International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

***

Abstract - The paper mainly focuses on the efficiency of the SRM and compares it with Single Phase Induction Motor (SPIM) which is presently in use in many low-power home appliances. Analytical and Finite Element Methods (FEM) are employed which is further validated through experiment. It is clear from the results that, SRM gives better performance is energy efficient and cost effective as compared to the commonly used SPIM and hence is a better alternative for domestic applications. Torque per unit volume equations are obtained for each of the motor, related to quantities such as magnetic flux density and electric loading and the speed performances are compared by using a washing machine application, which has a wide speed range. Motors of different types are evaluated due to their torque per motor volume, torque per ampere, efficiency and etc. over a widespeedrange to have an idea about the applications of these motors.

Key Words: SRM, Single phase induction motor, Torque, Motor

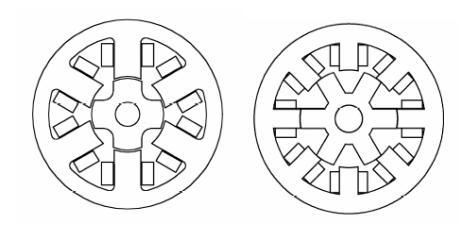

An induction motor is one in which alternating current is supplied to the stator directly and rotor by induction or transformer action from the stator. Thus each coil of the inductionmotorstator windingwiththeopposingcoilsof the rotor winding, may be considered a transformer and whole motor may be thought of as a series of such transformersarrangedradiallyaroundtheperiphery.Rotor ofaninductionmotormaybeoneoftwotypes,woundrotor orsquirrelcagerotor.Mostinductionmotorsaredesignedto operate from a three phase supply. If variable speed operationofthemotorisnecessary,thesourceisnormally aninverter.Theaimofthisstudyisthecomparisonoffour differenttypesofmotors,suchasinductionmotor,switched reluctancemotor,axialfluxpermanentmagnetbrushlessDC motorandradialfluxpermanentmagnetbrushlessDCmotor accordingtotheirtorqueperunitvolumeandapplicability to a variable speed washing machine application. It is evidentthat,tobeabletocomparetheperformanceofthese four different types of motors a framework should be set. Sinceitisadimensionlessquantitytorqueperunitvolume can be used as a common basis to compare these motors. Howeverallofthesemotorsneedtobeelectronicallydriven toachievethedesiredspeedrange.Thereforetheratingsof theswitchesareimportantfromthepointofviewofdrive cost.Inthisstudyisthecomparisonoffourdifferenttypesof

motors,suchasinductionmotor,switchedreluctancemotor, axialfluxpermanentmagnetbrushlessDCmotorandradial fluxpermanentmagnetbrushlessDCmotor.TheAxialflux externalrotornonslottedstatorpermanentmagnetmotor. Axial flux external rotor slotted stator permanent magnet motor. Axial flux internal rotor non-slotted stator permanentmagnetmotor.Axial fluxinternal rotorslotted statorpermanentmagnetmotor.

1. Sonali Vidhate, Prof. Pawan Tapre , Prof. Amit Solanki “BLDCMotorDriveforElectricVehicleApplication”The system needs to implement with a suitable control mechanism that will help to operate the motor in an efficientmanner.TheBLDCmotorprovidesanattractive candidateforsensor-lessoperationbecausethenatureof itsexcitationinherentlyoffersalow-costwaytoextract rotorpositioninformationfrommotor-terminalvoltages

2. NasserHashernniaandBehzadAsaei“ComparativeStudy ofUsingDifferentElectricMotorsintheElectricVehicles” Inthis paper,different electricmotorsarestudiedand comparedtoseethebenefitsofeachmotorandtheone that is more suitable to be used in the electric vehicle (EV) applications. There are five main electric motor types, DC, induction, permanent magnet synchronous, switched reluctance and brushless DC motors are studied.

3. P.Andrada, M.Torrent, B.Blanqué “Switched reluctance drivesforelectricvehicleapplications”Thispaperfirst tries to explain why the switched reluctance drive is a strongcandidateforelectricvehicleapplications.Itthen gives switched reluctance drive design guidelines for batteryorfuelcelloperatedelectricvehicles.Finally,it presents the design and simulation of a switched reluctancemotorpowertrain

4. Asok Kumar A., Bindu G.R “Analysis of Single Phase InductionandSwitchedReluctanceMotorforDomestic Appliances“Thepapermainlyfocusesontheefficiencyof the SRM and compares it with Single Phase Induction Motor (SPIM) which is presently in use in many lowpower home appliances. Analytical and Finite Element Methods(FEM)areemployedwhichisfurthervalidated throughexperiment

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

5. SwarajRavindraJape,ArchanaThosar“COMPARISON

FOR ELECTRIC VEHICLE APPLICATION” Electric vehicles with higher energy efficiency, low maintenance cost and pollution free operation, are offering great alternative to popular conventional IC engine vehicles. Also, with the advancement in technology, electric vehicle manufacturers are able to overcome the traditional drawbacksofelectricvehicles,makingitmoreandmore suitableformoderndaytransportation

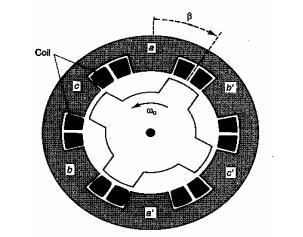

The switched reluctance machine is basically a doubly salient structure in which concentric coils are mounted aroundthestatorpolesandrotorhasneitherwindingsnor permanentmagnetsonit.Sothatitisadoublysalientsingly excited motor with different number of stator and rotor poles.

Whenthenearestrotorpolesarealignedwiththeexcited stator phase A poles, if the current is switched to the phaseBcoils,thecounterclockwiseforcewill continue actingonthenearestmisalignedrotorpoles.Asaresult rotor rotates in the counterclockwise direction by switching the stator currents sequentially through phases.

Therotorisalignedwheneverdiametricallyoppositepoles areexcited.Whiletworotorpolesarealignedtotheexcited two.Statorpoles,otherrotorpolesbecomeunalignedwith respecttotheotherstatorpoles.Thenanothersetofstator polesisexcitedtobringtheunalignedrotorpolestoalign positionwiththeexcitedstatorpoles

IfthecoilsofphaseAareexcited,misalignedrotorpoleswill beexposedtoaforcethatactstoaligntherotorpoleswith thephaseastatorpoles.

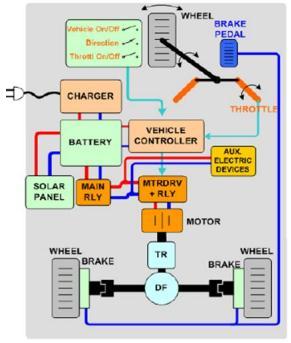

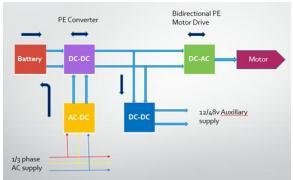

Fig3:Blockdiagram

The aim of this study is the comparison of four different types of motors, such as induction motor, switched reluctancemotor,axialfluxpermanentmagnetbrushlessDC motorandradialfluxpermanentmagnetbrushlessDCmotor accordingtotheirtorqueperunitvolumeandapplicability toavariablespeedwashingmachineapplication

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

similar.Sameelectricloadingvalue(28000A/cond.)is used.Knowingalltheunknownvaluesofequation,itis easytofindtheouterradiusofthemotortosatisfythe maximum torque requirement. Then using predefined outerradiustoinnerradiusratio,innerradiusandhence themassandvolumeofthemotorandstatorcorecanbe obtained.

Thebasespeedoftheinductionmotorshouldbechosen atsuchapointthatthemotortorqueisgreaterthanor equaltotheloadtorqueforeverypointintheoperating speed range and hence the load torque vs. load speed characteristicsfitsintothetorquespeedcharacteristics ofinductionmotor.

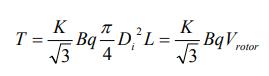

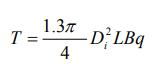

• Thetorqueequationoftheinductionmotor

Radial flux brushless dc motor

Nearly the same procedure is applied to the RF-BLDC motorasin thecaseofinductionmotor.AgainElectric loadingandpeaktoothfluxdensityaretakenas28000 A/cond. And T respectively as in the case of induction motor.Sincestatortoothwidthisassumedtobeequalto statorslotwidth,magneticloading“B”inequationcanbe determined.Theair-gapfluxisdetermineddependingon thepermanentmagnetusedontherotorsurfacebutthe peakfluxdensityshouldbelimitedbythesaturationand shouldnotexceedthemaximumpermissiblevalue

Thederivationofthetorque equationfortheRF-BLDC motor.

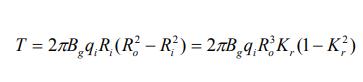

TorqueequationofAF-BLDCmotorwasderived

Axial flux brushless dc motor

“Kr” in equation (5.19) is the ratio of inner radius to outer radius and chosen to be “0.578” as the optimum value. NEOMAX-35 is used on the rotor surface of this motor. This motor is very similar to RF-BLDC motor except the flux path. So that the procedure also very

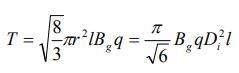

This torque equation is the starting point for the performance calculation of switched reluctance motor. Sincetheelectricloadingandstatorpolefluxdensityof themotoraretakenas28000A/condandTrespectively, itisnecessarytofindthedimensionsofthemotorwhere it meets the maximum torque requirement (2.5 Nm washingcycleand0.35Nmatspincycle).Forthesakeof simplicity,asinthecaseoftheothermotorsconsidered before,stacklengthofthemotoristakentobeequalto theborediameter

Thetorqueequationofswitchedreluctancemotor

• Hightorqueripple • Acousticnoisegeneration

• Highfrictionandwindagelossesathighspeedsdue tothesalientstructureofstatorandrotor

• LowManufacturingcost

DISADVANTGES

Itdoesnothavelinestartcapability.

ThemotorisabrushlessmachinelikeotherAC machines.

HighTorqueripple

HighDcbuscurrentripple

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

APPLICATIONS windenergysystems electricvehicles

Thesetheoreticalstudieswillbecomparedwiththeresults obtainedinthelaboratoryenvironmentinordertoseethe reliability of the equations. This is achieved by using the prototype BLDC motors, SR motor and induction motor, presentinthelaboratory.

Switchedreluctancemotordrivesemergeasoneofthebest candidates for powering the drive train of electric cars, mainlyduetotheirhighefficiency,extendedpowerregion, ruggedness and low foreseen manufacturing costs. The adventofvariousnewsemiconductordevicescantakecare of the drives to be used with SRM and hence this investigationholdsrelevanceinthepresentscenario

It is indeed a great pleasure and moment of immensesatisfactionforwetopresentaprojectreporton “Application and performance of switched reluctance motor and induction motor in electrical vehicle” amongst a wide panorama that provided us inspiring guidance and encouragement, we take the opportunity to thanks to thanks those who gave us their indebted assistance. We wish to extend our cordial gratitude with profoundthankstoourinternalguide Dr Yogesh Pahariya for his everlasting guidance. It was his inspiration and encouragementwhichhelpedusincompletingourproject.

Oursincere thanksanddeepgratitude to Head of Department, Dr. Mangesh Nikose and other faculty members; but also to all those individuals involved both directly and indirectly for their help in all aspect of the project.

At last but not least we express our sincere thanks to our Institute’s Principal Dr. Yogesh Burade, for providing us infrastructureandtechnicalenvironment

1. Sonali Vidhate, Prof. Pawan Tapre , Prof. Amit Solanki BLDC Motor Drive for Electric Vehicle Application InternationalJournalofLatestResearchinEngineering andTechnology-Issue09,September2020.

2. Prof. Nagaraj. DC, Keerthana HN , Loka Abhiram. A3, Meghana. K4, Naveen. B Comparative Study of Using Different Electric Motors in the Electric Vehicles

InternationalConferenceonElectricalMachinesOctober 2008.

3. P.Andrada, M.Torrent, B.Blanqué, J.I.Perat “Switched reluctance drives for electric vehicle applications” RE&PQJ,Vol.1,No.1,April2003

4. Asok Kumar A., Bindu G.R Analysis of Single Phase InductionandSwitchedReluctanceMotorforDomestic Appliances International Journal of Scientific & EngineeringResearch,Volume7,Issue6,June-2016

5. SwarajRavindraJape,ArchanaThosarCOMPARISONOF ELECTRIC MOTORS FOR ELECTRIC VEHICLE APPLICATION International Journal of Research in Engineering and Technology Sep-2017, Available @ http://www.ijret.org.

Tushar Dhanraj Burkul, has completed Bachelor of EngineeringinElectricalin2021 from Veermata Jijabai technological Institute(VJTI), MatungaMumbaiAndcurrently, Pursuing Master of Electrical power system from Sandip UniversityNashik.