International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Nithya B1, Devi M2

1 Assistant Professor, Department of Civil Engineering, Mahendra Engineering College, TamilNadu, India

2 Assistant Professor, Department of Civil Engineering, Mahendra Engineering College, TamilNadu, India ***

Abstract - Since ancient times, marble has been commonly utilised as a building material. The industry's disposal of Marble Waste, which consists of marble fragments and very fine powder, is currently one of the world's most pressing environmental issues. Rajasthan, which is renowned for its marble deposits, produces 95 percent of the nation's total marble production. Rice husk ash (RHA) is a paddy industry by-product. Rice husk ash is a highly reactive pozzolanic substance generated from the controlled combustion of rice husk. Partially substituting Marble Waste Powder (MWP) for natural fine aggregate and rice husk ash for cement. The destructive tests on hardened concrete included compressive strength test 7,28, and 56 days of curing according to IS: 516 1959. Flexural strength on beam at 28 days of curing according to IS: 516 1959, and split tensile strength on cylinder at 28 days of curing according to IS: 5816 1999. This study describes the impact of varied quantities of MWP and RHA on the mechanical properties of concrete, such as compressive strength, flexural strength, and split tensile strength, as they pertain to the behaviour of concrete made with cement containing a combination of MWP and RHA. The findings of the test were compared to conventional concrete mix.

Key Words: MarbleWastePowder(MWP),RiceHuskAsh(RHA),Mechanicalproperties,Conventionalconcrete,Sustainable.

Concreteisthemostprevalentman-madebuildingmaterialintheworld.Itisproducedbycombiningcementitiousingredients, water,aggregate,andsometimesadmixturesintheappropriateamounts.Sincethepriceofcementhasgrownduetohigher productioncostsormoredemand,thereisanurgentneedtoreplaceitinwholeorinpartwithlessexpensivealternatives.Due totheabundanceofrawmaterials,concrete'ssuperiorstrengthanddurability,inexpensiveproductionandmaintenancecosts, adaptabilityinformingdiverseshapesandlimitlessstructuralpossibilitieswhencombinedwithsteelreinforcement,concrete is a popular building material. Nevertheless, cement, which is an essential component of concrete, presents a significant obstacleforthesector.Themanufactureofcementisanenergy-intensiveoperation,andtheemissionofcarbondioxideduring cementproductionraisesenvironmentalissues.Furthermore,thereareagrowingnumberofinstancesinwhichcementcauses concretetodeteriorateunderhostileclimaticcircumstances.Theseissueshavepromptedtheconsiderationofreducingcement usageandtheexpansionofresearchintothepossibilitiesofboostingstrengthanddurabilityviatheuseofmineraladmixtures. ThisresultsinariseintheusageofcementitioussubstancesthatcanpartiallyreplacePortlandcement.Mineraladmixturesare used to counteract the detrimental effect of calcium hydroxide (CH) formed during cement hydration in concrete. These mineraladmixturesgeneratealowerproportionofcarbonmonoxidethanOrdinaryPortlandcement(OPC).Thisstudydeals withutilisationofricehushashandmarblewastepowderinconcretemix.Deepankaretal(2016)investigatedtheinfluenceof marbledustinconcrete.Comparingtestfindings,itwasdiscoveredthatmarblepowderenhancedthemechanicalqualitiesof concretebypartiallyreplacingsandandcementinpredeterminedamounts.Mohammedan(2012)investigatestheeffectof differentpercentagesofmarblepowderandsilicafumeasapartialsubstituteforcementonmortar.Inordertoimprovethe qualitiesofconcrete,Aliabdoetal.(2014)investigatedtheuseofmarblepowderinplaceofcementorsand.Itdemonstrates thatreplacingsandhassuperiorresultstoreplacingcement.Ankitetal.(2019)investigatedreplacingvaryingproportionsof ordinaryPortlandcementwithRHAtoproduceconcretewithstrengthsandqualitiesthatwerecomparabletoandsatisfactory compared to those of conventional concrete. The replacement percentages, which range from 5% to 15%, are chosen at intervalsof2.5%.Thecastconcretewastestedundercompressionatvariousages,andtheresultswerecomparedwiththose ofregularconcreteofthesamegrade.Itwasdeterminedthattheresultswerecomparable.

OrdinaryPortlandcement(OPC)53gradeisusedinthisstudy.Table1presentstheresultsofexperimentsoncement. Locally sourcedriversandisused(gradeIII)asperIS383:2016specifications.20mmsizeofnaturalcoarseaggregateisutilisedinthis study.Marblewastepowderistakenfromlocalmarbleseizingunit.Ricehushash(RHA)iscollectedfromPerundurai,India. potablewaterisusedmixingandcuringofconcretespecimensasperthespecificationsIS456:2000. Propertiesofallmaterials arelistedinTable2

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fig-1 SampleofRicehuskash Fig-2 Marblewastepowder

Table -1: TestsonOPC53gradecement

Testconducted Obtainedvalues Standardvalue

Normalconsistency(%) 32 -

Initialsettingtime(minutes) 41 Notlessthan30min

Finalsettingtime(minutes) 218 Notgreaterthan600min Fineness(%) 3.54 <10 Specificgravity 3.15 -

Table -2: Propertiesofmaterials

Properties Fineaggregate Coarse aggregate Marblewaste powder Ricehuskash

Specificgravity 2.62 2.81 2.90 2.81 Bulk density(kg/m3) 1698 1425 1218 925 Fineness modulus 2.6 7.32 2.34 -

ForM30grade,atrialmixhasbeendevelopedwithanassumedcompactionfactorof0.80inaccordancewithIS10262-1982. Thetrialmix,whichhasawatercementratioof0.45,is1:1.4:2.8.RHAispartiallyreplacedforcementbydifferentamounts(0to 25%),whileMWPispartiallyreplacedfornaturalfineaggregatebyvaryingamounts(0to25%).Fivetrailmixeshavebeen developedandarereferredtoasmixA,mixB,mixC,mixD,andmixE.themixproportionsofeachmixandmaterialsrequired perm3islistedinTable3.

Table-3: Materialsrequiredperm3

MIXID Mixcombination C kg/m3 CA kg/m3 FA kg/m3 MWP kg/m3 RHA kg/m3 Water Litres/m3

CM controlmix 413 1190 600 - - 186

MixA RHA5%+MWP5% 392.35 1190 570 30 20.65 186

MixB RHA10%+MWP10% 371.70 1190 540 60 41.30 186

MixC RHA15%+MWP15% 351.05 1190 510 90 61.95 186

MixD RHA20%+MWP20% 330.40 1190 480 120 82.60 186

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Aftertheappropriateperiodofcuring,castspecimensweretestedtoaseriesofmechanicalstrengthtests,includingcompressive strength,splittensilestrength,andflexuralstrength.

ThecompressivestrengthtestwasperformedinaccordancewithIS516:1959Cubespecimensof150mmx150mmx150mm wereutilised.Thetestswerecarriedoutinacompressiontestingmachinewithacapacityof1000KN.Thecompressivestrength ofaspecimeniscalculatedbydividingthespecimen'sultimateloadbyitscross-sectionalarea.Experimentaltestsetupfor compressivestrengthtestisdepictedinFigure3.Thediameterandlengthofcylindricalspecimensemployedare150mmand 300mm,respectively.Thecylinderwassplitalongitscentreplaneparalleltotheedgethroughoutthetest,andthecompressive load was applied to the adjacent edges. The test was conducted in accordance with IS 5816:1999. Prism specimens with dimensionsof150mmx150mmx500mmareusedtomeasuretheflexuralstrengthofconcrete.Thetestwasperformedin accordancewithIS516:1959.Figure4depictsthesetupforloadingtheflexuretestspecimen.Table4summarisesthetest resultsofmechanicalstrengthproperties.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

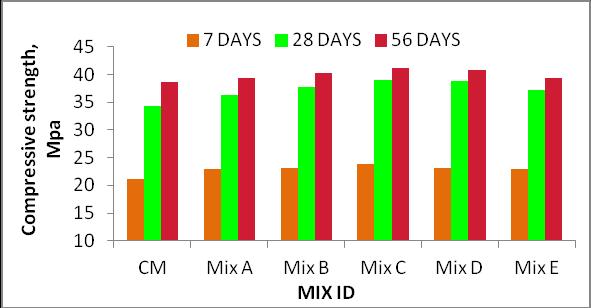

Chart-1: Variationincompressivestrengthofdifferentspecimens

Figure4showstheresultsofcompressionstrengthtestsperformedonvariousconcretemixcombinations,includingRHAand MWP,after7,28,and56daysofcuring.Thecompressivestrengthvaluesat28daysrangedfrom36.29MPato39.07MPa. Amongtheothermixes,MixID(MixC)attainedthehighestcompressivestrength.Atday56,mixChadstrengthof41.11MPa.It is6.20%increasedthestrengthwhencomparedwithcontrolmix.ThestrengthgraduallydecreasedaftermixC.At56days,it wasobservedthatthespecimencontainingRHAwithpozzolaniccharacteristicsincreasedcompressivestrength.Splittingtensile strengthofvariousspecimensat28dayscuringarepresentedinTable3.Splittensilestrengthvaluesofcylindricalspecimens rangedbetween3.52MPato3.90MPa.whilethe controlmixhada strengthof3.41MPa.ThesplittensilestrengthofMixDwas 3.90MPa.14.36%ofsplittensilestrengthwasincreasedthancontrolmix.Table3summarizesthefindingsofflexuraltensile strengthmeasurementsperformedonbeamspecimensofM30gradeconcrete.Aftercuringfor28days,theflexuralstrengthof beamswasexamined.Maximumflexuralstrengthwasrecordedatthecombinationof(15%)MWPand(15%)RHA,andthe strengthincreasedby14.83percentcomparedtocontrolconcreteafter28daysofcuring.

Fromtheaboveresults,thefollowingconclusionscanbemade:

Forvariousmixproportions,thecompressivestrengthofconcreteincreasesasthepercentagesofmarble wastepowderandricehuskashincreaseupto15%replacementofcement.

Thehighest28-daysplittensilestrengthwasproducedwithamixtureof20%marblewastepowderand20% ricehuskash,whichwasmarginallyhigherthancontrolconcrete.

Maximumflexuralstrengthat28dayswasattainedwithamixtureof15%marblewastepowderand15%rice huskash.

Ithasbeendeterminedthatricehuskashissuperiortoothermaterialssuchslag,flyash,andsilicafume.RHA, whichisreachinamorphoussilica,iseffectiveasapozzolanicmaterialinthisinvestigation.

DuetoRHA'slowspecificgravity,whichresultsinadecreaseindensityofconcrete,itsadditionlessensthe structure'sdeadload.

WhendisposingofextraMWPandRHA,theuseofricehuskashandmarblewastepowderhelpstoreduce environmentalcontamination.

[1] Aliabdo,A.A.,Elmoaty,A.E.M.A.andAuda,E.M.(2014),“Re-useofwastemarbledustintheproductionofcementand concrete”,ConstructionBuildingMaterials,50,pp.28-41

[2] AnkitGautam,Rahul Batra,NishantSingh(2019).AStudyOn UseOfRiceHusk AshInConcreteEngineeringHeritage Journal, 3(1):01-04

[3] DeepankarK.Ashish,SurenderK.VermaRaviKumarandNitishaSharma,(2016),Propertiesofconcreteincorporating sand and cement with waste marble powder, Advances in Concrete Construction, 4(2) pp. 145-160, DOI: http://dx.doi.org/10.12989/acc.2016.4.2.145

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[4] IS 12269-1987,Specification for 53 grade ordinaryPortlandcement,NewDelhi.

[5] IS:516-1959,Indianstandardofmethodsoftestforstrengthofconcrete,BureauofIndianStandards,NewDelhi,India.

[6] IS5816-1999,MethodofTestforSplittingTensileStrengthofConcrete.,BureauofIndianStandards,NewDelhi,India

[7] IS:7320-1974,Specificationforconcreteslumptestapparatus”,BureauofIndianStandards,NewDelhi,India

[8] IS:383-1970, Indian standard of specification for coarse and fine aggregates from natural sources forconcrete (secondrevision),BureauofIndianStandards,NewDelhi,India.

[9] Mohamadien,H.A.(2012),“Theeffectofmarblepowderandsilicafumeaspartialreplacementforcementon mortar”,Int. J.Civ.Struct.Eng.,3(2),pp.418-428.

[10] MuhammadHarunurRashid, Md. Keramat Ali Molla, TarifUddin Ahmed, (2010), Mortar Incorporating Rice Husk Ash: StrengthandPorosityJournalofScientificResearch,EuroJournalsPublishing,40(3)pp.471-477

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1486