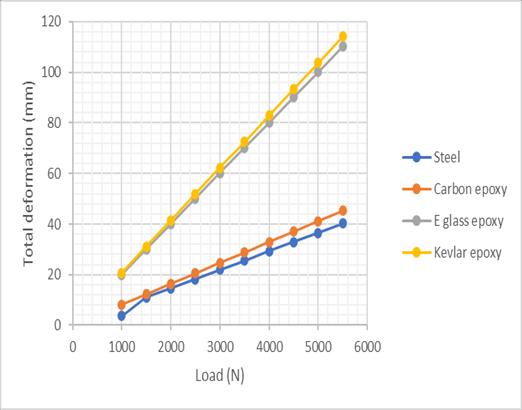

Chart -1:LoadVsdeformation

The chart represents the load vs deformation of various materials.TheCarbonepoxyandStructuralSteelreadings arealmostidenticaltoeachother.TheKevlarepoxyandE glassepoxyarealmostshowingthesameproperties.

The maximum deflection of Carbon epoxy and Structural Steelarelessthan50mm,thedeflectionofKevlarepoxyand E glassepoxyaregreaterthan100mmwhichisnotfeasible accordingtodesignconfiguration.So,theKevlarandE glass epoxyfailindesignconfigurationandhencecannotbeused asamaterialforleafspring.

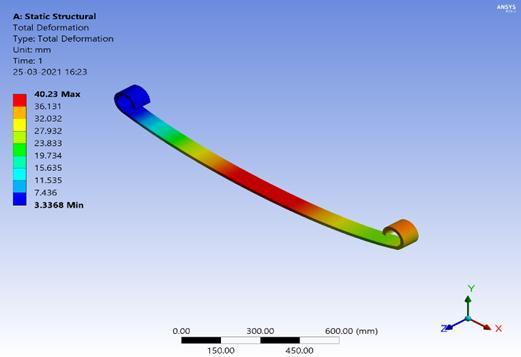

Fig -1:Schematicdiagramofdeformation(Steel)

Fig

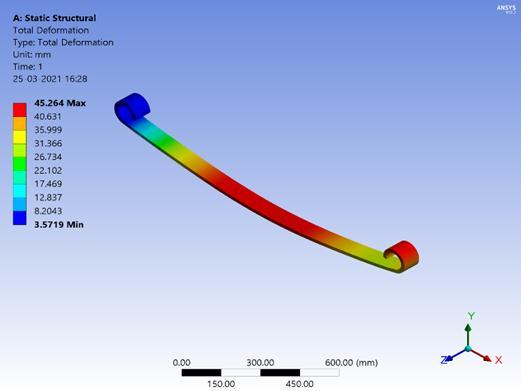

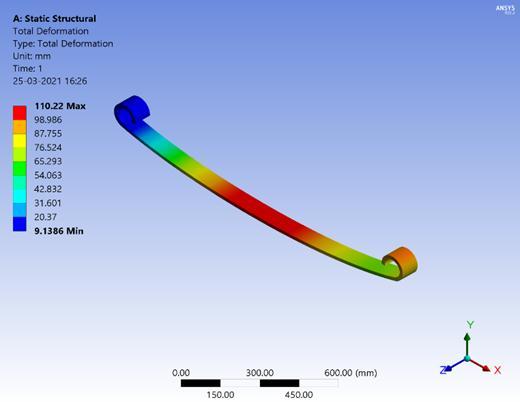

The schematic diagrams represent the static analysis of maximum deformation against the maximum load for variousmaterialssuchasStructuralSteel,Carbonepoxy,E glassepoxyandKevlarepoxyrespectively.Thehighlighted red part in the above schematic diagrams show the maximumdeflectionandthebluepartshowstheminimum deflectionoftheleafspring.

Themaximumdeflectionisatthecentreoftheleafspring becausetheleafspringactsa simplysupportedbeam and the force is on mid span of the length of leaf spring and causesittodeform.

Fig 4

Schematicdiagram

deformation

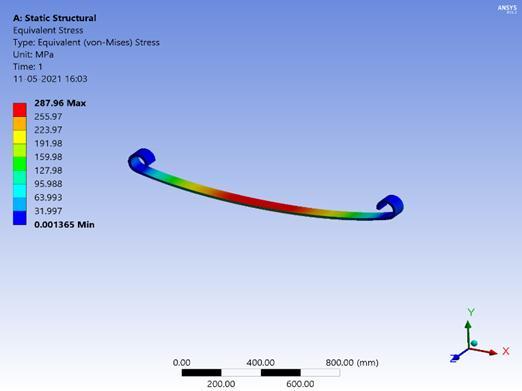

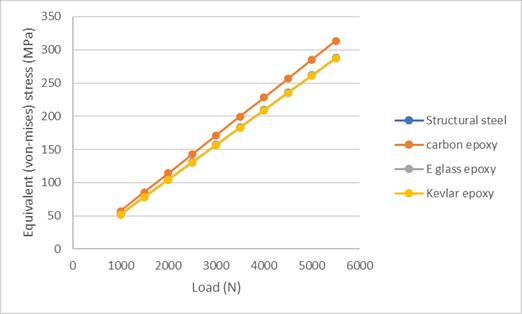

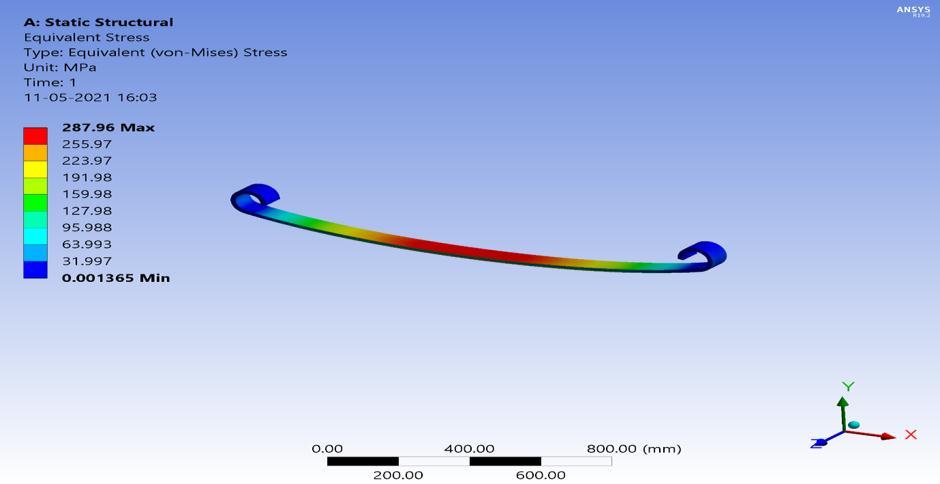

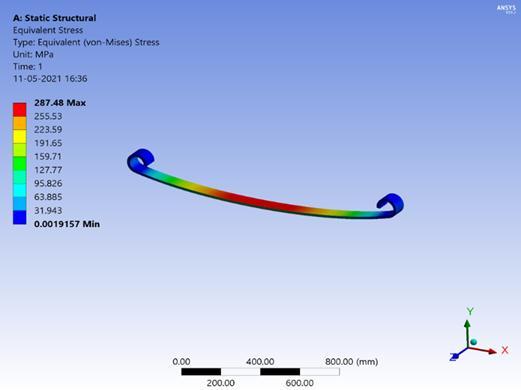

Load Vs Equivalent (von-mises) stress

The chart represents the load vs equivalent stress for variousmaterialssuchasSteel,Carbonepoxy,E glassepoxy and Kevlar epoxy respectively. The carbon epoxy is sustainingthelargeamount ofstressatmaximumloadas comparetotheothergivenmaterials.Theothermaterials suchasSteel,E glassepoxyandKevlarepoxyaresustaining nearlysameamountofstressatthegivenload.

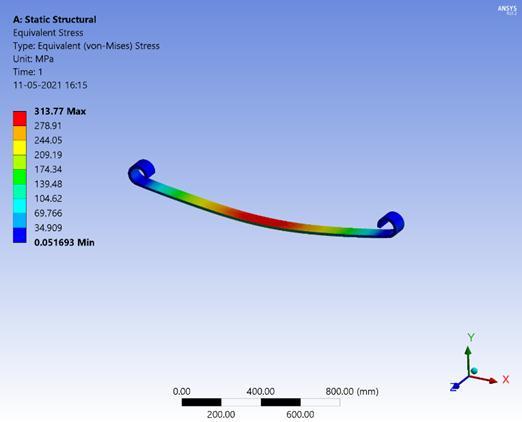

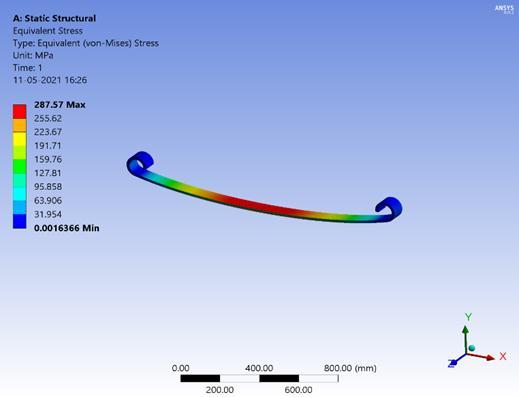

ThevaluesofstresswhicharesustainedbytheSteel,Carbon epoxy, E glass epoxy and Kevlar epoxy are 287.96MPa, 313.77MPa,287.57MPaand287.48MParespectively

(von mises)stress

Fig

Theaboveschematicdiagramsrepresentthestaticanalysis ofequivalent(von mises)stressagainstthemaximum

forvariousmaterialssuchasStructuralSteel,Carbonepoxy, E glassepoxyandKevlarepoxyrespectively.Thehighlighted red part in the above schematic diagrams shows the maximum stress and the blue part shows the minimum stressinducedintheleafspring.

The maximum stress areas are showing that the force inducedinthatareaismaximum.Thus,inducesthestressin thatparticulararea.

Fig

Fig

3.3. Load Vs maximum principal elastic strain

3.5 Weight reduction of composite materials with respect to the structural steel

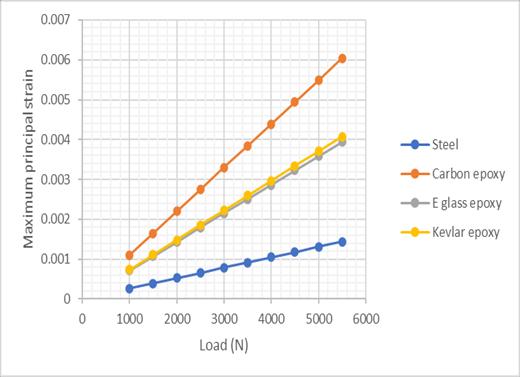

Chart 2:LoadVsmaximumprincipalelasticstrain

Theabovechartrepresentsthemaximumloadvsmaximum principalelasticstrainofvariousmaterials.HeretheCarbon epoxyhasthemaximumvalueofmaximumprincipalelastic strainwhichis0.006.

TheKevlarandE glassepoxyhavethevalueof0.004andthe structural steel has the value 0.002 which is less than the othermaterials.

3.4. Load Vs strain energy

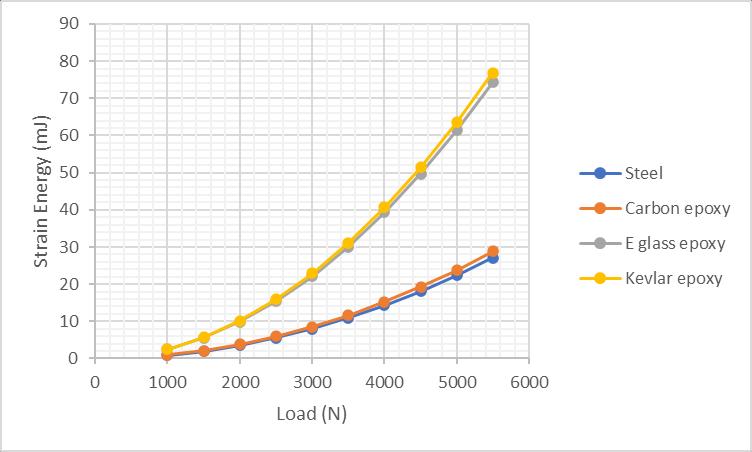

Chart 3:LoadVsstrainenergy

The above graph represents the load vs strain energy of variousmaterials.Byobservingthegraph,Inthiscasestudy thevaluesofStructuralSteelandCarbonepoxyandKevlar andE glassepoxyarealmostidenticaltoeachother.

ThestrainenergystoringcapacityofSteelandCarbonepoxy are almost 30 mJ. The strain energy storing capacity of KevlarepoxyandEglassepoxyarealmost80mJ.

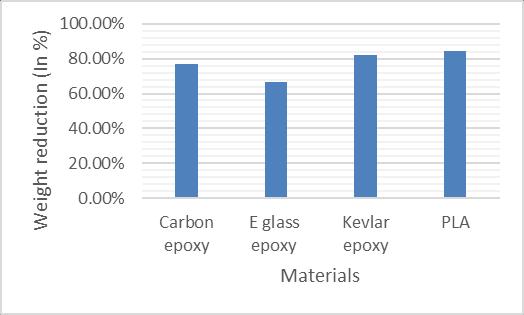

Chart 3:Weightreductionofcompositematerialswith respecttothestructuralsteel

Theobjectiveofthisprojectistoachieveweightreduction above50%incomparisonwiththeconventionalsteelleaf spring.Aftertheanalysistheresultsforweightreductionare greaterthan50%.

By observing the above chart of the weight reduction of Carbon,Kevlar,EglassepoxyandPLAis77.07%,82.16%, 66.87% and 84.07% respectively in comparison with the weightofconventionalSteel leafspring.Theweightofthe conventionalleafspringis18.84Kg.

The readings of composite material PLA is taken only to inspect whether it is suitable to use as a material for leaf spring.Ithasgiventhereductionof84.07%butcannotbe usedasamaterialforleafspring.

4. Conclusion

Asloweringweightandincreasingstrengthofcomponents ofvehiclesarethemostdemandedresearchtopicsaround the globe, composite materials are getting to be up to the markofsatisfyingtheseneeds.Inthispaperloweringweight of automobiles and increasing the strength of the componentsisconsidered.

Asleafspringcontributessizablequantityofweighttothe vehicleandneedstobestrongenough,asinglecomposite leaf spring is designed and it is shown that the resulting designandsimulationstressesaremuchbelowthestrength propertiesofthematerialsatisfyingtheutmoststressfailure criterion.

Fromthestaticanalysisresults,weseethatthedeflectionin thesteelis40.23mm.AndthedeformationinE glassepoxy, Kevlar epoxy and Carbon epoxy is 110.22mm, 114.12mm and45.264mmrespectively.Amongthethreecompositeleaf springs,onlycarbonepoxyhasthelessdeflectionwhichis under design configuration. Carbon epoxy composite leaf

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

spring can be suggested for replacing the steel leaf spring from the analysis. In terms of strength and weight, a comparison was made between steel and composite leaf springs. Composite PLA leaf spring reduces the weight by 84.07%forE GlassEpoxy66.87%forKevlarEpoxy82.16% and77.07%forCarbonEpoxyoverconventionalleafspring.

TheCompositematerialhasamoderatedeflectionw.r.tload ascomparedtosteelhencecompositematerialisbetterthan steelonbaseofdeflection.Asweconsiderthestiffnessthe compositematerialhasahigherstiffnessthanthesteelleaf spring hence it is better than steel. Gerber and Goodman approachisfoundtogivebetterresultsfortheanalysisof life data for parabolic leaf springs. According to total life approach, the fatigue life of Carbon Epoxy composite parabolic leaf spring is higher than that of steel EN45 parabolicleafspring.Fromtheaforementionedpointsitcan be concludedthat replacing conventional Steel leafspring withCarbonepoxyleafspringresultsintremendousweight reduction,increasesoverallengineefficiency.

4.1. Future scope

Thedesignandanalysisoftheleafspringiscarriedoutby theanalyticalmethodandstaticanalysis,onecanvalidate the results by manufacturing the prototype and by performingthedynamictestsonit.

Use of UTM (Universal Testing Machine) to find out the actual results and to compare the results carried out by dynamicanalysiswithstatic analysisforvalidationof this project.

Vibration analysis of leaf spring is to be carried out for materialfatigueanalysis.

Acknowledgement

Wetakethisopportunitywithgreatpleasuretoexpressour sincereregardsanddeepsenseofgratitudetoourguideDr. AnilMaheshwari,AssociateDeanSchoolofEngineeringand Technology, Sandip University, Nashik for his valuable guidance,practicalsuggestionsandencouragementtobring aboutthecompletionofproject.

Itisthroughhisproficientknowledge,valuableguidanceand support that this project has been set right. We are also thankfultoallfacultymembersofMechanicalEngineering DepartmentofS.O.E.TSandipUniversityNashikwhohave alwaysco operatedwhilecarryingouttheprojectwork.

References

1. M. M. Patunkar, D. R. Dolas, “Modeling and Analysis ofComposite Leaf Spring Under the Static Load Condition byUsing FEA”, International Journal of Mechanical&IndustrialEngineering,Volume1Issue1 2011,pp1 4.

ISSN: 2395 0056

ISSN: 2395 0072

2. Kumar Krishan and Aggarwal M.L., “A Finite ElementApproach for Analysis of a Multi Leaf Spring usingCAETools”,ResearchJournalofRecentSciences, Vol.1(2),InternationalScienceCongressAssociation,pp 92 96.

3. N.P.Dhoshi , N.k.Ingole , U.D.Gulhane. “Analysis andmodification of Leaf Spring of Tractor Trailer usinganalytical and Finite element method.” InternationalJournalofModernEngineeringResearch (IJMER)Vol.1,Issue.2,pp 719 722ISSN:2249 6645.

4. Mahmood Shokrieh, Davood Rezaei. “Analysis andoptimization of a composite leaf spring CompositeStructures60(2003)pp317 325

5. Perttu Kainulainen, “Analysis of Parabolic Leaf SpringFailure”,SavoniaUniversityOfAppliedSciences, 2011.

6. Wiesaw Kraso, Józef Wysocki, “Analysis Of Vibrations OfTheSimplifiedModelOfTheSuspensionSystemWith ADouble Springand A Fluid Damper”, Journal Of KONESPowertrainAndTransport,Vol.18,No.12011.

7. M.Venkatesan, D.Helmen Devaraj, “ Design And AnalysisOf Composite Leaf Spring In Light Vehicle” , InternationalJournalofModernEngineeringResearch (IJMER),Vol.2,Issue.1,pp 213 218.

8. Muhammad Ashiqur Rahman, Muhammad Tareq Siddiquiand Muhammad Arefin Kowser, “design and nonlinearanalysisofaparabolicleafspring”,Journalof MechanicalEngineering,vol.ME37,June2007,pp47 51.

9. RajaleRanjit, Rana Mayuresh, Praveen k Mali “Design and analysis of composite leaf spring review paper” Vol5issue1,jan2016.

10. L.Ramesh,KVeeranjaneyulu,BBikshamfabricationand experimentalanalysisofcarbonfibre/epoxycomposite leafspringinternationaljournalofcurrentengineering andscientificresearchvolume 5,issue 4,2018.

11. A.Manikandan, A.Balamurugan, G.Kannan, M.Karthikeyen Design and analysis leaf spring using agave tequeilana , lotus and madar fibre with epoxy, International Journal of Engineering, Science and Mathematics Vol. 7 Issue4, April 2018(special issue NCIME)ISSN:2320 0294ImpactFactor:6.765.

12. B. Shushma | Ch. Pavan | D. Vikas Reddy | G. Venu Madhav|A.MukhulVamshi"DesignandModellingofa LeafSpringusing3DPrintingTechnology"(ijtsrd),ISSN: 2456 6470,Volume 4|Issue 2,February2020,pp.71 75.

2021, IRJET | Impact Factor value: 7.529 | ISO 9001:2008