International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1,2,3,4

***

Abstract – Soil stabilization may be defined as alteration or modification of one or more soil properties to improve the engineering characteristics and performance of a soil. Utilization of industrial wastematerials in the improvement of soils is a cost efficient and environmental friendly method. In this study density is found by ultrasonic testing method. This method can provide fast and simple approach for determining characteristics of compacted stabilized soil. This is a non- destructive method can be used as an alternative to existing methods to analyze laboratory or field compacted soils. In this study ultrasonic velocity measurements determine the compactioncharacteristics of stabilized soil. Variation of ultrasonic velocity with water content and density of compacted stabilized soils was analyzed. Effects of soil type and compaction conditions by velocity were analyzed.

Keywords: soilstabilization,ultrasonicpulsevelocity,non-destructivemethod,density

By examining the relationship betweensoil'sdrydensity(unitweight)andwatercontent,compactionfeaturesofsoilcan beidentified.Inthelab,Proctorcompactiontests(ASTMD698)arefrequentlyusedtoassesshowdrydensitychangeswith water content. A compaction curve is used to show the relationship between the soil's drydensity and water content. To ascertainwhetherconstructionmethodsareefficient,thecompactionparametersoffieldsoilsarecomparedtothoseofsoils studied in a laboratory. When in-situ methodology is employed, additional time is required. This study work attempts to present analternateapproach to decrease thistime: the ultrasonic pulse velocitymethod.Determinethecharacteristicsof compacted soils quickly and easily with ultrasonic testing. Toexamine laboratory or field compacted soils,this nondestructivemethodmightbeemployedinplaceoftheonesnowinuse.

After performing conventional tests on soilsamples with varying degrees of plasticity, such as clayey soil, the ultrasonic pulse velocitytestwasconductedon thesamples,andagraphshowingtherelationship between densityandvelocityand water content was created. The association was then established by interpolating the outcomes of earlier conventional experiments, and an ultrasonic pulse velocity test brought the results to a conclusion. The standard values are obtained whilethelaboratorytestsareperformed,andtheresultsarethenconfirmedusingthelaboratoryultrasonic pulsevelocity result.[1]

The procedures call for core-cutting pavement samples to be taken for subsequent laboratory testing in order to do conventionalqualitycontrolinthefield.

This process is too time-consuming, expensive, and only valuable for official records; it cannot be used to correct errors discoveredwhilelayingandcompactingsoilsubgradeinthefield.Thereforequickon-the-spotmeasurementsarerequired for thecontrol of the soil subgrade of the pavementlayer. These factors contribute to the creation of the ultrasonic pulse velocitymethod.Thepurposeofthe researchistoassessthephysical characteristicsofclayeysoilandthe stabilizationof clayeysoilbystabilizers, utilizing analternativein-situtesting methodcalledultrasonictestingThemainobjectives ofthe studyare:-

toresearchhowstabilizersaffectClayeysoil'sengineering performanceandtodetermine whethertheymaybeused assoilstabilizers

ifthesoilstabilizerhasgoodvolumestabilityanddurabilitywhichinturnalsoincreasesstrengthandstiffnessofthe soilspecimen.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Toprovide the soil specimen withvolume stability and durability through the analysis of the data acquired through theultrasonicpulsevelocitytest

Toevaluatetheprojectspecimenthroughthenondestructiveteststoavoiddamagingthething

Theearthwasdugup1.5metresbelowthesurfaceoftheground,rammedtobreakupanylumps,andthendriedintheair. Stabilizerthathadbeenoven-driedwascombinedwithclayeysoil.Thecompactionandstrengthcharacteristicsofmixesin accordancewithISwereascertainedusingavarietyofsoilandstabilisercombinations.

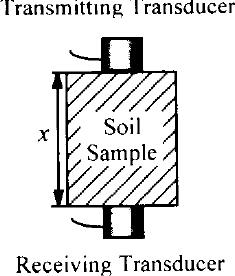

Foursuchcombinationswerecreatedinall,andthelaboratorytestedthemixes' strengthandcompactioncharacteristics. Inorder to determine the P-wave velocity in the test compacted stabilised soil, two transducer arrangements one for transmittingandtheotherforreceiving wereusedintheultrasonictestscarriedoutforthiswork.[1]

The non-destructive ultrasonic pulse velocity test has been around for a while.The basic idea behind this test is the relationship between a material's density(ρ) and elasticity modulus(E), or square root of the ratio E/ρ, determines the velocity(V)ofsoundinthatmaterial(V).FollowingistheequationusingPolishstandards: E=V2 Ρ

This relationship can be used to calculate the elasticity modulus and, as a result, to assess the soil's quality. The test is therefore valuable for identifying voids, damage from fire or frost, and consistency of soil in related elements. The ultrasonic pulse velocity test measures the density of the soil and cantherefore be used to determine the strength of the soil. The time it takes forthe ultrasonic pulse to pass through the soil and the aggregate determines the velocity of the pulseasitpassesthroughthesoil.Theaggregate'smodulusofelasticityandtheamountofaggregateinthemixbothaffect thesoil'spulsevelocity.

P-wavetransducers, Pulser-receiver,and Dataacquisitionsystem.

For measurements, two transducers are utilised, one for transmitting ultrasonic waves and the other for receiving them after they have passed through the test sample. A pulse receiverthat is attached to the data acquisition system for data digitizationactivatesthetransducers.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Ultrasonicmeasurementsareusedtodeterminethefirstarrivaltimeofthewavesatthereceivingtransducer,whichisthe traveltimeforbothtesttechniques.Thedelaybetweenthetimethetransmittingtransducerappliedthepulseandthe time the waveform arrived inthereceivingtransducer was usedtocomputetheinitial arrival time. The digitaldata boardand thepulsereceiverweresyncedsothatdatacollectionbeganwhenthepulsewasapplied.Thevelocityofthewavesasthey travel from the transmitterto the receiveralongthecompacted earthisalso measured alongwiththeir journeytime. The datacollectedarehelpfulinanalysinghowsoilcharacteristicsandcompactionconditionsaffectvelocity.

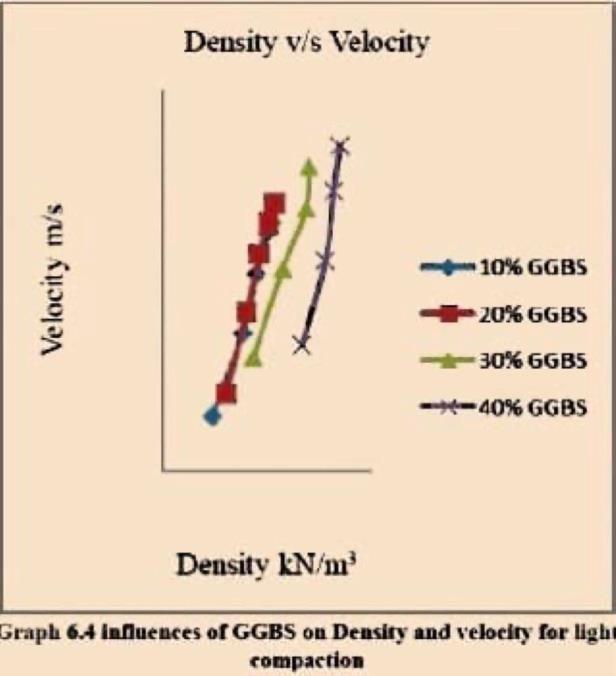

Traditional compaction plots (dry density vs. water content) and compaction plots generated from ultrasonic measurements were compared (velocity vs. water content). Using normal and modified Proctor efforts, the soil that has beenstabilised withstabilizer toanincreasing proportioniscompactedwith varied watercontents.The ultrasonic pulse velocity test is performed on the compacted soil mass. Samples were utilisedto measure density, water content, and Pwave velocity during tests utilising the through-transmission test technique. Each sample that wasutilised to assess the soils'compactionpropertieshaditsvelocitydetermined.Drydensityvs.watercontentandvelocityvs.watercontentwere usedtocreatecompactionplots.

Engineersviewsoilasacomplicatedsubstancethatresultsfromtheweatheringofsolidrock.Theongoinggeologicalcycle that occurs on the surface of the planetresults in the development of soil. The cycle entails weathering or denudation, transportation,deposition,upheaval,weatheringagain,andsoon.

GGBS,(GroundGranulatedBlast-furnaceSlag)isacementitiousmaterialwhosemainuse is inconcreteandisaby-product from the blast-furnaces used to make iron. At a temperature of roughly 15000C to 16000C, molten slag floats above the molten iron as iron, ore, and limestone are permitted to fall into the furnace. After the molten iron is trapped off, the remaining molten slag is quickly cooled under water, leading in the creation of a glassy granule. The molten slag is composedofbetween30%and40%silicondioxide(SiO2)andabout40%calciumoxide.Theterm"groundgranulatedblast furnace slag" refers to this glassy granulated that has been dried and ground to a specific size (GGBS). The degree of compaction in soil mixtures is influenced by theamount of GGBS added to the soil. Because GGBS has agreater specific gravity than expansive soil, the maximumdry unit weight increases as the amountof GGBS increases. Additionally, it was foundthatwhentheGGBScontentincreased,theidealmoisturecontentdecreased.[1]

Thefield-receivedsoilsampleis driedintheair.Tospeedupdrying,theclodswereshatteredusinga woodenmallet.The sampleiscleanedofanyorganicmaterial,suchastreerootsandfragmentsofbark.Similartohowoilissegregatedfromthe mainsoilmass,shellsareanothertypeofnon-oilmaterials.

When samples are taken for estimationof organiccontent,limecontent, etc., the complete sampleis taken for estimation withoutremovingshells,roots,etc.,andtheseremovalsarenotedtogetherwiththeirpercentageofthetotalsoilsample.[3]

4.3 Laboratory Tests

be conducted: 1. SpecificGravitytestofsoil

GrainSizeanalysisofsoil

Hydrometeranalysisofsoil 4. FSI(FreeSwellIndex)testofsoil

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Thephysicalandchemicalpropertiesofthespecimen(soilandstabilizer)aregivenbelow

S.NO PROPERTY

SOIL

SpecificGravity 2 Grainsizeanalysis

1

%ofgravel

%ofsand

%ofsiltandclaysize 3 Atterberg’slimits

Liquidlimit%

Plasticlimit% 4 Plasticityindex 5 Soilclassification 6 Freeswelldata 7 Compactioncharacterstics

Max.drydensity(kN/m3)

Optimummoisturecontent(OMC)%

TABLE 5.1 Physical properties of soil

S.NO PROPERTY SOIL

1 SpecificGravity 2 Grainsizeanalysis

%ofgravel %ofsand %ofsiltandclaysize 3 Atterberg’slimits

Liquidlimit%

Plasticlimit% 4 Plasticityindex 5 Freeswelldata

TABLE 5.2 Physical properties of stabilizer

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

SLNo Chemicalcomposition

Percentage 1

SiO2 40% 2 MgO 3.6% 3 CaO 39.2% 4 Al2O3 13.5% 5 Fe2O3 1.8% 6 SO3 1.7% 7 L.O.I 0.2%

TABLE 5.3 Chemical properties of stabilizer

Theresultsofthevariousteststobeconductedinthelaboratorywerealsotakenintoaccountwhiledoingtheanalysisand drawingouttheconclusionsfortheexperiment.

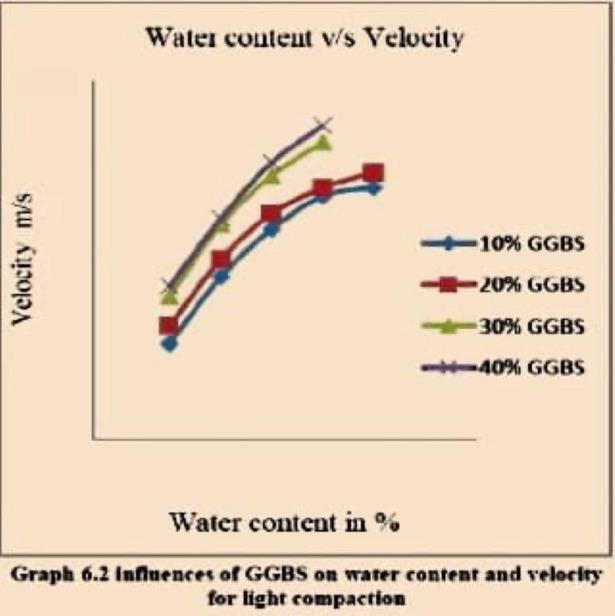

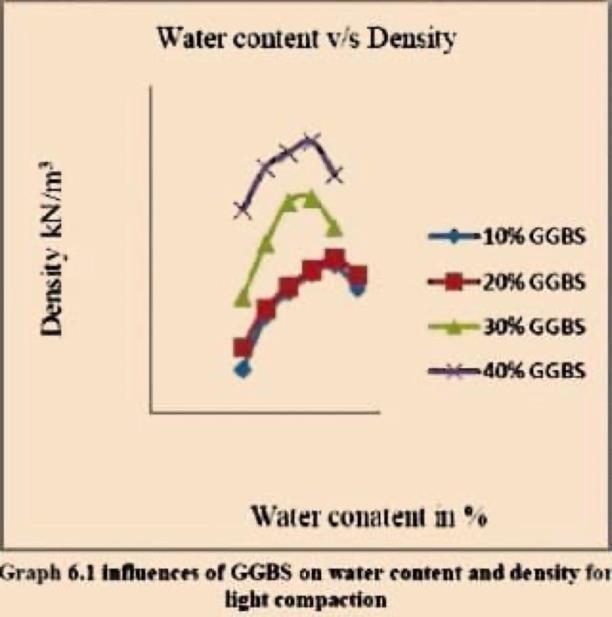

Through various tests that are conducted throughout the whole project, the effect onthe various properties of the soil with the influence of stabilizer at different percentages are obtained by evaluation andgenerating the relation between variousparametersofstabilizedsoil.

Theresultsaredepictedusingthenatureofthegraphsderivedfromdatafromvariousexperiments,

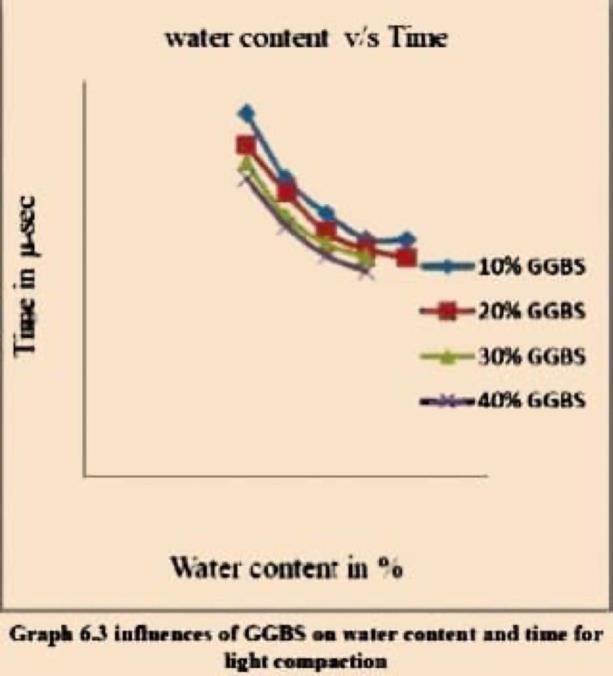

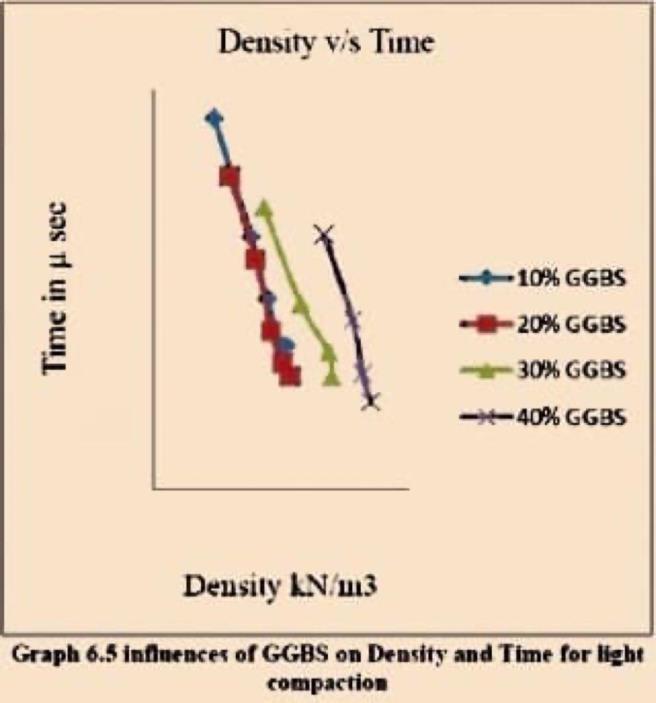

Forlightcompaction,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

The different nature of graphs show the influence of different amount of stabilizer (GGBS) on the water content and densityofthesoilforlightcompactiononthesoil

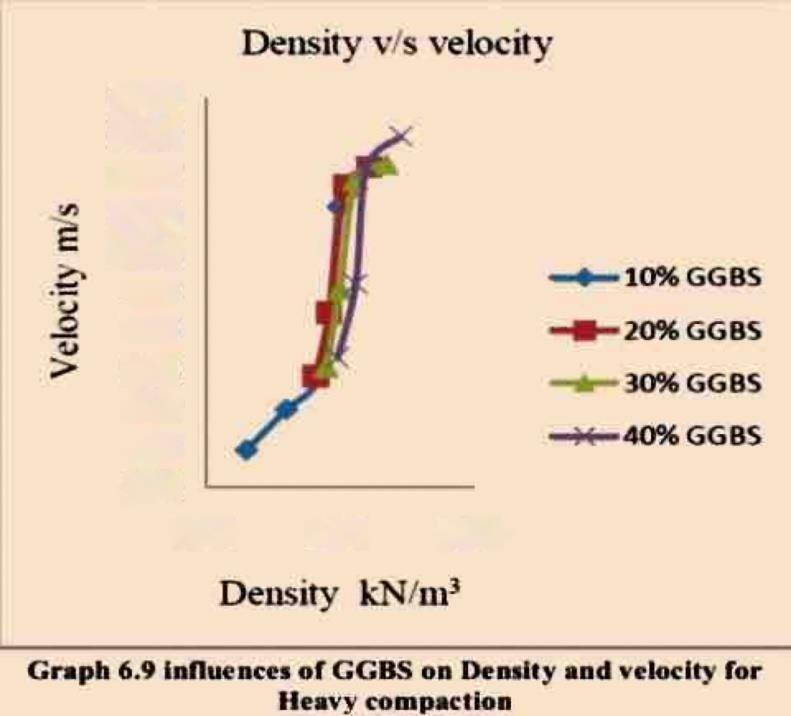

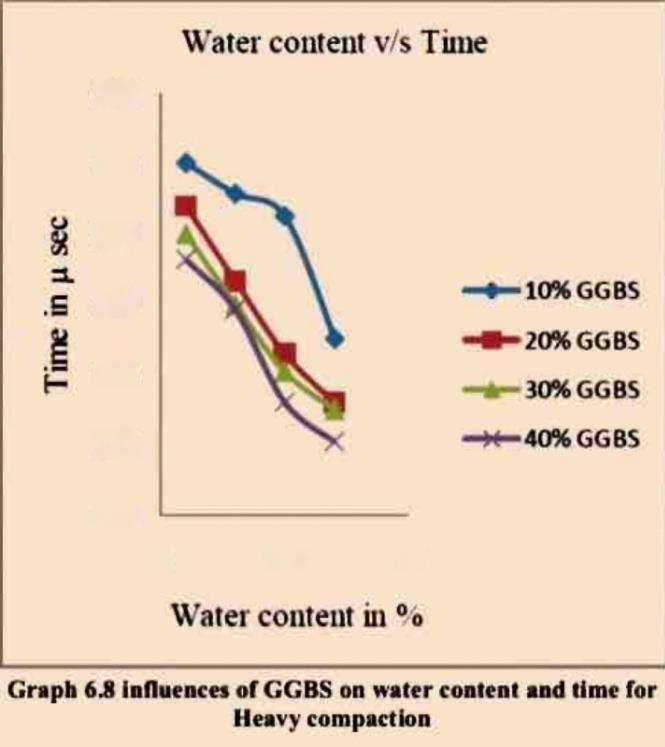

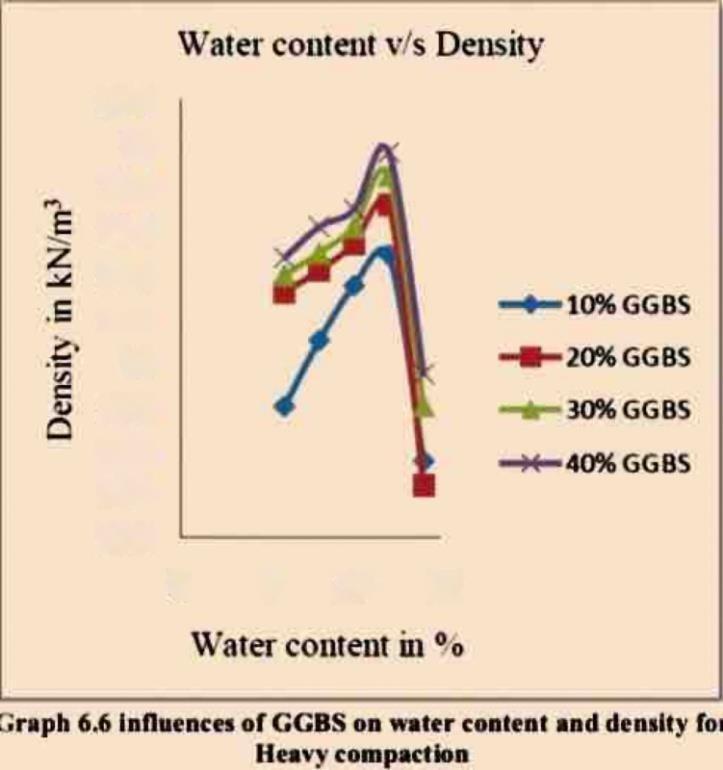

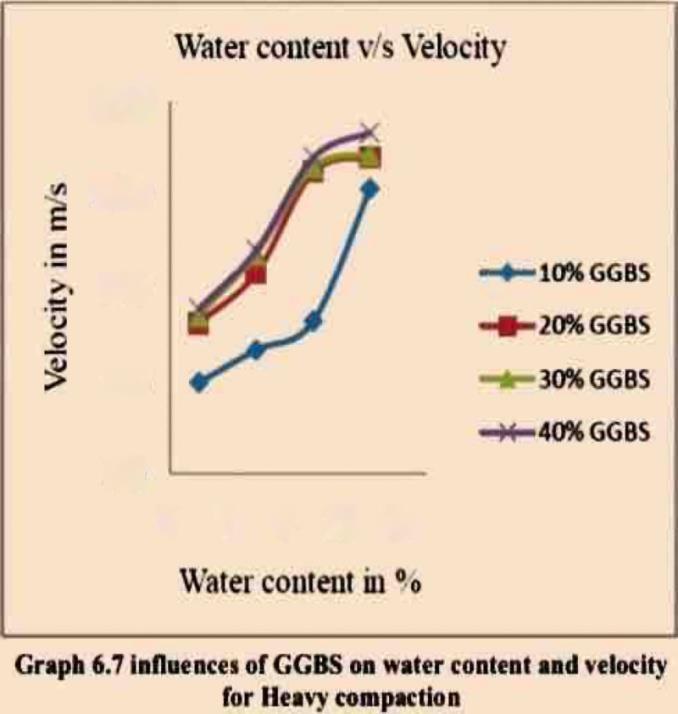

Forheavycompaction,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Thedifferentnatureofgraphsshowstheinfluenceofdifferentamountofstabilizer(GGBS)onthewatercontentanddensity ofthesoilforheavycompactiononthesoil.

Fromtheobtainedanalyzedresults,thefollowingconclusionsweredrawn: Since stabilizer has considerablyimproved the geotechnical characteristics of soil,it can be utilizedtostabilize clayey soil.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Withtheadditionofstabilizertothesoil,maximumdrydensityincreasedwhileidealmoisturecontentfell.

Thesoil'stendencytoswellhassignificantlydecreased.

Ultrasonictechnologywasusedtoexaminethecompactioncharacteristicsofsoilwiththeadditionofstabilizer.

Asstabilizerpercentageincreases,plasticlimit,liquidlimit,andplasticityindexdecrease.Inthestabilizedsoil,p-wave velocityismeasuredusingultrasoundmeasurements.

Withthesamewatercontent,itwasfoundthattherewasnodifferenceinthevariationofeithervelocityordensity.

Compactedsoilmasswasexaminedinseveralstages,andtheresultsshowthathighsolidcontents,lowwaterandair voids,andlowsolidcontentsandhighwaterandaircontentsresultinanincreaseinvelocities,respectively.

For varying percentages of stabilizeradded to soil, different proportion of stabilizers, the rate of velocity increases withdensitywashigher.

ThemixeddirtcomplieswiththeMORTH(MinistryOfRoadTransportandHighways)subgradecriteria

[1] Dr.VinayA,A.V.Pradeepkumar,UltrasonicPulseVelocityassessmentofGGBSstabilizedsoil

[2] JackKatzerandJanuszKobaka,conferencepaperSeptember2006,UltrasonicPulseVelocityTestofSFRC

[3]NiteshAshokBhange,Pritiradheshyamnandagawali,EngineeringCharacterizationofClayeySoilbyUltrasonicPulse VelocityTests

[4] Slavova,D.Z.,Weidinger,D.M.,Sevi,A. F.,&Ge,L.(2010).Evaluationofcompactedsiltcharacteristicsbyultrasonic pulsevelocitytesting.Proc.ofGeoFlorida,1284-1293.

[5] Weidinger, D. M., Ge, L., & Stephenson, R. W. (2009). Ultrasonic pulse velocity tests on compacted soil. Characterization, Modeling, and Performance of Geomaterials, Hunan, ASCE, Geotechnical Special Publication, (189), 150-155.

[6] Vinay.A,Dr.A.V.Pradeepkumar,Dr.M.RRajashekhara(2018),"Alternateassessmentofstrengthcharacteristicsof clayeysoilforcompactionusingultrasonicpulsevelocitymethod",InternationalJournalofEngineering&Technology,7 (2.1)(2018)15-19

[7] VasanthS.D,Vinay.A,A.VPradeepKumar,ShubhalakhsmiBS(2018),"AnExperimentalStudyonPhysicalProperties of Clayey Soil by Using Destructive and NonDestructive Tests", International Journal of Engineering Research & Technology(IJERT)ISSN:2278-0181

[8] Vinay M, Vinay A, A V Pradeep Kumar(2019), "Ultrasonic Pulse Velocity Assessment of Cement Stabilized Soil", InternationalJournalofScientificResearchandEngineeringDevelopment-–Volume2Issue3,May-June2019

[9] Maciej Miturski , Wojciech Sas, Algirdas Radzeviˇcius, Raimondas Šadzeviˇcius, Rytis Skominas, Mateusz Stelmaszczyk and Andrzej Głuchowski(2021), "Effect of Dispersed Reinforcement on Ultra sonicPulse Velocity in StabilizedSoil",Materials2021,14,6951.

[10] Kondekar,V.G.,Jaiswal,O.R.,&Gupta,L.M.(2018).Ultrasonicpulsevelocitytestingofgadhisoiladobebricks.Int. J.Eng.Re