International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Mechanical

Engineering departmentUsharama college of Engineering and Technology-[Autonomous]-Vijayawada-AP-521109-India *** -

ABSTRACT: -

Thispapershowsoneoftheadvancedfinishingprocessesas comparedtoconventionalfinishingprocessandit’srequired tool’sspecificationalongwithspecialtyandanalysis.

Abrasive flow machining processes is one of the most advancedfinishingprocesseswhichisinventedin1960for deburring process in USA but later it is well-known as advancedfinishingprocessorAFM.Thisprocesscangiveus superfinishing machine members for simple to complex structure.Oneofthemostadvantagesofthisprocessisthat itusedtoproducemicrotonanosurfacefinishingwhichis thecurrentrequirementofmostproductsinthiscompetitive environment.ThreebasiccomponentsofthisAFMsystem areMachine,ToolingandMedia.So,media playamajorrole for the finishing process. Media is nothing but the composites of abrasive, natural polymer as SBR and oil (Paraffin) along with some additives. As we are using abrasive either Silicon carbide, Al2O3, Dimond, boron carbideetc.,thisisalsocalledasmultipointcuttingtool.This isflexibletoolwhichcanprovidesuperfinishingatlowcost, lessfinishingtimebesidesverysimplemachinestructure.

Noofparametersareresponsibleforproducingthefinishing products as raw material’s initial structure, types of raw materials, operating process, operating pressure, no of working stroke, stroke time, properties of media like rheological properties, thermal properties, mechanical, chemical properties properties etc. So, media and its characterizationoranalysisareveryimportanttodesignthe best tool and its combination to improve the finishing standard of a workpiece. So, this paper focus on the composites of multipoint tools along with analysis result. After doing some analysis it has been found that that the combination of 0.68 Sic 0.2 SBR 0.12 oil gives the superfinishingforEn8andAlmaterials.

Key Words-AFMsystem.SBR.SiC,Media,MediaAnalysis

INTRODUCTION:-

After having made the characterization of commercially available media following properties has been observed whicharehelpedtodeveloptheandfabricatetherequired andneedfulmedia.Sonew mediahasbeenfabricatedwith thereferenceofexistedcommercialstandardmedia.

1.Measurementofthermalstabilityofviscoelasticcarrier:TGA-Thermogravimetricanalysisisananalyticaltechnique used to determine a material’s thermal stability and its fraction of volatile components or to identify the decomposition products by monitoring the wight change duringheating.Themeasurementisnormallycarriedoutin airorinaninertatmosphere.Inadditiontoweightchanges, it is also possible to record the temperature difference betweentherestedmaterialandreferencematerials.

The measurement was carried out for commercially availablemediausedinAFMsystemforsampleweightof5-6 gmwithSBRasacarrier.

2.Measurementofcrystalstructure:-

CommerciallyavailablemediausedinAFMsystemconsists of viscoelastic material, abrasive particles and other additives. Diffraction study was carried by XRD diffractometer.

3.FTIR -Fourier transform infrared spectroscopy -FTIR is usedforquantitativecompoundsofanunknownmixtureor toidentifythechemicalbonds.FTIRstudieswereconducted by IR spectrophotometer for SBR which is used in commercialmedia. FABRICATION OF MEDIA: -

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Properties ASTM Paraffinic Naphthenic Aromatic Specific gravity D1250 0.85-0.89 0.91-0.94 0.95-1.0

Pourpoint D97 -18to-9 -40to-18 +0to+32

Refractive index D1747 1.48 1.51 1.55

Aniline point D611 95-127 65-105 35-65

Molecular weight D2502 320-650 300-460 300-460 Aromatic content D2007 19-30 20-40 35-85

3.SBR Styrenebutadienerubber(SBR)areusedtoprepare themedia.

Properties:Properties AverageValue Boundstyrene(%) 23

Volatilematter(&) 0.75 MooneyviscosityMLat1000C 52

Ashcontent(%) 1.50 Stabilizer Non

Formulation; - The percentage ingredients by weight for eachformulationisgivenby

% of particular ingredients = (Weight of particular ingredients/Totalweightofcompound)X100

Themixingofabrasiveparticlesandprocessoilwascarried outanopentwo-rollmill(150mmdiameterroll,7.5HP)with friction ratio of 1: 1.1 and temperature of 500C to 75 0C supplied by Slash Hydrate Equipment Pvt Ltd-India. The clearancebetweenrollwasadjustablefrom0.2mmto8mm. ThemixingwasperformedaspertheASTMD3182-89 with mastication(breakdownofmolecularchain)ofviscoelastic carrier.Thisisessentialbecauseitimprovetheacceptability ofviscoelasticcarrierforabrasiveandadditives(ifany)and ultimatelypromotestheuniformdispersion.Thebatchwas cut¾ofthedistanceacross therollwiththehelpofknife and held the knife at this position until the bank just disappears. Next successive ¾ cuts made from alternate ends of the roll. Allowing 20 sec. between each cut. After sufficientmasticationthepre-decidedabrasiveaddedevenly across the roll at uniform rate. The total oil quantity was added alternatively in small-small quantity with abrasive.

Thefallingmaterialcollectedcarefullyandaddedbacktothe mix. For ensuring uniform dispersion batch is pass six to eighttimesthroughmillwithopeningof0.8mmandfinally passedfourtimeswithopeningof6mm

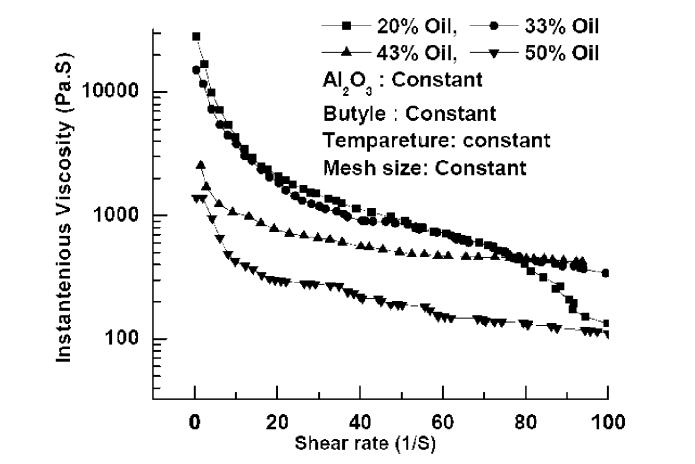

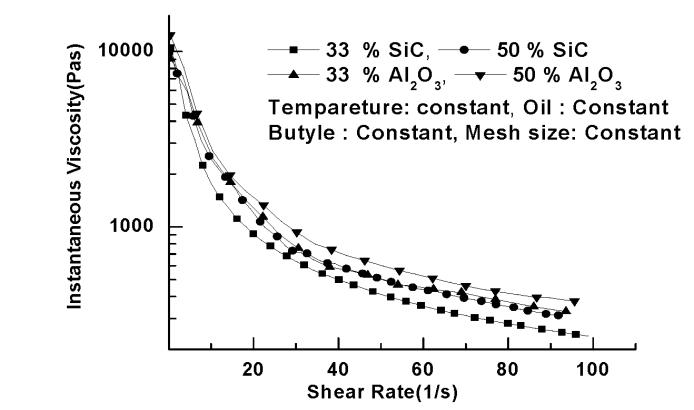

Followinggraphshasshowsthebasiccharacteristicsofthe mediaalongwithvariationoftheresult.Mediaperformance aredependingonthespecificproperties,physicalproperties, chemicalproperties,rheologicalpropertiesetc.ofthemedia andalsoingredientspercentage.

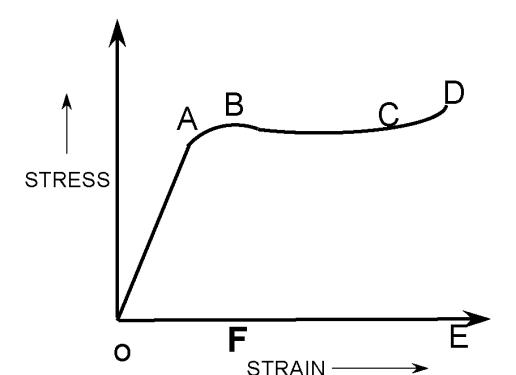

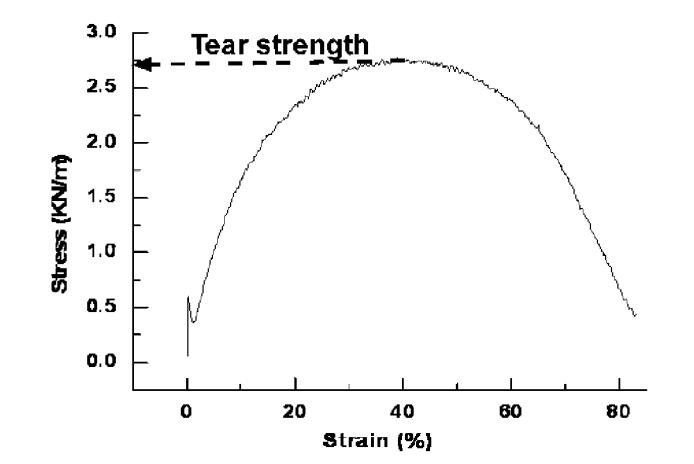

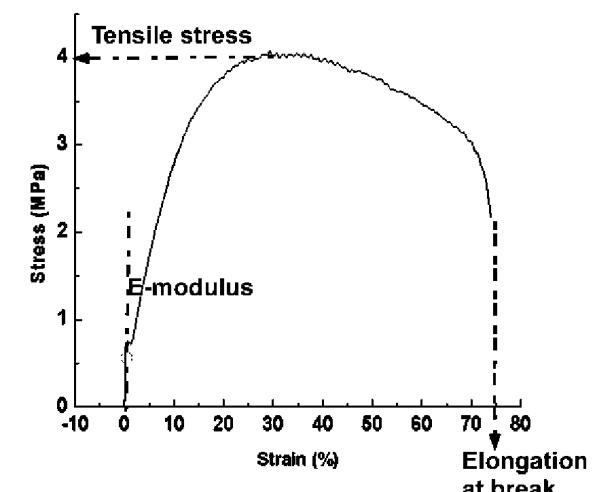

Stress-strain diagram of media -Through stress strain diagram it is possible to justify the performance of media underloadingconditionmeansactualworkingcondition.

(ASTMD412-98a)

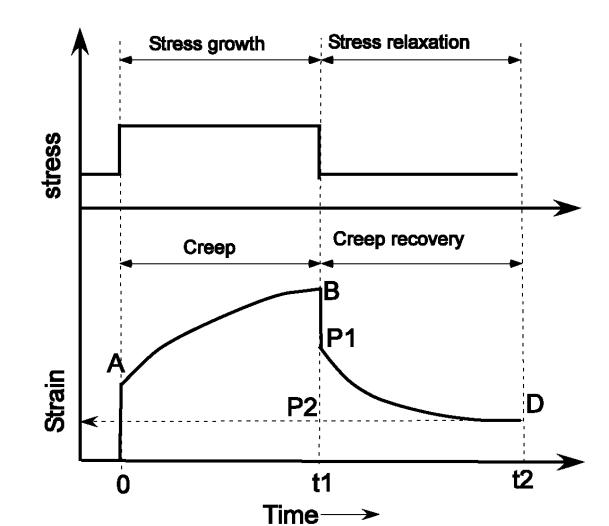

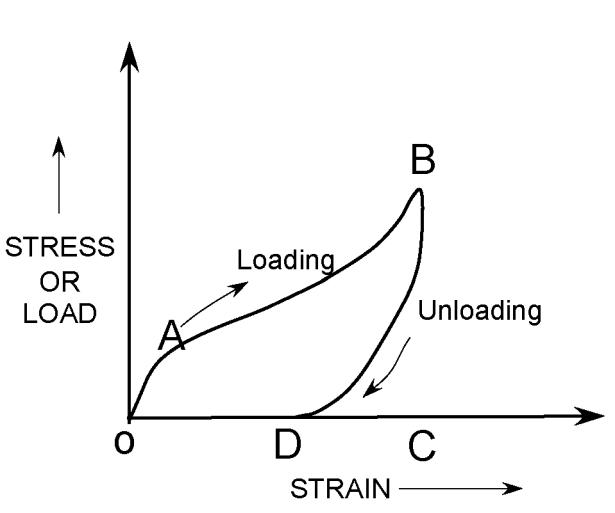

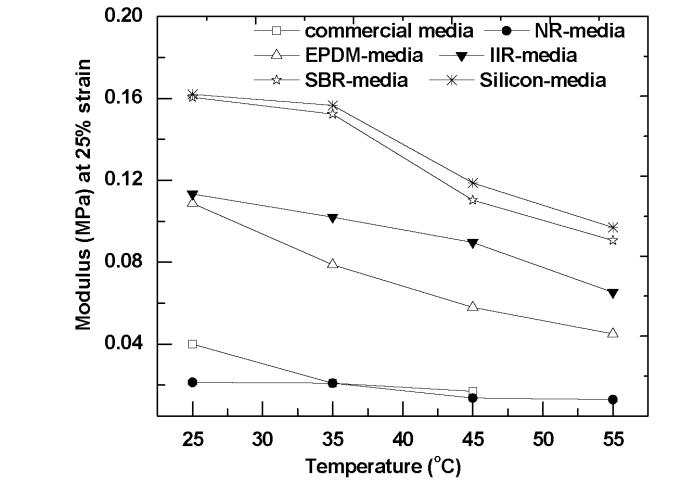

Varioustesthasbeenconductedtochecktheperformanceof themediaandobservedthevariousmechanicalproperties as elasticity, resilience, stiffness, modulus, creep etc. Following graph shows the behaviors of the media under temperaturerangeofthe25to550Cwithmaximumloadof 10kN.

Stress-Staindiagram

2021, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

HysteresisLoop

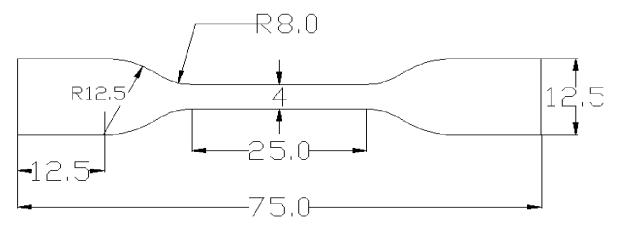

MeasurementofTensilestrength

MeasurementofCreep

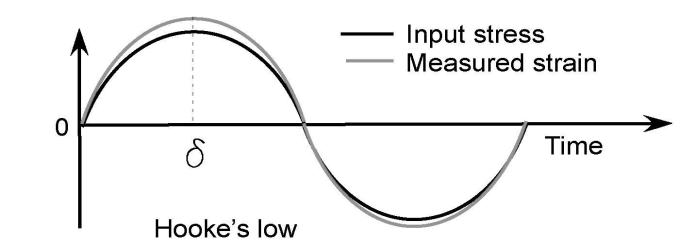

Measurementofoscillation

PERFORMANCE OR ANALYSIS OF MEDIA: -

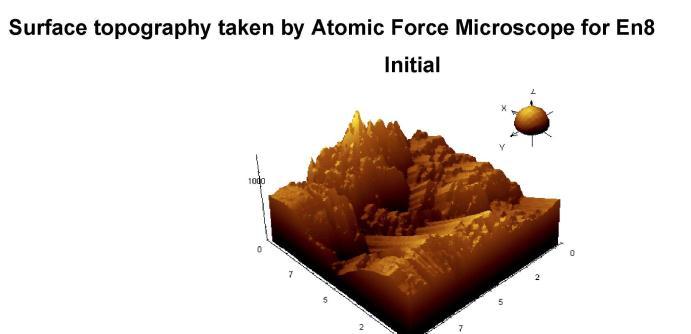

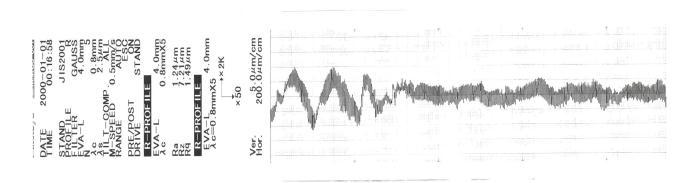

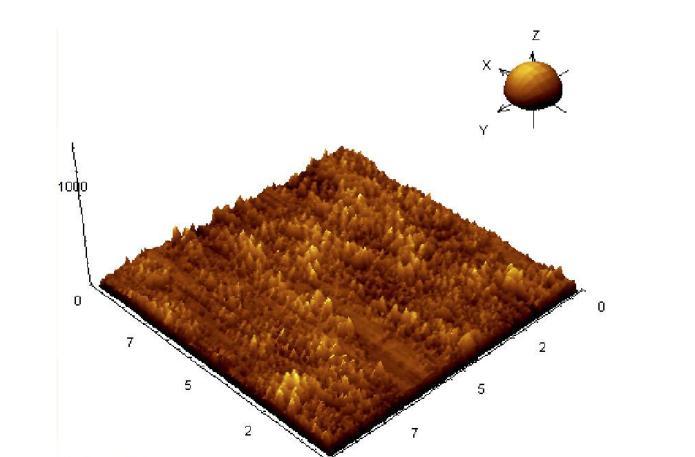

Media performance are analyzed by doing the finishing operation ontheworkpiece likeEn8andAluminumusing AFM system. Before performing the operation clean the material with acetone and measured its initial value of hardness and surface roughness. Materiel should be free formtexturesandshouldbepreparedbyprecisionmachine so that it led to yield superfinished materials. Roughness valuearemeasuredbystandardsurfaceroughnessTesteras ModelSJ301

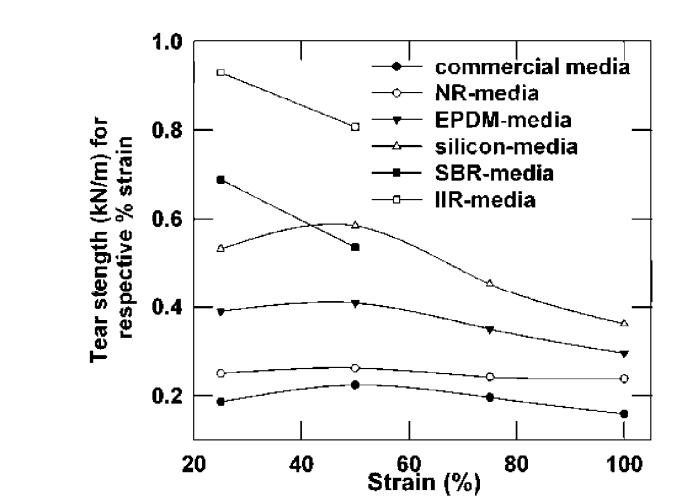

MeasurementofTearstrength

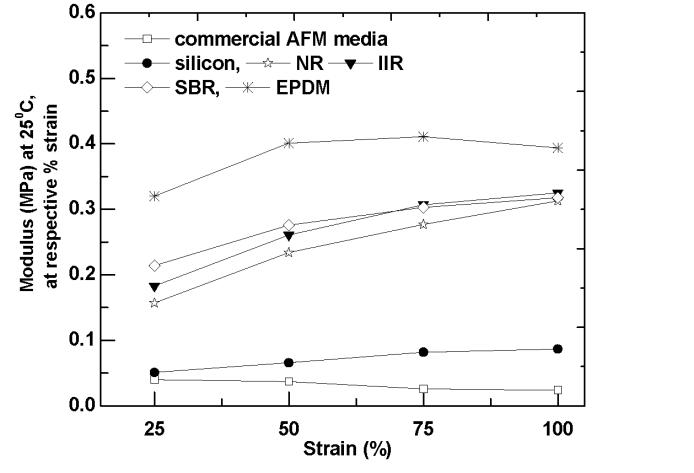

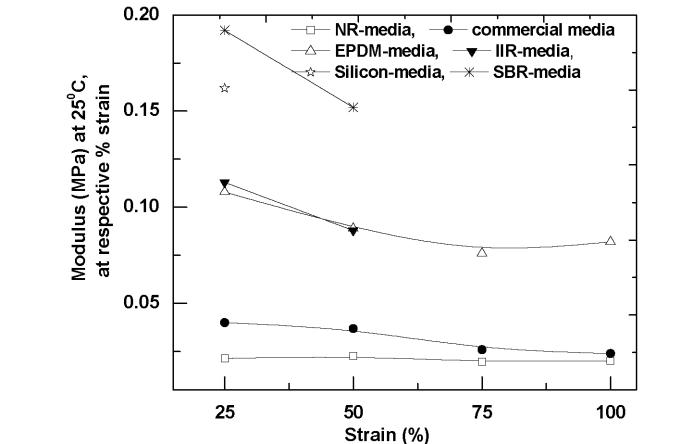

Effectofstrainonmodulusundertensilemode

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

EffectofstrainonModulusat25 0Cforthecombinationof 0.68SiC0.2SBR0.12oilundertensilemode

Effect of shear rate on viscosity by changing types of abrasives.(RheologicalTest)

Effectoftemperatureonmodulususingvariousviscoelastic materialsundertensilemode.

Effectonshearrateonviscosityofvariouspercentageofoil. RESULT

EffectofStrainontearingstrengthofviscoelasticmedia.

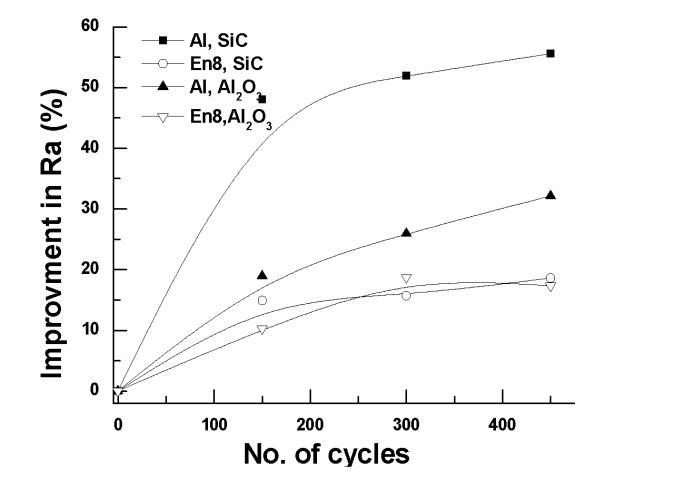

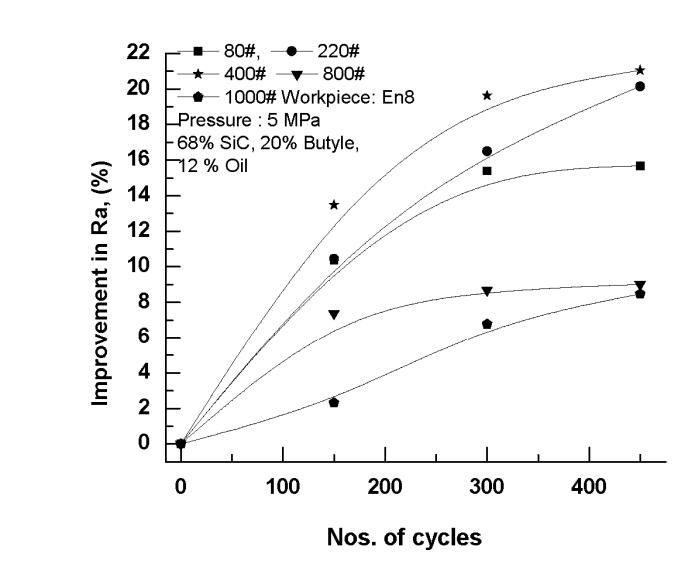

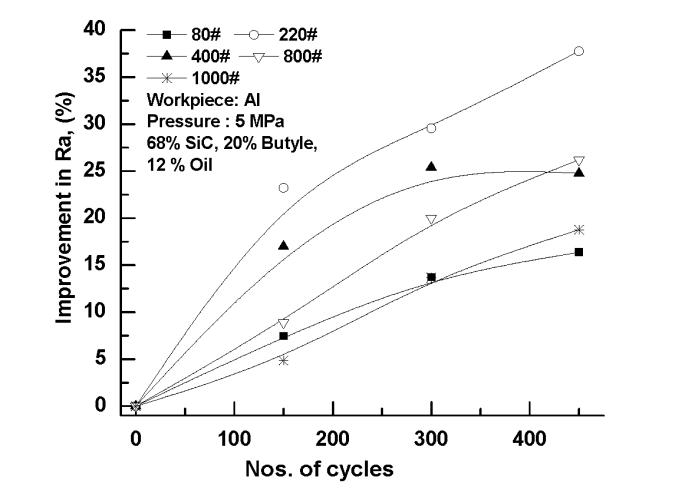

EffectofnumberofcyclesonRavalue

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

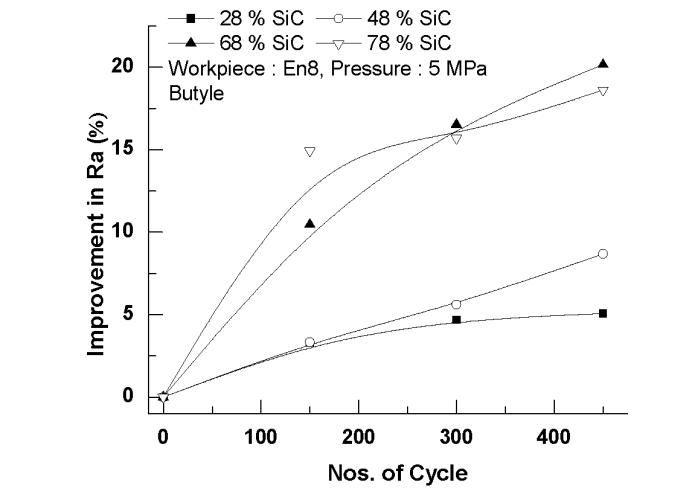

EffectofnumberofcyclesandRoughnessRavalue ForEn8material.

EffectofNumberofcyclesonRavalueforthecombinationof 0.68SiC0.2SBR0.12oilforEn8material

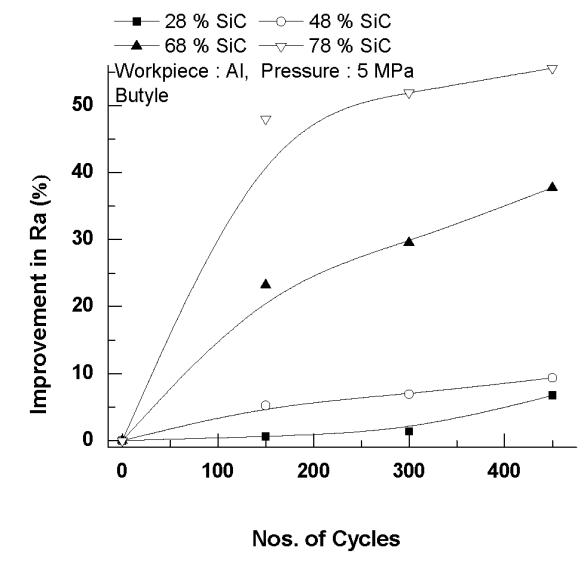

EffectofnumberofcyclesandRavalueforAlmaterial

1. Initial Ra=1.24 micron on En8 for continuous finishingusing220,400,800and1000meshsizefor 450cycleswith5MPapressure.

EffectofNumberofcyclesonRavalueforthecombinationof 0.68SiC0.2SBR0.12oilforAlmaterial

2. Final Ra=0.120-micron micron on En8 for continuous finishing using 220,400,800and 1000 meshsizefor450cycleswith5MPapressure.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Wick, Charles and Raymond F. Veilleux, eds. Materials, FinishingandCoating.Vol.3ofToolandManufacturing

Engineers Handbook. 4th ed. Dearborn, MI: Society of ManufacturingEngineers,1983.

RahulG.Karmankar

Asst.Professor

UshaRamaCollegeofEngineeringand Technology-Vijayawada State-A.P.- 521109I-NDIAmech.rahul@usharama.in

-

After having made the result analysis of media and its performancestatusitisinferthatmediacharacteristicplaya major role for the improvement of the finishing of the surface.Operatingenvironmentandcompositionofmedia cangiveusmicrotonanofinishedstructure.Studyhasbeen shownthatabrasivetypes,percentage,viscoelasticcarrier, oilandotheradditives,operatingpressure,numberofcycles aremajorgoverningparametersforthesuperfinishingofthe materials.Underproperselectioncriteriaandanalysisusing advanced technique can be improved the performance of AFM-systemtoimprovethequalityoftheproductandalso helptoachievesuperfinishedproducts.

REFERENCES: -

Hoffman,E.andR.McCarty."UltimateDeburringwithSilly Putty."Tooling&Production,February1966,pp.53-70.

Kohut, Tom. "Surface Finishing with Abrasive Flow Machining."Vol.2oftheProc.oftheFourthInt'l

Aluminum Extrusion Technology Seminar. 11 - 14 April 1988.Washington,DC:TheAluminumAssociation,

Machinability Data Center. Vol. 2 of Machining Data Handbook.3rd ed.Cincinnati:MetcutResearchAssociates he.,1980.

Rhoades, Lawrence. "Abrasive Flow Machining." ManufacturingEngineering,November1988,pp.75-78.

Rhoades,Lawrence."AbrasiveFlowMachiningwithNot-SoSillyPutty."MetalFinishing,July1987,pp.27-29.

Rhoades,Lawrence,Ed.CostGuideforAutomaticFinishing Processes.Dearborn,MI:Societyof ManufacturingEngineers,1981.

RanjitKumarNandeti

Asst.Professor

UshaRamaCollegeofEngineeringand Technology-Vijayawada State-A.P.- 521109I-NDIA-

VidyaYKondru

Asst.Professor

UshaRamaCollegeofEngineeringand Technology-Vijayawada State-A.P.- 521109I-NDIA-