Optimizing Process Parameters on SR and MRR of Steel by EDM

Hussain

Abhishek Thakur

M.Tech Scholar,Department of Mechanical Engineering, Universal Institute of Engineering Technology, Lalru

Institute of Engineering Technology, Lalru

Abstract: Electric discharge machining (EDM) is a successful non conventional machining technology that is chosen for cutting hard materials, geometrically complicated products, microscopic holes, and other challenging applications. EDM, on the other hand, cannot be used to manufacture non conductive materials. It is the purpose of this paper to examine the practical impact of different Electric Discharge Machining process parameters on surface roughness (SR) and materials removal rate in a manufacturing setting (MRR). It was decided to machine the SS 316 steel samples with a Copper electrode and to measure the flushing pressure, discharge current, pulse off time, and pulse on time as process parameters for the experiment. In this article, stainless steel 316 workpiece was employed using Taguchi L18 design to perform tests on electrical discharge machine (EDM) (EDM). Pulse on time (Ton), Current (A), and Voltage (V) are treated as separate factors and optimize the response variables material removal rate (MRR), tool wear rate (TWR) and surface roughness (SR) (SR). Analysis of variance (ANOVA) and signal to noise (S/N ratio) was performed to figure out optimal independent parameters and their values.

Keywords: ElectricDischargemachining;MaterialRemovalrate;Surfaceroughness;ANOVA.

Abbreviations:MRR:MaterialRemovalRate,TWR:ToolWearRate,SR:SurfaceRoughness

1. Introduction:

Innovative manufacturing principles such as acoustic, chemical, mechanical, and electrons are used in non conventional machining processes. Increasingly difficult to manufacture materials are being developed as the industry progresses, with a high strength to weight ratio and a broad variety of uses in semiconductors, nuclear power, and aerospace engineering, among other fields of endeavor. EDM has taken the role of grinding, drilling, rolling, and other conventional machining methods, and it is capable of machining difficult to machine materials such as heat treated tool steels, heat resistant steels, composites, ceramics, and so on. It is often used in the processing of difficult to machine materials such as temperature resistantmetals.

Strake and Husova [1] studied the effects of various EDM settings on MRR and Tool Wear Rate (TWR) on tool steels (ENX210Cr12), using copper as the electrode. The results showed that copper had the greatest influence on MRR and TWR. Ton,dischargecurrent,TOFF,andgapvoltagewereselectedastheinputparametersforthisexperiment.Thecombinationof thesecomponentshadasubstantialimpactonthemagnitudeofthecrater.AstudyconductedbyKumaretal.[2]evaluatedthe impact of EDM parameters such as gap voltage, discharge current, and other variables on the machining of AlSi420 stainless steel. The output responses that were recorded were the MRR and TWR values. Taguchi and Taguchi grey techniques were utilizedtooptimizethecontrolvariablesofthemachineunderconsideration.Khan[3]investigatedthemechanicalresistance and thermal conductivity of an aluminum oxide/copper composite. The experiment was optimized with the help of the L8 Orthogonalarray.ThemachiningparametersEDMTON,TOFF,current,andvoltagewereselectedbasedontheirperformance. SurfacemorphologyandcompositeanalysiswereinvestigatedusingSEMandEDXtechniques.

ResearchersRaoetal.[4]lookedattheexperimentalfindingsofcanolaoilbeingusedasadielectricontheMRRandTWR.The input machine parameters selected were the pulse on time, the gap voltage pulse off time, and the pulse on time. Electrodes madeofcopper,brass,andtungstenwereusedinthisexperiment(alloy).Vimalaetal.[5]performedanexperimentalinquiry inwhichcopperwasusedasanelectrodetomanufacturehotdiesteel,andtheresultswerepublished.InEDM,theparameters thatareemployedincludecurrent,tone,voltage,andmagneticfield.TheoutputreactionsMRR,SurfaceRoughness(SR),and TWR are examples of the types of reactions. Verma and Sajeevan [6] used a L9 orthogonal array to optimize parameters in EDMusingtitaniumAlloyGrade V,andtheresultswerepromising(Ti6Al4V).Asignificantamountofenergyisreleasedasa resultofhighvoltageandpulseontimecombinedwithlowdielectricfluidpressure,causingthetemperaturetoincreaseanda

Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

09 Issue:

p ISSN:2395 0072

deepercratertoformonthesurfaceoftheplanet.AstheTongrew,theMRRandSRincreasedaswell,owingtothefactthat thesparkstayedincontactwiththeworkpieceforagreaterlengthoftime.

Dhar and Purohit [7] utilized the PS LEADER ZNC EDM machine to compute the MRR and TWR on Al 4Cu 6Si alloy 10wt percentsiCpcompositesusingtheMRRandTWRformulas.Karthikeyanandcolleagues[8]performedresearchanddeveloped a mathematical model to predict the effects of current, pulse length, and SiC volume percent on the performance of a semiconductor laser. The ANOVA test was used to evaluate the whole factorial design with three levels. Mohan and Satyanarayana[9]studiedtheeffectsofdischargecurrent,pulselength,andelectroderotationontheM.R.R.,T.W.R.,andS.R. electrodes,aswellastheeffectsofelectroderotationontheT.W.R.andS.R.electrodes.AccordingtoNarenderSinghetal.[10], theimpactofdischargecurrent,Ton,anddielectricpressureonthemagneticresonanceresonance,time domainreflectance, taper(t),S.R,andotherparameterswasexamined.Soveja etal.[11]investigatedthesurfacelasertexturingof TA6Valloy in furtherdetail.TaguchiandRSMweretheexperimentalapproachesusedinthisstudy.Itwasdecidedtodevelopanempirical model to evaluate the link between operational parameters and performance indicators such as the standard deviation and meanrelativedeviation(SDR).ItiscriticaltoevaluatetheMRRandSRfeaturesinthisresearchsincetheyhaveanimpacton machiningperformance.Itwasdecidedtoutilizestainlesssteel316gradeforthisinvestigationsinceitincludes18percentCr and8 10percentNi.Itissometimesreferredtoas18 8stainlesssteelaccordingtothecompositionofthesteel.Thematerial is non magnetic at room temperature, but following exposure to cold, its structure changes to martensite and the material becomes weekly magnetic. It has a high level of resistance to corrosion caused by the environment. Ton, Toff, discharge current, dielectric pressure, gap voltage, and other essential machining parameters, such as corrosion, are all discussed in detailinthissection.

2. Methodology and Work Plan:

ItwasdecidedtoemployanEDMmodelofthediesinkingtypewithaservoheadfortheexperiment.Thepositivepolarityof the electrode is attached to it. In order to perform experiments, a round electrode with a diameter of 2.5 mm is employed. Different stages in positive polarity were subjected to different levels of discharge current application. The stainless steel is being utilized for the experiments. The stainless steel 316 grade is often chosen since it is commonly seen in daily life. The mechanicalandchemicalcharacteristicsofstainlesssteelarementionedinthefollowingtable.

shown in

Table3.PilotStudyInputandOutputResponsesValues

varietyof

190.3 18.98

3 as a

515.7 23.45

915.8 19.23

1050.3

1180.8 15.67

1320.33 15.65

1610.9 10.67

1515.1 11.48

1480 11.90

theS.R.

M.R.R.Thisgraph

when current

M.R.R.

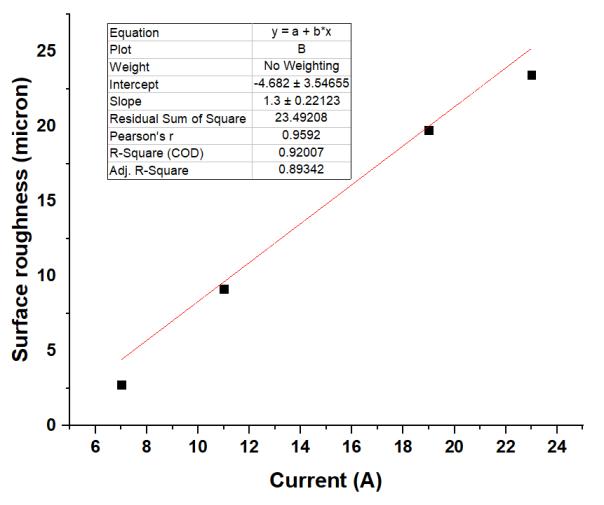

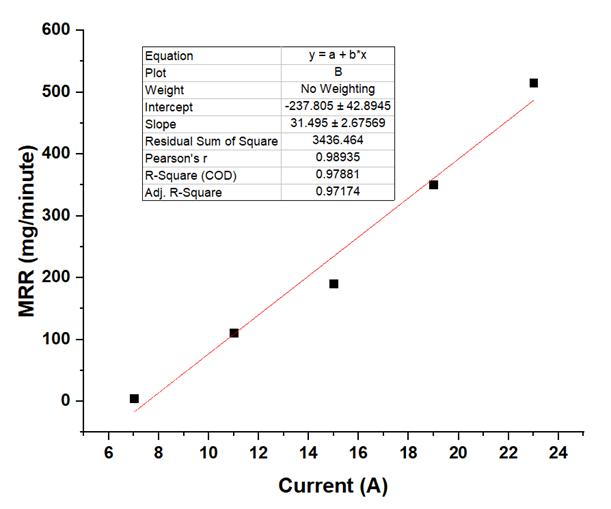

the amount of current, the greater the material removal rate discovered in the pilot research analysis, according to the graph. This happens because an increase in current causes a rise in the intensity of the spark, which results in an increase in temperature. As a result, the material is removed by the process of melting and vaporization. According to the results of the pilot research, surface roughness (SR) riseswithanincreaseincurrent,andaloweramountofcurrentsuggestsalowerlevelofsurfaceroughness.Thishappensasa result of an increase in spark intensity, which results in a huge discharge energy and an increase in surface roughness.

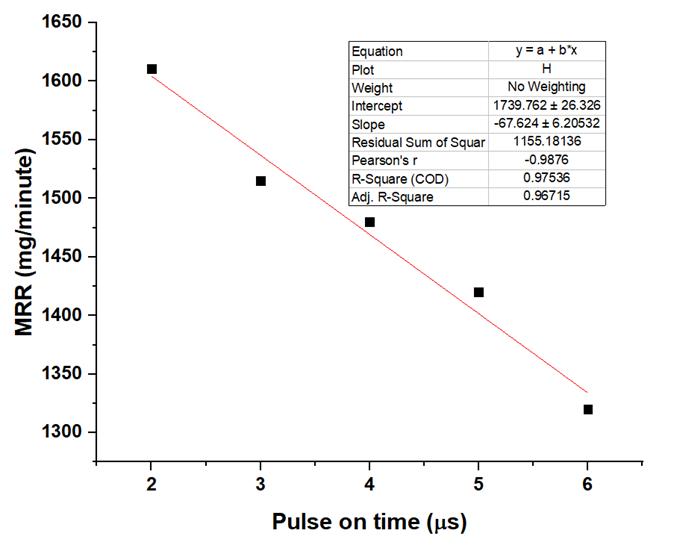

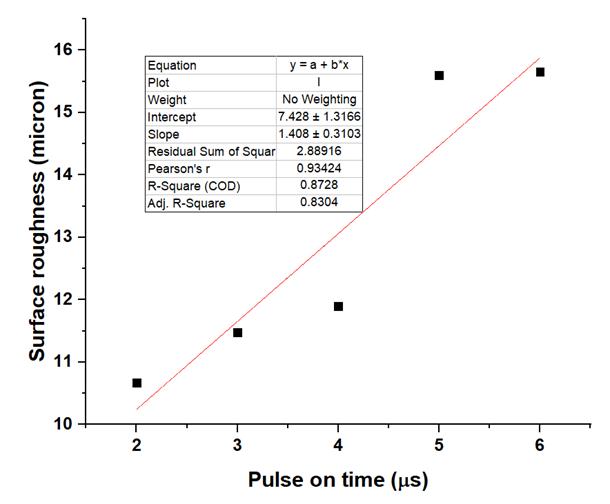

removalratehappensinEDMasaresultofthemeltingandvaporizationofthematerialinsuccessivephases, which resultsintheformationofcratervolume.TherelationshipbetweenpulseontimeandMRRhasbeenestablishedasaresultof the pilot research testing. With a rise in Ton, the M.R.R. lowers as a result of a reduction in the intensity of the spark, which resultsintheexpansionoftheplasmachannel.Ifthepulseontimeislonger,morecurrentwillflow,resultinginanincreasein SR and a degradation in the quality of the surface. Therefore, the optimal value of the pulse on time is required while doing tests;otherwise,theexperimentswouldfail.

International

09

3.1. Effect of MRR

Engineering

Technology (IRJET)

ISSN:2395 0056

ISSN:2395

SincesparkenergyincreasesasaconsequenceoftheincreaseinthevalueofTon,therateofmaterialremovalincreaseswhen thevalue of Ton islow. Material removal ratedecreasesasthe valueofTon, M.R.R. israised becausethe inter electrodegap andenergytransferhidersareimpeded,resultinginafallinmaterialremovalrate.Ton,M.R.R.isaconstantvalue.

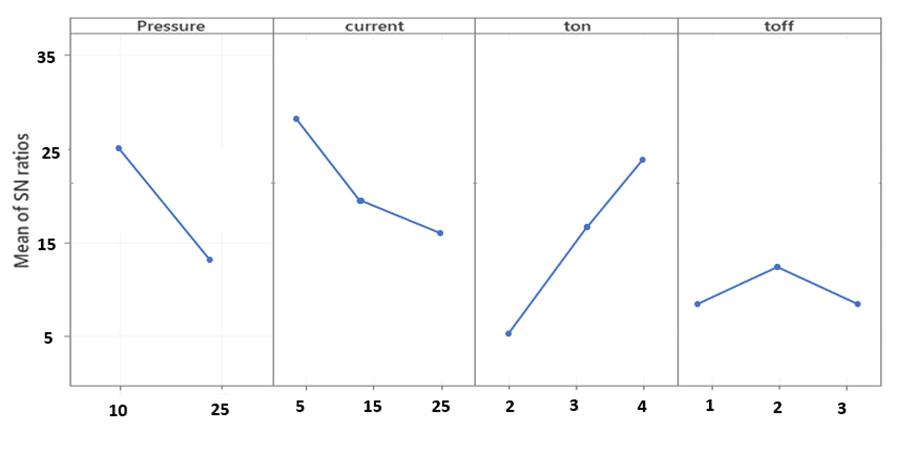

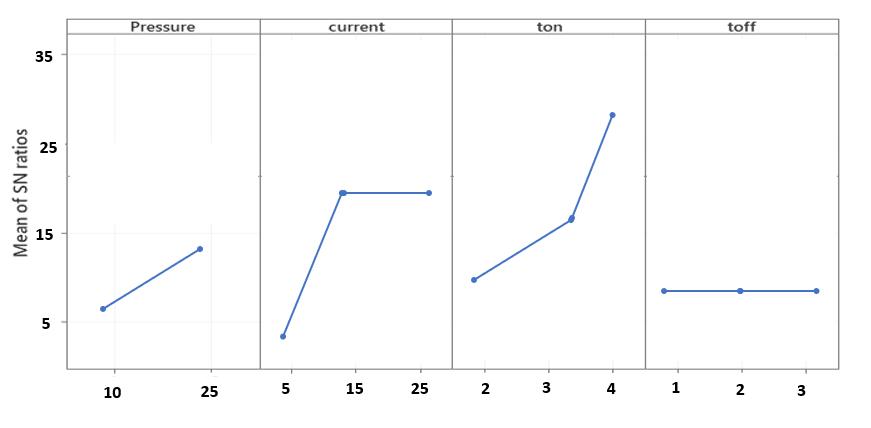

Fig.5 Maineffectplotformean.

Fig.6MaineffectplotforS/NRatio:

Figure 6 shows that the ton and discharge current are the significant parameters that have the greatest influence on the material removal rate (MRR). As the current increases, the material removal rate increases due to the increasing spark intensity,andthematerialisremovedbymeltingandvaporization,asshowninthepreviousparagraph.Thematerialremoval ratereduces asthepulseon timeisincreased becauseit extendsthewidthof theplasma channel,whichresultsina dropin the material removal rate as the pulse on time increases. It is possible that the dielectric pressure has some impact on the material removal becauseasthedielectricpressureincreases,thedebristhatisremovedstopsthematerial fromsolidifying. Theamountoftimebetweenpulseshasnomajorimpactontheoutcome.AnalysisofVariance(ANOVA)forsurfaceroughness shows that the lesser the value, the better. From the table above, it can be seen that Toff has the least impact on the S.R. currentandTonhasthemostsignificantinfluence.

ISSN:2395

CONCLUSION

TheM.R.R.andS.R.ofstainlesssteelsareinvestigatedinthisstudy,whichmakesuseofaflatbasecoppertool.Thedischarge current, Ton, Toff, and dielectric pressure are the machining parameters that will be used for the tests.. The L18 orthogonal arraywasappliedwiththehelpoftheMinitabprogram.ByusingANOVA,theresearcherswereabletoconfirmtheirfindings. The MRR is significantly influenced by the discharge current and the Ton. Toff is the person who has the least amount of influence. Becauseoftheincreaseindischargecurrent,thestrengthofthespark rises,whichcausesthetemperatureto rise, resultingintheremovalofmaterial,whichtakestheshapeofcavities,viatheprocessofmeltingandvaporization.

References

[1]Straka,Ľ.andHašová,S.,2018.OptimizationofmaterialremovalrateandtoolwearrateofCuelectrodeindie sinking EDMoftoolsteel.TheInternationalJournalofAdvancedManufacturingTechnology,97(5),pp.2647 2654.

[2] Kumar, S., Ghoshal, S.K., Arora, P.K. and Nagdeve, L., 2021. Multi variable optimization in die sinking EDM process of AISI420stainlesssteel.MaterialsandManufacturingProcesses,36(5),pp.572 582.

[3]Hussain,M.Z.andKhan,U.,2018.EvaluationofmaterialremovalrateandelectrodewearrateindiesinkingEDMwith toolmaterialAl2O3/CucompositethroughTaguchimethod.InternationalJournalofMaterialsEngineeringInnovation, 9(2),pp.115 139.

[4] Rao, K.M., Kumar, D.V., Shekar, K.C. and Singaravel, B., 2020. Experimental analysis of canola oil as dielectric fluid in electricdischargemachiningofAISID2Steel.InMaterialsScienceForum(Vol.978,pp.49 54).TransTechPublications Ltd.

[5] VIMALA, N., RAO, C. and REDDY, C.V.S., 2018. Optimization of Process Parameters using Taguchi Method While MachiningH13HotDieSteelMaterialonDieSinkEDM.

[6]Verma,V.andSahu,R.,2017.Processparameteroptimizationofdie sinkingEDMonTitaniumgrade Valloy(Ti6Al4V) usingfullfactorialdesignapproach.Materialstoday:proceedings,4(2),pp.1893 1899.

[7]Dhar,S.,Purohit,R.,Saini,N.,Sharma,A.andKumar,G.H.,2007.Mathematicalmodellingofelectricdischargemachining ofcastAl 4Cu 6Sialloy 10wt.%SiCcomposites.Journalofmaterialsprocessingtechnology,194(1 3),pp.24 29.

[8]Karthikeyan,R.,Narayanan,P.L.andNaagarazan,R.S.,1999.Mathematicalmodellingforelectricdischargemachiningof aluminium siliconcarbideparticulatecomposites.Journalofmaterialsprocessingtechnology,87(1 3),pp.59 63.

[9] Mohan, B., Rajadurai, A. and Satyanarayana, K.G., 2002. Effect of SiC and rotation of electrode on electric discharge machiningofAl SiCcomposite.JournalofMaterialsProcessingTechnology,124(3),pp.297 304.

[10]Singh,P.N.,Raghukandan,K.,Rathinasabapathi,M.andPai,B.C.,2004.ElectricdischargemachiningofAl 10%SiCPas castmetalmatrixcomposites.Journalofmaterialsprocessingtechnology,155,pp.1653 1657.

[11] Soveja, A., Cicală, E., Grevey, D. and Jouvard, J.M., 2008. Optimisation of TA6V alloy surface laser texturing using an experimentaldesignapproach.OpticsandLasersinEngineering,46(9),pp.671 678.