International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1

1Associate Professor Department of Civil Engineering

Mahendra Engineering College, Namakkal, Tamilnadu, India ***

Abstract - Efforts are required to provide environmentally friendlyconstructionmaterialsinordertoreducegreenhouse gas emissions. The manufacturing of Portland cement (pc) is being closely examined since a significant amount of carbon dioxide gas is being discharged into the atmosphere. Due to the expanding need for infrastructure development, As a result, there is an urgent need for careful attention and to minimize their impact on the sustainability of our living environment. One tone of carbon dioxide is released into the atmosphere for every tone of Portland cement during the decarbonation of limestone in the kiln during cement production. The cementitious by-products like GGBFS, RHA & FA are utilized as a alternate binder with different molar concentration and various temperature effects. The compressive strength was increased with increase in molar concentration and also with temperature effect.

Key Words: (Size10&Bold)GreenConcrete,GGBFS,RHS FA,MolarConcentration,TemperatureEffect.

ThemanufacturingofPortlandcement(pc)isbeingclosely examinedsinceasignificantamountofcarbondioxidegasis beingdischargedintotheatmosphere.Asaresult,effortsto usericehuskashinplaceofsomeoftheportlandcementin concretearegainingtraction.Geopolymerconcrete,onthe other hand, is a "new" substance that does not require portlandcementtoactasabinderbecause,inindustrialby productshavingtheequivalenttocementbinders[1-4]i.e., thesilicaandaluminapresentintheindustrialby-products likeGGBFS,RHA&FA.Thisproductsshouldbereactedwith catalytic liquid solution like sodium silicate and sodium hydroxide.

Thetestsinvolvemixingthenecessaryamountsofflyash andGGBFs,reactingthemwithanalkalineliquidsolutionof NaoHandNa2SiO3,thencuringthecastedcubesinahotair ovenataregulatedtemperature.

Forthisexperimentalstudy,lowcalciumflyash,orClassC flyash,whichhashighersilicaandcalciumcontent,isused. Forthegeopolymerizationreaction,theproductshouldhave higher silica and alumina content.in cambria font. Type 3 fonts must not be used. Other font types may be used if neededforspecialpurposes.

Because the GGBFS is also rich in silica and alumina content, which is the higher responsibility for the geopolymerizationreaction;itischosenforthisproject.

TheRHSistheresiduefromthericemill,whichisusedas afirewoodtoboiltherawpaddy,theburntashiscalledRHA this is rich in silica and alumina which can be used a the greenbindersintheconcrete.

Inthisexperimentaleffort,fineaggregatefromanatural riverwasemployed,anditwasexaminedinaccordancewith IS:2386.1970.Sandutilisedhasafinenessmodulusof2.81 andaspecificgravityof2.7.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

For the current experiment, coarse aggregate made of crushedgranitewithangularparticleswasutilised.2.83is thespecificgravity,andfineness.

Thereactionofthegeopolymerconcreteisdependsonthe catalytic liquid solution (CLS), the reaction start working withsilica and alumina elementspresentinthe industrial by-productslikeflyash,GGBFSand RHA.

Thesodiumhydroxideusedforthisprojectispelletsform andtyhesodiumsilicateisinliquidstate.

Thesodiumhydroxidesolutionismixed withthesodium silicatesolutionandatthenecessarymolarconcentrations, 24hoursbeforecastingofthecubes.

Themolarconcentrationisthepercentageofthesodium hydroxide dissolved in the water, higher the percentage concentration the strength will be increased. The molar concentrationisdeterminedbyusingthe molecularweight ofthesodiumhydroxidewiththetimesofthedimesionloess number

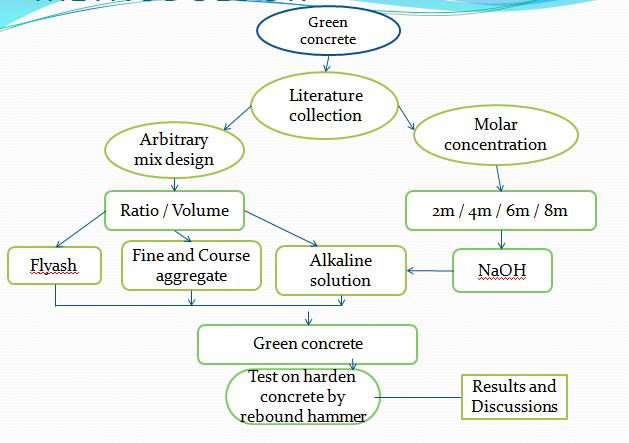

Fig-2:ResearchMethodology.

The flow chart shows that the green concrete is manufacturedbythearbitrarymixdesignconcept,fromthat thematerialsquanityisarrivedandthemolarconcentration ispreparedforthevariouspercentage,andmixcedwiththe drymaterialsandtheconcreteismanufactured.

In the arbitrary mix design concept, the density of concreteisassumedfromthatthevolume/weightratiothe individual materials are arrived including the sodium hydroxideandsodiumsilicatematerials.

Alkaline liquid-to-fly ash & GGBFS ratio

Sodium silicate solution-tosodium hydroxide

Mass of alkaline liquid solution Kg/m3

0.35 2.5 144 0.40 3.0 146 0.45 3.5 158

0.50 4.0 165 0.55 4.5 178 0.60 5.0 186 0.65 5.5 192

Table -1:Mass AlkalineLiquidsolution

Thesodiumhydroxidesolution'smolarconcentrationis itsconcentrationafterithasbeenmixedwithdistilledwater; forinstance,sodiumhydroxidehasmolarconcentrationsof 4,8,16,and32.itiscomputedbymultiplyingbythesodium hydroxide'smolecularweight.

The360gramsofsodiumhydroxideshouldbedissolved in1litreofdistilledwatertocreateasolutionwitha4molar concentrationsince4molarconcentration=40X4=360. The molar concentration ranges from 4M to 32M in this experimental investigation to evaluate the compression strengthofconcreteatvariousmolarconcentrations.

Fig-3:Variousmolarconcentrationpreparedinvarious jars.

ThecuringfortheGreenconcreteisdonebyhotair ovencuring,bythismethodthecuringisaccomplishedand thegreenconcreteattainsthestrengthbygeopolymerization reaction[6].TheSpecimenisplacedinthehotairovenfor various timings and temperature effects and the cube is tested for compressive strength. The temperature is the mainfactorforthereaction,whenthetemperatureincreases the geopolymerization reaction will increased and the concretereachestheearlystrength,thetimefactorwillalso influencethestrengthofconcrete,thetimeincreasesi.ethe periodinwhichtheconcretekeptinsidethehotairoventhe strengthfactorwillincreased.

Table -1: EffectofMolarConcentration

FlyashandGGBFSarewellblendedinthedrymixfor2to3 minutes, followed by the addition of fine and coarse aggregate.Thecatalyticliquidsolutionismadeupofsodium hydroxide and sodium silicate solution, which have been combinedearlierthan24hours.Thegreenconcreteisthen mouldedintocubesof150X150X150mminsize.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

ALKALINE FLY ASH RATIO TEMPERATURE Period in HRS COMPRESSIVE STRENGTH kN/m2

0.30 2 10 0.35 4 16 0.40 8 18 0.45 1 18 0.50 12 21 0.55 14 26 0.60 16 26 0.65 18 27

Table -3: EffectofTemperatureVariation

Theresearchshowsthatthetemperaturevariation andmolarconcentrationincreasesthecompressivestrength of the concrete increased the molar concentration started frem 2M to 18M the strength increased significantly, similarlyforthetemperatureeffectstartedfrom2hoursto 18 hours the strength consistently increased. The higher compressive strength attains in the molar concentration parameter is 28kN/mm2 for 18M and for temperature variations,theperiodof18hrsconsideredtobemaximum strengthof27kN/m2

Theresearchrevealsthatthegreenconcreteshows goodresultswithincreaseintemperatureaswellasincrease ntimeperiod.Theresearchworklimiteduptothealkaline flyash ratio up to the 0.65 and the period of 18 hrs the concreteattainsthe27kN/mvaluesbeyondthatthevalueto betestedandexaminedthattherewillbesignificantchanges in the strength. The The final results show that, the minimumtimetheconcreteattainsthehigherstrengthand the concrete to be considered as the green concrete by reducing the emission of carbon-di-oxide to the environment. Thegreenconcreteishighlyversatileandit willbeconsideredaseco-friendlymaterial.

[1] Gourley.T.J Geopolymers: Opportunities for EnvironmentallyFriendlyConstructionMaterials”Adaptive Materialsforamodernsociety,Sydney2003.

[2]GartnerE,IndustriallyInterestingApproachesto‘LowCO2Cements“CementandConcreteresearch,34(9)2004, pp.1489-1498.

[3]McCafferyRClimateChangeandtheCementIndustry, GlobalCementandLimeMagazine(Environmentalspecial issue),2002pp15-19

[4]SuryaPrakashA,SenthilKumar.GExperimemntalStudy on Geopolymer Concrete Using steel fibres, International JournalofEngineeringTrendsandTechnology21(8)369399.

[5]TarunGehlot,andSankhla.S.SStudyofConcreteQuality AssessmentofStructuralElementsUsingReboundHammer Test, American Journal of Engineering Research 5(8) pp 192-198.

[6]ShatharamY,ANovelApproachonFlyAshAndGGBFS BasedGreenConcreteByAdoptingtheNonDestructiveTest to Study their Strength Parameters, Journal of Emerging TechnologiesandInnovativeResearch6(6)pp209-213