International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Rahul G. Karmankar, Ranjit Kumar Nandeti, Vidya Y Kondru

Rahul G. Karmankar, Ranjit Kumar Nandeti, Vidya Y Kondru

Usharama college of Engineering and Technology-[Autonomous]-Vijayawada-AP-521109-India ***

ABSTRACT: - In a modern high-precision manufacturing environment, there is a general thrust towards complex shape with higher geometrical and dimensional accuracy, higher surface integegrity at low cost. The severe service requirementsofproductalsoleadtoutilizationofmaterials

Thisscenariochasedbymanufacturingindustriesthrough existing available process as well as by continuous developing an existing or new process. New process is generally known as ‘Advanced manufacturing Process’. Productperformanceanditslifecycledominatingbymany factors and surface finish is one of them. Surface finish. Presently therearemanyadvancedprocessesarebeingin use for this purpose and one of them is abrasive flow machiningprocess. Eventhoughitisfoundinmidof1960it isplayingimportantroleandcontinuouseffortsaremadeto exploit it for new challenging manufacturing process. Basically,itwasdevelopedbydeburringpurposebutlater useforsurfacefinishingprocess.Inthisprocessmaterialis removedbyextrusionactionofviscoelasticmedia.Themain ingredientsofmediaareviscoelasticcarriers,abrasive,oil and some additives. The performance of AFM is generally governed by properties and percentage of ingredients of mediaaswellasoperatingparameters.Designofthevarious parts of AFM machine also plays a major role for the operatingperformanceof AFMsystem.

AFM system is contribution of Machine, Tooling and Media.Sodesign ofvariouspartswithdimension asper requirementsofrawmaterialsaremoreeffectivelikeother parameters also. Main components of AFM machine are piston assembly, media cylinder, plates, Rods, Fixtures; power pack etc should have to design as per the requirementsoffinishingprocessandfinishingparts.This paper work show only the basic machineas per design of workpiecenotlikeasversatilemachine.Generally,machine are classified as one direction abrasive flow finishing process,twodirection abrasiveflowfinishingprocessand orbital abrasive flow finishing process. This design parameters are used for two-way abrasive flow finishing process.

Key words- AFM machine, Tooling, Fixtures, Media cylinder

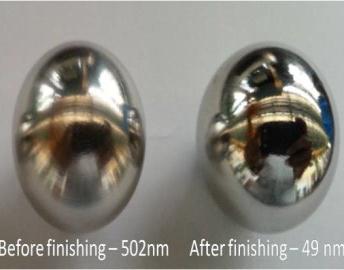

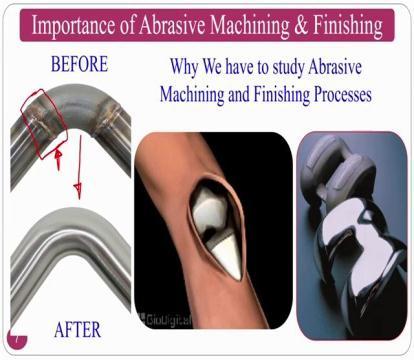

Thispapershowsthe detailsguidelineforfabricationand workingofadvancedAbrasiveFinishingProcesses,wherein you will see the advance versions and you will do the finishingofacomplexsurfacesaswellasthesimplesurfaces also,So,whatistheneedofadvancedfinishingprocesses? So, conventional finishing processes such as grinding, honing,superfinishing,lapping,theseareallyouhaveseen andwemoveontotheadvancedmachiningprocesseswere the MRR or the material removal is the primary criteria. Now,wemoveontotheadvancedfinishingprocesseswhere ourprimarycriteriaistofinishtothenanolevelofsimpleto complexgeometries.Advancedfinishingisneedfultoreduce friction,toimprovefatiguelife,toreducegenerationofcrack formation, to reduce corrosion effects. AFM produce predictable,repeatableandconsistentresult.Upto90%of time can be saved by using AFF as compared to hand finishingoperations.UsingthisAFMsystem,itispossibleto getsurfacefinishRaupto50nmanddeburrholesassmall as0.2mmradiusandedgefrom1.5mmto0.0255mm.Itis easy to integrate AFF in any automatic manufacturing environmentandalsobyunderstandingandcontrollingthe process parameters AFM can be applied to an impressive range of finishing. It helps for producing compressive residual stress and can be finish very complex machine parts.Oneofthe importanttermsisitgivesupersurface finishatlowercostthanothersconventionalmachine.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1. Mediahasbeenfilledinlowermediacylinder. Bykeepingthepositionofthepistoninthetopand upper media cylinder piston has been kept in bottomposition. 2. Afterfillingthesufficientamountofthemedia,the fixturehasbeenset.Withdummywork pieceand runatrequirepressurewithfewnumbersofcycle sothatthereisformfillingofmediaoccur 3. Next fixture has been taken out and again some amountofmediahasbeenfilledifrequire. 4. Fix the work piece along with the cleaning of surface with acetone and initial measuring of roughnessvalueinfixtureandcheckthesetup.

Settherequirepressure 6. Runthesetupforparticularnumberofcycles. 7. Aftercompetitionofcyclestakeoutthesampleand cleaneditwithacetoneandmeasureitsroughness value 8. Repeatthecycle 9. Checkforanotherabrasivealso

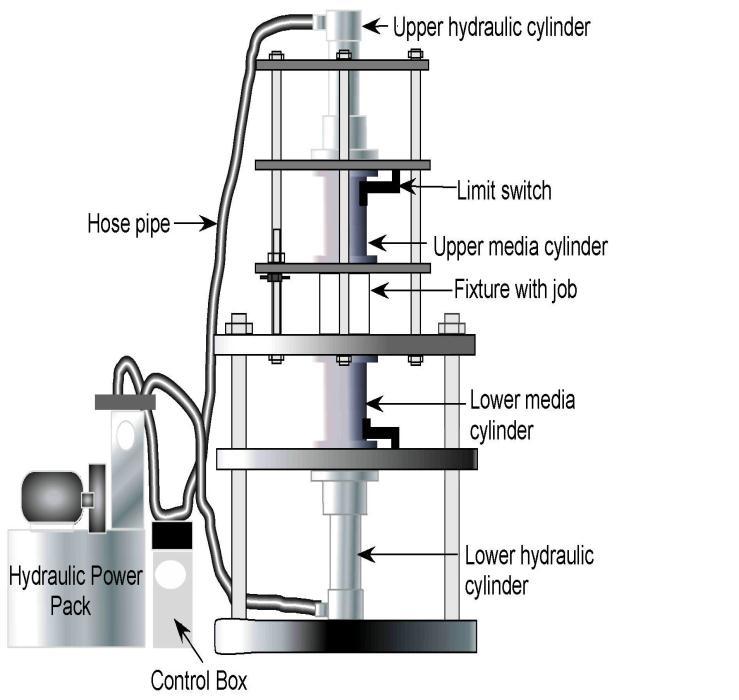

CONFIGURATION OF AFM SYSTEM:MAIN COMPONENTS OF AFM SYSTEM ARE

Upperhydrauliccylinder

Lowerhydrauliccylinder

Uppermediacylinder

Lowermediacylinder

Hydraulicpowerpack

Limitswitch

AFM SYSTEM’S MAIN ELEMENTS: -There are three main elementsforAFMsystem1.Machine2.Media3.Tooling

MACHINE-AFMmachineareavailableinavarioussizeand configuration depends on the require capacity and workpiece configuration. It consists of frame structure, hydraulic cylinders, hydraulic power pack and control system.Generalworkingpressurerangeisinbetween7to 220 bars and flow rate exceeding 380 liters per minute volumeofflowdependsonthedisplacementofeachmedia cylinderstrokeandtotalnumberofcyclesusedtocomplete theworkpiece.Thecontrolandmonitoringsystemcanalso beaddedtomaketheresultmoreefficientandreliable

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

MEDIA: -It is a mixture of polymer and abrasives. Most frequentlyusedpolymerforthepurposeispolyborosiloxane andmanyothersgradeofpolymersarealsouseddepending ontheconfigurationofworkpiece.Generally,useabrasives arealumina,siliconcarbide,boroncarbideordiamond.The functionofpolymerusedinmediaaretoactasabinderand to transfer the extrusion force where as the function of abrasive is to abrade the material when media is passing through restricted area. The rheological properties (viscosity) govern the performance of the media. Higher viscosityissuitableforlargepassage(thelengthissmaller than two times the passage width) and lower viscosity is suitableforradiusingandsmallpassage.Thelifeofmediais depended on many factors like initial batch quantity, abrasiveratioofmixtures

4. Self-weightofpartisneglected

5. Selectedfastenersandspacerpipesarefitforuse.

DESIGN CALCULATION: -

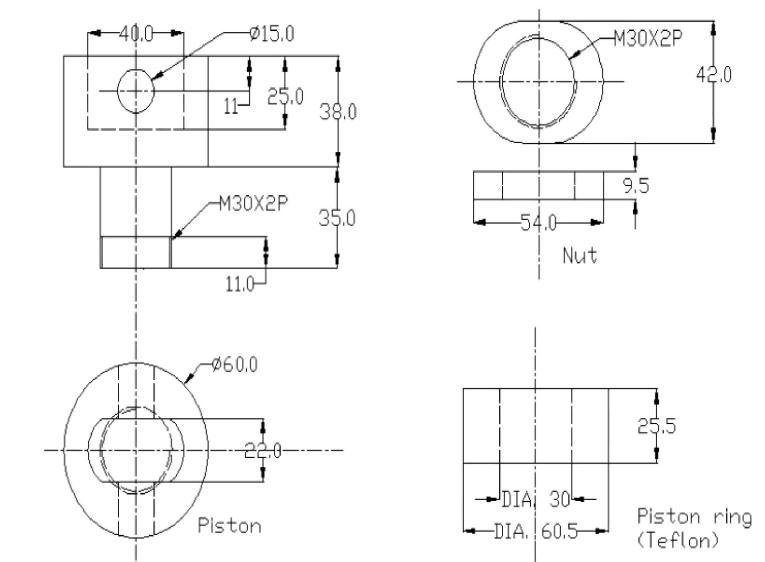

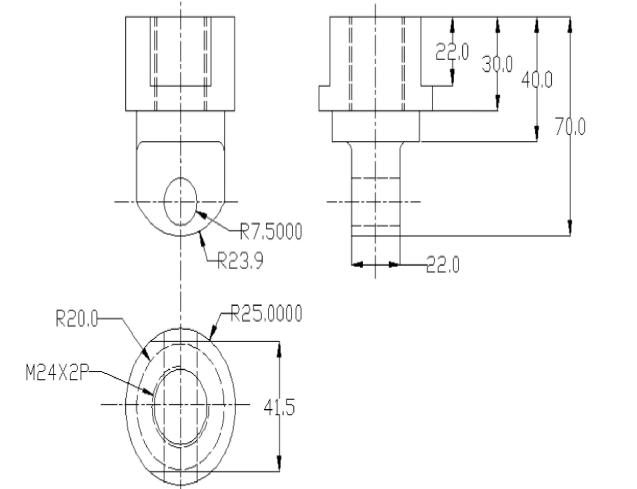

1.PISTONASSEMBLY:-

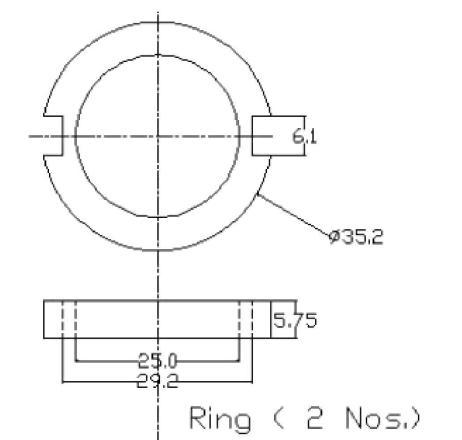

Themainfunctionof piston istotransmitthemediafrom one media cylinder to other media cylinder via restricted passage by compressive force which is exerted by the hydrauliccylinderonpiston.Thecommonmaterialsusedfor pistonarecastiron,castaluminums,forgedaluminum,cast steel and forged steel. The forged aluminum has been chosen for piston because of its light weight and good strengthcharacteristicreducefrictionbetweeninnersurface ofcylinderandpistonthe“Teflonring”isusedandthishasa verylowwear,frictionandgoodtemperatureresistance.Itis assumedthatnomuchtemperatureisrise

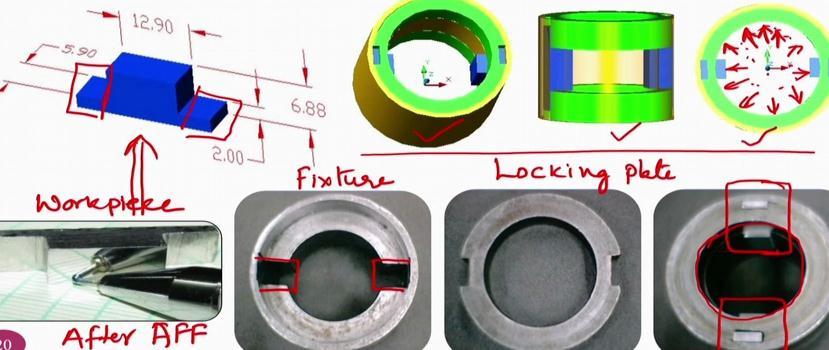

TOOLING:-Thefunctionoftoolingistolocateandholdthe workpiece in position and direct the flow of media. The toolingisdesignedinasuchwaythatitshouldrestrictthe flowatdomainmaterialremovalisdesired.Thecomplexity oftoolingdependsonthecomplexityofworkpiece,number of workpieces to be machined etc. The modern high level productiontoolingarealsodesignedforautomaticloading andunloading.

1. Set-up design by taking 10 MPa as maximum workingpressure

2. Strength is important for set-up, so set up is designedwithstrengthcriteria.

3. Dynamicsituationisnottakenintoaccount

1.Pistonthickness=13mm

2.Teflonpistonring=Radialthickness=15mm

Axialthickness=25mm

3.GudgeonPin=Outdia.=15mm,Innerdia.=10mm

Length=45mm

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

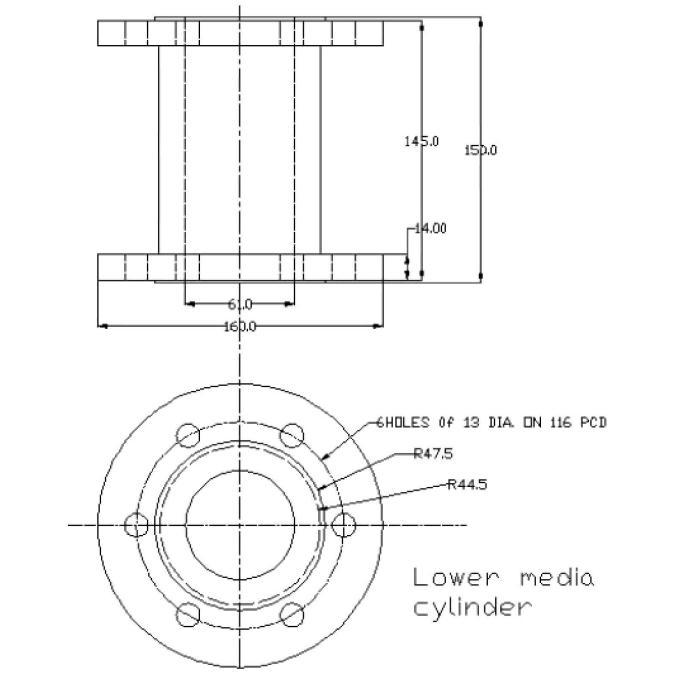

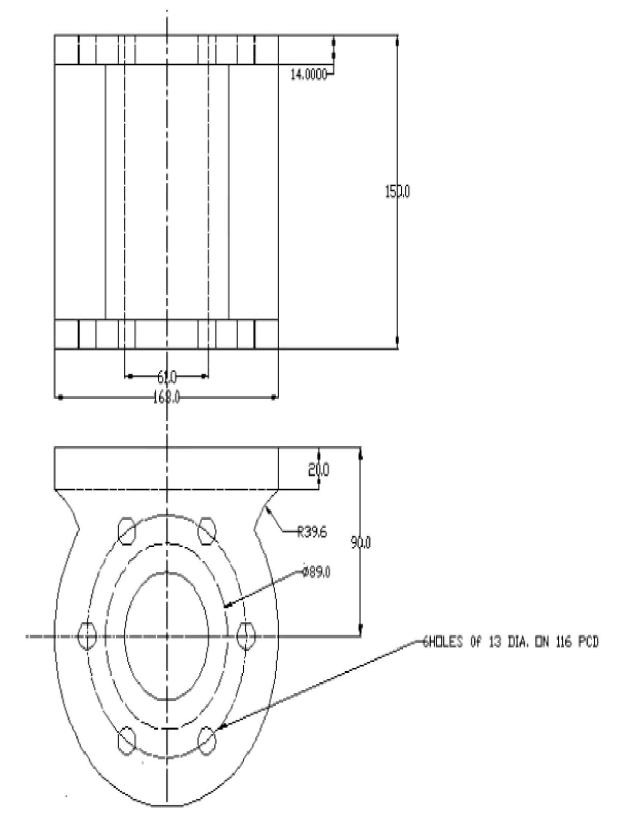

MEDIA CYLINDER:-

Themainfunctionofmediacylinderistocontainthemedia as well as to guide the piston under maximum working pressure.Tosatisfyingtheserequirementsinsidethepiston, linersare insertedandduringcalculationsitistreatedas openendedpressurevessel

1.Stressinducedinthewallisuniformthroughoutthickness

2.Effectofcurvatureofwallisneglected.

Lengthofthecylinder

Length of cylinder=Piston length +stroke length + Allowance=73+75+2=150mm

Diameterandwallthicknessofcylinder

The cast iron material (Brittle) used so design criteria is maximumnormalstresstheoryoffailure.Thefollowingwall thickness equation is applicable (both open and closed endedcylinders)

Lowermediacylinder

Design is safe as all limits of stress are low.

Uppermediacylinder

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

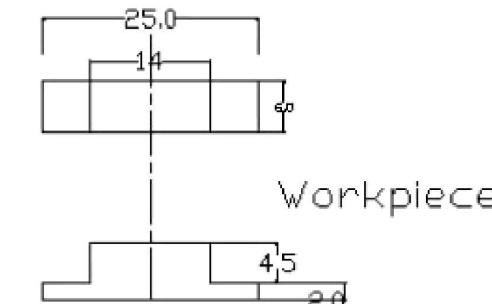

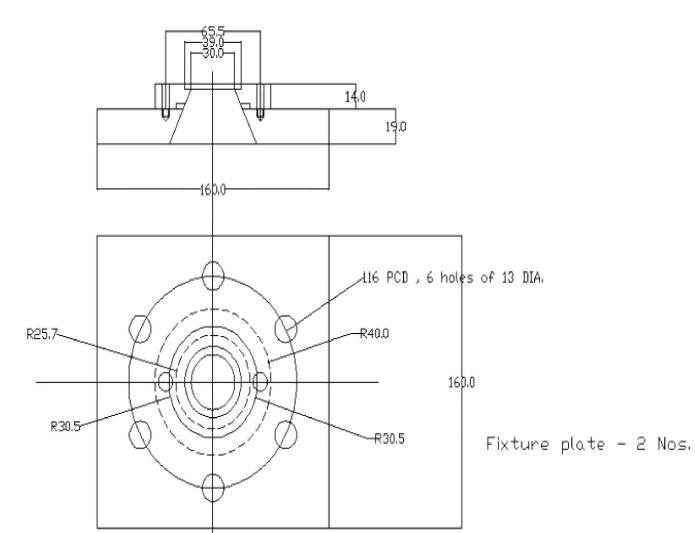

FIXTURES: -

The fixture has been made from En8 material. The main functionoffixtureistolocateandholdtheworkpieceaswell as enough strength against acting force during actual working. The dimension of fixture is fixed with respect to requirements and designing point of view. It is checked under compression with consideration as hollow short cylinderandbothendsfixed.

OuterdiameterDo=38.8mm

InnerdiameterDi=26.8mm MI=π/4[Do4–Di4] 109405.06mm4 andE=2x10 5 N/mm2

Compressionstrength=390MPa

Cripplingload=4[π2 EI/L2]whichcangivesafevaluecan becalculatedusingEuler’sformula.

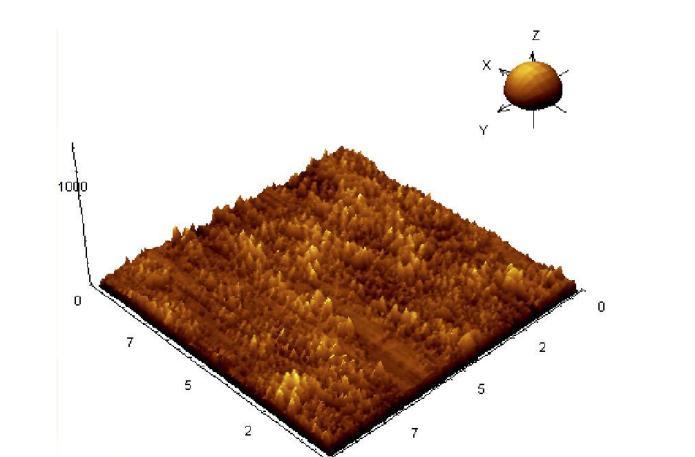

Fixturebarrelwithworkpiece. OBTAINED RESULT USING AFM SYSTEM

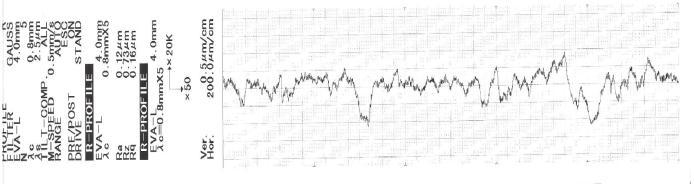

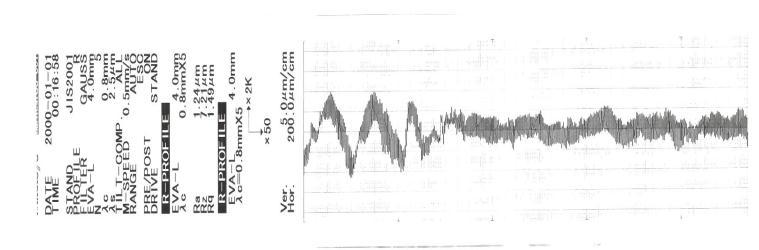

1. Initial Ra=1.24 micron on En8 for continuous finishingusing220,400,800and1000meshsizefor 450cycleswith5MPapressure.

1. Final Ra=0.120-micron micron on En8 for continuous finishing using 220,400,800and 1000 meshsizefor450cycleswith5MPapressure.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

RahulG.Karmankar

Asst.Professor

Usharama College of Engineering and Technology-Vijayawada State-A.P.- 521109I-NDIAmech.rahul@usharama.in

AfterhavingmadethestudyonconfigurationofAFMsystem alongwithspecificationsandparametersitisinferthatthis system can be utilize for deburring, finishing and superfinishingoperationbycontrollingandmonitoringthe actual performance of the system. Design parameters, configurationcanbemodifiedaspertherequirementsofthe workpiece and specification of machine to achieve superfinishinguptonano-level.

References: -

Hoffman,E.andR.McCarty."UltimateDeburringwithSilly Putty."Tooling&Production,February1966,pp.53-70.

Kohut, Tom. "Surface Finishing with Abrasive Flow Machining."Vol.2oftheProc.oftheFourthInt'l

Aluminum Extrusion Technology Seminar. 11 - 14 April 1988.Washington,DC:TheAluminumAssociation,

Machinability Data Center. Vol. 2 of Machining Data Handbook.3rd ed.Cincinnati:MetcutResearch Associates he.,1980.

Rhoades, Lawrence. "Abrasive Flow Machining." ManufacturingEngineering,November1988,pp.75-78.

Rhoades,Lawrence."AbrasiveFlowMachiningwithNot-SoSillyPutty."MetalFinishing,July1987,pp.27-29.

Rhoades,Lawrence,Ed.CostGuideforAutomaticFinishing Processes. Dearborn, MI: Society of Manufacturing Engineers,1981.

Wick, Charles and Raymond F. Veilleux, eds. Materials, Finishing and Coating. Vol. 3 of Tool and Manufacturing Engineers Handbook. 4th ed. Dearborn, MI: Society of ManufacturingEngineers,1983.