Experimental Research on Strength of Demolished Construction Waste as Partial Substitute of Coarse Aggregate.

Large amounts of building and demolition trash are still being created and are simply being deposited in dumpsters. This necessitates enormous tracts of land, which are becoming increasingly scarce. The greatest answer would have been to reuse the destroyed trash, that could not only assist to prevent climate change but will also aid in the disposal of building waste. As a result, it has a serious problem producing environmentally harmful trash and is also had to pay a large quantity of money. That speaks about the construction recycle trash crushed concrete counts (WCC) from either the lath loss of crushed concretereplacementfrom coarse aggregate 20 percent, 30 percent, 40 percent (WCC), 3 percent of shattered cementitious material (lathe waste) to minimize deconstruction losses. (This research of deconstructed crushed cement aggregate (DCCA) concrete in normal mold cast is to be completed in (7, 14, 28) days of hydration and inspection laying on cementitious materials. Strength of concrete and flexural strength are examples.) The use of waste matter to replace coarse aggregate and achieve the needed strength in traditional M20 grade concrete.)

1. INTRODUCTION

Sincethemetropolitanregionisexpandingatanalarming rate,theneedfornewstructuresandcommunicationshas skyrocketed. The need for traditional aggregates has increasedintandemwiththeverticalexpansionofthenew fangled constructionwith advancement of infrastructure development,theuseofconventionalconcreteisbecoming more prevalent. Recycled aggregate may be used as a substitute material for natural aggregate in order to minimize the consumption of natural aggregate. Many antique buildings and constructions have outlived their usefulnessandage.

New building promotes economic development and employment generation. Building trash is generated as a consequence of both natural and man made catastrophes. Destroyed concrete waste away obtained after the demolition of the structure is a living form that must be properly processed before the aggregates of it can be employed in concrete manufacturing. As a result of this procedure,coarseaggregatesareusedinconcreteascast off material.

Building trash is discarded at a rate of 5000 tons per day throughout India and South Asia, according to an overall

analysis.AccordingtotheHindu,thereisalso23.75million tonsoftrash.In2007,inIndia,itwasproducedonanannual basis.Itcausesseriousdamagetotheenvironmentsinceitis largeandoccupiesalargeamountofarea. Annually,8to12 billiontonsofintrinsicaggregateareusedbyinsideconcrete engineering at events across the world. Because of the constantuseofanticipatedsuppliessuchasstoneandsand, there is an extra major difficulty to change the climatic condition and humiliate the Planet and to confront by insisting in the coming through the reuse of demolished concrete wastes in the appearance of cast off aggregate concrete,anattemptintheaimofsavingnaturalresources, environmental conservation, and not wasting energy is visible.

THE INDIAN SCENARIO

Indianhousingindustryisveryjobintensiveandcontributes foraround50percentofthefundsoutlaidinsuccessive5 yearplansofournation.Theanticipatedspendinginsidethis construction sector continued to show an increasing tendency. Department Of Environment has evaluated currentquantityofsolidgarbagecreationinIndiatowards the extent of 47.5 million tons/annum of that which pollutionfrombuildingprojectsaccountsfor25percent.The entirequantityoftrashfrombuildingsectorisanticipatedto beTwelvetofourteenmilliontonsperyear. Thepurposeof thisresearchwasnotjusttofindoutuseofwasteitemson masonry in order to measure them from that on financial perspectivebutalsotoevaluatetheviabilityofrepurposing materials from dismantled structures. It’s expected that amongoutcomesofsuchstudieswillurgepractitionersto employ supplementary elements in rapidly growing constructionworks.

LITERATURE REVIEW

According to Asif Husain1, Majid Matouq Assas2, et al., (2013), theuseofdeconstructedaggregateintheproduction of new concrete whichwill assist inreducingsolid waste disposaloncurrentlandfillsites.

The repurposing of removed concrete will aid in the development of the region's overall ecosystem. First, by reducing mining, and second, by reducing air pollution caused by aggregate manufacturing (dust pollution) and

Shiraz Anas Quadri

Mohammed Shaz

Mohammed Arshad Khan

Research Journal of Engineering and Technology (IRJET)

2395

2395

aggregate transit from mine to end consumer (vehicular pollution). As a result, the research concludes that deconstructed concrete is really not waste generated but rather a usable element thatcan be recycledto build new concrete, saving cement and making concrete more cost effective.

According to Goudappa Biradar1 et al., (2015), recycled aggregatesderivedfromconcretespecimensprovidehigh standard concrete. Various surface treatment procedures, such as wiping the recycled aggregates using water and weak acid, were examined to enhance the quality of regeneratedcoarseaggregate.Tosavemoney,experimental runs may be built using recycled aggregate for structural concretepartsratherthandiscardingtherecycledconcrete.

Accordingto R. Kumutha1, K. Vijai2 et al., (2010), recycled aggregates may be used as a replacement for traditional coarse or fine aggregates in construction. The porosity, strengthproperties,splittensile,flexural,andpercentageof elongation of cementitious materials with and without repurposed particles were all determined via a series of experiments. Recycled concrete aggregates were used to substitute fine recycled aggregates in concrete in percentagesof0percent,20%,40%,60%,80%,and100%. Recycledcrushedaggregateswereusedtosubstitutenatural finematerialinconcreteinpercentagesof0percent,20%, 40%, 60%, 80%, and 100%. In lieu of smashed stone aggregate,aggregatesmaybeutilizedasa foundationand subbasematerialforsustainingaroadpavementsurface. Thesuitabilityofconcretes,smashedstoneaggregate,and gravelaggregateisstillthesame.

Sivakumar et al. (2004) performedrepeatedloadtestson concrete aggregate and building trash in a direct shear equipment and found that recycled and recyclable wastes had high shear capacity and may be used in a variety of geotechnical design. It was also suggested that the appropriatenessofthesesubstancesincivilandstructural conditionsrequiringhighlateralloadingshouldbecarefully considered.

After performing case studies, Winston F. K. Fong et al. (2004) explainedthemostproperimplementationexpertise of using recycled concrete in Construction Industry developmentsandindicatedthatrecycledaggregateshave indeedbeenillustratedtobecapableofproducingcomposite materialsforconstructionpurposes.Morescientificresearch isalsointendedtopromotetherepurposingideaandexpand therangeofusesforrecoveredaggregates,accordingtothe report.

Oikonomou (2005) recommended a set of tests and restrictionsforrecycledconcreteaggregatetobeusedasa foundationforpilotandlarge scaleprojectswheretheusage ofrecycledconcreteaggregatemaybeprojectedtobemore cost effectiveandenvironmentallyfriendly.Advocatedfora

QualityManagementSystem(QMS)forConstructionSiteto enhancequalitycontrolandinteractionamongprofessionals atdifferentOrganizationallevels.Accordingtotheanalysis, therehavebeentwokeycausesforworseefficiencyofthe construction sector: non use of wood products and bad fabrication methods. He remarked that there is indeed a misinterpretation about Total quality management implementation.[1]

AIM & OBJECTIVES

Themainaimofthisstudyistoreusethedestroyedbuilding waste concrete like in concrete production as that of the crushedconcretewhichdecreasesthepollutionsaswellas offeringacommercialbenefitforthewasteproducts.

The research relates to the following objectives:

a)

Toexaminetheusageofdemolitionactivitieswaste asasubstituteoffreshcoarseaggregate

b) Toexaminethephysicmechanicalcharacteristicsof Demolition and building waste aggregate by performingexploratoryinvestigation.

MATERIALS

The choosing and categorizing of materials used in the productionofjustaboutanyconventionalconcreteiscritical becauseallofthecharacteristicsaredependentonthem.

The substances used in this work are described below.

a) Riversand.

b) The coarse aggregate has been replaced by a recycledconcretemix.

c) Water.

d) OrdinaryPortlandCementof53Grade. Cement:OPCof53gradewasformerlyutilized.Thecement must meet the BIS standard IS: 12269 1987. having a minimumspecifiedstrengthfor28daysof53MPa.

Properties of cement:

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 04

www.irjet.net

Aggregates:Aggregatesareinactiveparticulatesubstances like dirt, rubble, or gravels that serve as a standalone finishedproduct.Theyareindeedtherawcomponentsused intheconcreteproduction.Aggregatesmustbefresh,firm, and robust granules that are devoid of ingested contaminants, mud coverings, as well as other fine contaminantsthatmightleadconcretetodeteriorate.

Aggregates are categorized based on their size.

a) Coarse Aggregate.

b) Fine Aggregate.

Fine Aggregate: Fine aggregate is made up of grains collectedfrom either the ground or the sea.Riversand or stonedustarethemostcommonfineaggregates,withthe majority of material passing throughout a 9.5mm screen. These may come from original, supplementary, or repurposedsources,muchlikecoarseaggregates.Thechoice offineaggregateisparticularlycrucialsinceithasadirect influence on the strength of cement when the amount of waterusedvaries.

Properties of Fine Aggregate:

S.no Properties Value

1 S.PGravity 2.62

2 Density 14kg/m3

3 Zone II

Coarse Aggregate: Coarse aggregatesaregranuleswitha dimension of more than 4.75mm but often ranging from 9.5mm to 37.5mm. They might come from fundamental, supplementary, or repurposed materials. Land Won or Oceanic aggregates are basic, aggregates. Sandstone is a roughmaritimeaggregate,whereasrubbleandcrushedrock arecoarsegroundaggregates.Gravelsmakeupthebulkof coarseaggregateincement,withstonedustaccountingfor thegreatmajority.

Recycled Aggregate: Debris from concrete construction destruction is collected, and aggregates are sorted into recycledaggregates.Forthisproject,thesuggestedrecycled aggregatesareemployedintheconcretemix.Gradingisused tocomplytherecycledaggregates.Forpartialsubstitution, 20 mm angled coarse aggregates were used as per the requirement.

© 2022,

ISSN: 2395 0056

ISSN: 2395 0072

Properties of Coarse Aggregate and Recycled Aggregate:

S.no Properties Normal Aggregate DCCA

1 Size 20mm 20mm

2 Waterabsorption .93 5.55

3 Bulkdensity .70 2.5

4 Abrasiontest 14.5 17

5 Crushingtest 17 28

6 Impactvalue 13.30 28.45

7 SpecificGravity 2.65 2.4

Water: PotableWaterisutilizedasaresourcethroughout the blending and hydrating process. Concrete is being prepared, and the water cement ratio operated for this objectivewasapproximately0.33

Experimental Investigations: Compressive Strength Test

Cement blocks of sizes 150mm×150mm×150mm were tested for compressive strength test. Strength of concrete relies on loads of aspect such as water to cement ratio, clinker stiffness, perfection of concrete ingredient and brilliance monitoring throughout production of concrete. Thosecubesareevaluatedbycompressiontestingmachine after seven days, fourteen days and twenty eight days of curing.Thespecimenisplacedcentrallyuponthatbaseplate ofequipmentandtheloadneedstobeapplyprogressively somewhere at rate of 130 kg/minute until the specimen breaks.Loadjustatfracturesplitbysurfaceofsamplegives thecrushingstrengthofconcrete.Thespecimentoincreased pressurestartstobreakdownandalsonohigherloadcanbe consistent. The highestapplied loadto sample would also havetoberecordedandanyexceptionalvaluedetectedat themomentoffailureshouldbebroughtoutintheanalysis.

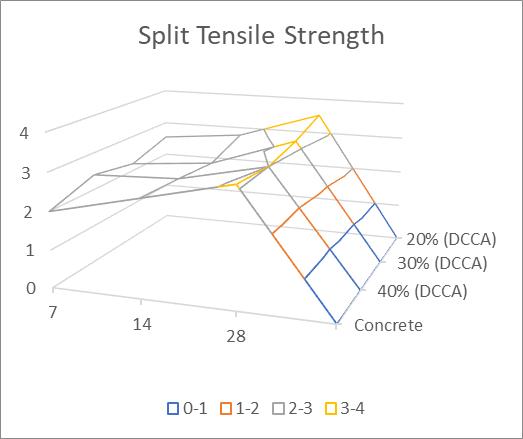

Split Tensile Strength of Concrete

The tensile strength of concrete has been one of the fundamentalessentialsignificantqualities.Splittingtensile testsonconcretecylinderisatechniquetoassessthetensile capacityoftheconcrete.Theconcreteisquiterelativelysoft owing to its elastic behavior and is not anticipated to withstand the direct stress. The cement forms fractures whenexposedtotensilepressures.Thus,itisimportantto estimatethecapacityoftheconcretetocalculatetheloadat whereby the concrete components may fracture. Splitting tensiletestsonconcretespecimenisatesttodiscoverthe tensile capacity of the concrete. Split tensile strength test wasperformedbyutilizingtheproceduregivenbyIS5816 1999.Moldsof150mm×300mmwereutilizedforthistest.

International

Engineering and Technology (IRJET)

The samples were examined for 7, 14, 28 days the tube sample was put in horizontal plane on the screening equipment.

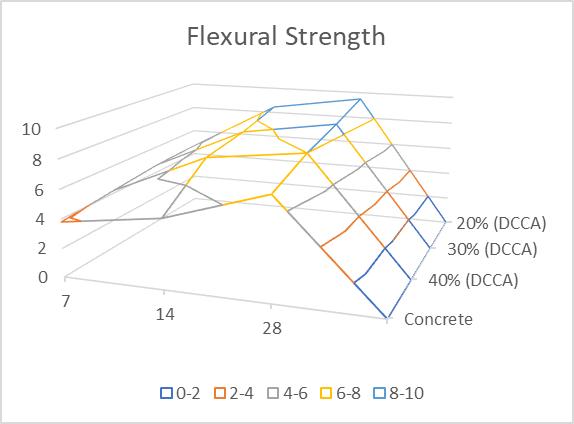

Flexural Strength Test

Flexural strength test on beam specimen to evaluate the conventionalconcrete.Flexuralstrengthtestwasperformed byutilizingthemannerdescribedbyIS516 1959.

Beams of dimensions 600mm×150mm×150mm were utilizedforparticulartest,thetestsampleisinsertedinthe equipmentatthebearingssidesoftheholdingandloading rollers.Suchthattheburdenmustbeadministeredwithout disruptionandrisingconstantlyatastressrisesataround7 kg/sqmmwhichisatapaceofloading400kg/minagainfor 150mmsamples.Theloadshouldberaiseduntilthefailure occurred,andalsotheultimateloadappliedtothematerial throughoutthetestmustbenoted.

EXPERIMENTAL RESULTS

The findings accomplished in the current research are reported in the format of Charts and Graphs for varied percentageofrepurposedaggregateasasubstitutetocoarse aggregate.Thefollowingaretheproportionssubstitutionof concretei.e.,20percent,30percentand40percent.

COMPRESIVE STRENGTH RESULT

Curing (days) Strength of Concrete (N/mm

SPLIT TENSILE STRENGTH RESULT

(days)

Strength of Concrete (N/mm

(DCCA) (N/mm

ISSN: 2395 0056

2395

(days)

(DCCA) (N/mm

(DCCA) (N/mm

(DCCA) (N/mm

Concrete (N/mm

(DCCA) (N/mm

(DCCA)

International Research Journal of Engineering and Technology (IRJET)

2395

2395

CONCLUSIONS

Concretereprocessingwillbecomethemostessentialfactors inensuringthelong termviabilityofinfrastructureprojects. Concrete in which the adhesives, preservatives, and aggregatesareall produced ofcementorcement likeraw material,andafterhardening,allofthesematerialscanbe usedascementbuildingingredients.'Green'concreterefers toconcretethatusespollutantsasaggregate.Thesuccessful implementationofusingwastematerialsaggregatetomake new green materials is the focus of this work. Utilizing recycledaggregate,avarietyofbasictestswereconducted. Theobservationsabouttheimpedanceofpartialsubstitute madewithRCAtoNCAinM20gradeconcretearebasedon minimalexperimentalanalysispertainingstrengthtestssuch ascompression,splittensile,andflexuralstrength.

a) Trashedaggregateexhibitssubstantiallylowerbulk crushing, density and impact criteria and greater waterabsorptionascomparedtopureaggregate.

b) Using destroyed recycled aggregate as a core material for roadways decrease the emissions associatedinhaulingmaterial.

c) Thestrengthofconcreteis raisedwithincreasing the proportion of destroyed aggregate till 30 percent.

d) Thesplittensileandflexuralstrengthofdestroyed concrete is also enhanced by increasing the proportionofdemolishedmaterial.

e) The utilization of deconstructed aggregate in building newconcrete will alsoaidindecrease of solidwastedisposaloncurrentlandfillsites.

f) The repurposing of removed concrete will aid in development of overall atmosphere of the area. Firstly, via decrease in mining sand secondly byreduction in air pollution arising from production of aggregates and mass transit of aggregatefromminingtoend consumer

g) Thenotionofrecyclingthewastematerialisquite interesting and encouraging specifically when it would be beneficial in minimizing destruction to planet's surface and green forest protection by virtueofreducedmining.

REFERENCES

[1] Mohd Monish, Vikas Srivastava, V.C. Agarwal, P.K. Mehta and Rakesh Kumar (2013) “Demolished wasteascoarseaggregateinconcrete”ISSN:2278 5213Feb 2013.

[2] Vaishali G. Ghorpade “effect of recycled coarse aggregateontheworkabilityandshearstrengthof fiberreinforcedhighstrengthconcrete”ISSN:2319 8753Vol.2,Issue8,August2013.

[3] TammiSaiKrishna“AnExperimentalInvestigation on Flexural Behavior of Recycle Aggregate Fiber Reinforcement Concrete” e ISSN: 2395 0056 Volumes02Issue04July2015.

[4] Shaman Preet Singh, Rajwinder Singh Bansal “Strength evaluation of steel fiber reinforced concrete with recycled aggregates” e ISSN: 2320 8163Volume4,Issue1(January February,2016).

[5] Abhishek Mandloi, Dr. K. K. Pathak Utilization of Waste Steel Scrap for Increase in Strength of ConcreteWasteManagementISSN(online):2321 0613Vol.3,Issue09,2015.

[6] AiyewalehinmiE.O.andAdeoyeT.E.“Recyclingof Concrete Waste Material from Construction Demolitionwaste”Volume2Issue10(2016)pp10 19ISSN(Online):2321 8193April,2016.

[7] PrakashSomani,BrahmtoshDubey,LavkeshYadav, Jitendra Kumar, Abhishek kumar, Mahipal Singh “Use of demolished concrete waste in partial replacement of coarse aggregate in concrete” (SSRGIJCE)Volume3Issue5May2016.

[8] JitenderSharma,SandeepSingla“StudyofRecycled ConcreteAggregates”(IJETT)Volume13Number3 July2014.

[9] MirjanaMalesev,VlastimirRadonjaninandSnezana Marinkovic, “Recycled Concrete as Aggregate for Structural Concrete Production” ISSN2071 1050 March2010.

[10] Chandrasekaran, Vijayvenkatesh. "Experimental Investigation on Concrete with Replacement of Coarse Aggregate by Demolished Building Waste with Crushed Concrete." Concrete Engineering, ResearchPapers(2018).