International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1PG Student(MPD), Department of Mechanical Engineering, G Madegowda institute of technology, bharathinagara-571422, Karnataka, India

2Principal, Department of Mechanical Engineering, G Madegowda institute of technology, bharathinagara571422, Karnataka, India ***

Abstract - This study aims to build "Multi-Purpose AgricultureVehicle."Indiaisfamedforitsagriculturalgoods andquality,andit'savitaleconomicengine.Mostfarmers arepoor andhavetinyfarms,thusa portable, economical agriculturalvehicleisneeded.Currentagriculturalvehicles havejustonepurpose,eitherseedplanting,water/fertilizer spraying,orploughing.Solarpanel,DCmotor,bodyframe, toggleswitch,solarpoweredpump,arduinounoarevehicle components.Thisagriculturalvehiclereliesonthequantity ofsolarenergythesolarpanelgetstooperateitsnumerous sections. Crystal solar panels charge 12 volt batteries. DC motorisdrivenbybattery-storedelectricalenergy.Switches regulatethemotortodowaterspraying,ploughing,andseed sowing.Powertransmissionusesspurgear,wormandspur gear,chain,andsprockets.Thisvehiclelowershumanlabour in agriculture and increases automation. This vehicle increases production on small farms. This car uses sustainablesolarelectricity.Itcansowseeds,spraywater, andploughusingchain-sprocketandworm-and-spurgear mechanics.

Key Words: DC motor, solar, agriculture, multipurpose.

Agricultureismainstayofmanynationsacross theglobe. Therearemultipleinterventionsbymanyscholarstoutilize technologyandmechanicalinterventionintoagriculture.In the early 1920’s itself there were attempts to implement robotics to help improve agriculture [2]. These were primitive models that required use of cable connection to operatethemachine.Revolutionaryattemptsinthefieldof applying robots to agriculture continued to develop especiallyafter1980sastechnologicaladvancementinthe mechanicalengineeringusingtheembeddedsystems.[1]

Seedplanting,asmentionedbySaurabhUmarkarandAnil Karwankar [1,] is an essential part of the agricultural process. Pneumatic high-precision planting has been perfected for a broad variety of seed sizes, allowing for consistentseeddistributioninseedspacingthroughoutthe

travel route, benefiting a wide range of crop types. A wirelessnetworkisemployedforthereceiver.Therobotcan only travel in one direction, which is the system's biggest drawback.Whenanobstructionisdetected,thepoweriscut offimmediately.In[2],agriculturalresearchersM.D.I.Sujon, R.Nasir,andJayasreeBaidyacomparedtheresultsofusing different planting methods and machineries, as well as applyingoilseedrapeatvaryingrates,ontheemergenceof plants from seeds and the resulting harvest. Using an approachsimilartoultrasonicdetection,therobotwillshift its location and farm. A major drawback of this method is thatitdoesnotfunctionoptimallyinallsoilconditions.The authors of [3] H. Pota R. Eaton, J. Katupitiya, and S. D. Pathirana conclude that the decline in the availability of competentsowingpersonnelhasmadetheuseofbullockdrawn planting machinery more necessary. A crop's production is directly proportional to many parameters, includingplantingdensityandspacing.TheMicrocontroller 8051 in this system is responsible for mediating the exchangeofdatabetweenthevarioussensorsandactuators. Theprimaryproblemwiththisparadigmisthatitreliesona single mechanism. The approach helps farmers with the fundamentaltaskofplantingseeds,asdescribedin[4]byS. Kareemulla,K. Shaik,E. Prajwal,B.Mahesh, and V.Reddy. Themethodofoperationforthisequipmentiselementary. Maximizing the overall yield is achievable. The labour shortage may be alleviated. Time and effort spent sowing withthisrobotequipmentarereducedcomparedtomanual andtractor-basedmethods.Likewise,thereislessneedless seedwaste.Unfortunately,thismodelhasonemajorflaw:it reliesononlyoneunderlyingprocess.Theaforementioned studies aided in comprehending the complexities of agriculturalrobotstudy.Manyproblemswithmobilityand grass-cuttingefficiencyplaguetherobotsdescribedinthe aforementioned literature reviews. This study provides excellentsolutionstotheseissues.Incontrasttoearlierbuilt robots,thisonemakesuseofthreedifferentsystems.The potentialofrobotsinthenearandfarfutureisalsoshownby thisstudy.

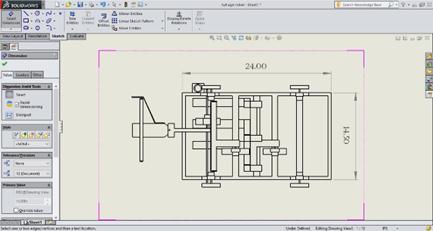

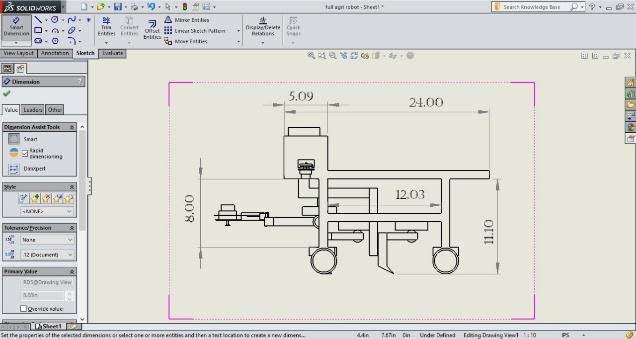

Thissectionprovidesthedetailsabouttheimplementation steps followed to construct the robot. The solid edge is

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

employed to design the dimensions of the tool and the Arduinoideisemployedtodumpthecodeandthehardware connectionsareemployedasperthedesign.

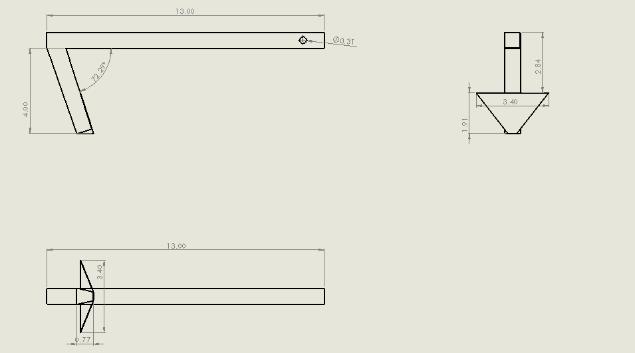

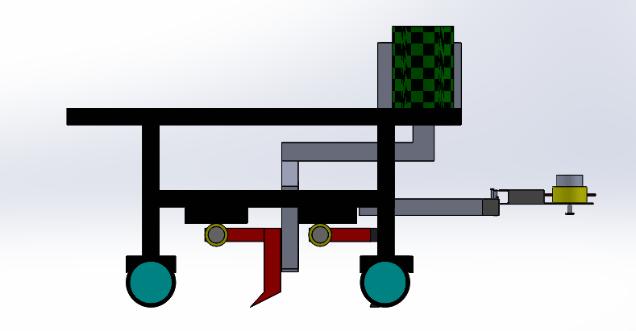

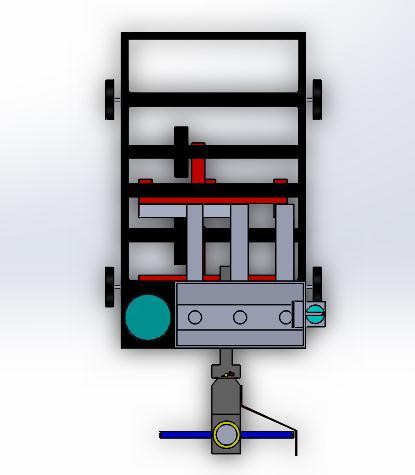

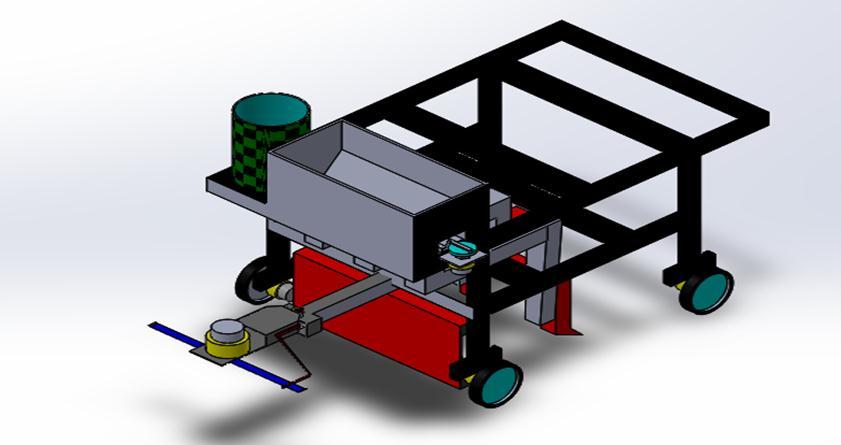

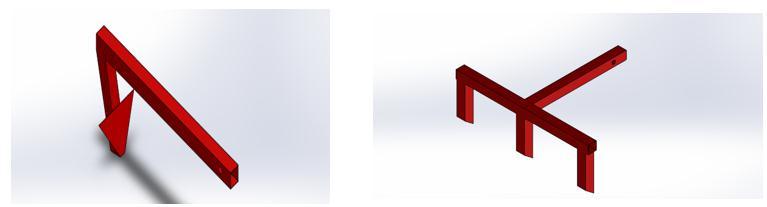

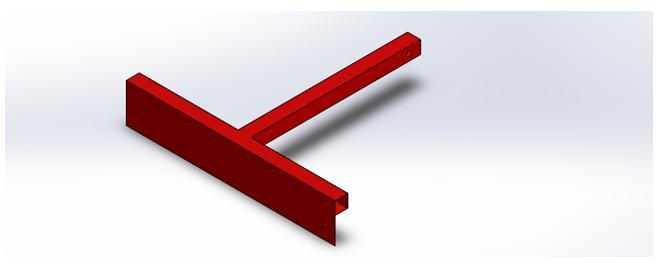

Before the implementation the design of the frame is the softwareisessentialtoavoidthewrongcalculationsandthe abovefigureshowsthedesignedmodelinthesolidedge.

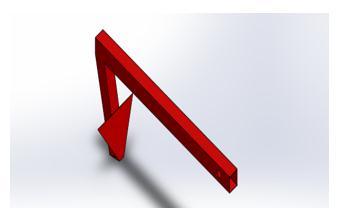

Thedesignofthebodyframeisasshowninthebelowfigure,

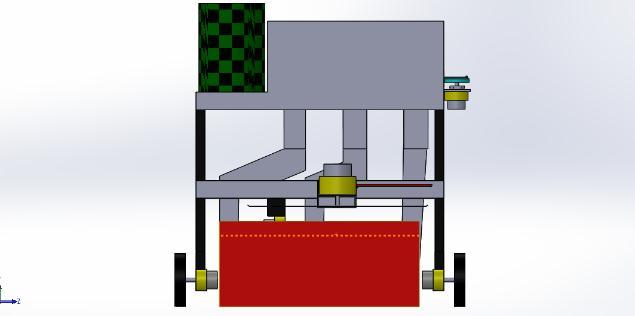

Placingofthecomponentsontheframeisasshowninthe belowfigure

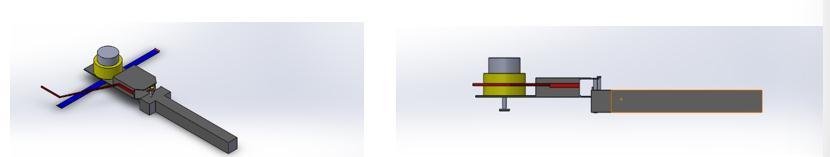

Toremovetheweeds,themotorwithdifferentbladeswere addedandthesoftwaredesignisasshownbelow,

Figure 4: Skelton view of the proposed model.

The compartments designed for the model to store the water/pesticidesandseedsisasshowninthebelowfigure

Figure

Todigtheland,theimplementationintheproposedmodelis asshowninthebelowfigure

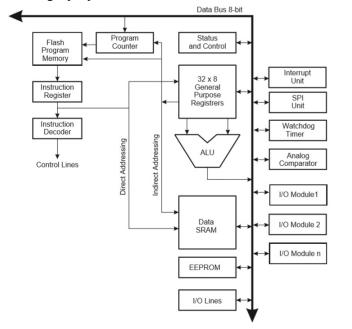

Arduino Atmega328 microcontroller as shown in figure is used to command the various components. The Arduino atmega328microcontrolleranditsarchitectureisshownin figure

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

The motor driver is a module for motors that allows to control the working speed and direction of two motors simultaneously.Themotordriverisdesignedanddeveloped onthebasisofL293DIC.L293Disa16pinmotordriver

ICasshowninFig.5.Itprovidesbidirectionaldrivecurrents atvoltagesrangingfrom5Vto36V.TheL293DisanICwith eight pins on each side to control two DC motors simultaneously.Itconsistsof4inputpins,4outputpinsand 2enablepinsforeachmotor[9-10].

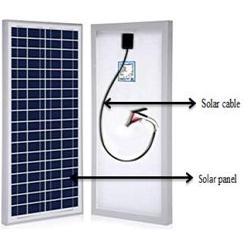

Thesolarcellsthatareseenonsatellitesandcalculatorsare alsocalledphotovoltaic(PV)cellsasshowninFig.3,whichas the name implies (photo meaning \light" and voltaic meaning \electricity"), convert solar energy directly into electrical energy. A module is a group of cells which is electrically connected and packed into a frame (most commonlyreferredassolarpanel).Solarpanelsareagreat way to cut your electricity that everyone wants to live on theirownoratleastreduceourhome’scarbonfootprint,and solar panels make this dream possible. Solar panels are made of photovoltaic a (PV) cell, which converts sunlight intoelectricity.

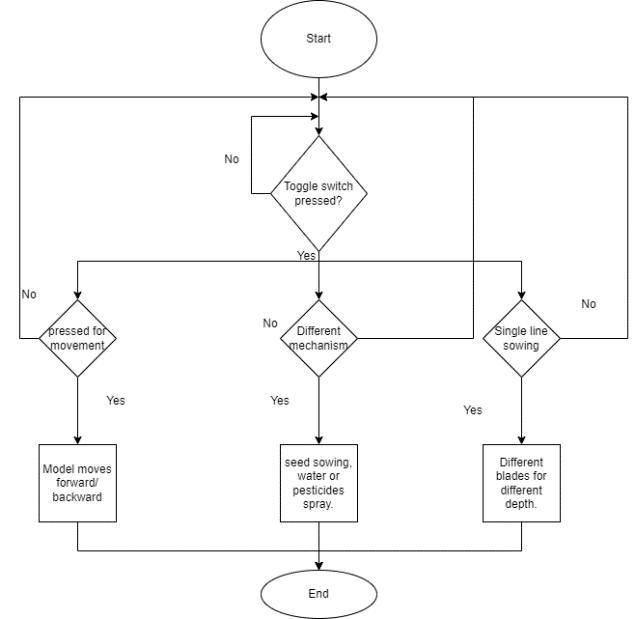

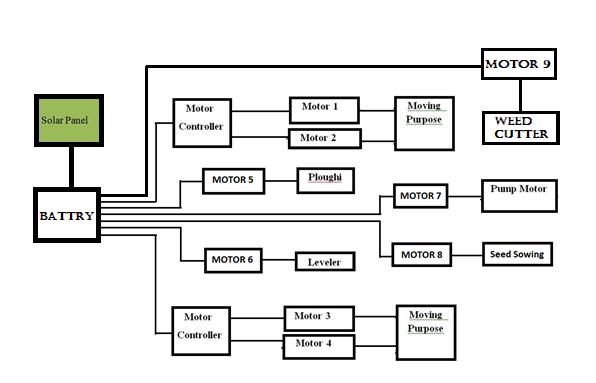

The flow chart of the proposed system is as shown in the belowfigure,

Figure 8: flowchart of proposed model.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

The primary goal of this project is to create a versatile machinethatcanbeusedtodigdirt,plantseeds,levelthe muck,andsprayfertilizerwiththeleastamountofaccessory changes and for the least amount of money. The versatile tool'swholepowersupplyisbatteryandsolarpowered.

•Designed for the four-wheeled multi-purpose tool A DC motorpowersthismachine,whichisprimarilydesignedto excavatetheground.

•Sheetmetalisusedtoconstructafunnelforstoringseeds, andtheseedspassthroughthefunnelandintotheploughed soilthroughaholeboredintheshaft.

•Aftertheseedshavebeensown,alevellerandasprayerare usedtolevelthesoilandprovidefertilisertotheplants.

•The batteryis recharged usinga solarpanel mounted on topofthemultifunctionaltool.

•Asaresult,thesolarpanelandbatteryareabletoextract thegreatestamountofenergypossiblefromthesun.

•The 12-volt battery is needed to power the whole multifunctionalgadget.

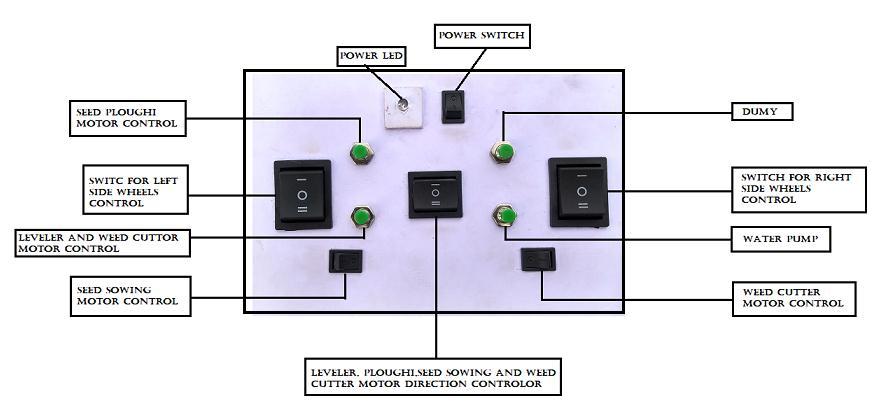

•Inordertooperatethevehicle,toggleswitchesareused.

Theproposedmodelshavethefollowingfeatures

•A new L-shaped leg has been introduced, and it is positioned at the rear of the frame, as seen in the image below. toggled switch controls motor and L-shaped leg is attachedtoit.Thebladesofthemotorareactivatedwhen thetoggleswitchispressed,asindicatedintheimagebelow.

• Perform seeding: For placing the seeds instead of plowingthethreelines,onlythewaterpump,levellerwill work and other actions are not performed. To place the seedsonlyonebladeisusedtodiglandwithmoredepthof soil.Byusingtoggleswitchthelargebladeisusedtodigthe land.

ForweedremovalonlyLshapedstructureismovedandrest threebladeswon’twork(seeding,levellerandwaterpump isnotused).

Forseeding,levellerandwaterpumpisusedonlythreelines aresownalloverthefield.

Thedifferentbladesareprovidingforobtainingthedifferent depthandwidthofsoilwhichisshowninthebelowfigure,

Figure 10: Single line sowing.

Thedesignedrobotwillperformtheseedsowing,pesticide sprayingandgrasscuttingoperationssimultaneously.When the solar panel gets heated it converts sunlight into electricity. This electrical energy is fed into the charging circuit. The pulsed voltage is given to battery in order to chargeit.Thechargingofbatteryiscontrolledwiththehelp ofvoltagesensors.Sincebatteryisbidirectionalitwillcharge andsupplyvoltagetoardunioatatime.Thevoltagesupply withsustainedoscillationisfedintoarduniowiththeaidof highpassfilter.Thechannelrelayprovidesvoltagesupplyto alldifferentmechanisms.Themotordriverisusedtodrive theDCmotorswhichruntherobot.

Theproposedbodymodelisasshowninthebelowfigure,

• If the weeds are growing between two plants, a particularfunctionisprovidedinthemodeltohandlethis situation.Plantsarepluckedandheldinplacewithdirtby theblades,whichareinsertedatthesidesoftheplantwith greaterbreadth.Thebladesthenremoveweedsandputthe plantbackinplacewithsoilthatdoesnotinjuretheplant.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Figure 11:Proposed flow for multi-purpose Robot.

The dimensions of the tool designed is explained in this subsection.

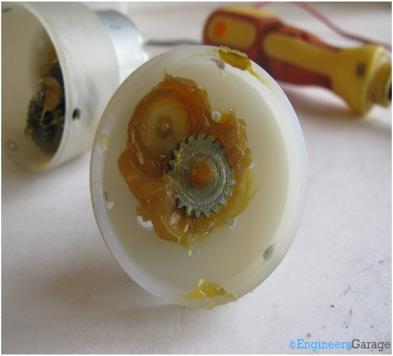

Withothertools,itmovestheframe.DCmotorsaregeared. DC motors are a kind of DC motor whose inner workings have been revealed. Geared DC motors have gears, unlike normalDCmotors.RPMisamotor'sspeedmeasuredinshaft rotationsperminute.Gearsenhancetorqueandslowthecar. Selectingtherightgearcombinationreducesagearmotor's speed.Gearreductionreducesavehicle'speakspeedwhile increasingtorque.ThisInsightcoverseverydetailofthegear head and geared DC motor's functioning. Internal and externalDCmotorconstructionisexplained.

ThegearstructurefortheDCmotorisasshowninthebelow figure,

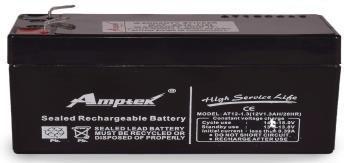

A12Vbatteryisemployedfortheimplementationwiththe characteristics such as, it has a weight of 750 g, having a capacityof1.3Ahanditisasshowninthebelowfigure,

Figure 13: Employed battery.

Tochargethebatterythesolarpanelsareemployedanditas showninthebelowfigure,

Figure 14: Solar panels

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Thewaterpumpisemployedtosprinklethepesticides or waterandthispumpissolarenabledwaterpumpwiththe dimension of 12*8*5 cms, operates with 6-12V, current ratingsofmaximumof1.2A.Thewaterpressureis5meters.

Theseedploughisasshowninthebelowfigurewhichcan beemployedbasedontherequirementanditisasshownin thebelowfigure.

ThecontrollingofthemodelisperformedbyusingtheDPDT switchandtheoperationsareofitisasshowninthebelow figure,

Tolevelthesoilafterploughingisalsoprovidedtotherobot anditisasshowninthebelowfigure,

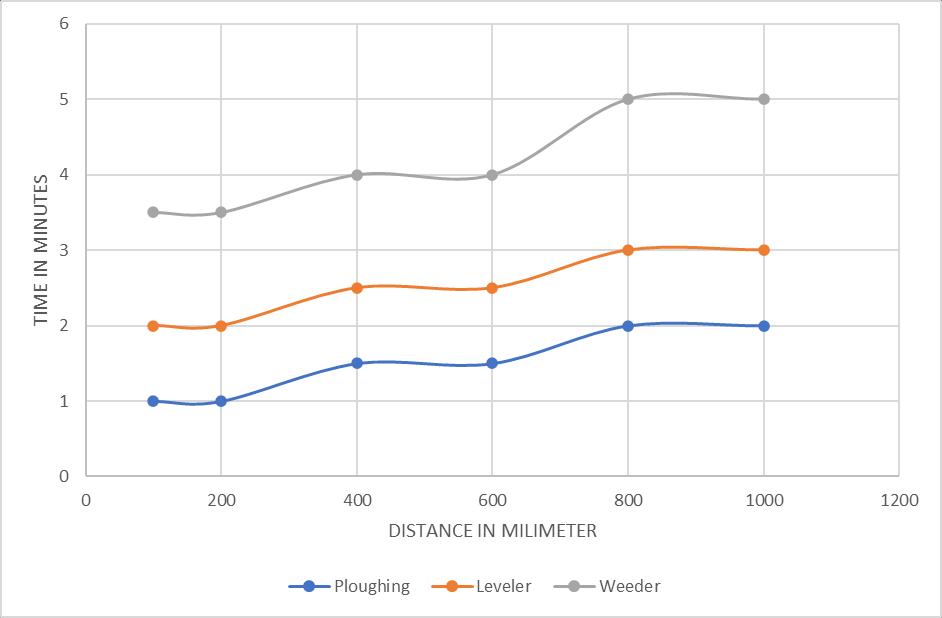

Theperformancefromthemodelwhichincludesploughing, levellerandremovalofweedsandthebelowgraphshowsit,

To remove the weeds from the field the various blads are providedanditisasshowninthebelowfigure,

The prototype of the proposed model is as shown in the belowfigure

Multipurposefarmingrobot haseffectivelyactualizedand tried for operations like ploughing, seeding, grass cutting and water sprinkling. An underlying result of this examination shows that the greater part of these frameworks that work with self-governing, are more adaptable than customary frameworks. The upsides of multipurpose horticultural robots are lessening human intercession, guaranteeing appropriate water system and proficientuseofassets.Infuture, itcanbereachedoutby utilizing ultrasonic sensors and cameras for playing out similar activities without human administrator for estimating the different parameters like soil condition, regionsecuredbytherobotandleveling.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

[1] S. Umarkar and A. Karwankar, “Automated Seed SowingAgribotusingArduino,"inIEEEConference on Communication and Signal Processing, April 2016,pp.1379-1383.

[2] M.D.I.Sujon,R.Nasir,M.M.I.Habib,M.I.NomaanJ. BaidyaandM.R.Islam“Agribot:ArduinoControlled AutonomousMultipurposeFarmMachineryRobot for Small to medium scale cultivation," in IEEE conferenceProceedingsoftheThirdInternational Conference on Electronics Communication and Aerospace Technology [ICECA 2019] IEEE ConferenceRecord#45616;IEEEXploreISBN:9781-7281-0167-5 978-1-7281-0167-5/19/$31.00 ©2019IEEE876Authorizedlicenseduselimitedto: SIDDAGANGA INSTITUTE OF TECHNOLOGY. DownloadedonMay15,2020at04:07:01UTCfrom IEEE Xplore. Restrictions apply. on intelligent autonomoussystems,March2018,pp.155-159.

[3] H. Pota, R. Eaton, J. Katapriya and S. D. Pathirana, “Agricultural robotics: A streamlined approach to realization autonomous farming,” in IEEE conferenceonindustrialandinformationsystems, 2007,pp.85-90.

[4] S. Kareemulla, E. Prajwal, B. Sujeshkumar, B. Mahesh, and V Reddy, “GPS based Autonomous Agriculture Robot,” in IEEE International conferenceondesigninnovationsfor3Cscompute communicatecontrol,2018,pp.100-105.

[5] HC-05 - Bluetooth Module, Available: https://components101.com/wireless/hc-05bluetoothmodule",accessedonSeptember2018.

[6] P.V. Santhi, N. Kapileswar, V.K.R.Chenchela and C.H.V.S Prasad, “Sensor and vision based autonomous agribot for sowing seeds,” in IEEEE Internationalconferenceonenergycommunication, dataanalysisandsoftcomputing(ICECDS),2017,pp. 242-245.

[7] P.V.S.Jayakrisna,M.S.Reddy,N.J.Sai,N.Susheeland K.P. Peeyush, “Autonomous seed sowing agriculturalrobot,”inIEEEConferenceonadvances in computing, communications and informatics (ICACCI),2018,pp.2332-2336.

[8] N.S. Naik, V.V. Shete and S.R. Danve, “Precision agriculture robot for seeding function,” in IEEEE Internationalconferenceoninventivecomputation technologies(ICICT),2016,pp.1-3.

[9] M.U. Hassan, M. Ullah and J. Iqbal, “Towards autonomyinagriculture:Designandprototypingof a robotic vehicle with seed selector,” in IEEEE Internationalconferenceonroboticsandartificial intelligence(ICRAI),2016,pp.37-44.

[10] S. Konam, N. Srinivasa Rao and K. Mohan Krishna,“Designencompassingmechanicalaspects of ROTAAI: Robot to aid agricultural industry,” in IEEEEInternationalconferenceonsoftcomputing andmachineintelligence,2014,pp.15-19.

[11] C.M. Barber, R.J. Shucksmith, B.M. Donald and B.C.Wunsche,“Sketch-basedrobotprogramming,” in IEEEE International conference of image and visioncomputingnewzealand,2010,pp.1-8.

[12] A. Srinivastava, S.Vijay, A. Negi, P.Shrivastva, A.Singh, “DTMF based intelligent farming robot vechile:Aneasetofarmers,“inIEEEEInternational conference on embedded systems, 2014, pp. 206-210. Proceedings of the Third International Conference on Electronics Communication and Aerospace Technology [ICECA 2019] IEEE Conference Record # 45616; IEEEXploreISBN: 978-1-7281-0167-59