1,2,3

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1,2,3

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

***

Abstract - The demand for materials is increasing and the availability of the materials are decreasing presently. Because of these factors, the reuse of solid waste products such as lime powder was considered to study.

In this study, the compressive strength of lime cement concrete was examined. C25 concrete was made with Ordinary Portland cement which was partially replaced with quick lime got as a waste product from company in proportions ranging from 10% to 30% by weight.

There is a fundamental problem with this sort of cement replacement, the alteration of the physical properties of concrete. This study investigates the effect of substituting lime for cement on the compressive strength of concrete, as well as its other physical qualities. With a 10% substitution of lime, the compressive strength of lime concrete cube specimens increased significantly, whereas with a higher proportion, the strength decreased significantly.

Key Words: Lime powder, Waste, Concrete, Compressive strength

Concreteisabindingmaterialcomposedofcalcium,silicon, aluminium,iron,andavarietyofothermaterials.Itismostly utilisedasabindingmaterialthroughouttheworlddueto propertieslikehavingstrongcompressivestrength,setting time,andsoon. Calciumhydroxide(alsoknownasslaked lime)isaninorganicsubstancehavingtheformulaCa(OH)2 Quicklime or calcium oxide when mixed with water producesapowderwhiteincolourortranslucentcrystals Thesematerials,limestoneproducts,cement,concrete,and mortar, are still widely utilised in Engineering and Construction. Lime improves the fresh and hardened properties of mortars when mixed. It enhances water retention and workability, increases utilisation efficiency, andallowsforhigh-qualityworkonfreshconcrete.Increases resistancetonaturalmovementwithoutexperiencingsevere cracking or debonding, such as thermal expansion and contraction and creep, increases resistance to frost, increases overall toughness, decreases the likelihood of efflorescence(stainingcausedbysaltdeposits)onhardened concrete.

Lime has been utilized in building construction for many years, and it may be utilized as a strong, long-lasting substancethatreducesitsenvironmentalimpact.However, incircumstanceswherecuringtimeisoftheutmost,cement may be required. Cement and lime are frequently used in concrete applications to take advantage of their unique qualities.Naturallimestoneisconvertedintolimebyheating therock ina kilnuntil onlyquicklime calciumoxide remains. The quicklime is then combined with small quantitiesofwatertoproducehydratedlime,whichcanbe addedtocementorusedasabinderwhencombinedwith water. Cement comprises of compounds containing silica that, when combined with water, rapidly harden. Lime becomes harder over time by slowly absorbing carbon dioxideandrevertingtolimestone.

The aim of the investigation is to investigatereplacing cement with lime in the production of normal weight concrete in order to reduce greenhouse gas emissions producedbyPortlandcementmanufacturers.

Thestudyincludesthefollowing:

Toknowtheimportanceof physical propertiesof materials used in concrete by some tests on fine aggregate,coarseaggregate,andcement.

To study the behaviour of lime concrete by conducting series of experiments to compare the quicklime-addedconcretetoconventionalconcrete andexamine the impactof replacingcement with quicklimeatpercentagesof10%,20%,and30%.

Hemanshu Veram et al. (Maurya, N. K., Faldu, S., & Thakur, R. 2019), thisstudyexaminedthehydrauliclime cement concrete and mortar's compressive strength and shearbondstrength.M-30concretewaspartiallyreplacing OrdinaryPortlandcementwithhydrauliclimeinquantities rangingfrom0%to35%inconcreteandfrom0%to100% inmortar.Italsostudiestheeffectsofreplacingcementwith limeonthecompressivestrengthandshearbondstrengthin mortar.Thestrengthoftheshearbondofatripletspecimen

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

increasedasthelimecontentofamortarincreased.When limewasreplacedbyupto15%,thecompressivestrengthof cube specimens of lime concrete increased, but rapidly decreasedasthequantityincreased

Omar M. Omar et al. (Abd Elhameed, G.D., Sherif, M.A. and Mohamadien, H.A 2012),referstoastudyconducted todeterminethechangesinthequalitiesofconcretechange whensandissubstitutedwithlimestonewasteandmarble powder is added. 25%, 50%, and 75% of the sand in the concretemixtureswassubstitutedwithwastelimestone.In addition,theconcretemixescontained5%,10%,and15% powderedmarble.Theeffectsofemployingwastelimestone asfineaggregateonvariousconcretecharacteristics,both fresh and cured, were investigated. As part of the investigation,thematerial'scompressivestrength,indirect tensile strength, flexural strength, elastic modulus, and permeability were all assessed. There were no changes to the unit weight of concrete. However, good results were observedwhenlimestonewasteandmarblepowderwere usedasthefineaggregate

Acharya, P.K. et al. (Patro, S.K., 2015), this study investigatesincorporatingFerrochromeash(FA)asapartial replacement for traditional Portland cement in the production of concrete. FA was substituted for Ordinary PortlandCement(OPC)atfourdifferentsubstitutionrates (10%,20%,30%,and40%),whereaslimewassubstitutedat a rate of 7%. Lime and FA were examined for their water permeability, splitting tensile strength, elastic modulus, compressive strength,andultrasonicpulse velocity. At 28 days,thepropertiesofcontrolconcreteandconcretemade with 40% FA and 7% lime in place of 47% OPC were identical.Itwasdiscoveredthatacombinationofupto40% FA and 7% lime can be used efficiently in concrete preparation without affecting or even boosting concrete performance. Petrography analysis promotes the improvementofconcretepropertieshavingFAandlime.

Adesina, P.A. et al. (Olutoge, F.A., 2019) inthiswork,Rice Husk Ash (RHA) and lime were used to replace ordinary cement in varying proportions to produce RHA-Lime concrete. According to the findings of the strength tests, RHA-Limeconcreteexhibitedgreaterearlystrengththanthe controlconcrete.RHA-Limecementcombinationswerealso shown to be appropriate for usage in structural concrete, havingthecapacitytosubstituteupto25%ofconventional cement.RHA-Limemixturescanserveasaviablealternative toconventionalcementinconcrete.

Borinaga -Treviño, R et al. (Cuadrado, J., Canales, J. and Rojí, E., 2021),thisstudyshowstheuseoflimemud,abyproductofthepaperindustry,asapartialreplacementfor cement in mortar to lessen its environmental impact. For this,mortarscontaining10%,20%,30%,and40%limemud beingreplacedwithcementbyweightarecomparedtoa

typical cement mortar. Physical, thermal, mechanical showedthatlimemudcouldreplaceupto20%ofcement while still maintaining the mortar's thermal properties. Studiesconductedinthelaboratoryonradiantfloorheating slabs has revealed that 20% lime mud mortar has same stationarybehaviourasthatofreferencemortar

The following methodology was used to study of strengthbehaviourofconcretewithlime.Here,thebasic properties like specific gravity of fine aggregates, sieve analysisofcoarseaggregates,consistencyandsettingtime of cement were done. C25 mix was designed and for the concrete samples, weight-based batching was used. Mixture mixing was used to mixaggregates, cement and water. Vibration compacting was used for compacting concretesamples.Curingofconcretespecimenwasdone by keeping samples inside the water tank. Testing of compressivestrengthtestwasdoneusingtheCompressive strength testing Machine. Cement was partially replaced with10%,20%,and30%byweightwiththeLimepowder Compressive strength tests for C25 grade concrete with variedamountsoflimepowderweredoneafter7and28 days of curing. The strength results obtained were comparedtothoseofstandardconcreteandtheresultsfor compressivestrengthwerestudied.Thetestsweredonein thelaboratoryandtheresultsaretabulatedgiven.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

2395-0072

Materials:Inthisresearchstudy,the53gradeofordinary Portlandcement(OPC)wasused. Thecoarseaggregateused inthisstudywasangularshapedbecauseangularaggregate providesmorestrength. C25gradeconcretedesignmixwas done Theaggregatesizesusedinthetestwereintherange between 10mm and 20mm. Fine aggregate was having a specificgravityof2.449.Locallyavailabletransportablewater wasused.

Table

S. No. Cement (kg) Fine aggregate (kg)

Coarse aggregate (kg)

W/C

1. 10.44 18.06 25.5 0.55

In In this study, Rejected Lime from Majan industry, Salalah, Omanwasusedasapartialreplacementofcementtoprepare lime concrete. The cement used in this study was replaced 10%,20%and30%byweightwithlimepowderformaking concreteandresultscomparedwithNormalconcrete.

Table – 3: %Replacementoflimewithcement

S. No. %Replacementof limewithcement Limeadded (kg) Cement (kg) 1 0 0 10.44 2 10 1.044 9.396 3 20 2.088 8.352 4 30 3.132 7.308

Testing:Compressivestrength-Compressivestrengthtests are performed on cubes, 150 mm 150 mm 150 mm specimens. The compressive strength of concrete is dependingontheconcretemixdesignused,concretequality, cement strength, water cement ratio, curing, and other factors. It is also influenced by other elements such as concretemixing,concreteplacementandconcretecuring.By compressivetestingmachine,the compressivestrength of concretewasfound.

CompressiveStrength=P/Awhere,P=Compressive loadinkNandA=Areaofcubeinmm2

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Figure -5: Compressivestrengthtest

The7daysand28daysaveragecompressivestrengthof6 specimensweretakenandresultsareshownbelowin Table-4

Table -4: 7daysand28daysCompressivestrengthtest

% Replacement oflimewith cement

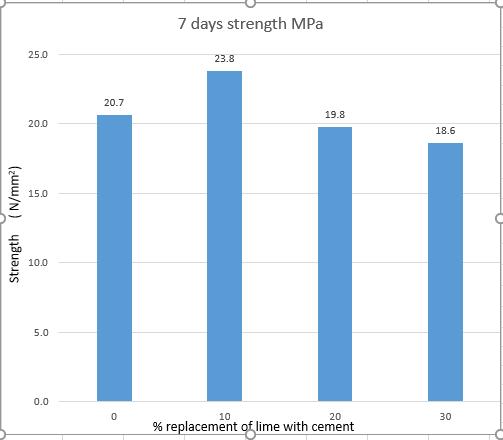

Figure -6: 7daysCompressivestrength(MPa)

FromtheaboveFigure6,thecompressivestrengthof limeconcreteat7daysstrengthcanbestudied According to the graph above, when lime is added up to 10% by weight of cement, lime concrete has an optimum compressive strength of 23.8 MPa. When lime content exceeds10%,compressivestrengthgraduallyfalls.

Strengthin7days (N/mm2)

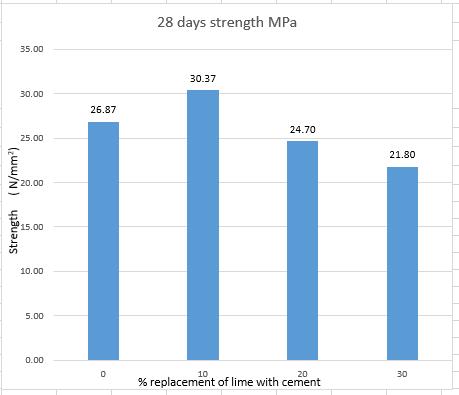

Strength In28days (N/mm2) 0 20.7 26.8 10 23.8 30.3 20 19.8 24.7 30 18.6 21.8

The7daysand28daysaveragecompressivestrengthof6 specimens were taken and results are shownbelowinfigure6andfigure7.

Figure -7: 28daysCompressivestrength(MPa)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

FromtheaboveFigure7,thecompressivestrengthof limeconcreteat28daysstrengthcanbestudied.According to the graph above, when lime is added up to 10% by weight of cement, lime concrete has an optimum compressive strength of 30.37 MPa. When lime content exceeds10%,compressivestrengthgraduallyfalls.

1. The compressive strength of lime concrete cubes increaseduntillimewasaddedto10%byweightof cement. When the amount of lime used exceeds 10%,thecompressivestrengthofthelimeconcrete cubedecreasessignificantly.

2. As the lime concentration increased, the compressive strength increased more rapidly at earlierstages.

[1] Verma,H.,Maurya,N.K.,Faldu,S.andThakur,R.,2019. “TheInfluenceofLimeasPartialReplacementofCement on Strength Characteristics of Mortar and Concrete Mixes” .

[2] Omar, O.M., Abd Elhameed, G.D., Sherif, M.A. and Mohamadien,H.A.,2012.“Influenceoflimestonewaste as partial replacement material for sand and marble powder in concrete properties” HBRC Journal,8(3), pp.193-203.

[3] Patro, S.K., 2015. “Effect of lime and ferrochrome ash (FA) as partial replacement of cement on strength, ultrasonic pulse velocity and permeability of concrete” Construction and building materials,94, pp.448-457.

[4] Adesina, P.A. and Olutoge, F.A., 2019. “Structural propertiesofsustainableconcretedevelopedusingrice husk ash and hydrated lime.”Journal of Building Engineering,25,p.100804.

[5] Borinaga-Treviño,R.,Cuadrado,J.,Canales,J.andRojí,E., 2021. “Lime mud waste from the paper industry as a partial replacement of cement in mortars used on radiant floor heating systems.”Journal of building engineering,41,p.102408.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal