An Attempt of Green Building Construction Using GFRG Panels

Green construction involves more than just putting together a collection of the newest green technologies and materials. Rather, it is a process in which every aspect of the design is optimised first, followed by a re-evaluation, integration, and optimization of the

interplay of numerous different parts and systems inside the building and site as part of a whole building solution. India's rural housing need is estimated to be 44 million units. The urban housing shortfall in India is 18.78 million units, with 96 percent of them belonging to the Economically Weaker Section (EWS) and Low Income Group (LIG) categories. As a result, given India's severe housing scarcity, rapid strategies for timely and cost effective execution of construction projects, such as the use of alternate building materials and fast construction processes, are critical. One of the inventive methods to solve this difficulty is the use of Glass Fiber Reinforced Gypsum (GFRG) panels (also known as the fast wall). This product was developed and has been used for mass scale building construction in Australia since 1990. GFRG Panels are made from gypsum, which is widely available as a waste product from the industrial sector. These lightweight panels are fire resistant, thermally insulated, earthquake tested waterproofed, rot resistant, termite resistant, and 100 percent recyclable, making them ideal for eco friendly or green architecture.

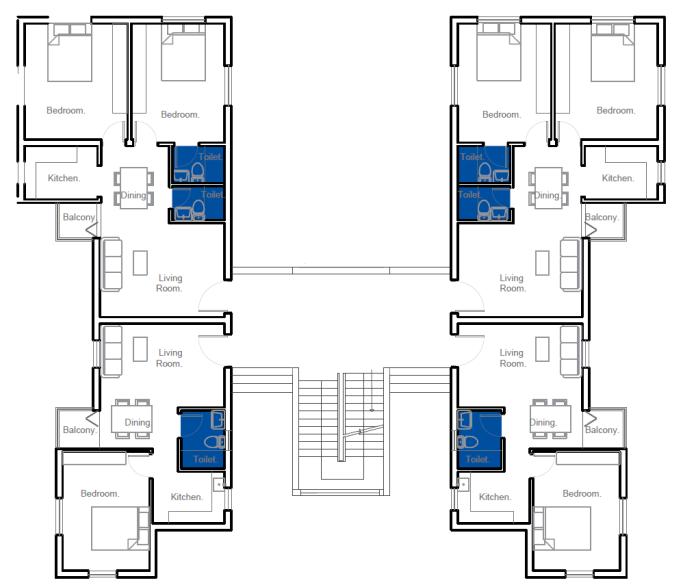

This article compares the use of GFRG panels in the Indian building industry to traditional construction technologies on the basis of numerous functional, structural, and economic considerations, utilising Autodesk Revit Architecture to create a 3D model and Primavera to schedule the project. Preparation of an estimate using Microsoft Office Excel and a thorough drawing using Autodesk Autocad, as well as the installation of solar panels as a sustainable energy source and the creation of a vertical garden to enhance interior air quality.

Keywords Green Building, Revit Architecture, GFRG Panels, Primavera, Autocad, MS Excel, Solar Energy, Vertical Garden.

I. INTRODUCTION

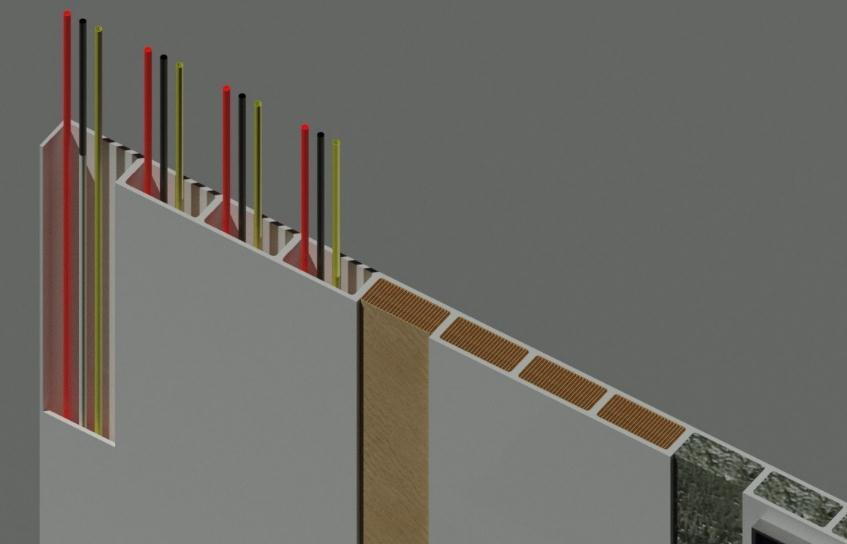

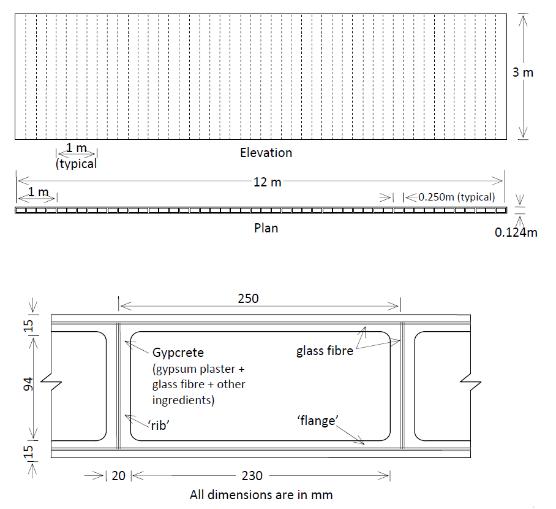

Everyyear,theneedfortraditionalmaterialssuchasclay,sand,stone,gravels,cement,brick,block,tiles,distemper,paint, lumber, and steel, which are employed as important construction components in the housing sector, grows. The cost of construction materials is gradually rising. It is also vital to discover functional/innovative replacements for traditional building materials in the construction sector due to high transportation costs of these raw resources, demand, and environmentalconstraints.Thekeychallengesfacingthemasshousingsectortodayarereducingtheuseoftheseenergy intensive construction materials and delivering housing units quickly and at a reasonable cost. Buildings made of green buildingmaterialGlassFiberReinforcedGypsum(GFRG)panelsholdpromiseasaquick,economical,andlong termmass housingsolution.GFRGPanelsare prefabricatedtoasizeof12mlength,3mheight,and124mmoverallthickness(with cavities) and are relatively light weight (44 kg/m2). They are made of calcined gypsum and reinforced with glass fibres. Theyareprefabricatedtoasizeof12mlength,3mheight,and124mmoverallthickness(withcavities).Thesepanelscan becuttoanysizeneeded.Therearefourcellsineach1.0msegmentofthepanel(cavities).Eachcellis250mmbroad,124 mmthick,andhasa230mmx94mmhollow.Thecavities/createdcellswithinthepanelcanbeutilisedtohousebuilding services such as plumbing and electrical conduits, or they can be filled, partially filled, or left empty depending on the structural requirements. To enhance strength and ductility, the panel has chambers that may be filled with concrete and reinforcedwithsteelbars.

Theload bearingcapacityoftheseintegratedcompositeGFRGpanelsisupto8 10storieswithouttheusageofbeamsand columns.Although these panelsaremostcommonlyutilisedin wall construction,theycanalsobeemployedinfloor and roofslabswhencombinedwithreinforcedconcrete.

Monocrystaline solar panels are used. Monocrystalline silicon, also known as single crystal silicon and abbreviated as mono c Si or mono Si, is the foundation material for silicon based discrete components and integrated circuits found in almost all modern electronic equipment. Mono Si is also used in the production of solar cells as a photovoltaic, light absorbingmaterial.

Topreserveahealthyatmospherebothwithinandoutsidethebuilding,averticalgardenhasbeenbuilttothebuilding's outside facades.Vertical gardenscan buildon thisconcept by'naturally' blockinghigh frequencysounds.With a layerof air between the plants and the wall, these walls act as additional insulation. They also have the ability to reduce noise levelsbyrefracting,reflecting,andabsorbingacousticradiation.

II. AIMS & OBJECTIVES

The purpose of this research is to examine and evaluate the possibilities of GFRG wall panels in the Indian construction industryusingperformancemetrics.Toachievethisaim,thefollowingaretheobjectives

1. On the basis of the identified parameters, compare the GFRG panel construction system to the RCC frame constructionsystem.

2. Estimates,scheduling,anddetaileddrawingswereusedtoinvestigatetheutilisationoftheGFRGPanelsystem.

3. Installationofa solar energysystemanda vertical gardensystemintheGFRGbuildingona budgetthatwassaved Whencomparedtotraditionalconstructionmethods

III. AREA OF STUDY

The total planning, coordination, and control of a construction project from start to finish is known as construction management. It is a professional service that oversees the planning, design, and construction of a project from start to finish,employingspecificprojectmanagementtechniques.Constructionmanagement'sgoalistokeepaproject'stimeline, budget, and quality under control. Time, quality, and cost are all factors that affect project management success. This trianglehasspawnedaslewofotherbuildingsystems.InAustralia,theGFRGsystemwasoneofthesesystems.Itisawall panelmadeofphospogypsum,whichiswidelyaccessibleasawasteproductfromchemicalandfertiliserplants.Itsgoalis to achieve long term growth. The goal of this project is to undertake a detailed research of GFRG panels in terms of constructionmanagementintermsofcostandtimebydetailedactivityscheduling,aswellastocomparetheseaspectsto traditionalbuildingsbyimplementinginareal worldsetting.

International

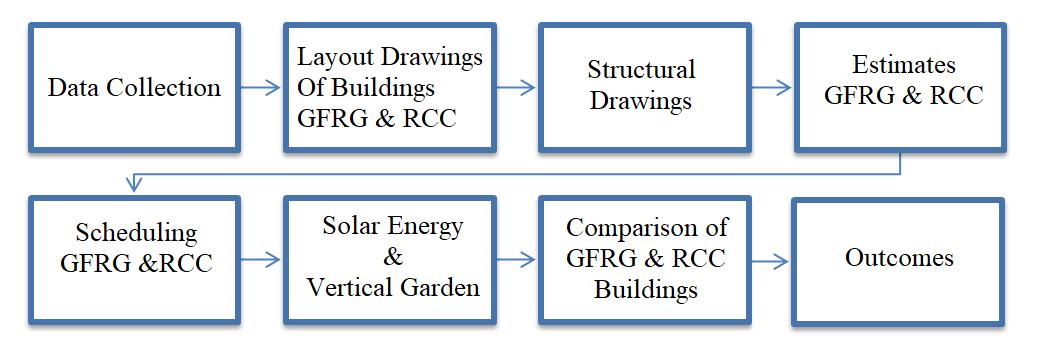

IV. METHODOLOGY

Following

1.Data Collection

manufacturing

the

Preparation of detailed layout drawings for GFRG building and RCC building

2.Layout Drawings of GFRG

usingAutodeskAutocad.

3.Structural Drawings Preparation of structural drawings for GFRG building and RCC building by using Autodesk Autocad.

4.Estimate GFRG & RCC Building Preparation of detailed estimate for GFRG building and RCC building by using MS Excel.

5.Scheduling GFRG & RCC Buildings Preparation of detailed scheduling for GFRG building and RCC building by using Primavera.

6.Solar Energy & Vertical Garden Provision of solar energy system and vertical garden system in GFRG building (ManualCalculation&PreliminaryEstimate)

7.Comparison of GFRG & RCC Building - ComparisonofGFRGbuildingandRCCbuildingwithVariousparameters.

8.Model Preparation Using Autodesk Revit,

9.Outcomes

a 3D model of the GFRG building with a sustainable energy source

GFRGBuilding

RCCBuilding.

V.

1. RAPID AFFORDABLE MASS HOUSING USING GLASS FIBRE REINFORCEMENT

Devdas Menon [2014] described a structure constructed at IIT Madras. The structure is built up of GFRG Panels, which are made up of mineral, usually in the form of phosphogypsum, a waste by product of the fertiliser industry, and glass fibre as a reinforcing agent, which increases the panels' strength. The building panels are suitable for affordable mass housing, offering cost effectiveness and speed of construction. GFRG panels have cellular chambers betweentheouterflangesandtheinteriorribs,which maybestuffedwithconcreteandreinforcedwithsteel barsif necessary to achieve the requisite load bearing capability. In low to moderately unstable zones, buildings designed usingthistechniquewithnocolumnsandbeamswillgoallthewayupto8to10storeys,andinhighunstablezones, toa lowerheight.Electrical wiringandalternateplumbingoperations might beconcealedin thevacantholes within thepanels.

The use of GFRG Panels in building construction is a novel concept.This construction approach makes a major step towards sustainable living by lowering the negative environmental effect that is commonly associated to traditional constructiontechnologies.

2. CRITICAL REVIEW OF USE OFGLASS FIBRE REINFORCEMNT GYPSUM [GFRG] PANELS IN HOUSING IN INDIA

Kuldeep Kumar [2020] describedGFRGPanelsaremadefromgypsum,whichiswidelyavailableasawasteproduct from the industrial sector. These lightweight panels are fire resistant, thermally insulated, earthquake tested waterproofed,rot resistant,termite resistant,and100percentrecyclable,makingthemidealforeco friendlyorgreen architecture.theutilisationofGFRGpanelsintheIndianbuildingsectorbycomparingthemtotraditionalconstruction systemsusingavarietyoffunctional,structural,andeconomiccriteria.

3. PERFORMANCE EVALUATION OF VERTICAL GARDENS

Ratih Widiastuti [2016] describesAfieldmeasurementwastakenwiththeobjectiveofresearchingtheeffectiveness ofusingverticalgardenstoreducesurfacetemperatureintheinsideofabuilding'sfacade.Theinitialstudywasbased on measurements of the interior façade thermal efficiency of vegetated and bare facades of the Pertamina branch office building in Semarang.The results showed that the plant layer on the façade successfully decreased the inner surface temperature on the façade. The internal surface temperature of the vegetated façade was always lower than the naked façade, as can be observed. The thermal lag of the vegetated façade was similarly slower than that of the nakedfaçade,indicatingthatitmightbeadvantageoustominimisecoolingdemandsduringpeakhours. Whentheair temperatureclimbed,theeffectivethermalresistanceofaplantlayersteadilyreduced.

4. A POWER CASE STUDY FOR MONOCRYSTALINE AND POLYCRYSTALLINE SOLAR PANELS

According to Ali Vardar [2016], Solar energy is most commonly employed in the form of polycrystalline and monocrystallinepanels,eachhavingitsownsetofcharacteristicsandefficiency.Climateconditions,thetypeofsolar cells employed, and other factors all affect the effectiveness of photovoltaic panels, according to this study. For monocrystalline and polycrystalline solar panels, the daily average efficiency was 6.65 percent and 5.38 percent, respectively.Morestudyisneededtofigureoutwhichprecisefactorstriggereachtypeofcancer.

2395

The

resultinginfoundationsavingsandreduceddesignfor seismicstresses,especiallyinmulti storybuildings.

constructionhasthe

/LIMITATIONOFGFRGBUILDINGSYSTEMS:

traditionalconstruction.

Tobuildahouse

this

alotofexperience.Thesepanelsrequireslightlydifferenthandling, mounting,andequipmentthan

typepanels.

the Panels are customised to the design (including

no adjustments may be made during the installationprocess.

such as a crane

required to construct

using the GFRG panel method. Furthermore, crane movementnecessitatesalargeamountofareasurroundingtheplot.

When storing the panels, extra caution is required. In addition, compared to cement/blocks, more room is required. Thismakesafull scaleadoptioninIndiaproblematic(masshousingoraffordablehousing).

Curvedwallsordomesarenotsuitedforthepanels.Usemasonry/concreteforthatspecificlocationifitisrequired.

VII. RESULT

RCC

COST OF BUILDINGS

Because

GFRG

Because

International

Technology

ISSN:2395

ISSN:2395 0072

With the inclusion of a solar energy system and a vertical garden, the cost of the GFRG building is estimated to be Rs. 81,82,664/ ,saving Rs. 121336/

Even after factoring in the cost of a solar energy system and a vertical garden system, the cost of constructing a GFRG Building is less than the estimated cost of constructing an RCC building, demonstrating that GFRG Buildings are more sustainable,cost effective,time efficient,andenvironmentallyfriendly.

VIII. CONCLUSION

During this study, a thorough examination, assessment, and analysis of the GFRG Panel based construction system was conducted,leadingtothefollowingconclusions:

Environmental Benefits: Reducewaterwaste,Protectbiodiversityandecosystems,Conservenaturalresources,Improve airandwaterquality,Protectbiodiversityandecosystems

Benefits to the Economy: Lower operational expenses, Increase occupant productivity, Create a market for environmentallyfriendlyproductsandservices.

Benefits to society: Improve quality of life, Reduce demand on local infrastructure, Improve occupant health and comfort

Thismethodmaybeappropriateforlow costhousingorEWS,aswellassituationswhererapidconstructionisnecessary. It's a suitable option for rehabilitation housing, temporary housing (in the event of a natural disaster, for example), or whenthere'sahighneedforaccommodationinashortperiodoftime.

Evenifthedwellingunitsareready(inashorttime)inisolation,theentireprojectcannotbeoperationalintheabsence of external ancillary and supporting services, according to the completion of the overall project, which includes the infrastructureandexternaldevelopmentrequiredforaprojecttobecomeoperational(drainage,electricalsupply,water supply, storm water, roads, etc.). As a result, if this technology is to be employed in large scale housing developments whereexteriordevelopmentiscritical,additionalplanningisnecessary.

IX. REFERENCES

[1] Kuldeep Kumar (2020) Critical Review of use of Glass Fiber Reinforced Gypsum (GFRG) Panels in Housing in India, International Journal of Engineering Research & Technology (IJERT) ISSN: 2278 0181 http://www.ijert.org

IJERTV9IS020407Publishedby:www.ijert.orgVol.9Issue02,February 2020

[2]GlassFibreReinforcedGypsumPanelSystem,BuildingMaterials&TechnologyPromotionCouncilMinistryofHousing &UrbanPovertyAlleviationGovernmentofIndia.

[3] BMTPC, 2014. Prospective Construction

Mass Housing. Building Materials & Technology Promotion Council.

[4] Ratih Widiastuti1;_, Eddy Prianto2 and Wahyu Setia

Performance Evaluation of Vertical Gardens International JournalofArchitecture,

No

March2016,13 20

[5] Use of Glass Fibre Reinforced Gypsum (GFRG) Panels in Buildings STRUCTURAL DESIGN MANUAL Structural Engineering Division Department of Civil Engineering IIT Madras Published by Building Materials & Technology PromotionCouncilMinistryofHousing&UrbanPovertyAlleviationGovernmentofIndia

Monocrystalline and Polycrystalline Solar Panels, International Journal of Photoenergy

[6] Ali Vardar, A Power Case Study

Article

RAPIDANDAFFORDABLEMASSHOUSING,SCHEDULEOFITEMS & RATEANALYSIS

[7]GFRGBUILDING

GFRG

978

928379 2 5August,2015