International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

2

1M.Tech. Scholar, Dept. of Mining Engineering, College of Technology and Engineering, Maharana Pratap University of Agriculture and Technology, Udaipur, Rajasthan, India

2 Professor and Head, Dept. of Mining Engineering, College of Technology and Engineering, Maharana Pratap University of Agriculture and Technology, Udaipur, Rajasthan, India ***

Abstract – Technical evidence has been presented in order to increase the ultimate pit angle of an open pit marble mines from 45 degrees to further 75 degrees in order to enhance the extraction limit of the mines. Which will boost the production of the mine. Flac slope software has been used in order to calculate the factor of safety of the ultimate pit slope so that the ultimate pit angle can be increased from 45 degrees to further 75 degrees in an open pit marble mines.

Key Words: Marble Mining, Flac Slope, Extraction Limit etc.

Theaimofthestudyistoprovidetechnicalevidenceagainst presentlegislationregardingopen-pitmineworking.Weaim toincreasetheultimatepitangleinsmallandmediumopenpit mines in order to boost production and overcome a patriarchal problem. Analysis of the core samples by calculating the geo-mechanical properties, will help to calculatefactorofsafetyoftheslopetherebywecantrimthe bench even further increasing the overall pit width. The studywillhelptopushthemineralproductioninsmalland medium size open-pit mines as the lease boundary is extreme limit of working. More mineral can be recovered which was earlier considered as irrecoverable due to restrictionsinworking.

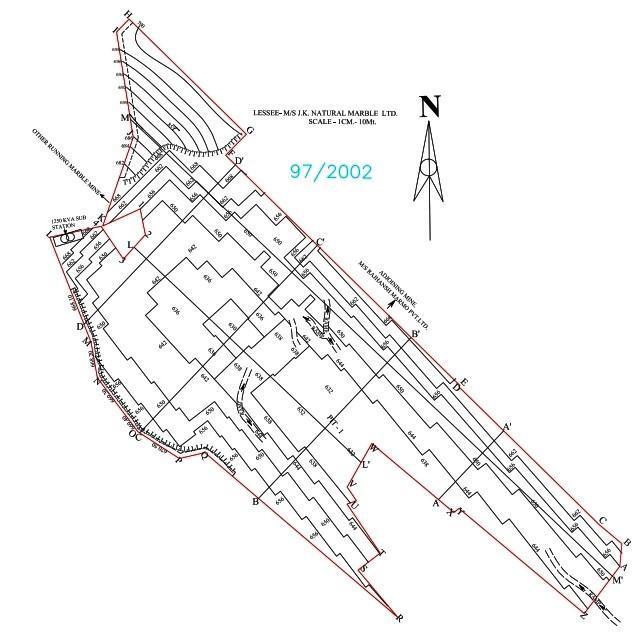

ThestudyareaselectedforthefieldexperimentsisArora’s J.K. Natural Marble Ltd, Morwad, Rajsamand, Rajasthan, India.The area is approachable by a tar road near NH-8 Udaipur-Ajmer route at about 78 km from Udaipur the nearestrailwaystationisKankroliatabout18kmfromthe mining area. The nearest airport is Dabok, Udaipur, Rajasthanwhichisatabout113kmfromtheminingarea. The area has rocky & hilly terrain. The general strike directionoftherocksformationisNW-SEwithdippingdue western dips. Highest elevation is of 700mRL and lowest elevationbeing682mRLinthearea.Theregionaldrainage pattern of the area is almost in SW direction. Area is characterized by low rounded excessively stony smooth rolling and deeply dissected country of banded gneissic

complex with highly resistant strike ridges of marble and quartzite.

Weathered marble intermixed with amphibolites and hornblendeschistisexposedonentirethesurfaceareaand withinthepitjointedandfracturedmarbleisexposedand some placesgood quality marble isexposed.Itis white in colourandgrainsizeiscoarsegrain.Someplacesmarbleis found intermixed with amphibolites rock. Calcite is dominant minerals having well developed twinning with sub-ordinateamountofmuscovite,dolomite,quartzarealso presentasimpurities.

The mining in the lease area has been done by semimechanizedmeanbyopenpitmethod.Presentlyextraction ofmarbleisdonewithdrillmachine;wiresawmachine(for cuttingofblock)&crane(usedforliftingofblocks).Dressing

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

machinedoesthedressing ofblock. Excavators&dumper areusedtoremovethefracturematerials.

Physcio-mechanicalpropertiesofthemarblewereevaluated which include compressive strength, angle of internal friction,drydensity,cohesion.

Table -1: PhyscioMechanicalPropertyofMarble

Physcio Mechanical Property of Marble Value Unit

CompressiveStrengthMeasurement 117.28 MPa Drydensity 2872 kg/m3 Angleofinternalfriction 75.81˚ Degree Cohesion 9.86 MPa

TheRQDvariationofrockatthemineshavevariedinthe range74–92%,55–88%&28–96%.Itisobservedthat RQD is relatively low in the range of 20-45 in the upper regionuptoadepthof30mandisfoundtogoodbeyondit. Accordingly,onanaveragetherockqualityisdescribedas mostlygoodtoexcellentbeyondadepthof25m.

Table -2: Dipdirection

Fig -2:StructuralMappingoftheMine

Structuralmappingoftheminehasbeendoneandslopesare demarcatedinordertoknowthedipdirectionasinfigure2 The dip directions of the four slopes were evaluated with strike,tablenumber2

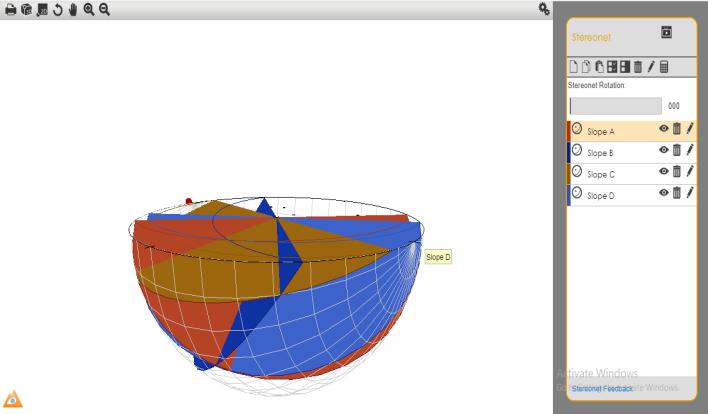

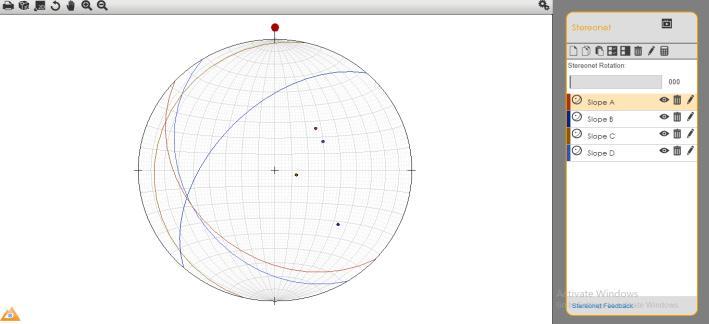

Fig -3:StereographicProjectionoftheJointplaneinmine

Fig -4:3DProjectionoftheJointPlaneinMine

Slope stability analysis was performed using FLAC slope which is a mini-version of FLAC which is designed specificallytoevaluatefactorofsafetycalculationsforslope stability analysis. It is operated entirely from FLAC’s graphicalinterfacewhichprovidesrapidcreationofmodels forrockslopesandsolutionoftheirstabilitycondition.The factorofsafetyisbasicallydefinedastheratioofresisting shearstrengthtothedrivingshearstress.Theshearstrength parameter viz. cohesion and angle of internal friction

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

obtained from the laboratory testing of rock core. By evaluatingthefactorofsafetyofslopewecansuggestthat theultimatepitanglemaybeincreasedthusmoremineral canberecoveredwithoutcausinganyseriousharmtothe mineenvironment.

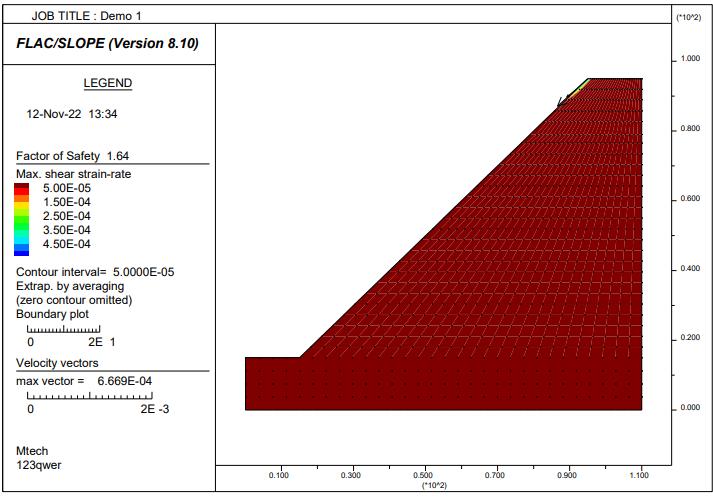

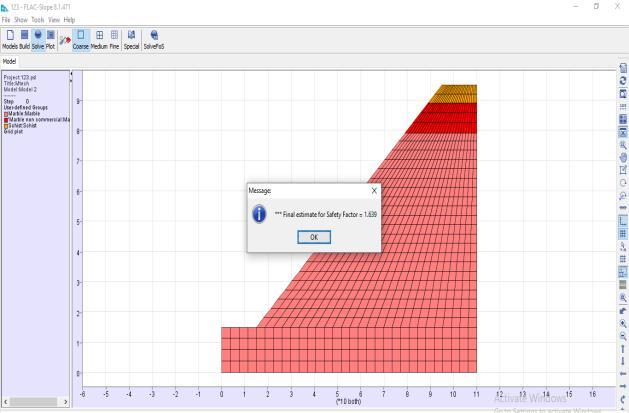

(i) UsingFlacslopesoftwareaslopewithanangleof 45˚ and height of 80 m was designed with the properties of marble having cohesion, angle of internal friction, dry density etc. The joints in the slope face are present at the two corners of the slopealsothereisnointrusionofwaterintherock mass.Thestresseswereexaminedforcoarsegrain blockusingthesoftwareanditwasfoundthatthe slopewiththeminerallikemarbleatanangleof45˚ andwithaheightof80miscompletelystable.The factorofsafetywas1.64

Fig -5:FOSResultat45˚

Fig -7:FOSResultat75˚

Fig -6:ProjectionImageat45˚

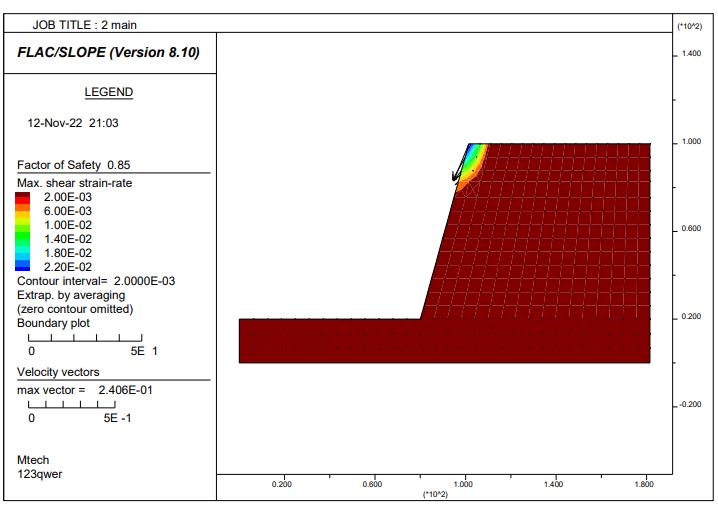

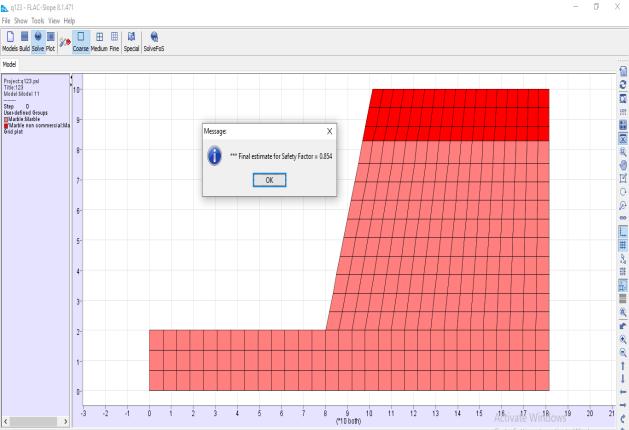

(ii) Inordertofulfilltheaimtoenhancetheextraction limit we need to increase the ultimate pit angle, here a slopehas been designed at an angle of 75˚ andtheslopeconsistofmineralscommercialgrade marble.Thefactorofsafetyoftheslopeis0.85

Fig -8:ProjectionImageat75˚

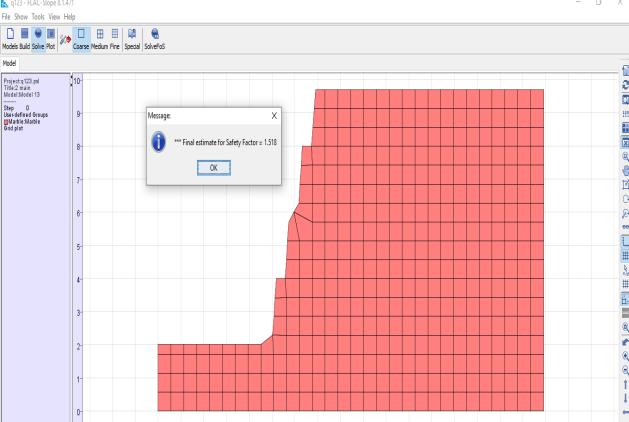

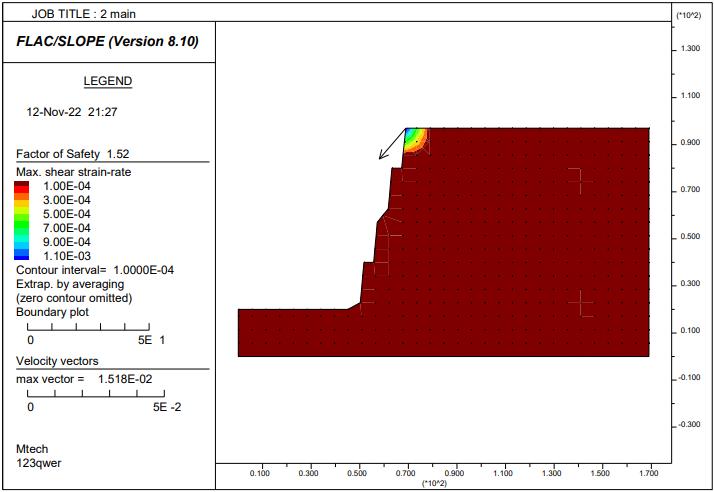

(iii)Finally a slope was designed with an angle of 75˚ andanoverallheightof80mwith benchheightof 20metersandbenchwidthof4meterscomprising marble as the mineral and eventually factor of safetyoftheslopewascalculatedwhichwasfound tobe1.518.

Fig -9:FOSResultat75˚with80mheight

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

stabilityoftheslopedependsupontheheightandwidthof thebenchincasesiftheintrusionortensioncrackdevelops simultaneous adjustment in the bench height and bench width can be done in order to maintain the safety of the slope. In the final diagram, figure 10 bench height of 20 meters has been considered with the bench width of 4 metersandanoverallslopeheightof80metersthebench heightcanalsobeincreasedupto30metersperbenchand widthcanbeincreasedto4.5metersperbench.

Fig -10:ProjectionImageat75˚with80mheight

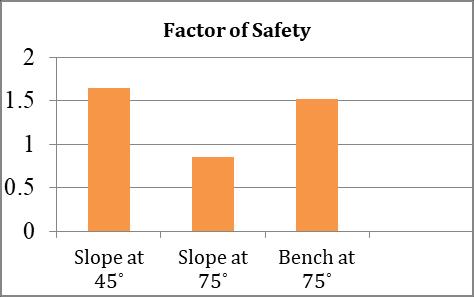

In the present study slope at the North East side of the Arora’s J.K. natural marble limited mines was selected in ordertoincreaseitsanglefrom45˚to75˚.Thepresentstudy conducted at Arora’s J.K. natural marble limited aims to enhancetheextractionlimitofanopenpitmarblemines.In ordertoincreasetheextractionlimitweneedtoenhancethe slope angle up to 75˚ in order to extract more valuable mineral from the earth crust. Laboratory and field experimentationsresultsshowthatthereisnohazardsoas toincreasetheultimatepitanglefrom45˚to75˚.Thestudy alsopresentstechnicalevidenceagainstpresentlegislature as in MMR 1961, Government of India, rule 106 Opencast miningwhichstatesthatthesidesshallbeslopedatanangle ofsafety not exceeding45degreesfromthehorizontal, in ordertoincreasetheultimatepitanglefrom45˚tofurther 75˚,slopesweredesignedbothat45˚and75˚andfactorof safetyoftheslopewereevaluated

Theultimatepitslopedesignfortheminesassuggestedmay beachievedduringfinalminingoperationbytheprogressive reduction of bench width as indicated. The width of interveningbenchbetweenoverburdenandmarbleshould bemaintainedataminimumof4.5m.Theindividualbench slope angle in overburden benches is to be maintained at around 85°. During the normal mining operation, it is however suggested that the bench height & width be maintained as per the statutory and the operational requirements. The existing bench height of 12 m may be maintained in the overburden rock mass. The final bench heightinmarblerocksmaybemaintainedintherangeof20 – 30 m. However, the final bench height in marble will be limitedto20monlywithacorrespondingminimumbench width of 3.5 m in that slope section, where waste rock intrusionisfoundinthemarblerock.

We canseethatthereisno drasticchangeinthefactor of safety of the slope design at two different angles, also the

Fig -11:ComparisonofFactorofsafety

Thisstudydemonstratethat usingFlac slopesoftware we caneasilycalculatefactorofsafetyoftheslopewhichisvery importantinordertoenhancetheextractionlimitofanopen pitmarbleminebyincreasingtheultimatepitangleofthe mine.

Basedonthefieldstudyandtheresearchworkcarriedout followingconclusionsandrecommendationsweredrawn:

(i) Laboratoryandfieldexperimentationsresultsshow thatthefactorofsafetyoftheslopedesignedatan angleof45˚foraminerallikemarblewasfoundto be1.64alsothefactorofsafetyoftheslopedesign atanangleof75˚withaslopeheightof80meters wasfoundtobe1.52.Theaboveresultsshowthat wecanincreasetheextractionlimitinanopenpit marbleminewithoutanydrasticchangeinfactor ofsafetyoftheslope.

(ii) Recovery of the mineral can be increased by increasingthebenchheightfrom12mto20mand increasingthebenchwidthfrom3mto4mfora slope height of 80 m, without compromising the safety of the bench. Thus production will be enhanceddrasticallykeepinginmindthemarket demandandavailabilityofminerals.

(iii)Thestudyalsopresentstechnicalevidenceagainst presentlegislatureasinMMR1961,Governmentof India,rule106Opencastminingwhichstatesthat

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

thesidesshallbeslopedatanangleofsafetynot exceeding45degreefromthehorizontal,inorder to increase the ultimate pit angle from 45˚ to further75˚,slopesweredesignedbothat45˚and 75˚andfactorofsafetyoftheslopewerefoundto be sufficient in both cases, thus it can be easily inferredthatthepitslopeincasemarblemaybe increasedto75˚.

IwouldliketothankmyHeadoftheDepartmentandmy guide Dr. Anupam Bhatnagar, for his valuable advice and technicalassistance.

[1] Akbari, A.D., Osanloo M. & Shiraz M.A., 2008. Determinationofultimatepitlimitsinopenmines using real option approach. IUST International JournalofEngineering Science,Vol.19,No.5-1.

[2] Alejanoa,L.R.,Filgueiraa,U.C.,Reya,I.P.,&Arzuab,J., 2017. Stabilityanalysisofanover-tiltedslopeina granite quarry: the role of joint spacing. Procedia EngineeringVol.191pp.:402–409

[3] Bieniawski,Z.T.1973.Engineeringclassificationof jointedrockmasses.Trans.S.AfricanInst.Civ.Eng. 15,pages:335-344

[4] ChingLiu,Y.,&ShiChen,C.2007.Anewapproachfor applicationofrockmassclassificationonrockslope stabilityassessment.EngineeringGeology,Volume 89,Issues1–2,Pages129-143

[5] Chowdhary ,R.N.,V.U.NguyenandJ. A.Nemick,1986.Slope stability considering progressivefailure.MiningScienceandTechnology, 3(1986)127-139.

[6] Francioni, M., Salvini, R., Stead, D., Giovannini, R., Riccucci, S., Vanneschi, C., & Gullì, D. 2015. An integrated remote sensing-GIS approach for the analysis of an open pit in the Carrara marble district, Italy: Slope stability assessment through kinematicandnumericalmethods.Computersand Geotechnics,Volume67,pages:46-63

[7] MetalliferousMinesRegulations,1961,Government ofIndia,Rule106Opencastmining,subrule(a)(i).

[8] Naghadehi, M.Z., Jimenez, R., Kakaie, R.K., & Jalali, S.M.E.2013.Anewopen-pitmineslopeinstability indexdefinedusingtheimprovedrockengineering systems approach. International Journal of Rock MechanicsandMiningSciences,Volume61,Pages 1-14

Swapnil Sanadhya, completed the B.Tech. degree from RTU Kota in 2020. He is currently a final year M.Tech. student of College of Technology and Engineering, Maharana Pratap University of Agriculture and Technology, Udaipur,Rajasthan,India

Dr.AnupamBhatnagar,Professor & HEAD, Dept. of Mining Engineering, College of Technology and Engineering, Maharana Pratap University of Agriculture and Technology, Udaipur, Rajasthan, India, Ph.D. (Marble Waste Minimization), M.Tech.(Mining)IITKharagpur,B. E.(Mining).

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified