International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

2

1Assistant Professor, VPKBIET College Baramati, Pune, Maharashtra, India 2Research Scholar, P.V.P.College, Pravaranagar, S.P.P.University, Pune, Maharashtra, India ***

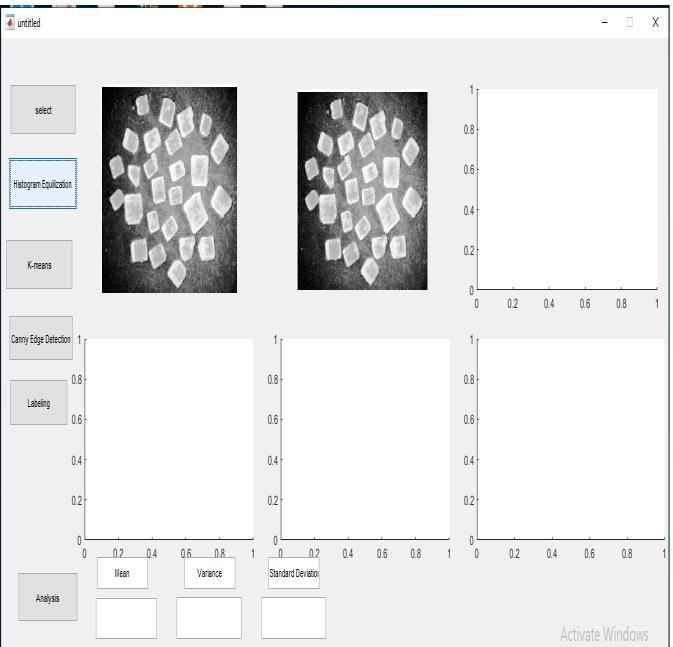

Abstract - Automaticdiscoveryofthesize ofsucrosecrystal is performing a series of contrast improvement techniques, including momentary statistical analysis through standard deviation.Inanyproductionindustry,afeatureoftheproduct is an essential factor. The proposed method measures the quality of sugar crystals after production and at the time of crystal formation itself. Quality measurement depends upon size and shape. A series of algorithms for automatic determination of sugar crystals size using digital image processingwasdeveloped.Statisticalanalysisisimplemented toautomatetheprocedureofqualityregulator.Thissupports to match the intensity dissemination in the massecuite pictures at the preprocessing step. The proposed work recognizes the crystal cluster from the massecuite, which supports to characterize crystal size distribution in the crystallization pan. This benefit to equalize the intensity distribution in the massecuite images at the preprocessing stage. It avoids future errors appearing in the product formation.

Qualitycontrolisavitalpartofthesugarproductionprocess as manufacturers must ensure that the product complies withthecustomer'sspecifications.Thelooktextureofthe final product and the solubility, tendency to aggregate, agglomerate, and other properties are important for industrialprocessesusingsugarasrawmaterial[1].Hence, carecanbetakenthatparticlesareneithertoosmallnortoo big.Traditionally,theparticlesizedeterminationwascarried out by sieve analysis, which was a rather slow, laborintensive method and commonly subject to measurement faultssuchastoomuchexamplematerial,wornoutsieves, wrong sieve parameters, or simple calculation errors [2]. The key attention is to improve the model that uses a computer algorithm for the automatic dimension of sugar crystal.Particularlyinthesugarindustryold-stylephysical controlofcrystallizationisexperienced.Itisthepan-mans accountabilitytoregulatewhenseedingshouldbeapplied andwhentotakemeasurementmostlybyfeedingmorefeed syrup to reduce super-saturation in order to stop further nucleation[3]. The pan-man takes examples from the massecuite on a small glass plate to define if there are alreadyenoughgrainsforthebatch.Hereliesonhisvisual

experiencetodismissthenucleationofthemassecuite.Itcan observethattheresultofshockseedingdependsverymuch on super-saturation and on the length of the time of nucleation [4]. If the entire process is left to the pan-man withoutassistancefrominstrumentation,itisunbearableto control the guaranteed quality of this significant process. Sincehumancontrolissubjecttoexhaustion.Inthisresearch work,techniquescanbeclassifiedintothefollowingsetsas histogram equalization, K-means, edge detection based, distancetransformtechniques,crystallabeling[5]

The process of sugar crystallization occurs through the mechanisms of nucleation, growth, and agglomeration of sucrose crystals. In the crystallization pan stage, crystal sugar is manufactured from syrup [6]. The crystallization pan is loaded with sub-saturated syrup and then heated under partial vacuum until the oversaturation phase is reached.Atthesuper-saturationstage,thesugarpowderis fed in to pan as seed crystals that grow throughout the boiling process[7]. Several stages of procedure sequences areexecutedinthevacuumpan;thesearetheChargestage, Concentration stage, Seeding stage, Crystallization, and Tighteningstage.Duringthechargestage,thecrystallizeris fed with syrup. At the concentration stage, the syrup is acceptabletoreachthesuper-saturationlevel.Seedcrystals areannouncedintothepantoprovokecrystallizationatthe seeding stage[8]. The materialization of crystals occurs at the crystallization stage. The final preferred size of the crystal is obtaining at the tightening stage. The quality of sugar and best control of sugar crystal growth during the crystallizationstagedependsonthecoefficientofvariability of the crystal size distribution. The key factor in crystallization control is super-saturation, followed by crystal content present in the massecuite. The ideal finale product consists of well-formed unbroken crystals of the required size and number in a unit volume. Crystal size distribution,theamountoffineandconglomeratescrystal, andcrystalcolorareimportantparametersthatdetermine theproductquality[9].Theformationofconglomeratesin thecrystallizationpanwilldamagecrystalsizedistribution andproductcolor.

To the growth of income from sugar export and continue competitivenessintheworldmarketplaceonasustainable basis,itisessentialtoconductmillingtechnologyresearchto governorthequalityandprogressoftheeffectivenessofthe rawsugarproductionprocess.Onekeyfeatureofsugargrain

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

production is essential to enhance and monitor the grain growthrateinthecrystallizationpans.First,monitoringthis processattheseedingstageofcrystallizationisrequiredto inaugurate an adequate population of sugar grains at the beginningoftheprocess.Secondly,itisrequiredtoestablish whetherornotthesizedistributionisbimodal,whichwill affect the overall crystal growth rate. Once a problem is detected,thenecessaryprocesscontrolconditionsneedto beadjustedinordertoassurethequalityofthefinaloutput fixed by commercial specifications (adequate size and homogeneous grains). The crystallization process is determinant for the crystals size distribution. The main influencing factorsareseed quality,super-saturationfield distribution, and secondary nucleation[10]. The principal objectiveofsugarmanufacturingoperationsistoachievea consistentandacceptableproductquality,whichisachieved at a low cost. High sugar yields in conjunction with good mother liquor exhaustion during crystallization are important requirements to achieve this target. As a consequence, process control is of major importance. The critical feature that needs to be monitored during the crystallization process is the super-saturation of mother liquorsandthecrystal content ofthe massecuite[11]. The search to boost production has led to numerous measurement methods to regulate crystals growth in the sugarindustry.

The general objective of this learning is to discover the feasibilityofobtainingthe real-timemeansugarcrystal size directly from sugar images captured using a 0-500X portable Digital Microscope Endoscope Lab measurable cameramagnifierwith640x480optimumresolutions[12]

Thehistogramisoneoftheessentialfeatureswhicharevery linkedtoimageenrichment.Thehistogramdoesnotonlygive usageneralsummaryofsomeusefulimagestatistics,butit also can be recycled to prophesy the appearance and intensitycharacteristicofanimage[13].Ifthehistogramis focused onthelowsideof the intensityscale,the imageis generallyadarkimage.Ontheotherside,ifthehistogramis focusedonthehighpartofthescale,theimageisgenerallya brightimage.Ifthehistogramhasashortdynamicrange,the imageusuallyisanimagewithapoorcontrast[14].

The sample size is a key factor to obtain reliable and meaningfulresults.Therearemanymethodstogetthesizeof thesample,inthecaseofgrainiscommontousestratified sampling,probabilisticorrandomsampling[15].

Animagebinarizationmethodcoveringthestepsofsettinga threshold value range for a value regarding a Y value representingbrightnessofapixelparticularfromanimage andextractingapixelwiththevalueconcerningtheYvalue intheimagewithinthethresholdvaluescope,whereinwhen apixelisnominatedintheimage,thethresholdvaluescopeis setinarangeofaddingapredeterminedvaluetothevalue concerningtheYvalueofthechoosepixeland/orsubtracting thepredeterminedmarkpoint,andwhereinwhenafterthe pixelischoose,apixelvariousfromthatpixelischoose,ifthe valueconcerningtheYvalueofthechoosepixel isgreater thanthevalueconcerningtheYvalueofthepixelforwhich thethresholdvaluescopeisset,betweenthepredetermined valueaddedtothevalueconcerningtheYvalueofthechoose pixelandalowerlimitvalueinthethresholdvaluescope,a newthresholdvaluescopeisset,orifthevalueconcerning the Y value of the choose pixel is smaller than the value concerningtheYvalueofthepixelforwhichthethreshold value scope is set, between the predetermined value subtractedfromthevalueconcerningtheYvalueofthescope pixelandanupperlimitpointinthethresholdvaluerange,a newthresholdvaluerangeisset[16].

ThebinarizationMethodconvertsthegreyscopeimage(0up to256graylevels)intoblackandwhiteimages(0or1).The resultofOCRhighlyrelatestobinarization.Thegreatclass binarized image can give maximum accuracy in character recognition as compared original image because noise is presentintheoriginalimage[17].

Edgedetectorsofsomekind,particularlystepedgedetectors, havebeenanessentialpartofmanycomputervisionsystems. Theedgedetectionprocesshelptosimplifythecriticizeof

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

images by drastically reducing the amount of data to be processed,whileatthesametimepreserving

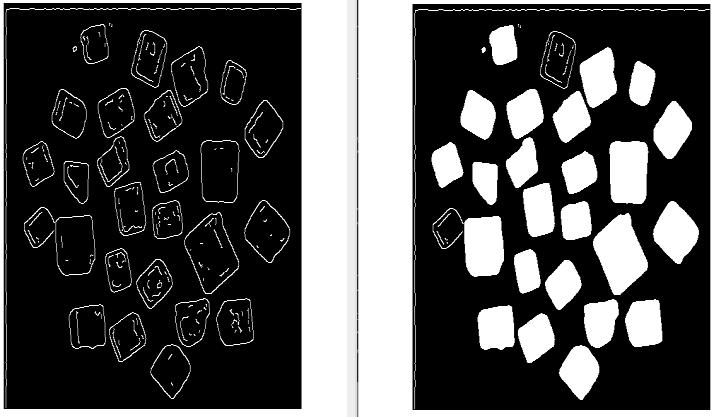

TheCannymulti-stageedgedetectionalgorithmisrecycledto identifytheedgesinthesegmentedimage.Crystaledgepixels have strong intensities compared to other pixels. It is an optimaledgedetectoralgorithmwithalowerrorrate.The canny algorithm ensures that edges occurring in images shouldnotbemissed;also,thereshouldnotbeanyresponse tonon-edgepixels[18].Thedistancebetweenthecalculated edgepixelsandtheactualedgeisminimumtoensureedge localization.Thisalgorithmisensuringonlyoneresponsetoa single edge, therefore, eliminating the chance of multiple possibilities.Inthistechnique,initiallyperformsmoothing techniques with a Gaussian filter to reduce desired image detailsandthencalculatetheimagegradientateachpixel.If thegradientmagnitudeatapixelissuperiortothoseatits twoneighborsinthegradientdirection,thepixelisobserved as the crystal edge. Otherwise, the pixel is marked as the background.Inconclusion,theweakedgesareremovedby hysteresisThresholding[19].

Edgedetectionisa processthatrecognizestheavailability andplacesofedgesconstructedbycorrectchangesincolor intensity(orbrightness)ofanimage.Itprovidesamodern contour detector, combining local and global image information. It gives extensive quantitative evaluation and thereleaseofanewannotateddataset.

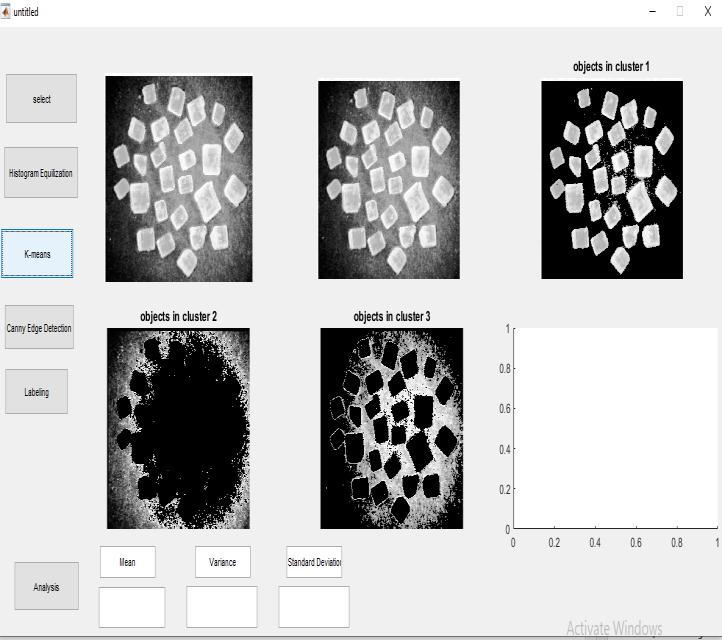

Data clustering is the method of grouping data features constructed on a specific aspect of similarity between the features in the group. EM clustering will eliminate the problemofoverlapping.Clusteringistheforemostmethod appliedfortheclusteringofmathematicalandimagedatain data mining and image processing applications. Clustering can perform the job of image retrieval easy by finding the imagesasequalasgiveninthequeryimage[8].Theimages are clustered combine in some given number of clusters. Imagedataareclusteronthebasisofafewattributessuchas tone, shape color etc. consist of the images in the form of pixels.Forthesubjectofefficiencyandbetterresults,image dataaresegmentedbeforeapplyingclustering.Clusteringis theunsupervisedgroupingofpatternssuchasobservations, dataitems,orfeaturevectorsintogroupsnamedasclusters. Applicationsofclusteringaregrowingnowadaysveryrapidly becauseitsavestimeperiod,andtheresultsobtainedfrom theclusteringalgorithmisverysuitableforthealgorithmsin the later stages of the applications[9]. The data in every grouparesimilartoeachother,butshortlydissimilartothe data in different groups. So, the data which are clustered togetheraresimilartoeachother.

WhereXjisavectorrepresentingthemthdatapointandup isthegeometriccentroidofthedatapointsinSj.

Thesizeandshapeofacrystalaresignificantfeaturesinthe processofqualitycontrol.Crystalshavearegularshapeto meetthisconstraint,soconsidertheareaofacrystalmustbe almostthesamethattheareaofaboundingboxcontaining it[10].Therefore,MatchingAttribute(MA)isdefiningasthe ratio between the area of the crystal and the area of the boundingbox,thus: 100% c b

A MA A (2)

Eq.(2), Ac is the area of the crystal and Ab the area of the boundingbox.Thetypicalvaluescouldbebetween60%and 80%.

Themeanparticlediameteristhemostvitalsinglestatistical parameterbecauseitallowustocomputeotherparameters ofinterestsuchasparticularsurfaceareaandthecoefficient ofvariation.TheMeanDiameterWeightedbyParticle(dwp) isareferencemeasureusedinthefoodindustrytodetermine theidealcrystalsizesugarcanbecalculatedbysummingall equivalent diameters (MA) and dividing the result by the numberofcrystals,thatis, i wp

MA

Where MAi represents the MA for each crystal and N the numbersofcrystals.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Diameter Weighted by Volume (dwv), which can be calculatedby, ii wv i

MAV d V (5)

WhereMAirepresentstheMAforeachcrystal,andViisthe crystalvolumemodeledassphere.

Fig -2:ImageSegmentationusingK-meansAlgorithm

Fig -3:EdgeofSegmentedImage

Thecoefficientofvariation(CV)isameasureofthespreadof thecrystalsizesisbasicallystandarddeviationexpressedasa percentage.TheCVcanbeweightedbyparticlesorvolume. Hence,theCVweightedbyparticlesCVwpcanbecalculated by: .100%

ExpressthesizeuniformityofsugarcrystalsbyusingaCV weightedbyVolumeCVwp.AlthoughtheCVwpisappliedto estimate the crystal sizes, the CVwp is the most benefited methodtocompute the morphologyvariation inthesugar industry. The CVwp consists of modeling the crystal as perfect spheres [11][4]. The CVwv is based in the Mean

OncetheMAiiscalculated,theCVwvcanbecomputedfrom, 2() *100%

iwvi i

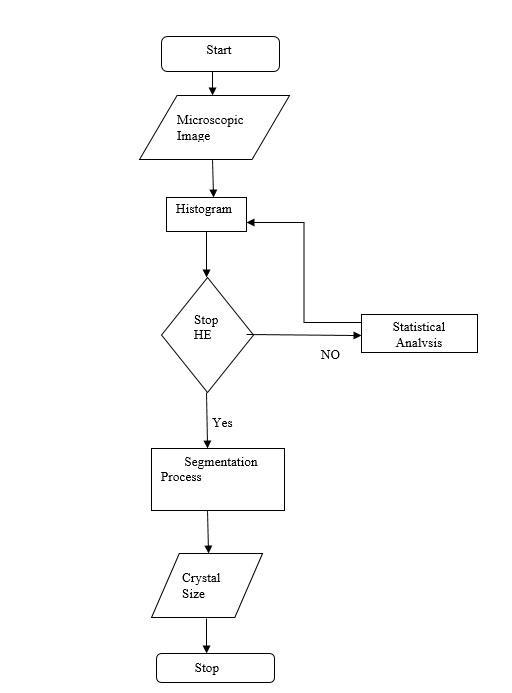

Fig -4:FlowchartofSugarCrystalImageAnalysis

Table -1: StatisticsObtainedForSugarCrystalSampleof Fig.2

Statistic By Particle By Volume

Mean(x) 0.9781 01.3487 Variance(σ2) 0.0914 10.4470 Standard Deviation(σ) 0.2975 00.3547 Coefficientof Variance(CV) 31.25 20.8421

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Thepossibilitytomeasuresucrosecrystalsizeparameters usingdigitalimageprocessingwasannounced.Anautomatic computerized method has been industrialized to measure sucrosecrystalsizeparametersdirectlyfromimages.Since theimagecontainsmultipleobjectsofinterest,thealgorithm was speedily and fruitfully executed using MATLAB. Individual objects were identified after segmentation operationandimplementedtheregionofinterestaccording totheirconnectedcomponents.Thecrystalsizedistribution of the individual crystals was estimated as well as the background of the image was openly identified from the focal point by a separation process. In this project, 25 samplesofthesucrosecrystalweretakenunsystematically todeterminetheregionofinterest'scrystalsizedistribution using Distance Transform and Foreground Background algorithms.Inconclusion,theresultofthealgorithmswas compared with manually clicked images and wellestablished techniques used in the factory for the determinationofgrainsizeparameterspreciselyMAandCV.

[1] Manuel Cardona," Sugar Crystals Characterization for Quality Control Inspection Using Digital Image Processing," Conference: 2016 IEEE 36th Central AmericanandPanamaConvention,Nov.2016

[2] SreedhanyLR,Philomnia,LancyThomas,"Automated MassecuiteSucroCrystalSizeCharacterizationSystem for Crystallization Pan in Sugar Industry," 2016 International Conference on Information Technology (InCITe)-ThenextGenerationSummit,pp.82-86,2016

[3] Paithane, Pradip Mukundrao, and S. N. Kakarwal. "Automatic Pancreas Segmentation using A Novel Modified Semantic Deep Learning Bottom-Up Approach."InternationalJournalofIntelligentSystems andApplicationsinEngineering10.1(2022):98-104.

[4] N. Faria et al., "Quantification of the morphology of sucrose crystals by image analysis," ELSEVIER Power technology133(2003),54-67

[5] Paithane, Pradip M., and S. A. Kinariwal. "Automatic determination number of cluster for NMKFC-means algorithms on image segmentation." IOSR J. Comput. Eng.(IOSR-JCE)17(2015):12-19.

[6] Dalzlel et al., "An image analysis system for sugar crystal sizing" in Proc.Aust.Soc.Sugar Cane Technol,21:366-372,1999.

[7] Paithane, P. M., & Kakarwal, S. N. (2018, December). Automatic determination number of cluster for multi kernel NMKFCMalgorithm onimage segmentation.In

InternationalConferenceonIntelligentSystemsDesign andApplications(pp.870-879).Springer,Cham.

[8] Ingram and steindll, "Rapid Crystal Sizing on the pan stage by Digital Image Analysis," Proc.Aust.Soc.Sugar CaneTechnol,23:361-368,2001

[9] B. Zhang et al., "Monitoring crystal growth based on imagetextureanalysisusingwavelettransformation," IFAC,2012

[10] Paithane,P.M.,Kakarwal,S.N.,&Kurmude,D.V.(2020). Top-downmethodusedforpancreassegmentation.Int. J.Innov.ExploringEng.(IJITEE),9(3),1790-1793.

[11] A.K.Jain,"FundamentalsofDigitalImageProcessing," EnglewoodCliffs,NJ:Prentice-Hall,1989.

[12] Paithane,P.M.,Kakarwal,S.N.,&Kurmude,D.V.(2020, December). Automatic Seeded Region Growing with LevelSetTechniqueUsedforSegmentationofPancreas. In International Conference on Soft Computing and PatternRecognition(pp.374-382).Springer,Cham.

[13] W.K.Pratt,"DigitalImageProcessing."NewYork:Wiley, 1978

[14] J.Canny,"Acomputationalapproachtoedgedetection," IEEE Transaction on Pattern Analysis and Machine Intelligence,vol.8,pp.679698,1986

[15] Kakarwal,S.,&Paithane,P.(2022).Automaticpancreas segmentationusingResNet-18deeplearningapproach. Systemresearchandinformationtechnologies,(2),104116.

[16] Wagh, S. J., Paithane, P. M., & Patil, S. N. (2021, December).ApplicationsofFuzzyLogicinAssessmentof Groundwater Quality Index from Jafrabad Taluka of MarathawadaRegionofMaharashtraState:AGISBased Approach. In International Conference on Hybrid IntelligentSystems(pp.354-364).Springer,Cham.

[17] PArbelaez,"ContourDetectionandHierarchicalImage Segmentation" IEEE Transaction on Pattern Analysis andMachineIntelligence,vol33,No5,2011

[18] Soong-DerChen,Abd.RahmanRamli,"MinimumMean BrightnessErrorBi-HistogramEqualizationinContrast Enhancement, "IEEE Transactions on Consumer Electronics,Vol.49,No.4,2003

[19] Paithane,P.M.,Kakarwal,S.N.,&Khedgikar,S.S.(2020). Semantic Web Technology and Data Mining for Personalized System to Online ECommerce. InternationalJournalofProgressiveResearch in Science and Engineering, 1(5),136-139.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1’st Author Photo

Dr.Pradip M. Paithane is working asAssistantProfessorinComputer engineering department of VPKBIETBaramatiCollege Hehas 9 years teaching experience He published 4 scopus index paper and5internationaljournalpaper

2nd Auth

Ms.SaritaJibhauWaghisworking as research scholar in SPPU university. She has 2 years teachingexperienceandpublished 3internationaljournalpaper.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified