International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1 Asst. Prof. Mechanical Deptt. Subharti University Meerut (U.P.), 2 Asst. Prof. Mechanical Deptt. Subharti University Meerut (U.P.), 3 Associate Prof. Mechanical Deptt. Natioanal Institute of Technology Warangal (A.P.) ***

Abstract - In the Di engine heat losses to the cooling system and surrounding plays a important role in the power output & in term the thermal efficiency reduction in heat loss to the surrounding directly increases the desired work output also thermal energy carried away by the exhaust gas which must be utilized to produced some useful work for the desired results by thermally insulating engine components like piston head, cylinder head & valves with a 0.5mm thickness of mullite(3A2O3.2SiO2)as a thermal barrier coating over a 150µm thickness of NiCrALY. Application of TBC improve the bsfc 9.90% with PME when compared to diesel fuel with TBC, brake thermal efficiency (BTH) increases 1.92% by use of TBC with PME as compared to conventional DI diesel engine. Exhaust gas temperature of PME with TBC is increases by 26.7% when compared to diesel fuel with TBC andreductionof 27% & 47% in CO & HC emissions respectively were obtained in LHR engine when compared to standard dieselengine at full load. PME-Pongamia Mehtyl Ester, TBC-Thermal Barrier Coating, BTH-Brake Thermal Efficiency & 3A2O3.2SiO2Alumina Silicate.

Key Words: Mullite, Pongamia Methyl Ester (PME), TBCThermal Barrier Coating, BTH-Break Thermal Efficiency, LHR-Low Heat Rejection.

Thedesiretoreachhigherefficiencies,lowerspecificfuel consumptions,thermalEfficiencyandreduceemissionsin moderninternalcombustionengineshasbecomethefocus ofengineresearchersandmanufacturersforthepastthree decades.Dieselenginesgenerallyrejectingeachonethirdof fuel energytocoolantandexhaust.Thus onlyonethird of fuel energy is utilized as work output. By the thermally insulating heat rejection to the coolant can be reduced or minimize. Pioneer work was done in diesel engine technologybyDavidJ.Duval&SubhashH.Risbud[5]and different surfaces of combustion chamber was thermally coated with material like silicon nitride. Thermal barrier coatingsareusedtoimprovereliabilityanddurabilityofhot sectionmetalcomponentsandenhanceengineperformance andefficiencyininternalcombustionenginebyHejwowskiT & Weronski A [10], the material used were partially stabilizedzirconia(PSZ)andZrO2&theinvestigationsleads

toloweringoffuelconsumptionby2to16%andincreasing thermalefficiencyintherangeof2to2.6%ascomparedto conventionaldieselengine.Mulliteisanimportantceramic material becauseofitslow density,highthermal stability, stability in severe chemical environments, low thermal conductivityandfavorablestrengthandcreepbehavior.Itis a compound of SiO2 and Al2O3 with composition 3Al2O3.2SiO2ComparedwithYSZ.DavidJ.Duval&Subhash H[5]Mullitehasamuchlowerthermalexpansioncoefficient andhigherthermalconductivity,andismuchmoreoxygenresistant than YSZ. For the applications such as diesel engines where the surface temperatures are lower than those encountered in gas turbines and where the temperaturevariationsacrossthecoatingarelarge,mullite is an excellent alternative to zirconia as a TBC material. Enginetestsperformedwithbothmaterialsshowthatthe lifeofthemullitecoatingintheengineissignificantlylonger thanthatofzirconia.Above1275K,thethermalcyclinglife ofmullitecoatingismuchshorterthanthatofYSZ.Mullite coating crystallizes at 1023–1275 K, accompanied by a volume contraction, causing cracking and de-bonding. Mullite is the most promising coating material for the SiC substratebecausetheirthermalexpansioncoefficientsare similarbyllhanA.Aksay&DanielM.Dabbs[11].

Table -1:

Properties Melting point Thermal conductivity (λ)

Young's modulus (E)

Thermal expansion coefficient (α)

Mullite 2123K 33W/mK (1400K) 30Gpa (293K) 53x10 6 (2931273)

Oneofthemostpromisingismullite.Mulliteisanimportant ceramic material because of its low density, high thermal stability, stability in severe chemical environments, low thermal conductivity and favorable strength and creep behavior. It is a compound of SiO2 and Al2O3 with composition3Al2O3.2SiO2ComparedwithYSZ,mullitehas higherthermalconductivity.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Theexhaustemissionsareaffectedbytheuseofbiodiesel.It isknownthatbiodieselgenerallycausesasincreaseinNOx emissionanddecreaseinHCandCOemissionsrelative to diesel fuel. The purity of biodiesel was 99%. Parker D & BonarJfound[7]that100%biodieselexperiencedlowerCO, HC emissions, while slight increased is NOx emission is realized by the Sukumar Puhan & N Vedaraman [12]. The biodieselfromPongamiaoilistermedasPongamiamethyl ester.Finallyexhaustgasemissionswithbiodieselhavebeen investigatedandcomparedwiththoseofneatdieselfuel.

fuel and then is converted to LHR DI diesel engine by installing mullite coated piston crown, cylinder head and valves.ExperimentalwerecarriedoutLHRengineatnoload ,20%,40%,60%and80%load,appliedontheenginewith thehelpofahydraulicdynamometerandfullloadcondition with&withoutusingPMEasafuelandtheresultsare

Properties PME Diesel fuel Density(22°C), kg/m3 850 847

Kinematic viscosity at 400C, mm2/s 4.86 3.05

Calorific Value (MJ/kg) 39.40 43.66

Cetane No. 50 50

Table -2: Finally exhaust gas emissions with biodiesel have been investigatedandcomparedwiththoseofneatdieselfuelby YoshiyukiK&ChanglinY[8].

Asinglecylinder,fourstroke,constantspeed,watercooled, direct injection diesel engine is used for the experiments conducted.Thetechnicalspecificationsoftheengineareas below.

Table -3:

Name of Engine Kirloskar

Stroke 4

Stroke length 110mm bore 80mm No. of Cylinder 1 Comp. Ratio 16.5:1 R.P.M 1500 Vdisp 552.94cc Rated output 3.68kw(5.0hp) Injection advance 23°BTDC Loading Hydraulic

CrudeoilextractedfromPongamiaoilwastransesterification intoPMEwiththebestof 905mlyieldofnetbiodieselper literofrawoil.Dieselengineisinvestigatedfirstwithdiesel

Compared with standard engine. Nitrous oxides (NOx), carbonmonoxide(CO),hydrocarbon(HC)weremeasuredby NETELgasanalyzer.

BytheexperimentalinvestigationswerecarriedoutonDI dieselengineinwhichtheLHRversioni.e.withmulliteasa TBCoftheenginewasfuelledwiththewellpreparedPME& evaluation of BSFC, BTH, exhaust gas temperature and energybalanceforLHRenginewithandwithoutPMEfuel andiscomparedwiththatof LHRenginewithdieselfuel. PME showedthereductioninCOandHCemissions,while NOx emissions are increased and reduction in BTH is observed. Thus the final set up showed improved performance as well as exhaust emissions and not to be ignored heat loss to coolant is reduced with the effect of increaseinthermalenergyofexhaustgases.

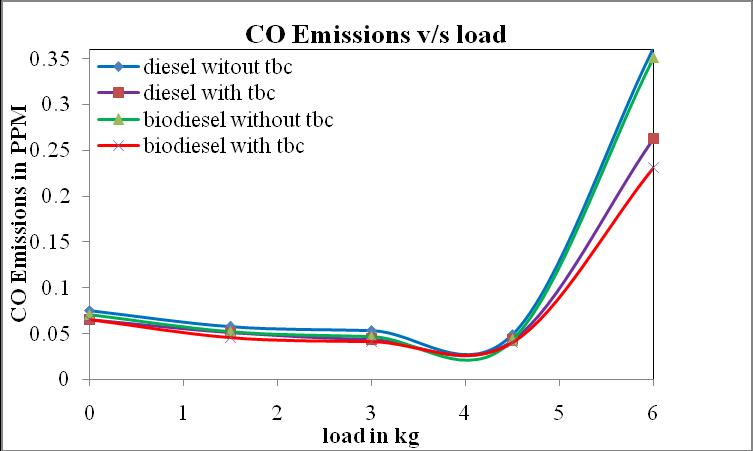

Inthechartno.1bsfcv/sloadat200barinjectionpressure with and without TBC. Here bsfc of diesel is less when comparedtoPME.bsfcofdieselwithoutTBCis10.6%less comparedtothatofPMEwithoutTBCat80%load.bsfcof PMEwithTBCisincreasedby9.9%whencomparedtodiesel fuelwithTBC.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

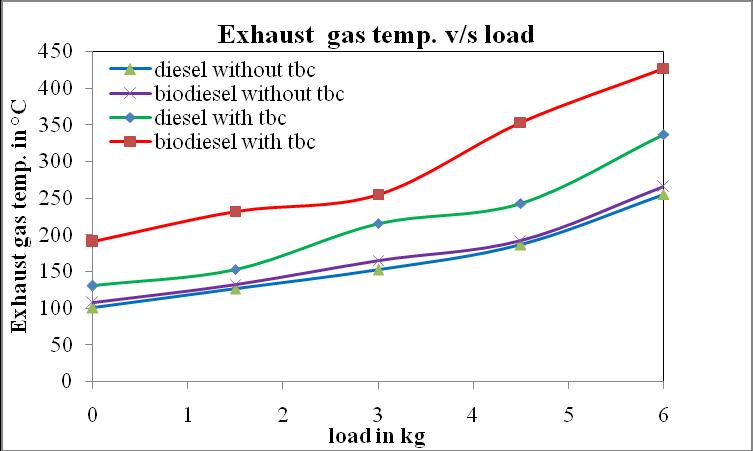

temperatureofPMEwithTBCisincreasedby26.8%when comparedtodieselfuelwithTBC.

Chart -1:bsfcv/sload

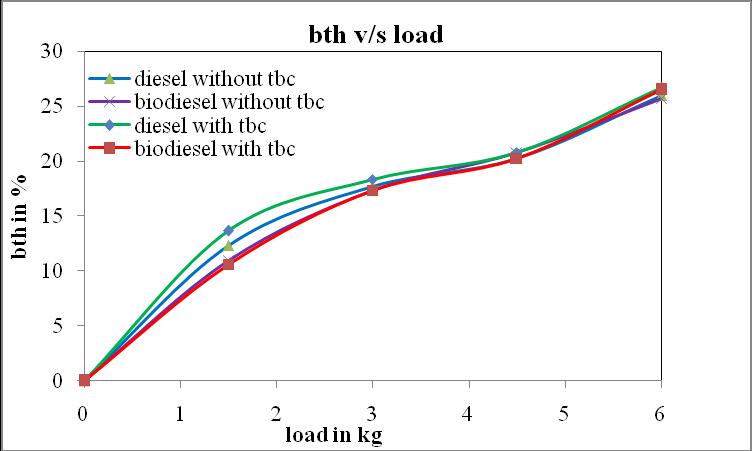

Thebrakethermalefficiencyv/sloadat200barinthechart no. 2 injection pressure with and without TBC. brake thermal efficiency of PME without TBC is 1.08% less comparedtothatofdieselwithoutTBCat80%load.Brake thermal eff. of PME with TBC is reduced by 0.8 % when comparedtodieselfuelwithTBC,thisdecrementisveryless aswearehavingremarkableimprovementinemissionswith PMEasfuelApplicationofTBCincreasesthebrakethermal efficiencyby1.92%withPMEascomparedtoconventional DIdieselengine.

2.4

Chart -3:Exhaustgastemp.v/sload

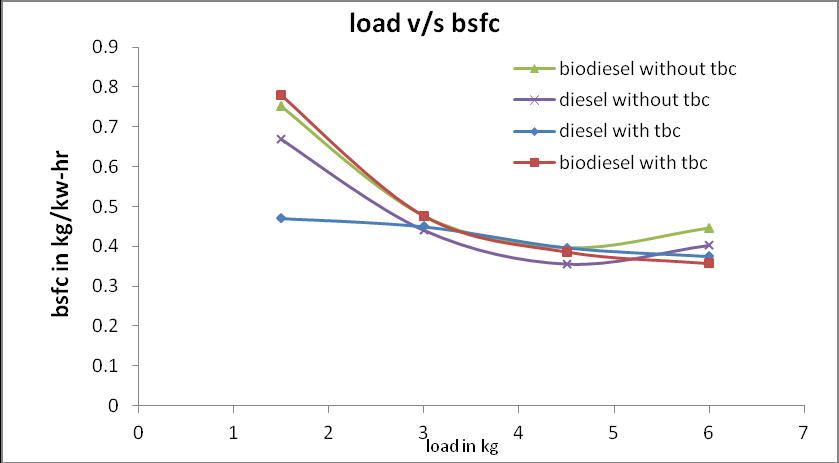

CO emissions of biodiesel are reduced by 27% when comparedtodieselwithoutTBC.COemissionsofbiodiesel with TBC are also reducedby 34% as compared to that of diesel with TBC at 80% load show in the chart no. 6. The reason of less CO emissions is that biodiesel have extra oxygenmoleculeascomparetodiesel.

Chart -2:brakethermaleff.v/sload

Inchartno.3 exhaustgastemp.v/sloadat200barinjection pressure with and without TBC. Here exhaust gas temperature of diesel is less when compared to transesterified Pongamia oil. Exhaust gas temperature of diesel without TBC is 4% less as compared to that of Pongamia oil without TBC at 80% load. Exhaust gas

Chart-4: COemissionsv/sload

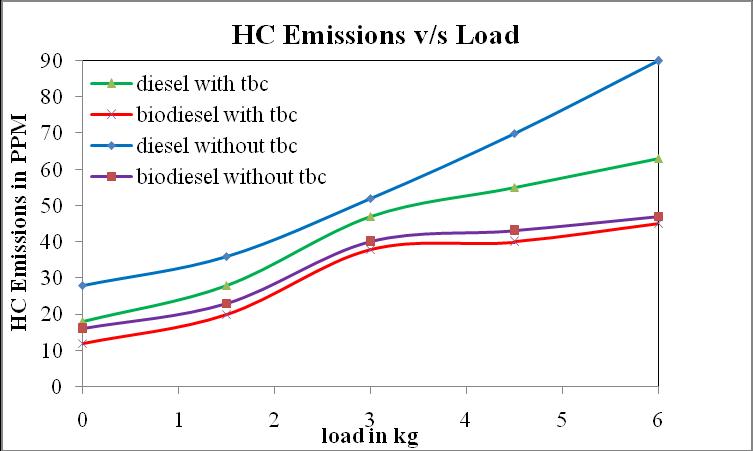

In chart no. 5 Comparison of HC emissions of diesel and biodieselat200barinjectionpressureareshowninchart. Here HC emissions of biodiesel are reduced by 48% when comparedtodieselwithoutTBC.HCemissionsofbiodiesel withTBCarealsoreduced29%ascomparedtothatofdiesel withTBCat80%load.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

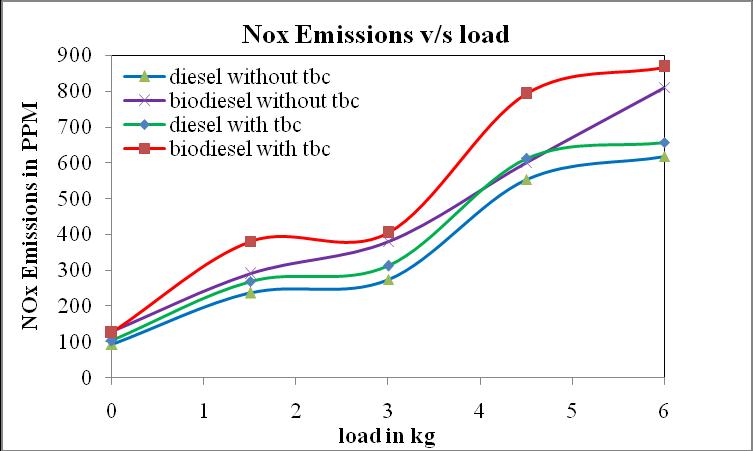

ComparisonofHCemissionsofdieselandbiodieselat200 bar injection pressure are shown in chart. Here NOx emissionsofbiodieselareincreasedby32%whencompared todieselwithoutTBC.NOxemissionsofbiodieselwithTBC arealsoincreasedby31%ascomparedtothatofdieselwith TBCat80%loadshowinChartno.6,Becausetheexhaust temperaturehigherwhenusecoatedpiston.

Chart -7: HeatbalanceofdieselwithTBC

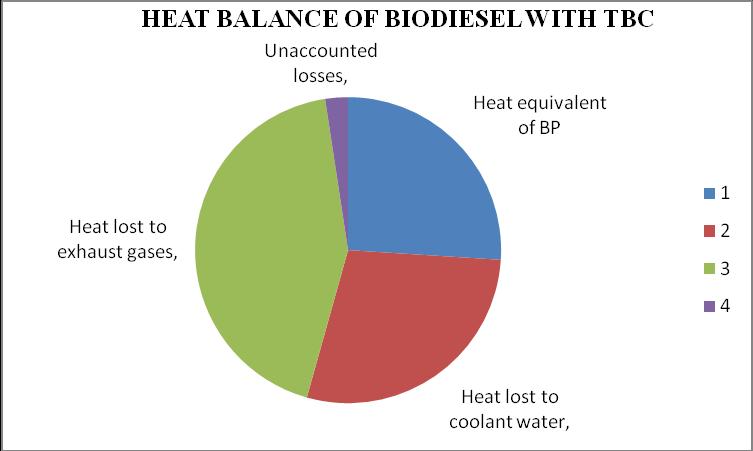

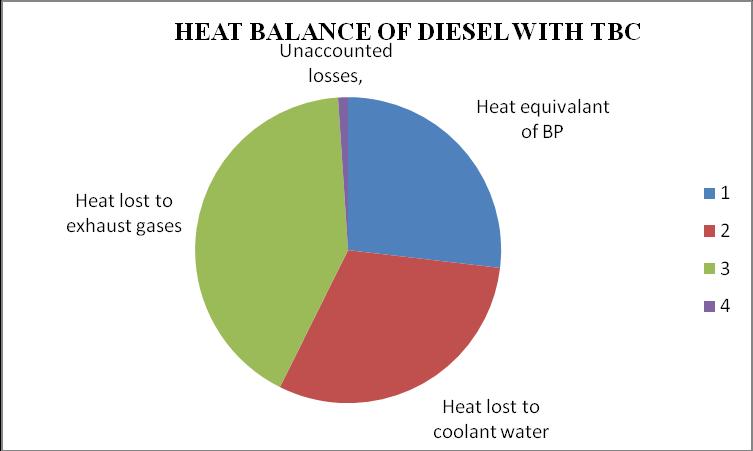

InChartno.7and8showtheusefulheatenergyandheat lostthroughvariousmeans.Withtheapplicationofthermal barriercoatingonthepistoncrown,heatlosstothecoolant water was reduced dramatically compared to standard diesel engine.Ithasbeenobservedfromtheteststhatthe heat equivalent of brake power is higher to biodiesel compared to the diesel engine. This is due the complete combustionofthefuelandreducedfrictionallosses.

Chart -8: HeatbalanceofbiodieselwithTBC

Whenbiodieselwasusedasfuel,incrementsintheengine efficiencyweremainlycausedbythehighermixtureheating valueofthebiodiesel.TheapplicationoftheThermalbarrier coatting, engine efficiency was increased mainly due to better combustion of fuel. Lower heating value of the biodiesel also reduced the exhaust gas temperature when biodiesel was used in standard diesel engine. With the application of the thermal barrier coating the exhaust gas temperature increases for both fuels in engine. CO, HC emissionsandsmokedensityofbiodieselwithTBCarealso reducedby35%,29%&27%ascomparedtothatofdiesel with TBC at 80% load. Application of the thermal barrier coating improvement in the specific fuel consumption causedanincreaseofthebrakethermalefficiencyforboth fuelsinLHRengine.

We extend our sincere gratitude to l.j. technology private limited hydrabad (a.p.) for providing ceramic mullite to carryonourresearchwork

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

[1]. T.Morel, R.Keribar, P.N.Blumberg and E.F.Fort, “ExaminationofKeyIssuesinLowHeatRejectionEngines”, SAEPaperNo.860316

[2]. Prasad CMV, Krishna MVSM, Reddy CP, Mohan KR. Performance evaluation of non-edible vegetable oils as substitute fuels in low heat rejection diesel engines. Proc InstrumMechEng2000;214(D):181–7.

[3].KawamuraH,HigashinoA,SekiyamaS.Combustionand combustion chamber for a low heat rejection engine. SAE paperno.960506,1996.

[4].T.Morel,R.Keribar,P.N.BlumbergandE.F.Fort,“Methods forHeatTransferandThermalAnalysisofInsulatedDiesels,” proceedingsofthe23rd

[5].DavidJ.Duval,SubhashH.Risbud,CeramicandGlass Materials:27(2009).

[6]. Brindley WJ et al., editors. Thermal Barrier Coating Workshop. Proceedings of a Conference, NASA Lewis ResearchCenter,Cleveland,OH,March27-29,1995.

[7].ParlakA,Yas-arH,S-ahinB.Performanceandexhaust emission characteristic of a lower compression ratio LHR dieselengine.EnergyConversManage2003;44(1):163–75.

[8].YoshiyukiK,ChanglinY,KeiM.Effectsoffuelproperties on combustion and Emission haracteristics of a Direct injection Diesel Engine, Society of Automotive Engineers paperNo.2000-01-1831,2000.

[9]. Transactions of Nonferrous Metals Society of China,Volume21,Issue7,July2011,Pages1574-1579Lan JIANG,Xiao-yanCHEN,Guo-mingHAN,YuMEN.

[10].HejwowskiT,WeronskiA.Theeffectofthermalbarrier coatings ondiesel engine performance. Vacuum 2002;65:427–32.

[11]. Mullite for Structural, Electronic, and Optical Applications“llhanA.Aksay,DanielM.Dabbs?andMehmet Sarikaya”2343-58-1991.

[12]. Performance and emission study of Pongamia ethyl esterina4-strokenaturalaspirateddirectinjectiondiesel engine, Sukumar Puhana, N Vedaramana, G. Sankaranarayanana,b, BoppanaV.BharatRamaR.H.Thring, “LowHeatRejectionEngines”,SAEPaperNo.860314

AmitKumar,(Asst.Prof)

Mechanical Department , Swami Vivekanand Subharti UniversityMeerut.

M.Tech(A.E.)-NITWarangal(A.P.)

SandeepKumar,(Asst.Prof.)

Mechanical Department , Swami Vivekanand Subharti UniversityMeerut.

M.Tech(ProductionEngr).

Dr.A.VeereshBabu(Asso.Prof.)

MechanicalEngineeringDeptt., NationalInstituteofTechnology, Warangal(A.P.)