International Research Journal

of

Engineering

and

Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal

Engineering

Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1Manager - Elkay Chemicals Pvt. Ltd., Aundh, Pune – 411007, India.

*

2Vice President, Technical - Elkay Chemicals Pvt. Ltd., Aundh, Pune – 411007, India.

3Scientist & Manager, Technical - Elkay Chemicals Pvt. Ltd., Aundh, Pune – 411007, India. ***

Abstract - The influence of organosilicone admixture (alkoxysilanes-siloxane), on concrete hydration, water repellency and compressive strength has been investigated systematically The concrete mortar hydration process was intensified on the pilotcommercial scale by silicone admixtures, which benefited in bringing down the conventional curing process (water evaporation rate) as well as assisting in good compressive strength. The compressive strength of concrete was increased by 11 % at 0.3 % addition of admixture as compared to reference concrete. Capillary water suction through fine interconnected pores in concrete was reduced significantly and the reduction rate was higher than 80 %. It was observed that used admixtures noticeably extend the initiation period and delay hydration of concrete mortar These results are further supported by RILEM, Dip and Slump analysis. Additionally, this admixture helps to maintain the workability of fresh concrete and enhance the self-life of concreter mortar with minimum water quantity. These findings are commercially useful, because, high compressive strength, less water consumption, higher workability and sufficient self-life are the essential requirements of the construction industries.

Key Words: Silicone admixtures, Alkoxysilanes-siloxane, Concrete applications, compressive strength, water repellency.

The sustainable building strategy places a high value on the better resilience and extended life of building materials and components. Notably for removing the ecological and financial effects of frequent maintenance and repairing work. Hence, continuous development in building material and concrete technology is growing over the past several decades. The substantial use of chemical admixtures and mineral additions is largely responsible for the significant advancement of concrete technology [1]. To produce structural concrete of the highest quality, chemical additives must be used. One of the pinnacles of twentieth-century civil engineering was the development of chemical admixtures for concrete [2]. These admixturesarecategorizedinaccordancewiththeEN934-2:2002standardbasedontheresultsofmodifications[3]

Typically, silicates, aluminates, calcium and ferrite-aluminates are the major components of cement and have a specific reactivity toward the water. Its hydration phenomenon causes the setting and hardening of the concrete. Cement hydrationisalengthyprocess,itcanrequireseveralyearstocure[4] Itdependsonthetypeofcementandblendedmineral additives.Oncecementandwaterhavebeencombined,polarwatermoleculesadheretothesurfaceofthecementgrains. The hydrolysis or dissolution of the cement stage occurs before this process and this layer is almost amorphous and forms in a matterofminutes.Thislayerismostlymadeofcalciumsulfateandhydratedcalciumsilicates(C-S-Hphases).Aftersaturation is reached, the liquid phase becomes supersaturated with hydrolysis products, which leads to fast nucleation. Consequently, with the crystallization of calcium hydroxide, hydrated calcium silicates develop a solid three-dimensional skeleton. This hydration of cement is an exothermic phenomenon, it might due to the chemical reaction of calcium aluminate, calcium alumino-ferrite,aliteandbelite Withinthefirstfewhours,thisreactionbetweenthecementcomponentsandwaterresultsin significant amounts of heat release (~ 250-400 kJ kg 1). Because of this heat emission, the hydration process is affected and thiscansignificantlyimpactthedurabilityofconcretemassivestructures[3–5].

The hydration of cement can be considerably impacted by admixtures. Products precipitating or solution-derived particles sticking to the surface of cement grains can cause hydration retardation. Numerous papers examine how various admixturesaffecthowcementhydrates,includingwaterreducers,accelerators,andretardants.However,thereisnotenough informationtodeterminehowwaterproofingadmixtureslikeorganosiliconeaffectPortlandcement'sabilitytohydrate.Afew

e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

researchers have worked to comprehend and explain Portland cement hydration in the presence of polymers [3,6–8]. A polymercoatingiscreatedprimarilybytheadsorbedpolymerparticlesonthesurfaceofthecementgrains.Itcanimpedethe nucleationofhydrationproductslikeC-S-Horthedissolutionofmineralphases.ByloweringtheCa2+ ionconcentrationinthe pore solution, it may delay the precipitation of the hydration product (C-S-H) and therefore lengthen the time needed to achieve the requisite supersaturation. For this, three potential mechanisms for polymer-cement reactions were listed by Ukowski and Kubens [6,9,10]: (1) electrostatic interaction between the polymer and cement grain surfaces, (2) steric hindrance of one polymer adsorbed particle to another adsorbed particle on adjacent cement grains and (3) hydrophilic mechanisminthecaseofadmixturesbasedonsurfactants.Themajorityofthemarestartedorcontinuewhenwaterispresent andfillingtheporesintheconcrete.Concreteshouldbekeptdryorwithlittlewatercontentinordertoincreaseitsdurability Theusageofhydrophobicadmixturesisoneapproachtoachievingthisobjective.

Typically,organosiliconeagentsareusedastheoutsidecoating.Apreferredalternativeistoincludethehydrophobic additive asone ofthe elementsintheconcrete mixture. Therefore, it becomescrucial to understandhow these hydrophobic organosiliconechemicalsaffectthehydrationofcement.Organosiliconematerialsarewidelyusedinthebuildingconstruction sector. They are used as sealing and protective coating materials, among other things. Organosilicone compounds are frequentlyutilizedinthebuildingsectorasmoistureprotectionduetotheirversatilecharacteristics.Therefore,theobjective of this study is to investigate the effects of organosilicone-based water repellents on concrete mortar hydration and gain a better knowledge of the interacting processes. In order to create the internal hydrophobic substance, the hydrophobic admixtures are intended to be introduced to the water used for mixing. Further, this study presents an in-depth analysis of concrete hydration, mortar workability and water evaporation of concrete blocks prepared from portland cement, crushed sand, coarse aggregate and silicone admixture. This study also explores the water repellency property and compressive strengthoftheresultingconcreteblocks.

In experimental studies, crushed mining sand that was accessible locally was used as the coarse aggregate. Table 1 displays certain fractions of crushed mining sand in various sizes. The respective ranges are specified in IS 383 Ordinary Portlandcement(ASTMTypeI)fromBirlaSuperandcrushedsandwasusedasthemainbinder.Normaltapwaterwasused forconcretepreparationand curing purpose Toprepareintegral waterrepellentconcrete, duringthemixing process0.1 %, 0.2%,0.3%and0.4%siliconeadmixturewasaddedtofreshconcrete. Thesiliconeadmixturewasanalkoxysilanes-siloxane emulsion(LK-AquaEm-290)with35%activesubstances,manufacturedbyElkayChemicalsPvt.Ltd.Pune,MaharashtraIndia (ELKAY SILICONES) The physical properties of major constituent material are shown in table 2 Particular tests were performedinCetrslab,Pune,Maharashtra,India(AnNABLaccreditedlaboratory).

Table1:Classificationconcreterawmaterials

Test Sieve size Weight Retained Passing Weight Passing % Aggregate Passing %

Crushed aggregates fractions

Specification IS 383 (1970)

40mm 0 0 0 100 100 20mm 86.2 98 1.96 97.12 95-100 4.75mm 0.1 2954 56.08 39.4 30-50 600mic 51 4362 87.24 12.52 10-35 150mic 25.2 4779 95.58 4.5 0-6

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Table2.Physicalpropertiesofconcreterawmaterials

Test performed Results Acceptance limit References

Specific gravity-20mm 2.89 2.85-2.90 (IS2386-III)

Specific gravity-10mm 2.85 2.85-2.90 (IS2386-III)

Waterabsorption20mm 0.97 <2% (IS2386-III)

Waterabsorption10mm 1.14 <2% (IS2386-III)

Aggregateimpactvalue 9.89 <30% (IS2386-IV)

Dryloosebulkdensity CA-20mm 1567kg/m3 - -

Dryloosebulkdensity CA-10mm 1575kg/m3 - -

Initialsettingtime 27min 30min (IS4031)

Finalsettingtime 284min 600min (IS4031)

Finenessofcement 1.90% <10% (IS4031)

Soundnessofcement 1.20mm <10mm (IS4031)

Strengthofcement(28 days) 61.30 N/mm2 - (IS4031)

Physical properties of silicone base admixture

Parameter Results Method

D2834-95

All concrete mixtures were prepared in the pilot-laboratory. The mixture design procedure was adopted from M-20 grade concrete process and maintained a water to cement ratio (w/c) of 0.55. The detailed mixture proportions of the concrete

International Research Journal

Engineering

Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

studied are given in Table 3. The proportion of cement, sand and other material was modified to achieve a compressive strength of more over 33 N/mm2 after 28 days. The absolute volume of the constituents was used to determine the characteristicsofthematerials.

Table3:Concretemixtureproportion.

W/C ratio Portland cement Sand Fineaggregate (10mm) Coarseaggregate (20mm) 0.55 335Kg/m3 763Kg/m3 480Kg/m3 720Kg/m3 1 2.28 1.43 2.15

Fivetypesofconcretemortarswereprepared.Includingonereferencesampleandfoursiliconeadmixturesbasedmortar.The admixture includes reactive polysiloxanes applied as a water emulsion. Alkoxysilanes and siloxanes are the active components. Amount of added hydrophobic admixture was 0.1 %, 0.2 %, 0.3 % and 0.4% (weight/weight) The details of mixtureproportionsaregiveninTable4.

Table4:Siliconeadmixtureandconcretemixproportion.

Mixer Description

Silicone admixture (%) Cement (Kg/M3) Sand (Kg/M3)

Fine aggregate (Kg/M3)

Coarse aggregate (Kg/M3) Water (lit/M3)

M0 Referencesample-M20 grade 0 335 763 480 720 203

M1 M20+Siliconeadmixture 0.1 335 763 480 720 203

M2 M20+Siliconeadmixture 0.2 335 763 480 720 203

M3 M20+Siliconeadmixture 0.3 335 763 480 720 203

M4 M20+Siliconeadmixture 0.4 335 763 480 720 203

Themanufactureofconcreteblocksconsistsofthreebasicprocesses:mixing,moulding,andcuring.

1.Mixing:Forhomogenousmixingofalltheconcreterawmaterial,usedarotarymixer.Itconsistsofrevolvingdrumorsquare box,rotatingdiagonalaxiswithdeflectorandbledtoimprovethemixing

2. Moulding: In a specialized cube mould, size: 150 X 150 X 150 mm, that specify the shape and size, the mix material was compacted.Thedevicehasmechanicalvibrations,whichcompactingtheconcreteblock.Threelayersoffilling,eachmeasuring fourinches,totaledaboutone-quarteroftheheightofthemould.Twenty-fivestrokesoftheroundedendofthetampingrod are required to tamp each layer. The strokes must be dispersed evenly across the mould's cross section, and for the second andsubsequentlayers,theymustpiercethelayerbelow(Fig.1)

3. Curing: After blocks established in mould machine, the blocks were put in shady place and allow the cubes to dry at a temperatureof24ºC±2ºCfor24hours Thenewlylaidblocksarekeptoutofthedirectsun.Theblockswerearrangedina stockpile the next day, and then new water was poured over them to ensure that the chemical reaction between Portland cementandwaterwentsmoothly.

e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

To create blocks with the required qualities, the three procedures mentioned above must be subject to systematic quality control.Toguaranteethattheblocksareproperlycuredandreach therequiredstrength,thecuringprocesswaswatered.In addition to quality control, the plain concrete block will keep evolving by architects and manufacturers to create new approachesormethods Buildingswillbeconstructedmorequickly,morerobustly,andmoreaffordablywiththeseinnovative techniques Aftercuring,removetheconcretecubefromthemould.Thespecimenswereweighedandsubmergedinwaterfor curing. Regular tap water was utilizedand it wasnotsaturated withlime. Thecuringtemperature was maintained to 23.0 ± 2.0ºC.Thevariationinpercentageofwatermayaffectthecompressivestrengthofconcreteandhenceconcreteblockswere madewithdifferentwaterpercentages(Fig.2).

e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

The slump test is used to gauge concrete's consistency. The results of a slump test reveal if concrete in various batches is uniform.Concreteslumps'shapesrevealdetailsaboutthematerial'squalityandusability.Makingafewtampingorblowsby tappingarodonthebaseplatecanalsobeusedtoassessthequalitiesofconcretewithregardtoitsinclinationtosegregate. Theapproachwasusedtodeterminetheslump wasASTM-C143.TheSlumpcone'sdesigndemonstrateshoweasilyconcrete canbeworked.Theproportionsutilisedfora metalliccone-shapedmouldare20cmatthebottom,10cmatthetop,and30 cmattheheight.A600mmlong,16mmdiametersteeltampingrodwithabulletend.Thefrustumconeisfilledwithconcrete. Afterremovedthefrustumcone,theresultantchangeinheightofconcreteisdefinedasslumpvalue.

Water repellency and capillary suction of water performance was assessed using RILEM test. ASTM E 514 outlines the accepted procedure for calculating water infiltration and leakage through brickwork. Here, the flat, circular brim of the pipe wasplacedbetweenapieceofputtytapeandthesurfaceoftheconcreteblockstosecurethe5mltube.Manualpressurewas beingappliedtothecylindertoguaranteeadherence.Waterwasthenpouredintothepipe'supperopenenduntilthecolumn reached the "0" gradation point. The graduated tube was directly read to determine how much water the substance had absorbed over a predetermined amount of time. The porosity of the material being tested will determine the proper testing intervals; typically, data collected at intervals of 24 hours is the most helpful. By weighing the samples after 24 hours, the amountsofabsorbedwaterwerecalculatedasafunctionoftime.

Diptest isone ofthe regularlaboratorytestmethodto measurewater gain percent.Italsoindicatesthe water repellenceof concreteblockswithrespecttotime Thistestcanbedoneafterthecompletionofcuringofconcreteblocks.Initiallyweighthe dryconcreteblocksanddipitinthewatertankforanhour.Afteronehourkeepouttheconcreteblockfromwatertankand dryfortwominutes,takenfirstreadingofweightgain.Repeatedsameprocedureandweighedtheallconcreteblocksin1hr time interval (i.e. 1 to 8hrs) and calculate the amount of water gain in the all concrete blocks. Make sure keep the same temperatureconditionforeachconcreteblock.

Thepercentwatergaincalculatedbyfollowingformula;

Where,W=%waterrepellenceinconcreteblocks;Iw=Initialweightofconcreteblocks;Fw=Finalweightofconcreteblock

e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

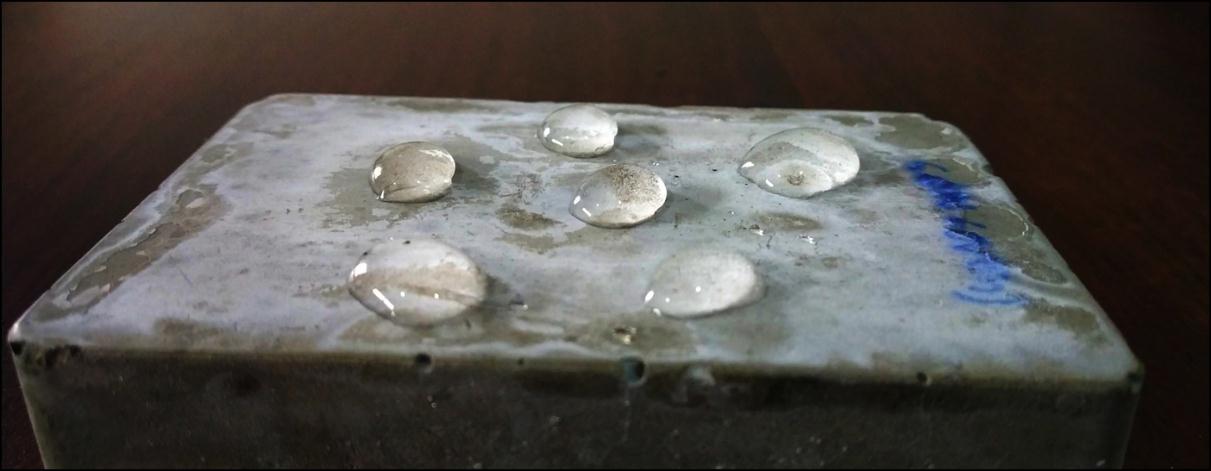

Thewaterrepellencyorwaterabsorbanceperformancewasassessedbymeasurethefootprintarea(cm2)ofthewaterdrops ontheconcretesurface.Herein,takenconcreteblockswerehavinga cleananddrysurface.Underroomtemperature,fiveto sixwaterdrops(havesame sizeandsameweight)wasputonthesurfaceofconcreteblocks.Afterhalfanhourmeasurethe foot prints of the every drops of water and calculate the area of the footprint. On the basis of area of drops footprint we concludethewaterrepellencyonconcreteblocks.

The water evaporation rate of the mortars and effect of silicone admixture on surface cracking of concreate blocks were evaluated and measuring weight loss over time. Record initial weight of concrete blocks and dip in water tank for one day After24hrs,removealltheblocksfromthewatertankandweighaccuratelybymaintainingsamemeasurementprotocol To calculatetheevaporationrate,measuredwaterlossafterevery30minintervaltillinitialweightoftheconcreteblock.

Percentrelativewaterevaporatedcalculatedbyfollowingformula; ( ) ( )

Where, Iw= Initial weight of concrete weight;Fw=Final weight of concrete weight; Dw=Dry weight of concrete blocks;R=% relativewaterevaporated

Thecompressivestrengthofconcreteblockswereexaminedbycompressionmachine.Thetechnicalstandardforthismethod shall be as accordance to the ASTM C-39. Ensure the dimensions and weight of the concrete cube and place it in the compression testing machine. Apply the load till the cubecompletely crushes or fails and record the same. The compressive strengthofthegivenconcretecubewasdeterminedbyusingthefollowingequation:

Where, ,

The effect of alkoxysilane-siloxane on the concrete in terms of water repellency and compressive strength properties were evaluated.Thesilicone-basedadmixtureincludedinthestudy,containsasiliconepolymer,surfactantandwater.This waterbasedemulsionordispersionswerepreparedcontainingthesiliconeactiveofabout35%.

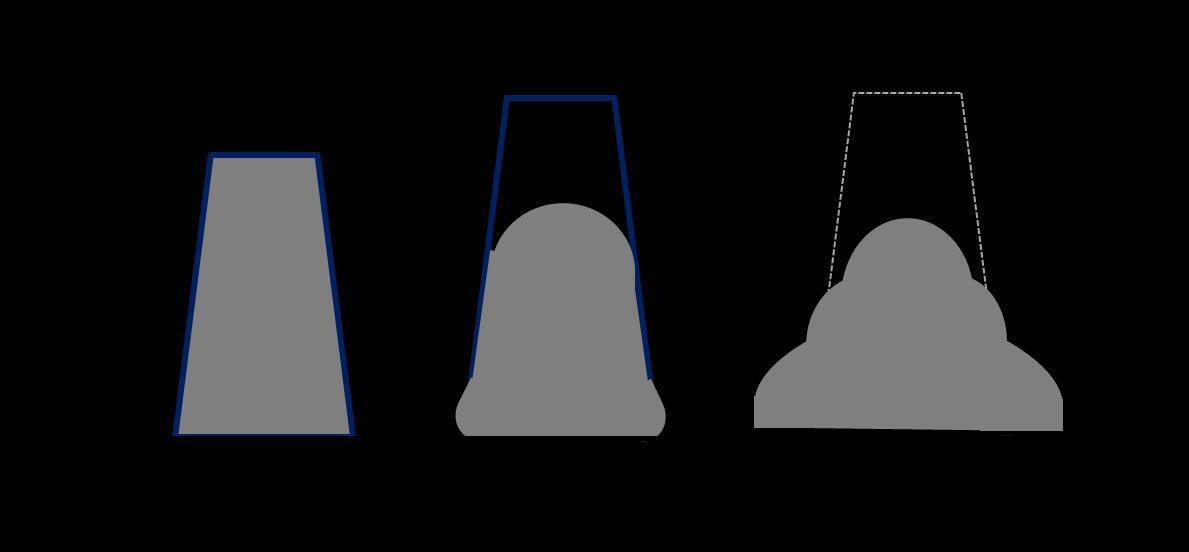

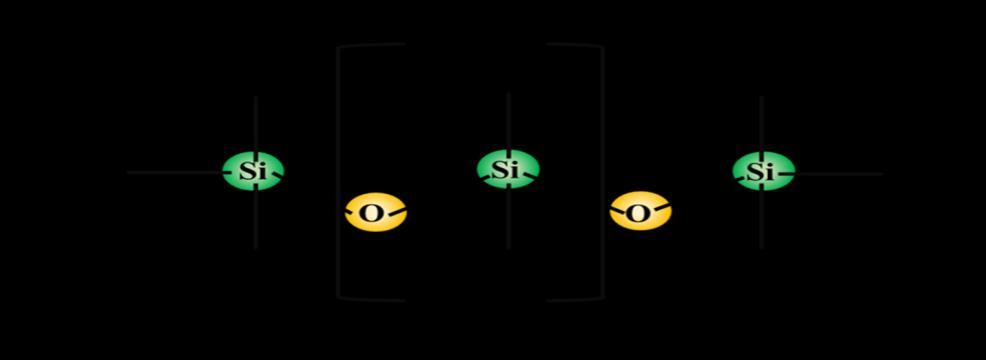

A stable connection between silicon and carbon, nitrogen, or sulfur is one of the distinguishing characteristics of organosiliconecompounds.Themajorityofthemshowthesamecharacteristicsasorganiccompounds,includingbeingstable, colorless,andhydrophobic. Inthemajorityof organosiliconecompoundsistetravalent. Thecarbon-silicon bond (186pm) is longerthan thecarbon-carbon bond (154 pm). Additionally,ithas lower dissociation energy (451kJmol1)thanthecarboncarbon bond (607 kJ mol1), which facilitates simpler atom separation [11]. The C-Si bond becomes more polarized toward carbon due to carbon's stronger electronegativity. Compared to carbon (2.5), silicon (1.8) is less electronegative. Hence, the silicon-oxygen bond acquires an ionic nature. The fundamental building blocks of organosilicone polymers are Si-O-Si, also knownassiloxane bonds,and Si-C-Si,alsoknownassilicon-carbonbonds. Organosiliconecompoundshavea basicstructure madeupofthepolysiloxanechain(-O-Si-O-Si-O),whichiscomposedofsiliconandoxygenatoms.Inasiloxanechain,theangle between silicon and oxygen is relatively large (approximately 120o). This makes the chain incredibly flexible [11,12] A repeating group, [R2Si-O], describes the structure of polysiloxanes. Organosilicone compounds are also referred to as

e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

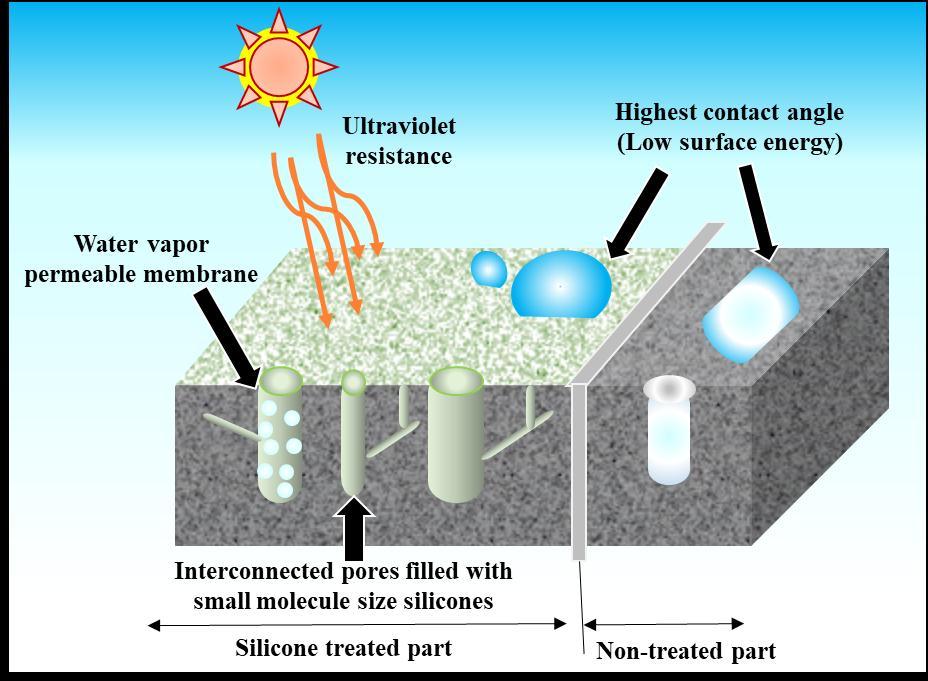

"silicones" in everyday speech. They are artificial organosilicone polymers made of siloxane chains, where silicon atoms are joinedtoalkyl (mostfrequentlymethyl or ethyl)oraryl (mostfrequentlyphenyl)groups.Alongthepolysiloxanechain,only one silicon atom has an organic group linked to it. The range of spatial systems that can be generated from basic chains depends on the structure of the substituents [12] Poly(dimethylsiloxane) (PDMS) is well-liked organosilicone polymers. A silicon atom is bonded to two methyl groups (-CH3) in the high-molecular polymer known as PDMS (Fig. 4(a). The polydimethylsiloxanechainscanbeorganisedinahelixwiththemethylgroupsfacingoutwardduetothetinysizeofthemethyl group. The hydrophobic characteristics are brought about by these organic substituents. Polysiloxanes have an amphiphilic characterdue toaninorganicchainwithstronglypolar Si-Obonds(Si-O bondshaveanioniccharacterin50% ofcases)and non-polarorganicgroupsconnectedtosiliconatoms.Duetotheiramphiphilicity,siloxanechains caneasilyadoptashapethat corresponds to the surface's minimum-free energy [13,14] A longer organic group chain results in greater water resistance. Fig.4(b)illustratesthewaterresistancephenomenonofsiliconeadmixturewithconcretemortar

Fig.4.Organosiliconeadmixturewaterresistancephenomenon(a)structureofpoly(dimethylsiloxane)(PDMS);(b)water repellentphenomenonofsiliconeadmixturewithconcretemortar

4.1. Relation of silicone admixture and slump characteristic of concrete

As described in the methodology, the concrete materials were prepared with and without admixture using a rotary mixer. After10minutesofmixing, transferthehomogeneous massinto apanandanalyzedtheconsistency,workabilityandfluidity ofconcretewiththehelpofaslumptest.

e-ISSN: 2395-0056

Theeasewithwhichconcreteflowsisdeterminedbyitsconsistency,whichisa termusedtodescribetheworkability or fluidity of freshly formed concrete. The degree of fluidity in the concrete mix is therefore measured on-site using the concrete slump test, also known as the workability test of concrete. Table 5 shows the slump test results of all the concrete samples.

M0 Referencesample-M20grade 45 0.87 Low

M1 M20+Siliconeadmixture 77.5 0.91 Medium

M2 M20+Siliconeadmixture 98.75 0.974 High

M3 M20+Siliconeadmixture 102.5 0.978 High

M4 M20+Siliconeadmixture 107.5 0.98 High

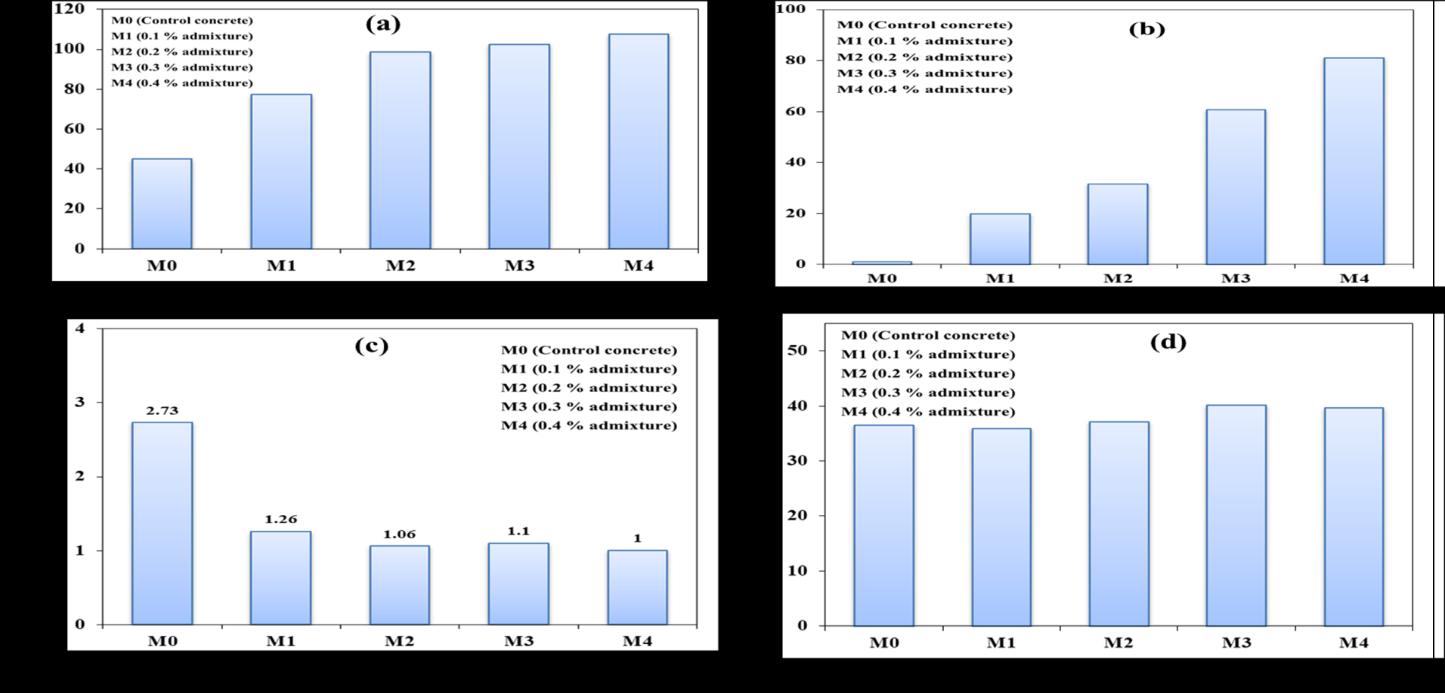

Theimpactofsilicone-basedadmixtureontheworkabilityofconcreteisclearlydifferentiatedinFig.5(a) Theslumpvalueof concrete is increasing with increased percentages of silicone admixtures. There is a sharp increase in slump gain as silicone admixtureincreasedfromM0toM2andthenobservedsmallchangesinitfromM2toM4.Although,thewaterparentagewas sameinallthe concretemixerandstillitshoweddifference slumpbehavior. This mightbebecauseof achangeinstructural propertiesofconcretematerialduetothesiliconechemistry. Assiliconeemphasizedconcretemixturestoboosttheaddition ofC-S-Hbridgesintothemortar.Itconstitutestheweldingpointsbetweenthegranulesandothercomponents andalsohelps inthesettingandhardeningofconcrete[4] Itresultinghigherworkability,constancyandsustainabilitytoconcreteslaps or blocks

Fig.5 Effectofsiliconeadmixtureonconcreteproperties(a)Slumptest;(b)Relationbetweensiliconeadmixtureandwater repellency;(c)Waterspreadingonthesurfaceofconcreteblocks(footprinttest);(d)Compressivestrengthofconcreteblocks.

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page565

e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

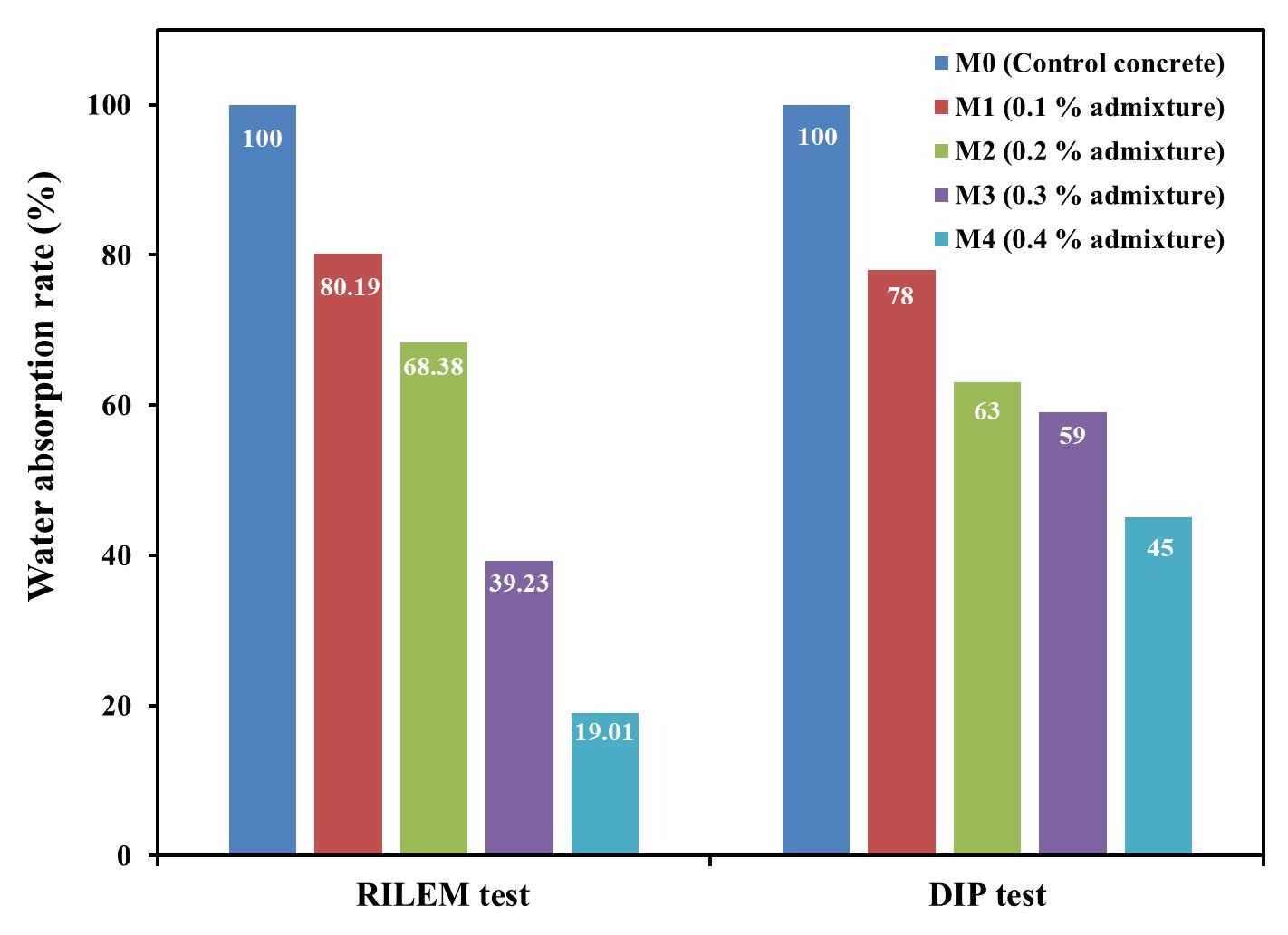

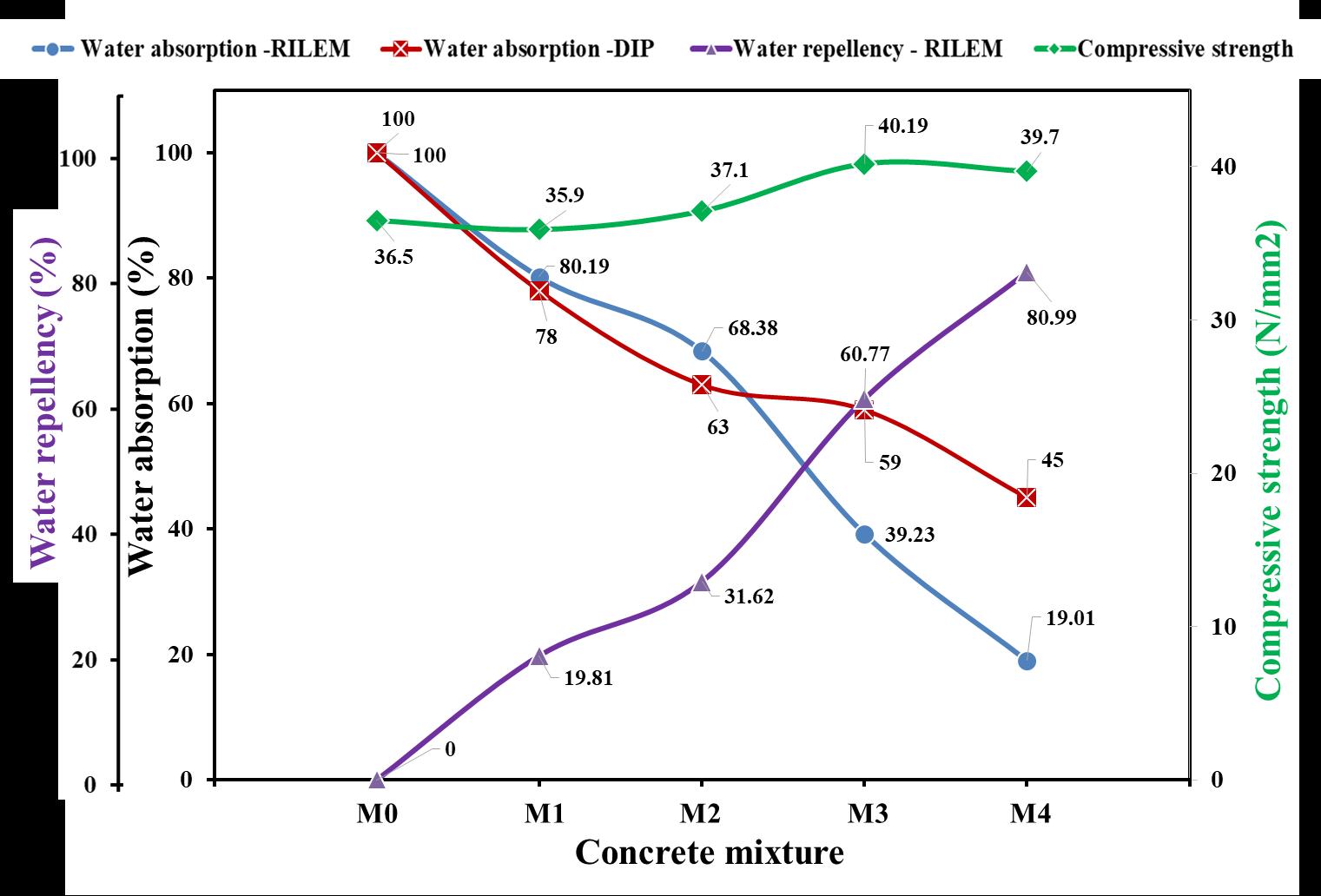

The effect of silicone on water repellency was characterized by the RILEM test, dip test and footprint test. These methodsprovideasimpleandeffectivemethodologyformeasuringthewaterrepellencyofconcreteblockswithinaspecified timeperiod. All of the masonry construction materials are porous and water permeable by nature. A network oftiny, linked pores makes up a masonry material's internal structure. A wetting liquid will be absorbed by capillary action into a porous material ifitcomesintocontactwiththeporous material'ssurface.Thisentailscapillaryconduction(suction), whichtravels alongbothverticalandhorizontalpathsthroughthisporesystem.Hence,waterpenetration(absorption)inconcretewithand withouttheadditionofsiliconeadmixturewasmeasuredandtheresultsareshowninFig.6

The reference sample M0 (without silicone admixture) absorbs 100 % water within 24 hrs. On the other hand, silicone admixture with 0.1 % (M1), 0.2 % (M2), 0.3 % (M3) and 0.4 % (M4) showed water gain by 80.19 %, 68.38 %, 39.23 % and 19.01% respectively. Asimilar trend of waterabsorption was found in the dip test.Thecontrol (M0)concrete block absorb 100%waterwithin24hrandM1,M2,M3andM4showed78%,63%,59%and45%respectively.Itmeansthatthereisan inversecorrelationbetweenwaterabsorptionandwaterrepellency.Withincreasedsiliconeadmixtureinconcreteblocks,the waterrepellencypercentagewasincreased(seeFig.5(b).Itmightduetothehydrophobicpropertyofsiliconeadmixture.The majority ofsiloxanesand silanesaremadeup of tinymoleculesthatpenetrate deeply into the internal poresoftheconcrete [15] To give endurance, they interact with the substrate and with one another. After curing, they let water vapor flow but preventliquidwaterthatmighthavedissolvedacidsorchlorideionsfrompenetratingthesubstrate. Hence,alinearfunction canbeusedtoexplaintheamountofwaterabsorbedasafunctionofthedurationoftimeincontactwiththewater,asshown inFig.7(a).

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Waterrepellencyofconcreteblockswasalsocheckedwiththefootprintareaofwaterdropsonthesurfaceofconcreteblocks Fig. 7(b) represent water repellency of silicone treated concrete block. Thus, footprint testing method were applied to quantify the water spreadability and results showed in Fig. 5(c). In which the control blocks (M0) show a larger water spreading area were 2.73 cm2 On the other hand, concrete blocks content with silicones admixture showed the less water spreading footprint area for M1, M2, M3 and M4 for 1.26 cm2, 1.06 cm2, 1.1 cm2, 1 cm2 respectively. It means that silicone admixtureconcreteblocksshowedgoodwaterrepellencyandsuper-hydrophobicsurfaces.Itmightbeduetothehydrophobic and low wetting properties of silicone admixture. The interfacial tension between the solid and liquid is low because the interactionbetweentheconcreteandwaterisnotthatstrong.Because,ithashighcontactangleandlowsurfaceenergy,which prevents water from spreading out over their surface [13,16]. The wetting angle of water droplets on silicone specimen surfacescanbeusedtoassesstheseverydesirableproperties.

e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Plastic shrinkage, which happens in the first few hours after casting when the concrete is still in a plastic stage, is the volumetric contraction of cement-based materials. Since the material cannot deform freely in constrained overlays, the contraction will produce tensile stresses that could cause surface cracking [17,18]The evaporation of mixing water and capillary pressure inside the cement pores is what causes the majority of plastic shrinkage cracking. Most of the surface evaporation or moisture absorption at the contact with the underlying substrate materials is the cause of the loss of mixing waterfromthefreshmaterial.Specificenvironmentalfactors,suchaslowrelativehumidity,hightemperatures,andexposure to strong winds, can worsen plastic shrinkage cracking severity by increasing the rate of water evaporation. It is crucial to preventthe emergenceof this kindofcrackingsinceit cancausesevere surfacecrackstoformonthematerial asa resultof largeplasticshrinkagedeformations,whichwillharmthematerial'slong-termdurability.

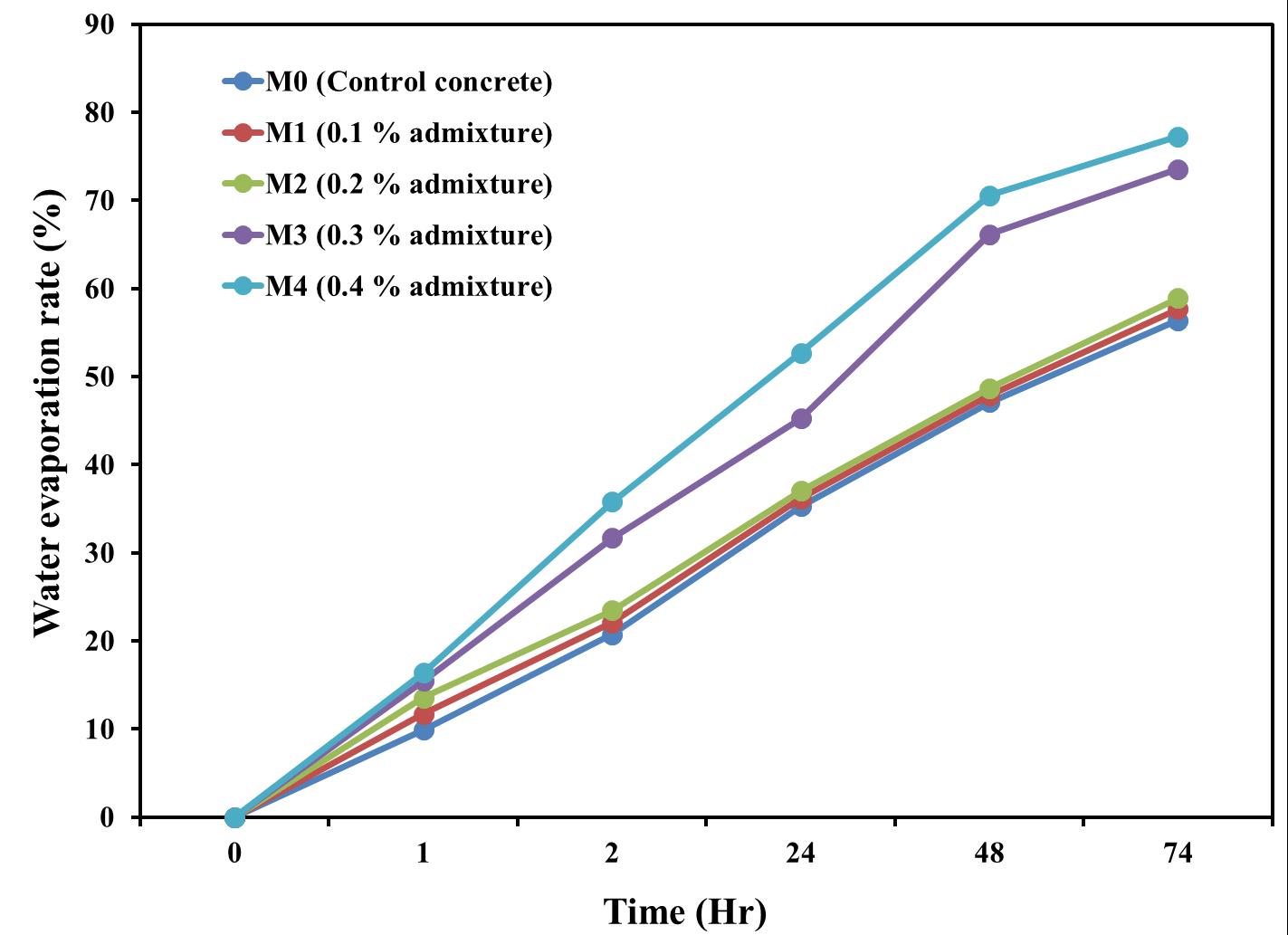

Additionofanykindofadmixtureinmortarmayaffectthewaterevaporations phenomenon.Hence,effectofsilicone admixture on water evaporation rate were evaluated and are illustrated in Fig. 8 The weight loss of unrestrained mortar specimenspreparedwithdifferent siliconeadmixtureconcentration.Thefigureshowsthat,whencomparedtothereference specimenwithoutsiliconeadmixture,theadditionofsiliconeadmixture(M4,M5)obviouslycreatesaconsiderabledifference in water evaporation (M0). The evaporation rate was a little bit slower for specimens M2 and M3. The concentration effect with a smaller percentage silicone admixture was presumably to blame for this. Hence there is a direct correlation between water evaporation tendency of silicone admixture and water repellency test. It was therefore concluded that alkoxysilanessiloxane is highly suitable as mortar admixture for concrete, because it enhanced the concrete water repellency and significantlywaterevaporationrate.

Fig.8.Waterevaporationrateofmortarspecimenspreparedwithdifferentsiliconeadmixture%.

e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

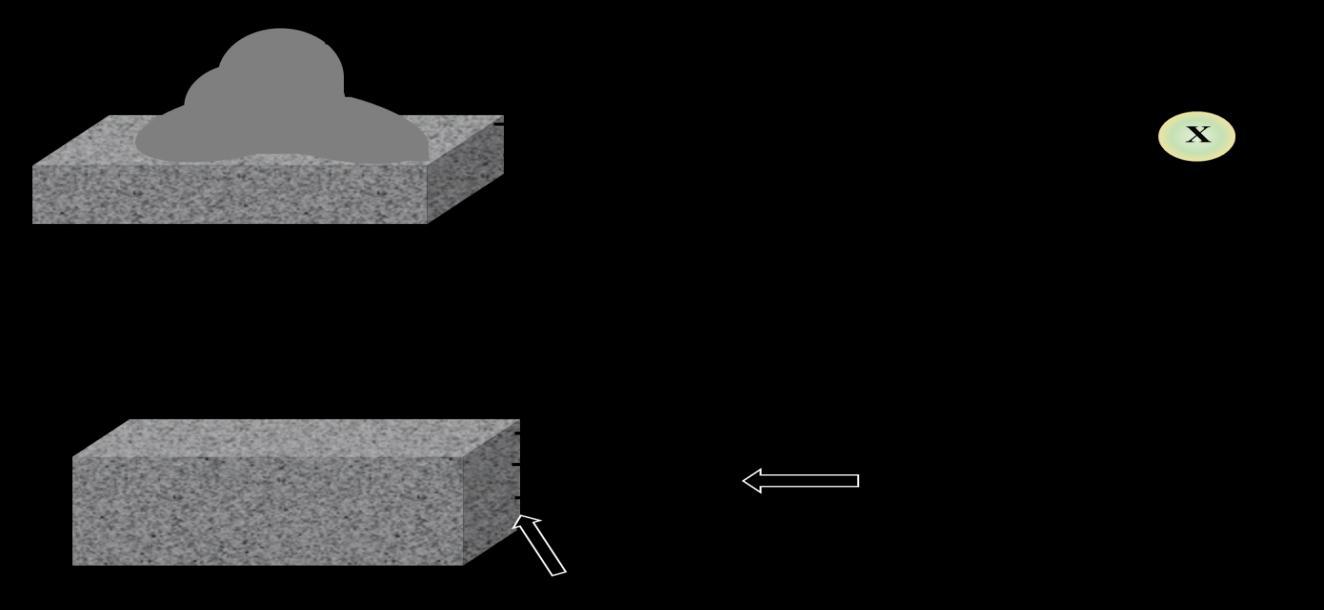

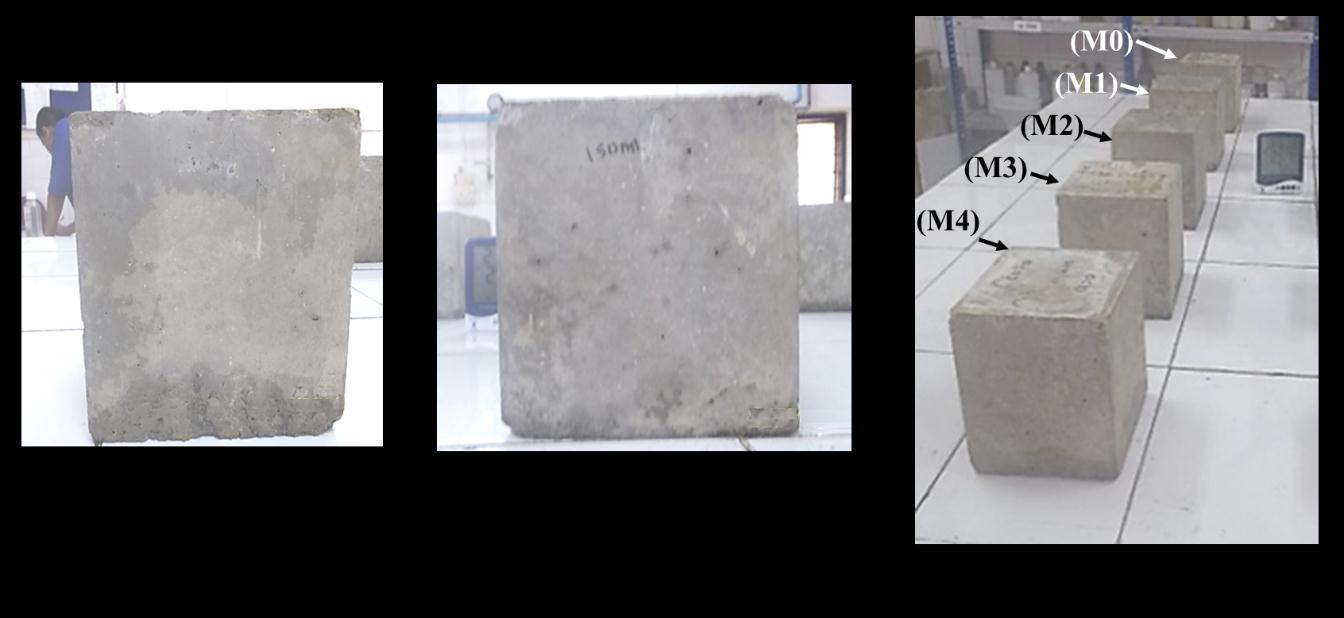

Higherwaterevaporationrategeneratetensilestressesthatmayresultinsurfacecracking.Hence,effectofsiliconeadmixture on surface cracking were evaluated and are illustrated in Fig. 9. It can clearly see in figure, the concrete blocks surface are intact and does not have any surface cracks. It means that, use of silicone admixture in mortar, which doesn’t influence the surfacemorphologyduringcuringandwaterevaporation

Fig.9 Effectofsiliconeadmixtureonsurfacecrackingofconcreteblocks.

Thetestforconcreteblockcompressionstrengthrevealswhetherornotconcretinghasbeendonecorrectly.After28 daysofcuring,thesespecimensareevaluatedusingacompressiontestingequipment.Tofracturethespecimens,aloadshould begivenprogressivelyatarateof150kg/cm2 perminute.Concrete'scompressivestrengthiscalculatedbydividingtheload at failure by the specimen's surface area. The minimum compressive strength for M-20 grade of solid concrete blocks are 20MPa Numerousvariables,includingthewater-cementratio,thetypeandquantityofconcreteused,andthemanufacturing process, affect compressive strength. Also, compressive strength of concrete is very much depending upon the hydration reaction. The major component of Portland cement is calcium silicate, which contributes to the strength of concrete. The majority of concrete's initial strength is due to tricalcium silicate. Hardening is the process of strength growth and may continueforweekormonthsaftertheconcretehasbeenmixedandplaced HardeningisdonelargelytotheformationofC-SH bonding as to cement continues to hydrate. The rate at which water molecules permeate through the calcium silicate hydrate layer now determines how quickly the process proceeds. Hence, Fig. 5(d) represents the results of the compressive strength of M-20 grade of concrete blocks. In which all the blocks pass the compressive strength test. As control block (M0) has compressive strength is 36.5 N/mm2 and concrete blocks with silicone admixture of M1, M2, M3 and M4 have 35.9 N/mm2,37.1N/mm2,40.19and39.7N/mm2respectively.Overalladmixtureusedintheconcrete enhancesthecompressive strengthofconcrete.

Overall,aninteresting relationshipcan beobservedinall thestructural changesof concrete blockssuchas% water absorption,%waterrepellencyandcompressivestrength.TheirinterrelationcanbeseeninFig10.Ithasbeenseenthatdropin water absorption of concrete, resulted in an increase in water repellency and compressive strength due to the hydration phenomenonasdiscussedearlier.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Fig.10.Correlationsbetween%waterabsorption,%waterrepellencyandcompressivestrengthatdifferentsilicone admixture%.

Fig.10,showsthesteepdropinthe%waterabsorptionwithincreasedofsiliconeadmixture%.Thisimpactedtheincreasein %waterabsorption inasimilarmanner.Thissignificantdifferencesinthestructuralchangeswereobserved incompressive strength [19] Siliconeadmixture impacts the hydration phenomenon of the concreateduring curing. The concrete materials hasporous interiorstructurewithfineinterconnected voids.Siliconesare penetratinginthis voidsand forming a protective repellentlayerwithinthesubstrate. Itenhanced watervaportransmissionratethroughporesandcapillaries. Itsignificantly improvestensilestressesofconcreteandresultinghighercompressivestrength.

New developments in construction industries with silicone admixture technology provide expanded options for creating stablesustainable building materials.Siliconeadmixtureofferversatilityfor buildingmaterialsaswellas concretematerials, presentingnewopportunitiesforcost-effectiveandhighlyinnovativeconstructionmaterial Theuseofalkoxysilanes-siloxane in concentrations higher than 0.3 %, showed an important influence on the water absorption and other properties of the concrete material, increasing the compressive strength by the water repellency phenomenon. The following conclusions can betakenfromthecollectedresultsandthedebatethatwaspreviouslypresented:

− Alkoxysilanes-siloxane is added to concrete to boost its compressive strength. When admixture is added at a rate of 0.3%, theincreaseabovecontrolconcreteisaround11%.

− Alkoxy silanes-siloxane can be added to the fresh mix in sufficient amounts to greatly lower the capillary water suction of concrete. Over 80% of the reduction has already occurred. Even after 2–7 mm of its surface abraded removed, integrated waterrepellentconcretestillexhibitssignificanthydrophobicproperties.

(IRJET) e-ISSN: 2395-0056

− The surface of concrete blocks are remain intact and does not have any surface cracks. It means that, use of silicone admixture in mortar, which doesn’t influence the surface morphology during curing and water evaporation. This could potentially increase the service life of reinforced concrete structures and reduce frequent maintenance and repair of conservingresources.

TheauthorsaregratefultotheELKAYChemicalsPvt.Ltd.forsupportingthisresearch.

[1] H.Faqe,H.DABAGHH,A.MOHAMMED,NaturalAdmixtureAsAnAlternativeforChemicalAdmixtureinConcrete Technology:AReview,J.Univ.Duhok.(2020)301–308.https://doi.org/10.26682/csjuod.2020.23.2.24.

[2] G.Albayrak,M.Canbaz,U.Albayrak,StatisticalAnalysisofChemicalAdmixturesUsageforConcrete:ASurveyof Eskisehircity,Turkey,ProcediaEng.118(2015)1236–1241.https://doi.org/10.1016/j.proeng.2015.08.475.

[3] K.Grabowska,M.Koniorczyk,InfluenceoforganosiliconadmixturesonthehydrationofPortlandcement,J.Therm. Anal.Calorim.147(2022)6131–6145.https://doi.org/10.1007/s10973-021-10978-x.

[4] K.B.Grabowska,M.Koniorczyk,Internalhydrophobizationofcementitiousmaterialsbyusingoforganosilicon compounds,E3SWebConf.172(2020)1–8.https://doi.org/10.1051/e3sconf/202017214006.

[5] A.M.Nevill,PropertiesofConcrete-A.M.Neville-,Civ.Environ.Eng.-Mech.Mater.Eng.(2020)(130). https://www.pearson.ch/HigherEducation/Pearson/EAN/9780273755807/Properties-of-Concrete(accessedAugust 23,2022).

[6] G.Chandra,L.D.Maxim,T.Sawano,TheSiliconeIndustryanditsEnvironmentalImpact,3(1997)295–319. https://doi.org/10.1007/978-3-540-68331-5_12.

[7] J.Suessmuth,A.Gerdes,ComputationalChemistrytoInvestigatetheChemicalBehaviourofSilanesandCSH–Gel, HydrophobeV.244(2008)233–244.

[8] V.Spaeth,J.P.Lecomte,M.P.Delplancke,J.Orlowsky,T.Büttner,Impactofsilaneandsiloxanebasedhydrophobic powderoncementbasedmortar,Adv.Mater.Res.687(2013)100–106. https://doi.org/10.4028/www.scientific.net/AMR.687.100.

[9] G.Rutkowska,P.Ogrodnik,J.Fronczyk,A.Bilgin,Temperatureinfluenceonordinaryconcretemodifiedwithflyashes fromthermallyconversedmunicipalsewagesludgestrengthparameters,Materials(Basel).13(2020)1–18. https://doi.org/10.3390/ma13225259.

[10] S.Kubens,Interactionofcementandadmixturesanditsinfluenceonrheologicalproperties,Int.Wissenschaftlicher Fachverlag.49(2010)192.https://cuvillier.de/de/shop/publications/752%0ACopyright:

[11] D.Barnat-Hunek,S.Duda,M.Garbacz,G.Łagód,Hydrophobisationofmortarscontainingwastepolyurethanefoam, MATECWebConf.163(2018)9–11.https://doi.org/10.1051/matecconf/201816304006.

[12] Y.Liu,SiliconeDispersions,CRCPress.(2019)387.https://www.routledge.com/SiliconeDispersions/Liu/p/book/9780367872564(accessedAugust23,2022).

[13] E.R.Martin,Carboxylicacid-functionalpolysiloxanepolymers,processforpreparingthesameandusethereof.,Eur. Pat.Appl.1999(2006)1–6.

[14] J.Chojnowski,M.Cypryk,W.Fortuniak,M.Ścibiorek,K.Rózga-Wijas,Synthesisofbranchedpolysiloxaneswith controlledbranchingandfunctionalizationbyanionicring-openingpolymerization,Macromolecules.36(2003)3890–3897.https://doi.org/10.1021/MA025920B/SUPPL_FILE/MA025920BSI20030317_125559.PDF.

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page571

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

[15] V.Lucquiaud,L.Courard,O.Gérard,F.Michel,M.Handy,S.Aggoun,A.Cousture,EvaluationoftheDurabilityof HydrophobicTreatmentsonConcreteArchitecturalHeritage,Restor.Build.Monum.20(2014)395–404. https://doi.org/10.1515/rbm14.20.6-0038.

[16] S.Gupta,SynthesisandCharacterizationofAmphiphilicmoleculesfortheiruseinhealthcareindustry,Angew.Chemie Int.Ed.6(11),951–952.(1967).

[17] I.M.G.Bertelsen,C.Kragh,G.Cardinaud,L.M.Ottosen,G.Fischer,Quantificationofplasticshrinkagecrackinginmortars usingdigitalimagecorrelation,Cem.Concr.Res.123(2019).https://doi.org/10.1016/j.cemconres.2019.05.006.

[18] J.Branston,S.Das,S.Y.Kenno,C.Taylor,Influenceofbasaltfibresonfreeandrestrainedplasticshrinkage,Cem.Concr. Compos.74(2016)182–190.https://doi.org/10.1016/j.cemconcomp.2016.10.004.

[19]A Sayyed,R.Kulkarni,Siliconechemicalsincosmeticsapplicationsandtheirimplicationstotheenvironment,healthand sustainability,EuroCosmetics.30-B50962(2022)18–24

Mr. Vinayak Dal is Manager, Technical at ElkayChemicals Pvt. Ltd. His research is based on specialty polymers, coating, paints, polymericsilicone

Dr. Rahul Kulkarni is a Vice President, Technical at Elkay Chemicals Pvt. Ltd. His research is based on specialty polymers, polymeric silicone, silicone fluid, emulsions, and interfacialscience

Dr. Anwar Sayyed is Scientist & Manager, Technical at Elkay Chemicals Pvt. Ltd. Hisresearch is based on special polymers, Cellulose, Polymeric cellulose, cosmetic silicone, silicoluid, emulsions, andinterfacialscience