International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

1PG Scholar (Structural Engineering)

2Professor & HOD (Civil Engineering Department)

CHALAPATHI INSTITUTE OF TECHNOLOGY, ANDHRA PRADESH, INDIA. ***

ABSTRACT:-Theworldisfacingchallengesindeveloping the infrastructure to meet the expectation of the growing population. The demand for concrete is very high. Production of concrete results in a rapid increase in demand for aggregates, natural resources of aggregates are depleting at an alarmingly fast rate. Thus, there is an urgent need to look for an alternate source of aggregates. This waste causes severe environmental and health hazardsafterbeingdumpedinlandfillsandopenland.

There is a need to comprehensively study sandstone cutting wastes in concrete from strength and durability considerations. The present study explores the possibility of using sandstone cutting waste as a partial replacement of fine aggregates with varying w/c ratios to represent all grades of concrete. Microstructural studies have further elaborated concrete's rheological, mechanical, and durabilitypropertieswithsandstonecuttingwaste.

Thestudywasconductedbypreparingthirty-oneconcrete mixes using four different w/c ratios, i.e., 0.3, 0.35, 0.40, and 0.45, and all concrete mixtures were designed according to provisions laid in IS 10262-2009. The fine aggregates were replaced by 10%, 20%, 30%, 40%, 50%, and 100% sandstone cutting waste (SCW), besides an additional mix proportion of 25% for a w/c ratio of 0.35, 0.4,and0.45wasalsoprepared.Themechanicalattributes of concrete with SCW in view of compressive strength, flexure strength, and tensile strength have shown encouraging results. There was an increase in strength of concrete samples up to an optimum level of 30% replacement of sandstone cutting wastes compared to the controlconcrete.

Concrete is utilized to a great extent worldwide as a fast consuming material in construction, made up of cement,fineaggregates,coarseaggregates,andwater.The development of any nation depends upon construction

activities which have been increased tremendously in a few decades, resulting in an encouraging demand for concrete. Extraction and mining of natural aggregates are rapidlyincreasingtocatertothedemandforproductionof concrete,whichfurtherresultingindepletionofresources, causing accumulation of stone wastes and slurry wastes. Thesewastesarebecomingdumpingyardinthevicinityof the mining area and further emission of dust causing the associated occupational exposure, deteriorates the baseline respiratory health status of workers and nearby human-being. Continual depletion of these natural resourcesimposingthreatsassociatedwiththedisposalof waste and health hazards, further indicating necessary utilization of the sustainable waste materials as a substitute for conventional fine and coarse aggregates in concrete. Raw materials like coarse aggregates and fine aggregates comprising 70%–80% of the concrete volume are the most important constituents of concrete, the studieswerecarriedoutinoptimizingofsustainablewaste materials in concrete based on various researchers’ findings.Varietyofwastematerialsincludingsludgewaste, groundgranulatedblastfurnaceslag,Kotastoneslurry,fly ash, granite powder, limestone slurry, ceramic waste & rubber waste, marble powder isbeingutilized inconcrete production. Crushed rock dust acts as a filler and helps to reducethetotalvoidsinconcrete

Thesewasteshaveshownaidedbenefitsonproperties of concrete and these include improvement in performance in terms of mechanical aspects as well as durabilityaspectsofconcretebesidesconservingearthlife balance&eco-friendlyapproachinconstruction.

Theuseofwastematerialsinplaceofvirginmaterials results in considerable energy savings by reducing the various engineering process for manufacturing the end product.

Sandstone have variation in composition depending uponlocations,types&theiroccurrenceandtheireffectis

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

observed differently towards the compressive strengths. The compressive strength of concrete comprising of sandstone approximately reduces 50% owing to clay content while the presence of carbonates in sandstones resultsinbetterlinksbetweencementpasteandaggregate withfurtherimprovementinstrength

Nominal strength is significantly affected by ageing & size effect of sandstone & different sizes of sandstone wouldhaveavariableeffectoncorrespondingstrengthby taking consideration of correct grading analysis of sandstone.

Preliminary studies of Compressive strength indicate increasingtrendswhileusingquartzsandstoneaggregates for varied ratios of combined aggregates, however, the strength decreases after achieving specific gradation owing to an increase in void spaces in bigger size aggregatesandsegregation.

Variation of strength properties of crushed limestone sandconcreteunderhightemperaturewasverysimilarto thatofnaturalsandconcrete

Quantity of sustainable stone fillers & powder waste generation has increased tremendously to a large extent . The cutting wastes of sandstone exclusively account for 30%oftheminingwastereserves.Sandcanbereplacedby rock flour up to 40% without affecting strength and workability.

The above literature studies suggest the influence of different sustainable waste on concrete properties and further coarse aggregates of quartz sandstone were utilizedbymanyresearchersinpastsotheauthorhasfelt toattempt the useoffine aggregatesinform ofsandstone cutting waste with objectives of the economy to scale in construction, conserving river beds and sustainable development.

Materials utilized in research:-

Cement :-Portland Pozzolana Cement confirming to IS 1489:2015 (Part-1) was utilized in our research program forallconcretemixesdesignedinthelaboratory.

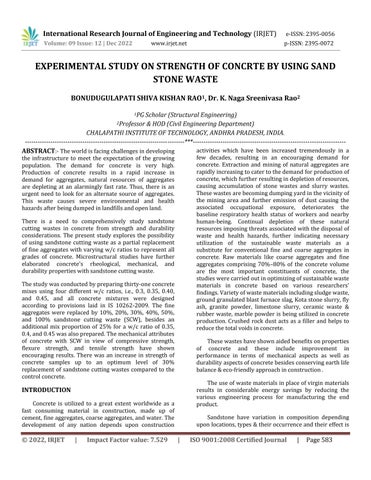

Fine Aggregates (Natural Sand and Sandstone Cutting Waste) :-Fine aggregates used in studies are River sand andSCW.

Figure 1 Graphs showing gradation of studied fine aggregates

Table 1 Chemical Composition of SCW and River Sand

Chemical Composition (%) by weight Chemical Compound SCW Natural Sand

SiO2 94.68 80.78

CaO Nil 3.21

Al2O3 0.24 10.52 Fe2O3 4.90 1.75

MgO Nil 0.77 LossonIgnition (LOI) 0.17 0.37

Coarse Aggregates:- The crushed aggregates of 20 mm and 10 mm were used in concrete obtained from a local crusher in, and the sampling was carried out as per IS 383-2016. Coarse aggregates were tested for gradation, moisture, impact value, and other tests as per the codal provisions for making concrete mix proportion. Most of theconcretemixestestedusingdifferentw/cratioshadan approximate 60% proportion of 20 mm size and 40% proportionof10mmsizecoarseaggregates.

Chemical Admixture :- ThepercentageincreaseofSCWin concrete mixes indicates the workability loss due to the demand for higher water than natural sand. The loss of workability in concrete mixtures was improved by incorporating the modified polycarboxylic ether (Master Glenium SKY 8233) with a relative density of 1.08 and

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

0.1% chloride content as per the specification of IS 91031999.

Water:- The water utilized for all concrete mixes was clean and potable and free from impurities such as suspended solids, organic matter, dissolved salts, and the requirementspecifiedinIS456-2000.

Description of Mix Proportion:- The research methodology comprised of detailed analysis by using the followingapproach:

Water/cement ratio proposed in the research Seriesof0.3,0.35.0.4and0.45w/cratios.

Chloride Penetration

3sample(50x100) 28days

Water permeability 3cubes(150×150×150) 28days

Water absorption Sixcubes(100×100×100) 24hrs. Carbonation 12cubes(100×100×100) 28days Acid resistance Sixcubes(100×100×100) 28days

Sulphate resistance 9cubes(100×100×100) 28days

Fine aggregates (river Sand) were replaced in experimental program at interval of 0%, 10%, 20%, 30%, 40%, 50% and 100% by SCW. The replacementpercentagewasdecidedbasedonthe trendsshownbytheliteraturesurveyandfurther thetrial testingcarriedout inthelaboratory with varying w/c ratios for understanding the effect of SCWonconcreteproperties.SCWmixeswith25% replacementwerealsopreparedexceptat0.3w/c ratios.

Table 2 Test samples matrix for mechanical attributes of concrete

Test Samples each mix Curing Period

Compressive strength 9cubes (100×100×100) [7,28and] [90days]

Splittensile strength 6cylinders(150×300) [28days] [90days] Flexural strength 6Beams (100×100×500) [28days], [90days]

Table 3The test samples matrix for durability attributes of concrete

Test Samples for each mix CuringPeriod

Abrasion Resistance Threecubes (100×100×100) 28days

Corrosion 1sample 28days

Shrinkage 3beams(75x75x300) 28days

Electrical Resistivity

2sampleofbeam 90days Ultrasonic Pulse Velocity (UPV)

3sampleofbeam 90days Sorptivity 3sample(50x100) 28days

Workability (Slump):- The Slump was measured by slump cone apparatus, and as per observations, it was identified, as the percentage replacement of sandstone cutting waste increases, the workability of concrete decreases. It could be attributed to the higher amount of water absorption by these fine particles and internal friction in sub-angular particles of SCW. The slump values for control mix were 115,115,100,110 mm and for 100% replacement of fine aggregates were 90,90,90,85 mm for 0.3,0.35,0.4 ,0.45 w/c ratio respectively (shown in Figure 4.1). However, the target slump was achieved in our research by adding a new generation modified superplasticizer, Master Glenium SKY 8233. The target slump (100±15) mm was obtained for all mixes. Quartzite sand has positively influenced the workability of concrete, as it reduces the workability at a higher replacement level in concrete. Similarly, slump loss was observed when the quartz sandstone waste was added, and it was due to the higher water absorption tendency of quartz sandstone powderthannaturalsand.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page585

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

Compressive Strength:-Thecompressivestrengthresults for varying w/c ratios at 7,28, and 90 days are presented in Figures 4.2, 4.3, and 4.4, respectively. The variation in compressive strength value was observed in the samples. ItwasobservedthatreplacingSandstonecuttingwasteup to 10 percent resulted in an increase in 7 days’ compressive strength for 0.3 and 0.45 w/c ratios compared to the control concrete. However, the rise of compressivestrengthwasupto30%forw/c0.35and0.45 w/c ratio. Densification of concrete was also observed whileaddingtheSCWintheabovecases.Thereplacement ofsandstonecuttingwasteinconcreteupto30%indicated anincreaseinstrength(38.85MPa,44.58MPa)at0.4w/c ratiosandanincreaseinstrength(37.2MPa,37.56MPa)at 0.45 w/c ratio for 28 and 90 days, respectively when comparedwithcontrolmixconcrete.

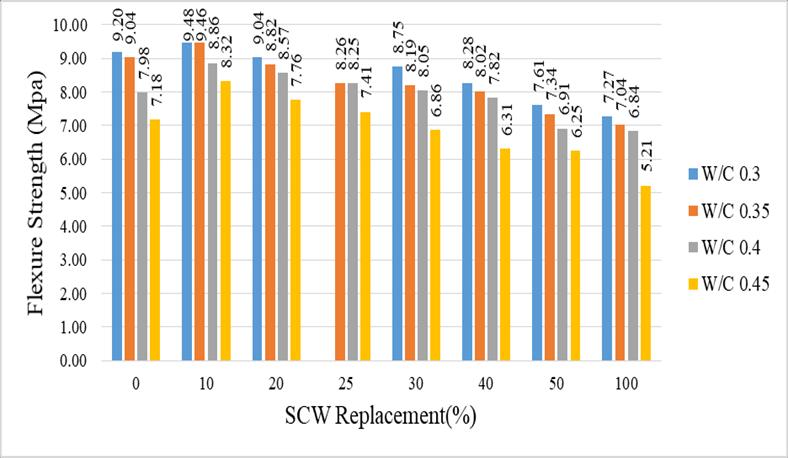

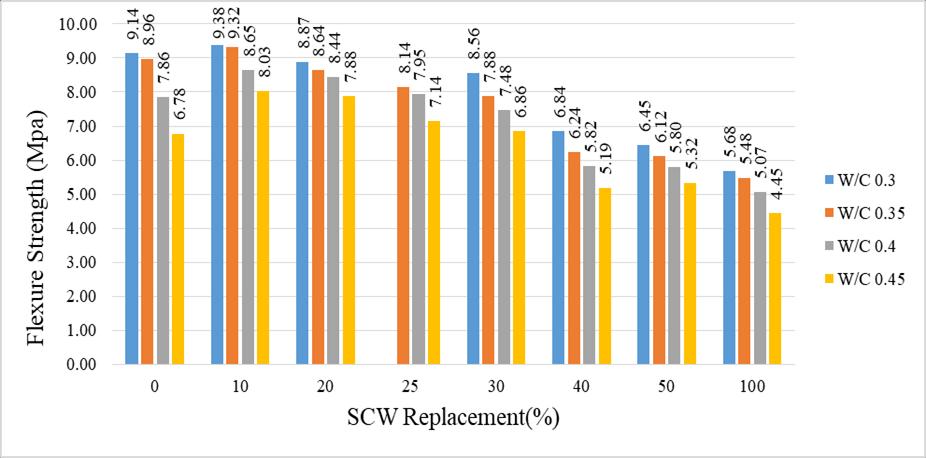

Flexural Strength:- Concretebeamsofsize(10cmx10cm x 50cm) were cast and tested on a flexure strength machine after 28 and 90 days of curing. Flexure strength test results (Figures 4.5 and 4.6) indicate higher strength values up to 25% to 30% replacement level of SCW in concretecomparedtocontrolmixconcreteat0.4and0.45 w/c ratio. Higher-strength values up to 10% SCW replacement in concrete at 0.30 and 0.35 w/c ratio were observed. However, the flexural strength was found maximum with 10% replacement of sandstone cutting wasteinconcreteatallthew/cratios

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

trends were observed in split tensile strength at 90 days withpartialreplacementofSCWinconcrete.

9

Split Tensile Strength:- Concrete cylinders of size (15cm x 30cm) were cast to measure the split tensile strength, and the test was performed on a compression testing machine after 28 and 90 days. Split tensile test results indicate the increase in strength with partial replacement of SCW in concrete and the trends shown in Figures 4.7 and 4.8. These indicate a higher strength value (2.71MPa) upto30%replacementlevelatw/cratioof0.4andhigher strengthvalue (2.7MPa)up toreplacementof25% at w/c ratio of 0.45, when compared with control mix concrete value (2.67 MPa, 2.67 MPa respectively) for both w/c ratiosat28days.Howeverhigherstrengthvalue(3.1MPa) was obtained up to 10% replacement level of SCW in the case of 0.35 w/c ratio and higher strength value (3.98 MPa) up to use of 10% SCW in concrete at 0.3 w/c ratios when compared with control mix concrete values (3.0 MPa,3.96 MPa respectively) at 28 days. Similar increasing

Abrasion:- This test was carried out to measure the average depth of wear on selected cubes of size (10cm x10cm x10cm). The analysis of results with an average abrasion value of 3 specimens is shown in Figure 4.9. It indicates a slight increase in wear depth for 0.3 0.35,0.4 and 0.45 w/c ratio for all replacement levels with SCW compared to control mix concrete. The Increase in the depthofwearwasmaximumfor100%replacementforall w/c ratios. However, with 40% SCW in concrete at a w/c ratio of 0.35 and 0.4, the wear depth was less with the valueof1.13mm

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

Theassessmentofpropertiesofsandstonecutting waste from the literature survey and testing carriedoutinthelaboratory,suggestthat25–30% sandstonecuttingwastecanbesuitablyutilizedin concretebyreplacingriversand.

The mix comprises of higher sandstone cutting waste requires a higher dosage of superplasticizer when the water-cement (w/c) ratio is low. This research shows that slump values are decreasing with increasing levels of sandstone cuttingwasteinconcretewhencompared

Flexure strength test results indicated higher strengthvaluesupto25to30%replacementlevel of SCW in concrete than control mix concrete at 0.4 and 0.45 w/c ratios, respectively, and higher strength value up to 10% SCW concrete at 0.30 and0.35w/cratios.

Split tensile test results show an increase in strength with partial replacement of SCW up to 30% replacement level at w/c ratio of 0.4 up to replacement of 25% SCW at 0.45 w/c compared with control mix concrete for both w/c ratios at 28 and 90 days. However, higher strength was obtainedbyupto10%replacementofSCWinthe case of 0.3and 0.35 w/c ratio compared with controlmixconcretevaluesat28and90days.

The analysis of results with an average abrasion valueof3specimensindicatedaslightincreasein weardepthfor0.30.35,0.4,and0.45w/cratiofor all replacement with SCW compared to control mix concrete. The higher wear depth was due to the large proportion of sedimentary processed cutting particles and further chipping action of sandstonecuttingwasteinconcrete.

:-

Abdullahi,M.(2012). Effect of aggregate type on compressive strength of concrete. International journalofcivil&structuralengineering,2(3),791-800.

Ashmole, I., & Motloung, M. (2008). Reclamation and environmental management in dimension stone mining. Southern African Institute of Mining and Metallurgy:SurfaceMining,155-178.

ASTM C 1012 1989, Standard Test Method for Length Change of hydraulic-cement mortars exposed to a sulphatesolution.

ASTM C 1202, 1991, Standard test method for an electrical indication of concrete ability to resist chlorideionpenetration.

Chouhan, H. S., Kalla, P., Nagar, R., & Gautam, P. K. (2019). Influence of dimensional stone waste on mechanical and durability properties of mortar: A review. Construction and Building Materials, 227, 116662.

Chouhan, H. S., Kalla, P., Nagar, R., Gautam, P. K., & Arora, A. N. (2020). Investigating the use of dimensional limestone slurry waste as fine aggregate in mortar. Environment, Development, and Sustainability,22(3),2223-2245.

DE LA RILEM,R E C O M MA N D A T I O N S (1988). CPC-18 Measurement of hardened concrete carbonationdepth.

DIN 1048, 1991 EN-Testing Concrete; Determination of depth of water penetration under pressure in hardenedconcrete,Berlin,Germany.

Dino, G. A., Fornaro, M., & Trentin, A. (2012). Quarry waste: chances of a possible economic and environmental valorization of the Montorfano and Baveno Granite Disposal Sites. Journal of Geological Research,2012.

Kumar, S., Gupta, R. C., Shrivastava, S., Csetenyi, L., & Thomas, B. S. (2016). Preliminary study on the use of quartz sandstone as a partial replacement of coarse aggregate in concrete based on clay content, morphology, and compressive strength of combined gradation. Construction and Building materials,107,103-108.

Lakhani, R., Kumar, R., & Tomar, P. (2014). Utilization of Stone Waste in the Development of Value-Added Products: A State-of-the-Art Review. Journal of EngineeringScience&TechnologyReview,7(3).

Langford, P., & Broomfield, J. (1987). Monitoring the corrosion of reinforcing steel. Construction Repair,1(2).