International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1Researcher, Faculty of Engineering, Fayoum University, Fayoum, Egypt 2 Lecturer, Department of Construction and Building Engineering, High Institute of Engineering, October 6 City, Egypt 3 Assistant professor, Civil engineering department, Faculty of Engineering, Fayoum University, Fayoum, Egypt ***

Abstract –The effect of using artificial cold-bonded coarse aggregate on the behavior of concrete based on both fly ash (FA) and ground granulated blast furnace slag (GGBFS) in addition to perlite is investigated in this study. Ordinary concrete is made with artificialcoarseaggregatesutilizing the fly ash-slag-perlite cold bonded process, which does not require the use of cement as a bonding agent. Three different combinations of manufactured coarse aggregate as a substitute for natural aggregateareasfollows:25%,50%,and 75%. In the mixtures, dolomite was employed as a natural coarse aggregate concrete (NCA). During the sieve analysis, specific and unit weights were recorded. The specific and unit weights were determined. Furthermore, on the 7th and 28th days of curing with fresh tap water, a compressive test was performed. There are additional comparison studies between using natural coarse aggregate and employing varying ratios of artificial coarse aggregate The results show that the mechanical and chemical properties of Slag and fly ash artificial aggregate generated by the cold bonded approach are comparable to natural aggregate, with the added benefit of recycling waste materials likeslagandflyash.By increasing the artificial aggregate content, the volume weight and compressive strength of Artificial Coarse Aggregate Concrete (ACAC) were also reduced. Compressive strength of (17.531.55) N/mm2 was obtained.

Key Words: recycledmaterials,Non-renewableresources, Coldbondedpelletization,GGBFS(Slag),Flyash,sustainable concrete,Alkalineactivator,Artificialaggregate

1. INTRODUCTION

Dedicatedtoaddressingtheissuesraisedbyindustrialwaste materials, as well as the depletion of non-renewable aggregates resources, to keep all of the earth's environmentalsystemsinbalance;additionally,ecological integrity is maintained while natural resources are consumedbyhumansataratethatallowsthemtoreplenish themselves, as a simple definition of environmental sustainability

Concreteisacommonlyusedstructuralmaterialalloverthe worldduetoitslong-lastinganddurableproperties,aswell asitsadjustablecompressivestrength[1].

One of the most important properties of concrete is its versatility. Depending on the intended use, it can be produced in any pattern, color, and/or shape. Thanks to improvementsintheconstructionindustry,concreteisnow available and practicable in any location and under any climaticconditions.[2].Ordinaryconcretecomponentsare mostlynaturalresources,withaggregateaccountingfor7080%ofthepercentage[3]. Sandisa fineaggregatethat is alsothethirdmostutilizednaturalmaterialafterwaterand air[4].Coarseaggregateincludesmaterialssuchasgravel, lime, basalt, and dolomite. Coarse aggregate is likewise a naturalandrestrictedresourcethatisbeingdepletedasa resultofitsnumeroususesintheconstructionsector[3].

In terms of natural aggregate consumption, artificial and recycled aggregates should be encouraged as a partial replacement for natural aggregates. Massive volumes of industrial solid wastes, sludges, reservoir sediments, and demolitionwastesarerecycledinthemanufacturingofboth concreteandaggregatesinthis context, whichisa critical problem in driving waste management toward a more sustainableconcreteconstructionfuture,inadditiontomore long-term development [5], [6]. The cement industry employs raw materials as the foundation of its manufacturingprocessandreleasesaconsiderableamount ofhazardousCO2gasintotheatmosphere,approximately 7%ofwhichisharmful totheenvironmentandpromotes global warming [7]. Because of the multi-production, ecofriendlyindustriesandrecyclingwastematerialsaretwoof themostdifficultchallengestoday

For example, fly ash is used in roughly 30% of low-tech applicationssuchasfillbuilding.aswellasbasictrainingin embankments, backfills, pavement foundations, and subbases; intermediate technical applications such as the manufacture of mixed cement, concrete pipes, and precast/lightweightconcrete,prestressedgoodautoclaved aeratedconcrete,andbricks/blocksaggregatelightweight [9], [10]. In addition, to fly ash, Ground Granulated Blast FurnaceSlag(GGBFS)isutilizedasapartialreplacementin cementpaste[11].Auniquemethodofproducingartificial lightweight aggregate was introduced into the literature around the turn of the century. The cold-bonding palletizationapproachwasusedondrypowderflyashasan alternatemethod.Flyashpelletsaremadebyagglomerating

Pelletizing artificial geopolymer aggregates with industrial recycled materials to produce sustainable concrete.

Alaa Hussein Kamal1 , Taher A.Tawfik 2 , A.Serag Faried3

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

flyashparticlesinatiltedrotatingpanatroomtemperature, usingwaterasawettingagentandPortlandcementand/or lime as a binder. This method uses far less energy than autoclaving or sintering to produce artificial lightweight aggregate [12]. The initial phase in the manufacturing of cold-bonded aggregates (CBA) is agglomeration, which is performedbytheuseofwasteandside-effectfinematerials. When fines are agglomerated into bigger particles using eitherpressureornon-pressureagglomerationtechniques [13] Many characteristics influence the manufacturing process.Forexample,usinglowanglesandhighvelocitiesin pelletizers restricts particle development routes, causing particles to clash with each other, and resulting in the formation of tiny aggregates with low efficiency [14]. As reviewedbyFerasTajraetal[15],manypublicationsincold bonded aggregate production use cement as a binder to obtainfreshpellets.Theyalsooutlinedthebenefitsofcoldbonded aggregate. Bui L A et al. [16] published work on makingcold-bondedlightweightaggregateusinganalkaline solution for high-performance concrete utilizing various combinationsofflyash,slag,andricehuskash.S.Geethaand K. Ramamurthy [17] also investigated the variables and characteristicsofcoldbondedaggregateproductionutilizing geopolymerised low-calcium bottom ash and an ambient temperaturecuringregime.Herecomesthesignificanceof employingacementreplacementtolimittheamountofCO2 gas released into the atmosphere, as well as finding alternative resources for aggregate usage by recycling industrial waste materials. Duetothescarcity of research papersthatusednon-cementitious materialsasabonding agent in the production of artificial aggregate, an alkaline solutionof(Na2SiO3)and(NaOH)molarity8mlwasusedin thisstudywithwaterasanalternativebondmaterialwith slagandflyash,aswellasaddingperlitepowdertoreduce theweightofartificial aggregateasa doubleadvantage of reducing cement usage and thus con emissions. Using geopolymerconcretetechnology,wecanalsorecyclewaste materialswith environmental benefits Alkaliactivationis used to make geopolymer materials from industrial aluminosilicatewastematerialssuchasflyash(FA),ground granulatedblastfurnaceslag(GGBS),metakaolin(MK),red mud(RM),andothers.Intermsofmechanicalandchemical properties,geopolymermaterialsgeneratedfromSi/Al-rich mineralssurpassregularconcrete[18],[19].Finally,thegoal of this study is to investigate the effects of using nonCementouscold-bondedaggregateasapartialreplacement of natural coarse aggregate in concrete in terms of mechanicalpropertiesanddurability.

2. MATERIALS AND METHOD

2.1. Materials

2.1.1. Raw Materials

ThisprojectmadeuseofOrdinaryPortlandCement(CEMI) grade42.5fromtheBani-Swiffactory.Itwassubjectedtoa

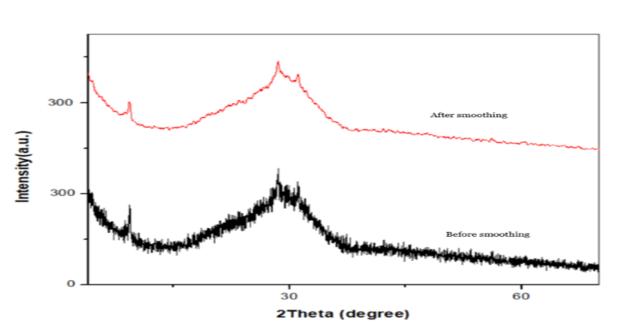

battery of testing to ensure that it fulfilled Egyptian standards.Ithasaspecificgravityof3.11,afinenessof3400 cm2/gm,aninitialandfinalsettingtimeof80minutes,and compressionstrengthof290and395Kg/cm2after3,7,and 28days,respectively.Whencoupledwithbottomashthatis farawayfromtheboiler'srockbottom,flyashiscalledcoal ashandisemployedinvariousindustrialandconstruction areas[7].Forchemicalproducts,weobtainflyashfromthe Sika firm. We also obtain used slag from Alexandria iron manufacturers(Ezzsteel).Figure1depictstheXRDpattern forGGBFS.Finally,asalightweightmaterial,weusedperlite powderfromECPon6OctoberCity.Tables1and2listsallof theproperties

Table -1: Thechemicalanalysisofmaterialsused

Items (% wt) Symbol

Cement Fly ash GGBFS Perlite

Calcium oxide CaO 62.50 5.50 34,16 1.15

Silicon dioxide SiO2 20.70 40.20 20,66 73.2

Ferrous oxide FeO 0,32

Iron oxide Fe2O3 3.01 32.70 0,06 1.60

iron Fe tot 0,46

Magnesium oxide MnO 0,05

Manganese oxide MgO 0.64 8.00 9,44 0.55

Phosphorus Pentoxide P2O5 0,01

Sulfur S 1,47

Chromic oxide Cr2O3 0,00 Aluminum oxide Al2O3 5.40 26.50 10,13 15.04

Sodium oxide Na2O 0.11 34.90 3.60

Potassium oxide K2O 4.10

Sulfur trioxide SO3 2.30 carbon C 1,01

Free lime F. L 2.65

Loss of ignition LOI 2.27 4.20

Table -2: Thephysicalpropertiesofmaterialsused

Items (%wt) Cement Fly ash GGBFS Perlite

Specific gravity 3.11 2.25 2.68 2.2

Mean particle size (µm) 23.4 15.2

Surface area (cm2/g) 3420 3110 4320

Bulk density (gm/cm3) 1.1

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Chart -1:XRDpatternofusedGGBFS

2.1.2. Natural Aggregate

Thecharacteristicsofcrusheddolomite(NCA)sizenumber1 were acquired from the El Minya quarry and used in this study.Toensurethatalldustwasremovedfromthecoarse aggregates,theywerewashedwithwaterbeforebeingused. Afineaggregatepassfroma4.75mmSievesand(NFA)from theHelwanquarrywasalsousedasafineaggregate.Itwas clean and free of contaminants and organic debris. ASTM C128andASTMC127standardswerealsomet.Table3lists theparametersofthenaturalaggregateusedinthisstudy

Table -3: Thephysicalpropertiesofnaturalaggregate

Items (%wt)

Natural sand Crushed dolomite

Specific gravity 2.52 2.65

Fineness modulus 2.4 2.98

Bulk density (t/m3) 1.75 1.55

Crushing strength (%) 19.3

Absorption (%) 1.7 1.9

Total moisture content (%) 0.1 0.5

2.1.3. Artificial Coarse aggregate

Wepresentamethodforproducingartificialaggregate andconductexperimentaltestingtoconfirmthepropertiesof one of our thesis's most efficient elements. To begin with, making the pelletization disc was a bit challenging, so we used a novel technique and simple method to make the artificialaggregateusingatoolthatalreadyexistedinthelab small mixer. We employed geopolymer reaction to encapsulate waste materials such as fly ash FA, groundgranulatedblast-furnaceslagGGBFS,andperlitepowderPP tomanufactureartificialaggregate,andwetriedtodiscovera suitable composition to generate a nice aggregate Many studiesemployedregularPortlandcementasabinderinthe cold bonded aggregate, thus we need to lower the cement percentage in the construction process as it is one of the primarycausesofCO2emissionsintotheatmosphere.Inthe geopolymerization process, we use sodium silicate and sodiumhydroxideasbinders.

Aminimixerisasuitable,available,andeconomictoolto produceartificialaggregateusingacold-bondedpelletization processcomparedtoapelletizationmachineaswedescribed previously the most important factors affecting the coldbonded pelletization process which we use a modified methodtoproduceartificialaggregateusingtheminimixer are the speed and angle of the pelletization disk. Many researchers found that the best speed is from 20 – 40 rpm/min[15],[20]sothespeedoftheminimixerisspeedis 30 rpm/min approximately. Also, the angle of the pelletizationdiskusedwasbetween70-90.theminimixer drumdiameterwas70cm.Thedurationofpelletizationwas between4-5min.thenextTable4.showsthemixtureofthe materialsusedinproducingtheartificialaggregateStepsof themanufacturingprocessusingtheminimixer.

Table -4: Thecontentofartificialaggregaterawmaterial

Items(%wt) GGBFS Fly Ash Perlite Solution/Binder

Mix (1) 3.5 kg 0.30 Mix (2) 3.5 kg 2 liters 0.40 Mix (3) 3.5 kg 2 liters 0.45

2.1.3.1.

The Steps of the manufacturing process using the mini mixer

Asdescribedheretheprocessingproceduresisthehigh affectthequalityofcoldbondedaggregatesohere arethe stepsfollowedinmanufacturingtheartificialaggregate,First, thealkalinesolutionwaspreparedbymixingsodiumsilicate and sodium hydroxide and left for 24 hours in a room temperature(a),Secondtheminimixersetat70degrees(b), Thirdrawmaterialsarepreparedandchargedtothedrum (c),Fourththeminimixerwasturnedonfortwominutesto mix the raw materials (d), Fifth the alkaline solution was addedgradually(e),Sixththemixerwassetto90degrees and let it turned on until the fresh pellets are formed and beforemudfreshpelletsarecreated(f),finallyunchargedthe mixerfromfreshpelletstoaplatethencuringregimeinthe airfor24hrs(g)followedbyintheovenfor24hrsat80C.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

2.1.3.2. Test Procedures on artificial coarse aggregate

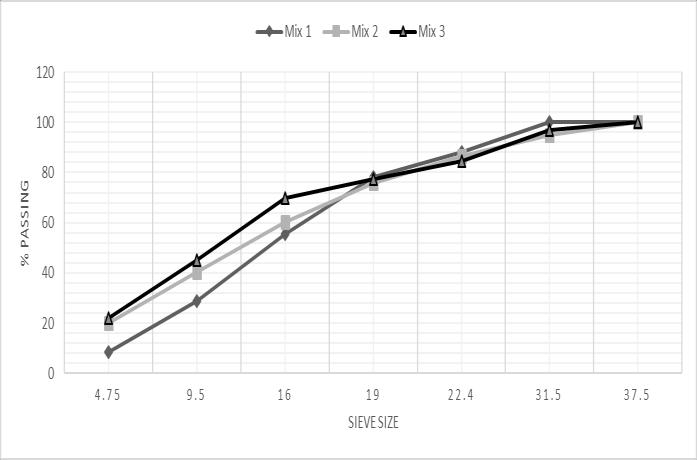

AftercuringthethreetypesofACAweconductedsome testsaccordingtoASTMC128andASTMC127toensurethe quality of the produced aggregate as a mechanical and chemicalsuchasgranulargradient,specificgravity,volume weight, crushing strength, water absorption, and chemical test.themechanicalparameters'speed,angle,andduration as we described before highly affect the mechanical propertiesofthecold-bondedaggregate[21].consequently, thecombinationoftheseparametershelpsustoproducea multi-granular size of the cold-bonded aggregate differing between4–20mm.

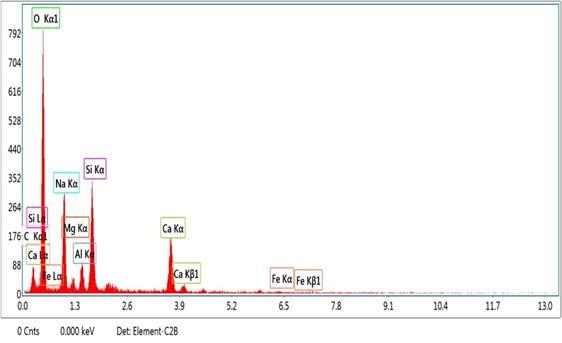

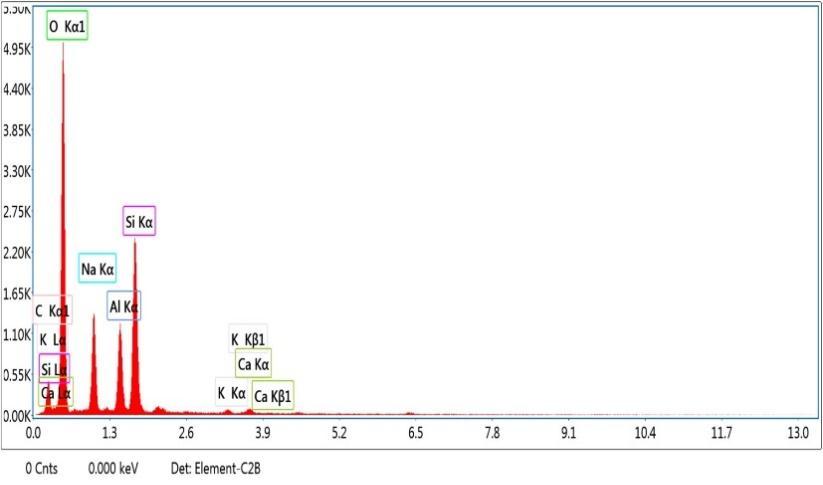

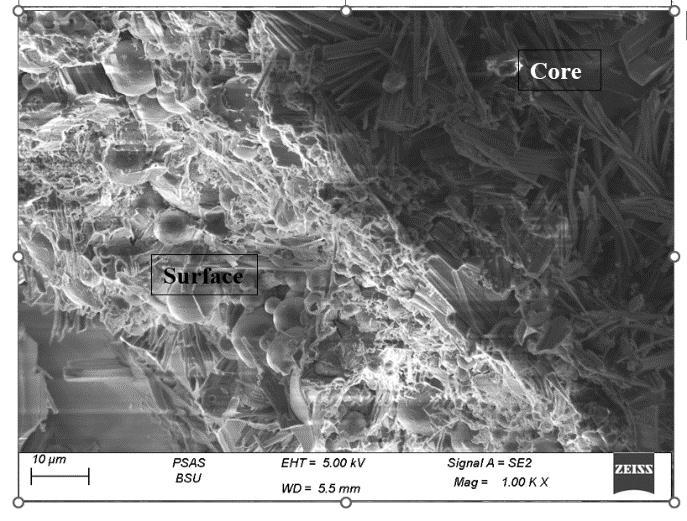

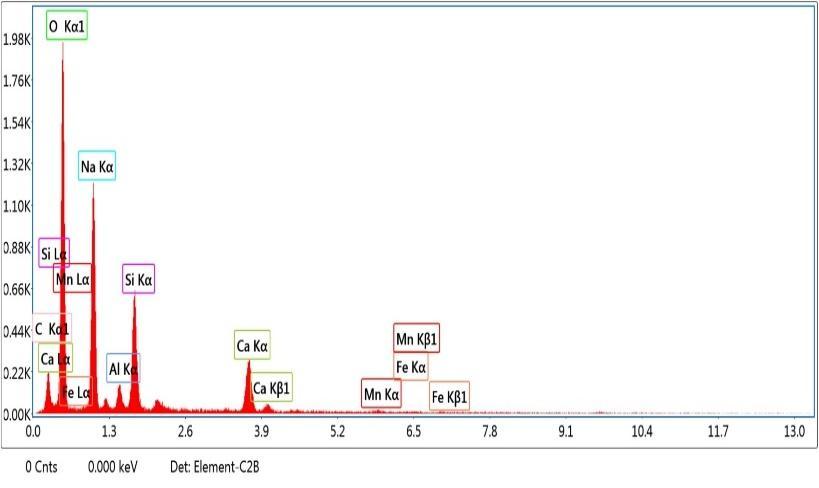

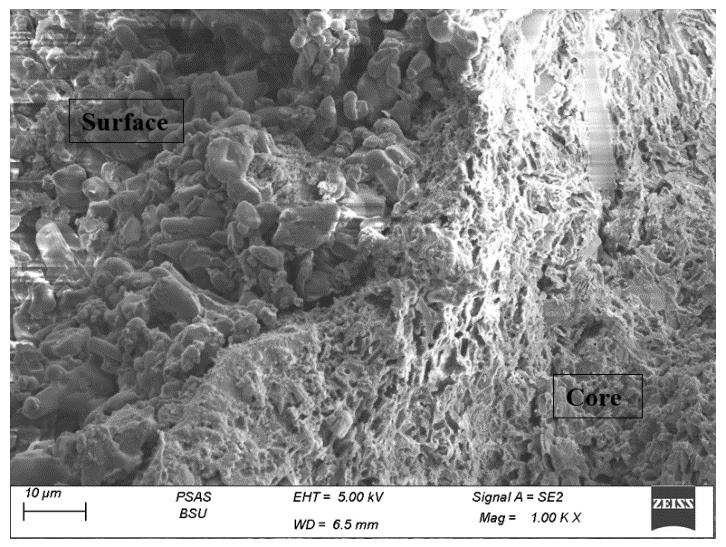

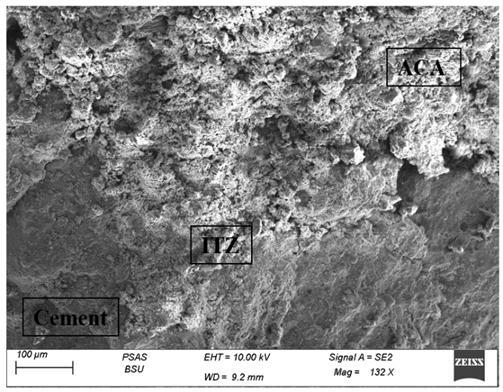

Besidesphysicalandchemical propertiesweusedthe SEM analysis to get high-resolution images to check for surfacecracks,defects,impurities,orcorrosioninavarietyof materials also EDAX checks are done to have a better understandingofthematerialonthesurface.Theelemental compositionofasamplemaybedeterminedquantitatively via EDX analysis with the technology of mapping wewere able to draw multiple color pictures illustrating the concentrationofchemicalmembersintheproducedACAAlso thecharacteristicsaretabulatedinTable5.

Table -5 Thephysical&Chemicalcharacteristicsof producedACA.

Items (%wt) Volume weight Specific gravity Crushing Strength % Absorption %

Chemical Cl and So4 %

Mix (1) 1.26 2.22 24.80 3.09 0.009, 0.13 Mix (2) 1.20 2.10 26.90 5.00 0.003,0.053 Mix (3) 1.08 1.90 23.10 9.00 0.043,0.064 chart -2:GradationcurvesoftheArtificialCoarseAggregate Fig -2:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Fig

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

2.2. Concrete Mixes & tests with ACA

AccordingtoASTMC192mixdesignofconcretelistedin Table 6. cubes which we used, curing regime and testing system for a different replacement to the natural coarse aggregatebytheproducedartificialcoldbondedaggregate with ratios 25,50and 75 % respectively to know the difference in the properties of the concrete by this replacementandtomakeacomparativestudybetweenusing natural and artificial coarse aggregate on the concrete physical, mechanical and durability properties besides the microstructureoftheconcrete.

Itisnoticedthatweneedmorewaterinthemixdesign [22] due to the high absorption of the artificial aggregate usedallsamplesandspecimenswerepreparedandcastin thesamewayandconditions.after24hoursfromcasting,we removedthesamplesfromthecubicmoldswithdimof100x 100x100mm,100x100x500beam,and150x300-cylinder moldwereusedandexecutethecuringregimebyputtingthe samplesinanovenat100Cfor24hoursormovedthemto moistcuringtank.after7or28daysofcuring,wepullupthe specimenstobepreparedforthetests.

Table -6 Concretemixdesign

Controlmix 1292.78 0 695.92 350 157.5 G r ou p ( 1)

M1-25% 969.58 323.2 695.92 350 157.5 3.09 %of ACA Wt M1-50% 646.39 646.39 695.92 350 157.5 M1-75% 323.2 969.58 695.92 350 157.5 G r ou p ( 2 ) M2-25% 969.58 323.2 695.92 350 157.5 5.00 %of ACA Wt

M2-50% 646.39 646.39 695.92 350 157.5 M2-75% 323.2 969.58 695.92 350 157.5 G r ou p ( 3 )

M3-25% 969.58 323.2 695.92 350 157.5 9.00 %of ACA Wt M3-50% 646.39 646.39 695.92 350 157.5 M3-75% 323.2 969.58 695.92 350 157.5 *NCA=Naturalcoarseaggregate. *M1,M2andM3refersto(GGBFS),(GGBFS+Perlite)and(Flyash+Perlite)respectively. *ACA=Artificialcoarseaggregate. *(M1-25)1referstotheACAmixcontainingGGBFSand25referstoACAreplacementratio%.

2.2.1. Volume weight

Cubespecimensofsize100x100x100mmwereformed for the volume weight of concrete at various ratios of artificial coarse aggregates. After 24 hours, the specimens were remolded and weighted. Their average value is presented to compute volume weight using the following formulae: Volumeweight=weight(g)/volume(cm3).

2.2.2. Compressive strength

It is a mechanical test that we used to measure the maximum compressive load a material can afford. A gradually applied load compresses the test item, which is commonintheshapeofacube,prism,orcylinder,between the platens of a compression-testing machine. Cubes are usedinthistest100x100x100mmaftercuringfor7and 28days.usingtheequation ofunknownstress=σ=(P)/A wecouldgetthevalueofcompressivestrengtheasilywhere PistheloadandAisthesurfaceareaundertheload

3. Results and discussion

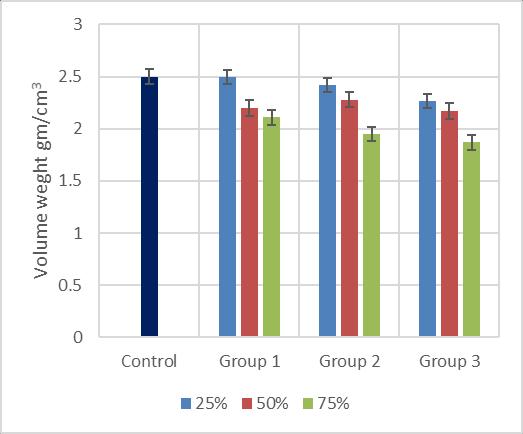

3.1. Volume weight

Themaximumvaluewasnoticedtobe2.5gm/cm3for 25%replacementofM1artificialaggregatewithdecreasing percentageof0%andtheminimumvaluewas1.87gm/cm3 for 75% replacement of M3 artificial aggregate with decreasingpercentageof25%.Aslistedintable7.Aresultof increasingthepercentageofcold-bondedcoarseaggregatein concreteisalsoduetothelightweightpropertiesofperlite andflyashcomparedtoslagandnormalcoarseaggregate.

3.2. Compressive strength

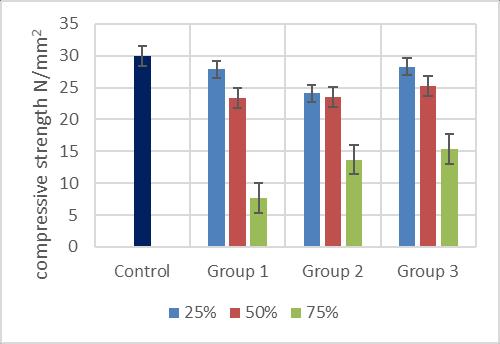

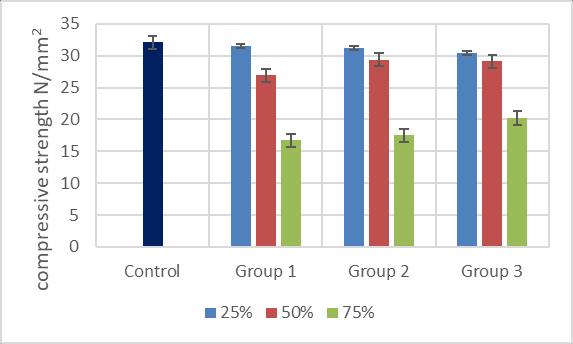

ThecompressivestrengthofCBACwas25percentlessthan thatofNACwhencoarseNAwasentirelysubstitutedwith coarseCBA[23]alsoReducingwater/binderratios,hasbeen shown to significantly improve the strength of CBAC concrete,particularlyinconcretecontainingupto18percent CBA[24]. As listed in table 8 the maximum compressive strengthvalueat7dayswasnoticedtobe28.3N/mm2for 25%replacementofFlyash+Perliteartificialaggregatewith decreasingpercentageof3%andtheminimumcompressive strength value at 7 days was 7.60 N/mm2 for 75% replacement of GGBFS artificial aggregate with decreasing percentageof74.0%.Themaximumcompressivestrength value at 28 days was noticed to be 31.5 N/mm2 for 25% replacement of GGBFS artificial aggregate with decreasing percentageof1.90%andtheminimumcompressivestrength valueat28dayswas16.70N/mm2for75%replacementof GGBFS artificial aggregate with decreasing percentage of 47.90%.Duetotheshortageincrushingstrengthalsothe weak core structure matrix of artificial aggregate consequentlythemoreincreasingtheartificialaggregatethe lesscompressivestrengthisachieved.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Table -7 Volumeweightofallmixesused

Series Volume weight gm/cm 3

%Increasin g And decreasin g

ACA Volume weight gm/cm3

Control mix 2.5 G r ou p ( 1 ) M1-25% 2.5 0 1.26 M1-50% 2.2 -12 M1-75% 2 11 -16 G r oup ( 2 ) M2-25% 2 42 -3 1 20 M2-50% 2 28 -9 M2-75% 1.95 -22 G r oup

Fig -10:Compressivestrengthofgroup(1,2,3)at7days comparison

Series

Table -8 Compressivestrengthofallgroups

Compressive Strength after 7 days N/mm2

% Increa sing And decre asing

Control mix 29.2 32.10 G r oup

Compressive Strength after 28 days N/mm2

( 1 ) M1-25% 27.9 -4.5 31.5 -1.9 M1-50% 23.3 -20.2 26.9 -16.2 M1-75% 7.6 -74.0 16.7 -47.9 G r oup

( 2 ) M2-25% 24.1 -17.5 31.2 -2.8 M2-50% 23.5 -19.5 29.4 -8.5 M2-75% 13.7 -53.0 17.5 -45.5 G r oup ( 3 ) M3-25% 28.3 -3.0 30.4 -5.3 M3-50% 25.2 -13.7 29.1 -21.8 M3-75% 15.3 -47.6 20.2 -37.1

( 3 ) M3-25% 2.27 -9 1.08 M3-50% 2.17 -13 M3-75% 1.87 -25 y=0.03x +1.42

%Increasi ng And decreasi ng

Fig -9:Volumeweightcomparisonforallmixesused

Factor value:

Fig -11:Compressivestrengthofgroup(1,2,3)at28days comparison

chart -3:CompressiveandUnitweightcorrelationofall groups(1,2,3)at28days.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Figure17. illustratetherelationbetweenthecompressive strengthandunitweightatdifferentratiosofreplacementas themorethereplacementratioisconductedthelesstheunit weightoftheconcreteproducedalsothelesscompressive strength of concrete produced as a result of decreasing in crushingstrengthoftheproducedartificialcoarseaggregate.

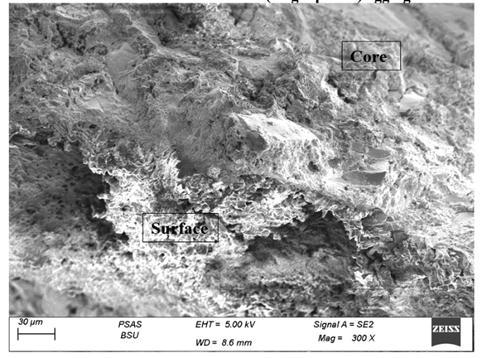

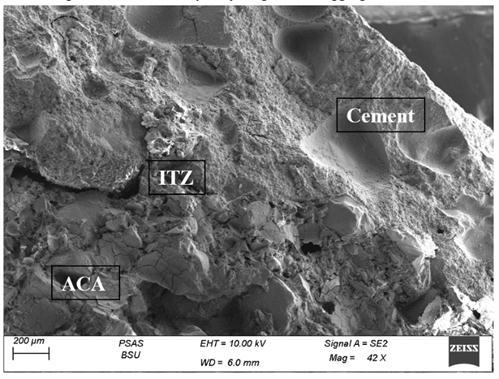

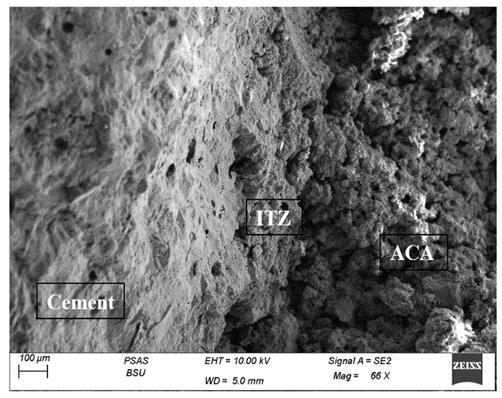

3.3. Microstructure of concrete

Concreteconsistsofthecementmatrix,aggregate,and InterfacialTransitionZonebetweenthemitisknownthatITZ influences the durability and mechanical properties of concrete so in normal concrete and due to big differences between aggregate and cement particles a weak area is createdonthesurfaceofaggregate.thisareaiscontaininga large amount of water and fewer cement particles which produce a weak ITZ leading to reduce bond between aggregateandcementpaste[30].

Inthenextfigures17,18and19,wecouldseethatITZ almostoverlapswiththeartificialaggregatesurfacebecause of the pores and the sinuosity in the surface of aggregate mainlyformedbythereactionbetweenSodiumhydroxide andsodiumsilicateinthecoldbondedprocessbesidesthe cement hydration process outputcalcium hydroxide could interact with the raw material we used in producing aggregate.

Thefailureoftheconcreteundercompressionseems tooccurawayfromtheITZbetweenartificialaggregateand thecementpasteeitherinthecoreoftheartificialaggregate orbetweentheITZofnaturalaggregateasshowninfigure15 weseeclearlythecracksappearinthesamplewaschosen afterfailureundercompressivetestmachine.

Fig -13:SEManalysisofFlyash+perliteMix(3)aggregate inconcrete

Fig -12:SEManalysisofSlagMix(1)aggregateinconcrete

Fig -14:SEManalysisofSlag+perliteMix(2)aggregatein concreteaftercompressionfailure

4. CONCLUSIONS

Thisstudyillustratesproducingartificialcoarseaggregate using waste materials such as Slag and Fly ash with cold bonded technology as a double solution to two main challengesweface,Firstrecyclingthewastematerialswhich is a by-product of industrial processes all over the world. Second, stop the bleeding of natural resources of our motherland by investigating the influence of using this artificial aggregate as a coarse aggregate in the concrete industryasasubstitutionfornaturalcoarseaggregateand how far this affects the behavior of concrete mechanical properties and its durability. This is conducted thus experimental plan using replacement strategy to find out gradually the differences in the concrete behavior in last figure4.18wecouldseethatITZalmostoverlapswiththe artificial aggregate surface because of the pores and the sinuosityinthesurfaceofaggregatemainlyformedbythe

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

reactionbetweenSodiumhydroxideandsodiumsilicatein the cold bonded process besides the cement hydration process output calcium hydroxide could interact with the rawmaterialweusedinproducingaggregate.Hencesome pointsarelistedbelow:

4.1. Artificial Coarse Aggregate

•Producing artificial aggregate with the traditional mini mixerisasuitable,economical,andeasytechniquewithslag andflyashasabasematerialbesidesbeinganeco-friendly recyclingmethodandcouldnotbejustawastematerial[13].

•Artificialaggregatehasaroundshapeandsinuositysurface whichleadstohighworkabilityandconsumeslesscement contentforbonding[5].

•ThemechanicalandchemicalpropertiesofSlagandflyash artificialaggregateproducedbythecoldbondedtechnique aresimilartothenaturalaggregateandwiththebenefitof recyclingthewastematerialssuchasslagandflyash.

4.2. Concrete using artificial aggregate

•The compressive strength of Artificial Coarse Aggregate Concretewasdecreasedbyincreasingtheartificialaggregate content.

•The volume weight of artificial aggregate concrete is decreasedbyincreasingtheartificialaggregatecontent.

• Semi-lightweightconcrete iscreated whenusinga 75 % replacementratioofartificialaggregatewithMix2(Slag+ perlite)andMix3(Flyash+perlite)

•AgoodITZiscreatedwithartificialaggregateandcement paste due to overlapping between aggregate surface and cementparticles[31].

•The failureof the compressivestrength test occursaway fromtheITZbetweenartificialaggregateandcementpaste.

•Compressive strength between (17.5 – 31.55) N/mm2 couldbeachieved.

•Themaximumcompressivestrengthat28dayswasata25 %replacementratioofgroup1(Slag)equalto31.55N/mm2 decreasingby1.7%comparedtothecontrolmixasaresult ofahighdensityofACAandlowcrushingstrength.

•The compressive strength of slag group (1) at 7 days is approximatelyequalto85%of28days.

•Thecompressivestrengthoftheslag+perlitegroup(2)at7 daysisapproximatelyequalto75%of28days.

•ThecompressivestrengthofFlyash+perlitegroup(3)at7 daysisapproximatelyequalto85%of28days.

•Usinga50%replacementratioofartificialaggregatewith Mix 1, Mix 2, and Mix 3 results in similar compressive strengthtothetraditionalconcretemixcontainingnatural aggregate.

•Using more than 50% replacement ratio of artificial aggregate with Mix 1, Mix 2, and Mix 3 results in semilightweightconcretethatcouldbeusedfornon-structural purposes.

•Besides fly ash, Slag is a suitable waste material used in producingartificialaggregate.

REFERENCES

[1] [1] H. Unis Ahmed et al., “Geopolymer concrete as a cleanerconstructionmaterial:Anoverviewonmaterials andstructuralperformances,”CleanerMaterials,vol.5, 2022,doi:10.1016/J.CLEMA.2022.100111.

[2] [2] T.R.Naik,“SustainabilityofConcreteConstruction,” Practice Periodical on Structural Design and Construction,vol.13,no.2,pp.98–103,May2008,doi: 10.1061/(ASCE)1084-0680(2008)13:2(98).

[3] [3] I.SimsandB.Brown,“ConcreteAggregates,”inLea’s ChemistryofCementandConcrete,Elsevier,1998,pp. 907–1015.doi:10.1016/B978-075066256-7/50028-X.

[4] [4] Y.Cao,Y.Wang,Z.Zhang,andH.Wang,“Recycled sand from sandstone waste: A new source of highqualityfineaggregate,”ResourConservRecycl,vol.179, Apr.2022,doi:10.1016/J.RESCONREC.2021.106116.

[5] [5] F.ColangeloandR.Cioffi,“UseofCementKilnDust, Blast Furnace Slag and Marble Sludge in the Manufacture of Sustainable Artificial Aggregates by Means of Cold Bonding Pelletization,” Materials 2013, Vol.6,Pages3139-3159,vol.6,no.8,pp.3139–3159,Jul. 2013,doi:10.3390/MA6083139.

[6] [6] T.R.Naik,“SustainabilityofConcreteConstruction,” Practice Periodical on Structural Design and Construction,vol.13,no.2,pp.98–103,May2008,doi: 10.1061/(ASCE)1084-0680(2008)13:2(98).

[7] [7] N.Ali,J.Abbas,M.Anwer,S.K.Alwi,M.Anjum,and R. Raja, “The Greenhouse Gas Emissions Produced by CementProductionandItsImpactonEnvironment:A Review of Global Cement Processing,” International JournalofResearchinScience,vol.2,Jul.2015.

[8] [8] S. Nandy, E. Fortunato, and R. Martins, “Green economyandwastemanagement:Aninevitableplanfor materials science,” Progress in Natural Science: MaterialsInternational,vol.32,no.1,pp.1–9,Feb.2022, doi:10.1016/J.PNSC.2022.01.001.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

[9] [9] G.BaykalandA.G.Döven,“Utilizationofflyashby pelletization process; theory, application areas and researchresults,”ResourConservRecycl,vol.30,no.1, pp. 59–77, Jul. 2000, doi: 10.1016/S09213449(00)00042-2.

[10] [10] C. R. Meesala, N. K. Verma, and S. Kumar, “Criticalreviewonfly-ashbasedgeopolymerconcrete,” StructuralConcrete,vol.21,no.3,pp.1013–1028,Jun. 2020,doi:10.1002/suco.201900326.

[11] [11] Y. Liu, X. Zhou, C. Lv, Y. Yang, and T. Liu, “Use of Silica Fume and GGBS to Improve Frost ResistanceofECCwithHigh-VolumeFlyAsh,”Advances in Civil Engineering, vol. 2018, 2018, doi: 10.1155/2018/7987589.

[12] [12] S. İpek, O. A. Ayodele, and K. Mermerdaş, “Influence of artificial aggregate on mechanical properties, fracture parameters and bond strength of concretes,”ConstrBuildMater,vol.238,p.117756,Mar. 2020,doi:10.1016/J.CONBUILDMAT.2019.117756.

[13] [13] A.SivakumarandP.Gomathi,“Pelletizedfly ash lightweight aggregate concrete: A promising material,”JournalofCivilEngineeringandConstruction Technology, vol. 3, no. 2, pp. 42–48, 2012, doi: 10.5897/JCECT11.088.

[14] [14] R. Manikandan and K. Ramamurthy, “Swelling Characteristic of Bentonite on Pelletization and Properties of Fly Ash Aggregates,” Journal of MaterialsinCivilEngineering,vol.21,no.10,pp.578–586, Sep. 2009, doi: 10.1061/(ASCE)08991561(2009)21:10(578).

[15] [15] F. Tajra, M. A. Elrahman, and D. Stephan, “The production and properties of cold-bonded aggregate and its applications in concrete: A review,” ConstructionandBuildingMaterials,vol.225.Elsevier Ltd, pp. 29–43, Nov. 20, 2019. doi: 10.1016/j.conbuildmat.2019.07.219.

[16] [16] L.A.T.Bui,C.L.Hwang,C.T.Chen,K.L.Lin, andM.Y.Hsieh,“Manufactureandperformanceofcold bondedlightweightaggregateusingalkalineactivators forhighperformanceconcrete,”ConstrBuildMater,vol. 35, pp. 1056–1062, Oct. 2012, doi: 10.1016/j.conbuildmat.2012.04.032.

[17] [17] S.GeethaandK.Ramamurthy,“Properties of geopolymerised low-calcium bottom ash aggregate curedatambienttemperature,”CemConcrCompos,vol. 43, pp. 20–30, 2013, doi: 10.1016/j.cemconcomp.2013.06.007.

[18] [18] J.L.Provis,A.Palomo,andC.Shi,“Advances inunderstandingalkali-activatedmaterials,”CemConcr

Res, vol. 78, pp. 110–125, Dec. 2015, doi: 10.1016/J.CEMCONRES.2015.04.013.

[19] [19] F.A.Shilar,S.v.Ganachari,V.B.Patil,T.M. Y.Khan,andS.DawoodAbdulKhadar,“Molarityactivity effectonmechanicalandmicrostructurepropertiesof geopolymer concrete: A review,” Case Studies in Construction Materials, vol. 16, Jun. 2022, doi: 10.1016/J.CSCM.2022.E01014.

[20] [20] G. K. George and P. Revathi, “Production andUtilisationofArtificialCoarseAggregateinConcrete -AReview,”inIOPConferenceSeries:MaterialsScience and Engineering, Oct. 2020, vol. 936, no. 1. doi: 10.1088/1757-899X/936/1/012035.

[21] [21] R. Manikandan and K. Ramamurthy, “Influence of fineness of fly ash on the aggregate pelletizationprocess,”CemConcrCompos,vol.29,no.6, pp. 456–464, Jul. 2007, doi: 10.1016/j.cemconcomp.2007.01.002.

[22] [22] P. Grübl, “Mix design of lightweight aggregate concrete for structural purposes,” International Journal of Cement Composites and LightweightConcrete,vol.1,no.2,pp.63–69,Dec.1979, doi:10.1016/0262-5075(79)90012-5.

[23] [23] M.Gesoǧlu,E.Güneyisi,T.Özturan,H.Ö.Öz, and D. S. Asaad, “Permeation characteristics of self compactingconcretemadewithpartiallysubstitutionof natural aggregates with rounded lightweight aggregates,” Constr Build Mater, vol. 59, pp. 1–9, May 2014,doi:10.1016/J.CONBUILDMAT.2014.02.031.

[24] [24] N.U.KockalandT.Ozturan,“Strengthand elasticpropertiesofstructural lightweightconcretes,” MaterDes,vol.32,no.4,pp.2396–2403,Apr.2011,doi: 10.1016/J.MATDES.2010.12.053.

[25] [25] H. Yıldırım and T. Özturan, “Mechanical properties of lightweight concrete made with cold bondedflyashpellets,”pp.23–25,2013.

[26] [26] P. Tang and H. J. H. Brouwers, “The durability and environmental properties of selfcompacting concrete incorporating cold bonded lightweight aggregates produced from combined industrialsolidwastes,”ConstrBuildMater,vol.167,pp. 271–285, Apr. 2018, doi: 10.1016/J.CONBUILDMAT.2018.02.035.

[27] [27] A.Terzić,L.Pezo,V.Mitić,andZ.Radojević, “Artificialflyashbasedaggregatespropertiesinfluence onlightweightconcreteperformances,”CeramInt,vol. 41, no. 2, pp. 2714–2726, Mar. 2015, doi: 10.1016/J.CERAMINT.2014.10.086.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

[28] [28] E.Güneyisi,M.Gesoglu,T.Özturan,andS._ Ipek,“Fracturebehaviorandmechanicalpropertiesof concretewithartificiallightweightaggregateandsteel fiber,”2015,doi:10.1016/j.conbuildmat.2015.03.054.

[29] [29] G.JosephandK.Ramamurthy,“Influenceof flyashonstrengthandsorptioncharacteristicsofcoldbondedflyashaggregateconcrete,”ConstrBuildMater, vol. 23, no. 5, pp. 1862–1870, May 2009, doi: 10.1016/J.CONBUILDMAT.2008.09.018.

[30] [30] M.H.ZhangandO.E.Gjørv,“Microstructure of the interfacial zone between lightweight aggregate and cement paste,” Cem Concr Res, vol. 20, no. 4, pp. 610–618,Jul.1990,doi:10.1016/0008-8846(90)901035.

[31] [31] X. Sun, B. Zhang, Q. Dai, and X. Yu, “Investigation of internal curing effects on microstructureandpermeabilityofinterfacetransition zones in cement mortar with SEM imaging, transport simulationandhydrationmodelingtechniques,”Constr Build Mater, vol. 76, pp. 366–379, Feb. 2015, doi: 10.1016/J.CONBUILDMAT.2014.12.014.

BIOGRAPHIES

AlaaHusseinKamalWorksasCivil EngineerattheEgyptianMinistry of water resources and irrigation also a researcher in the civil engineering department at Fayoumuniversity.

Dr. Taher Anwar Tawfik is a LecturerofStructuralEngineering CivilEngineeringDepartment High Institute of Engineering 6th October

Dr.AhmedSeragFaridis Assistant professor of Structural Engineering Civil Engineering DepartmentFacultyofEngineering FayoumUniversity