International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Abstract Concrete is a composite material composed of6570% of its volume with natural resources such as sand and crushed stones. Concrete industry is one of the major consumers of these natural resources. For sustainable development, these natural resources used in concrete should be replaced by alternative materials such as waste tyre rubber, ceramic tiles waste etc. Worldwide production of waste tyre is growing up due to rapid increase in the use of tyres in automobile industry. The disposal of waste tyres has become major problem even inIndia and most of the waste tyre rubber is used as a fuel in brick kilns and cement kilns. Unfortunately, this kind of usage is not environment friendly and hence the use of waste rubber in concrete has been thought as an alternative disposal method which is environment friendly. Similarly in recent constructions, the consumption of ceramic materials such as tiles is increasing day by day and a large quantity of the same is converting into wastage duringprocessing,transportingandfixingdueto its brittle nature. The use of this ceramic tile waste as aggregates inconcretecanreducethenegativeenvironmental effects and exhaustion of the natural resources. Hence, in this work both conventional coarse and fine aggregates are replaced by ceramic tile waste & waste tyre rubber in the proportions that yield optimum strength. Further, Concrete is knownto be brittle material whichhasmuchlowerstrengthin tension than in compression and the behavior of concrete can greatly be ameliorated by confining it with ties in order to achieve a ductile concrete. In this experimental study, the effects of confinement on the stress-strain behaviour of 100mm × 100mm × 200mm prisms of standard & high strength concrete(M40&M70grades)areinvestigated under the axial compression. Waste tyre rubber has been used as a replacement to both coarse aggregate and fine aggregate in proportion of 4% by weight in both grades of concrete mixes. In the same way, waste ceramic tile is used asa replacement to both coarse aggregate and fine aggregate with 4 percentage of replacement by weight in standard & high strength concrete mixes.Thelateraltiesof6mmdiametermild steel and 8mm diameter HYSD steel bars were used for confinement in both grades of concrete. The test specimens were provided with ties at different spacings. The test prisms

of specimens were cast with 0, 2, 3, 4, and 5 number of ties. Tests were conducted to determine fresh & hardened state properties such as slump, compressive strength, stress-strain behavior &confinement studies of prisms. A total of162 prism specimens of size 100 mm × 100 mm × 200 mm (81 no’s for M40 concrete & 81 no’s for M70 concrete) and 18 companion cube specimens of 100 × 100 ×100 mm size were caste and tested. Tests were conducted after 28 days of conventional water curing. Compressive strength was determined using companioncubes while stress-strainbehaviorwasdetermined using test prisms and from obtained results ductility factor, strain ratio and stress ratios were calculated.

Key Words: Confinementindex,Wastetyre,Ceramicwaste tile, Confinement, Compressive strength, Stress-strain behaviuor,Ductilityfactor,Stressratio,Strainratio

Concrete exhibits a brittle failure under compression, whichleadsto a rapidlossof loadcarryingcapacity. The confinementreinforcementisusedtorestraintheconcrete fromexpansionandthusprolongatesthefailure.Inrecent years, high strength concrete has been widely used in buildings, bridges and other structures. The use of high strength concrete in columns can significantly reduce the sizeofthecolumnandconsequentlyreducethedeadloadon thefoundation.Itisanacceptedfactthatthestrengthand ductilityofreinforcedconcretecolumncanbeimprovedby confiningitinsteelbinders,astiesincompressionmembers andasstirrupsinbeams.Thisimprovementensuresseismic stabilityofthestructureduringastrongearthquake.Hence, column confinement is an important component of earthquakeresistantreinforcedconcretebuildings.

Itisquiteuneconomicaltodesignastructuretorespond intheelasticrangetothegreatestlikelyearthquakeinduced inertiaforcessincethemaximumresponseaccelerationmay be several times the maximum ground acceleration, dependingonthestiffnessofthestructureandmagnitudeof damping.Thissuggeststhenecessityofdesigningstructures

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

in way that the energy can be dissipated by post elastic deformationsofmembers,whichrequirescertainelements tobedesignedforductilityandstrength.Aswellfurther,itis wellknownthattheductilebehaviourofconcretesections can be attained by carefully detailed transverse reinforcement,whichimprovesthepropertiesofconcreteby confiningit.

Theconfinementindexisdefinedas

Ci=(Pb - b)(fv/fc’)√(b/s)

where,Pbistheratioofthevolumeoftiestothevolume of concrete b is the ratio of the volume of ties to the volume of concrete corresponding to a limiting pitch (1.2 timesthe least lateral dimension). b is the breadth of the prismandsisthespacingofties.Thestressinthesteelbars is given by fv = Ɛv*Es and is always limited to maximum yieldstrength.ƐvisthestraininsteelandEsisthemodulus ofelasticityofthesteel.Inthe presentwork6mm &8mm steelwereusedfortieconfinement.

Tostudythestress-strainbehavioroftheconfined concreteunderaxialcompression.

Tostudytheinfluenceofconfinementonductility factoroftheconfinedconcrete.

Tostudytheconfinementeffectonthestrengthof theconcrete.

Tostudytheconfinementeffectonstrainratios.

To study the mechanical characteristics such as compressive strength of standard grade concrete (M40)andhighstrengthconcrete(M70)inwhich both coarse & fine aggregates are replaced with wastetyreandceramicwastetileinproportionsof 4%toyieldoptimumperformance.

Influenceofconfinementonstress-strainbehavior of ordinary concrete and high strength concrete with waste tyre and ceramic tiles waste as a replacement to both coarse & fine aggregate has not been taken up by the earlier investigators. Hence, a detailed experimental work has been plannedtostudytheinfluenceofconfinementon stress-strainbehaviourandfilltheinformationgap intheliterature.

Thescopeofthepresentinvestigationistostudy the stress-strain behavior of confined standard gradeconcrete(M40)andhighstrengthconcrete (M70)inwhicheachofcoarse&fineaggregatesare replacedwithwasterubbertyrewasteandceramic tileswasteinaproportionof4%toyieldoptimum performance.

In the present study variable parameters include gradesofconcrete,diaoflateraltiesreinforcement, numberoftiesandthereplacementmaterialsand 6mmmildsteelbarsand8mmTMTbarsareused forconfinement.

Basedontheliteraturereview,themildsteel and TMT bars have been used for confinement of rubberizedconcreteandceramicwasteconcrete. Acomprehensivereviewofpastworkintheareaof confinement, stress-strain characteristics and replacingcement,fineaggregate,coarseaggregate by alternate methods has been reviewed and an appraisalofreviewispresented.

The different materials used in producing concrete mixesrequiredinthisworkare

53gradeordinaryPortlandcement G.Iwire Steelreinforcementbars Coarseaggregate Fineaggregate Water Wasterubbertyre Ceramictilewaste Superplasticizer(SP430) Silicafume

The final mix proportions were arrived at on the trialanderrormethodbytryingvariousproportionsof silicafume&superplasticizerinthedesignedM40& M70concretestoachieveimprovementincompressive strength. All through this experimental program, the ACImethodwasadoptedforthedesignofcontrolmix. Thedesignedproportionsofcontrol mix(byweight) were 1 : 1.43 : 1.79 : 0.38 (cement : sand : crushed granite:W/C)and1:0.76:1.53:0.28(cement:sand: crushedgranite:w/c)forM40&M70gradeconcrete respectively.Tables(3.1&3.2)showthequantitiesof ingredients for control mix (S-0, H-0) and concrete mixescontainingceramictilewaste(ST-4,HT-4)and wasterubbertyre(SR-4,HR-4)anoptimummix(per m3)ofM40&M70concretemixes.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Table -1 Ingredientcontentofconcretemixes(kg/m3)M40gradeconcrete

Mi x co de

cem ent

Sili ca fum e

Fine aggreg ate

Fine rubb er tyre wast e

Coarse aggreg ate

Coar se rubb er tyre wast e

Wat er

S-0 526. 3 0 739.53 0 930.56 0 200 SR4 505. 2 21. 05 709.95 29.5 8 893.33 37.2 2 200

Table -2 Ingredientcontentofconcretemixes(kg/m3)M70gradeconcrete

Mi x co de

Ce me n t

Sil ica fu m e

Fine aggr egate

Fin e Rub ber Tyr e was te

Coar se aggr egate

Coa rse rub ber tyr e was te

Wa ter

Table -3 SlumpvaluesoffreshM40andM70gradeconcrete S.n o M40

Super plasti cizer (ml)

H0 668 .12 27. 84 532.7 7 0 1046. 88 0 18 1 7655. 56 H R4 668 .12 27. 84 511.4 6 21.3 1 1005. 2 41. 9 18 1 7655. 56

Astandardpanmixerof50litcapacitywasusedformixing the concrete. Initially, all the dry materials (Coarse aggregate, fine aggregate, cement, silica fume and waste glass)weremixedforabouttwominutes.Superplasticizer wasthoroughlymixedwithwaterandtheliquidcomponent was added to the mixture of dry materials and mixed for aboutthreeminutes.Carewasexercisedforallthematerials togetuniformlymixedup withoutgettingstuck uptothe wallsofthemixer.

Thepreparedcageofreinforcementwascarefullykeptinthe moulds of size (100 mm× 100mm × 200mm). Firstly, the uniformly mixed fresh concrete was poured in cast iron moulds of prisms (100mm × 100mm × 200 mm) up to one third height and then aneedlevibratorwasusedto compactthecoreconcrete.

Themouldwasfilledinthree layersandcompactedusing thesametechniquetocastthespecimens.thetopfaceofthe prismspecimenwasdecoupled24hoursaftercastingand curedfor28daysinthewaterfordeterminingcompressive strength and stress-strain characteristics of confined concretescontainingwasterubbertyreasbothcoarse&fine aggregate and waste ceramic tile as both coarse & fine aggregatealso.

Designati on of mix Slum p M70

Designati on of mix Slum p 1 S 0 H 0 2 SR 12 HR 5 3 ST 8 HT 4

Table -4 PhysicalpropertiesofOPC-53

S.No. Property Test Method Test Result

1 Normal consistency

Vicatapparatus(IS4031PartIV) 34%

2 Specific gravity Specificgravitybottle(IS 4031-PartII) 3.15 3 Initial settingtime Vicatapparatus(IS4031PartV) 45min 4 Finalsetting time Vicatapparatus(IS4031PartV) 175min 5 Fineness Sievetestonsieveno.9(IS 4031-PartIV) 6%

Table -5 PhysicalPropertiesofconventionalCA,FA&Waste TyreRubber,CeramicWasteTile

Conventi onal coarse aggregat e

S. No Proper ty

Fine aggreg ate

Wast e tyre rubb er (FA)

Wast e tyre rubb er (CA)

Wast e cera mic 1 Specific Gravity 2.79 2.67 1.79 1.13 2.34 2 Bulk density 1.47g/cc 1.298g /cc 0.42g /cc 0.47g /cc 1.33 3

Finenes s Modulu s

7.195 2.65 4.3 7.63 6.98 4

Water Absorp tion 0.48% 1% 2% 0.99 % 0.36 %

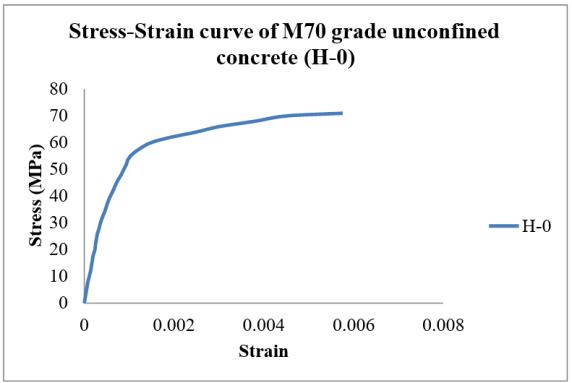

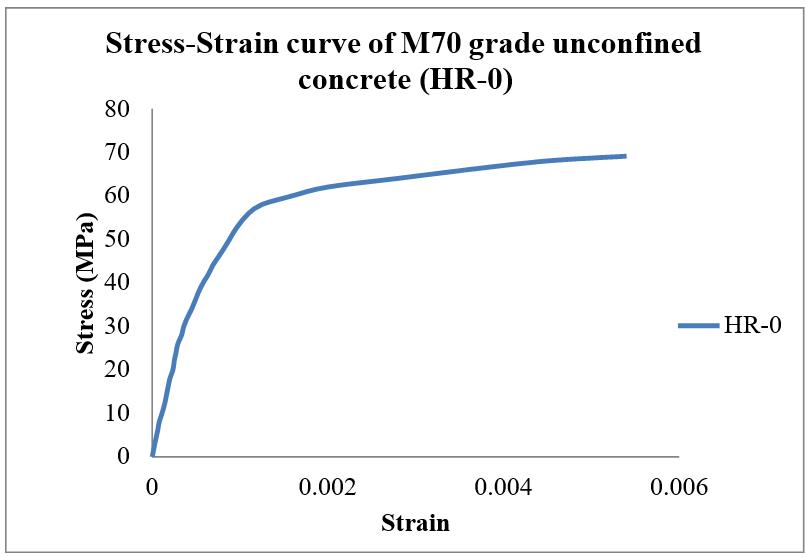

Fromtheexperimentalobservationsforagivenspecimen, the longitudinal deformation was calculated from the average reading of the two dial gauges of the compressometer.Asthereisnoseverespallinginconcrete specimensuntiltheloaddroppedbyabout20-25%ofpeak load,thespecimensweretreateddimensionallystableand hencethegrosscross-sectionalareaisusedincalculatingthe stressvalues.Thestress-straincurvesweredrawnforthree companionspecimensofasetwiththesameoriginandthe averagecurvewasconsideredtorepresenttheset.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

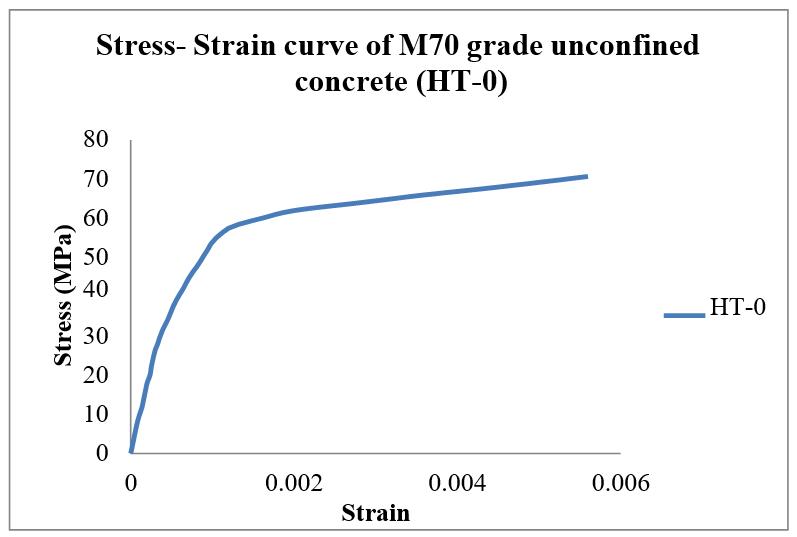

Thestress-straincurveisnotlinearforbothM40&M70 grade concretes and it was linear at small strains. The ductilityconcretewasfoundtoincreasewiththeincreasein levelofconfinement.TheShahandRangan(1970)reported that for the vertical spacingbetween the stirrups greater than or equal to one half of the specimen dimension, the confinementprovidedbythelateralsbecomesnegligible.An examinationofstress-straindiagramsforthespecimensof sameno.ofties&gradeofconcretedisplayedsimilarstressstrain behavior for all specimens irrespective of the replacement material used. The load carrying capacity of confinedconcretewasfoundtoincreasewiththeincreasein thelevelofconfinement.Whilecomparedtonormalconcrete and ceramic waste tiles concrete, rubberized concrete displayed slightly lower performance under confinement. Theloadcarryingcapacityofconcretespecimenswithtwo ties is found to be almost same as that of unconfined concrete. The specimens with 5 ties of 8mm diameter reinforcement were undergoing good ductility when comparedtoothers.Thespecimenfailedduetosustained verticalcracksandthedeformationswerehighatthetimeof failure.

Table -6 Compressivestrengthofconcrete-M40andM70 grade

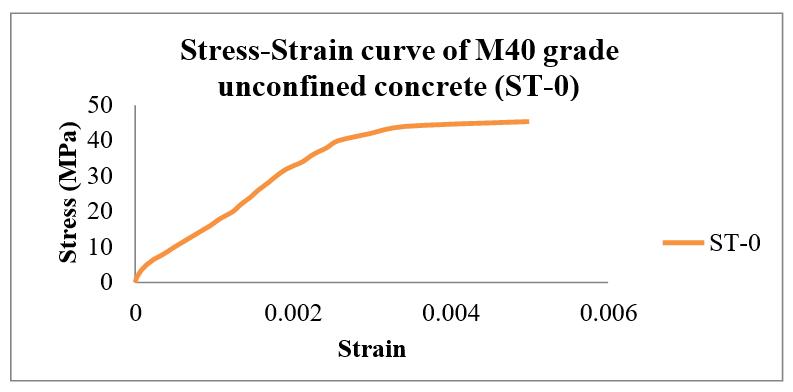

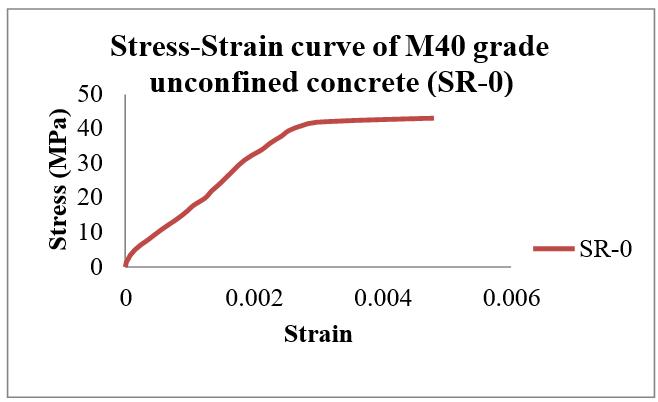

Chart-2: Stress-strainbehaviorofunconfinedrubberized M40gradeconcrete

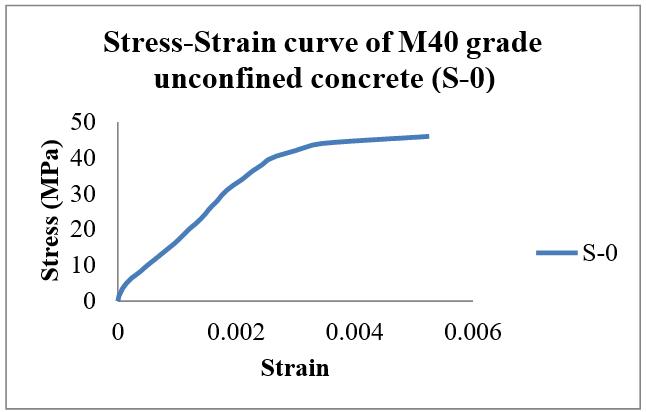

Chart-3: Stress-strainbehaviorofunconfinedM40grade concretewithceramicwaste

S. No M4 0 gra de

Designa tion of the mix

Compre ssive strength (N/mm 2) 28 days M7 0 gra de

Designa tion of the mix

Compre ssive strength (N/mm 2) 28 days 1 S 5.31 H 72.32 2 SR 49.9 HR 70.09 3 ST 52.2 HT 71.11

Chart-4: Stress-strainbehaviorofunconfinedM70grade concrete

Chart-5: Stress-strainbehaviorofunconfinedM70 gradeconcretewithceramicwastetiles

Chart -1: Stress-Straincurvesforstandardgradeconcrete (M40)

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Investigations can be carried out for developing the stress block parameters and moment curvature relationship.

Investigationscanbecarriedoutcombiningrecycled aggregate and waste ceramic tiles and waste tyre rubber.

[1] RathishKumar . rasadM.L.V(2011) “Structural Behavior of a Tie Confined Self Consolidating Performance Concrete (SCPC) under Axial Compression” RILEM International Conference Hong Kong University of Science & Technology, HongKong.

Chart-6: Stress-strainbehaviorofunconfinedM70 gradeconcretewithwasterubbertyre

Confinementofconcreteusinglateraltiesincreases thepeakload,peakstressandpeakstrainat85%of peakstress.

The peak stress, peak strain, ultimate strain and ductility were almost same for the conventional concrete,wasterubbertyre concreteandceramic waste concretes for prisms of given grade of concrete,tiespacing&diametertiereinforcement. The ascending portion of the stress-strain curves changedveryslightly,whilethedescendingportion hasbeenlesssteep,resultinginhigherductility.

The ductility factor of concrete will increase with theincreaseinno.ofties.Thesmallerthespacingof thetie,thegreaterwillbetheconfinementindexat thesamecross-sectionaldimension.

The ductility of concrete depends on quality of concreteandgreaterthequalityofconcreteused, smallerwillbetheconfinementindexforthesame tiespacing.

The load carrying capacity of concrete increased with the increase in level of confinement, i.e. confinementindex(Ci).

The stress ratio, strain ratio and ductility factor increased with an increase in the confinement index.

Companioncubestestedat28-daysofconventional curingyieldedBothM40andM70gradeconcretes with and without replacements showed good compressivestrength.

Investigationscanbecarriedoutwithdifferentsizesof specimenswithdifferentconfinementindex.

[2] rasad M. L. V (2012) “Behavior of Tie Confined Fiber Reinforced Self Compacting Recycled Aggregate Concrete” h.D. Thesis, Structural Engineering,DepartmentofCivilEngineering,N.I.T Warangal.

[3] Ramesh, K., Seshu D.R., Prabhakar M., (2003), “Constitutivebehaviorofconfinedfiberreinforced concrete under axial compression” Cem.Concr.Comp.,25.343-350.

[4] Carreira D.J., and Chu K. H., (1985) "Stress-strain relationshipforplainconcreteincompression".ACI Journal,82,6,797–804.

[5] Prasad,M.L.V.,(2011),"BehaviourofTieConfined Fiber Reinforced Self Compacting Recycled AggregateConcrete".PhDthesis,NationalInstitute ofTechnology,Warangal,India.

[6] Reddy, S.R., (1974) " Behaviour of Concrete ConfinedinRectangularBinderanditsApplication inFlexureofReinforcedConcreteStructures".PhD thesis,JawaharlalNehruTechnologicalUniversity, Hyderabad,India.

[7] Ahmed, S.H., and Shah, S.P.,(1982) "Stress–strain curves of concrete confined by spiral reinforcement".ACIJProc;79(6):484–90.

[8] Razvi,S.,and Saatcioglu,M., (1999)"Confinement model for high-strength concrete. Journal of StructuralEngineering".ASCE125(3):281–289..

[9] Seshu,D.R.,(1995)'Behaviourofconcreteconfined with ferrocement shell in addition to rectangular stirrups and its application in flexure of RC structures', Ph.D Thesis submitted to Kakatiya University,Warangal(India).

[10] Ramesh, K., Seshu DR, Prabhakar M. Confined fiber reinforced concrete (CFRC). In: Proceedingsofthe25thAnniversaryInternational Conference on our World in Concrete and StructuresSingapore.P.531–6.

[11] Mansur, M.A., Chin M.S., Wee T.H.,(1997) "Stress–strainrelationshipofconfinedhighstrength plain and fiber concrete". J Mater Civil Eng.; 51(05):353–63.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

[12] Sheikh, S.A., 'Comparative study of confinement models', Journal of AC179 (4) 296306.

[13] Waliudm,A.M.,andRafeeqi,S.F.A.,'Studyof behavior of plain concrete confined with Ferro cement',jlofFerrocement24(2)139-145.

[14] Alsayed S. H. (1992) ‘Confinement of reinforced concrete columns by square ties and steel fibers’ Magazine of Concrete research 44 (161)265-270.

[15] Blume J.A. (1961) ‘Design of multistory reinforced concrete buildings for earthquake motions’ ortlandcementassociation USA.

[16] Rao, A. K., Reddy, K. N and Reddy, V. M., (1979) ‘Effect of stirrup confinement on flexural beams of pre-stressed concrete simple beams’ JournalofIE(India)59.,258-266.

[17] Rajamallu, C., and Balaji Rao, A., (2014), BehaviorOfSelfCompactingConcreteUnderAxial CompressionWithAndWithoutConfinement(ISSN: 2348-4748,Volume1,ISSUE3)

[18] Ganesan, N., and Ramanamurthy, J.V., (1990) ‘Strength and behaviour of confined steel fiber reinforced concrete columns’ ACI Materials Journal87(03)221-227.

[19] IS: 12269-1987(Reaffirmed 1999), Specification For 53 Grade Ordinary Portland Cement.

[20] IS: 2386-1963, Method of Tests For AggregatesForCement.

[21] IS 456-2000, Indian Standard Plain And ReinforcedConcrete-CodeOfPractice,4thRevision, 1stReprint,September2000.

[22] Fafitis A. and Shah S. . (1985) “Lateral Reinforcement for High- Strength Concrete Columns” High-Strength Concrete, SP-87, ACI, Detroit,Mich.,213-232.

[23] Hoshikuma,J.,Kawashima,K.,andNagaya, K. (1995) “A Stress-Strain Model for Reinforced Concrete Columns Confined by Lateral Reinforcement” Journal of Materials Concrete StructuresandPavements,JSCE,No.520/V-28.

[24] Cusson D. and aultre . (1994) “HighStrength Concrete Columns Confined by Square Ties” Journal of Structural Engineering ASCE Vol.120,No.3.

[25] Cusson D. and aultre . (1995)“StressStrainModelforConfinedHigh-StrengthConcrete” Journal of Structural Engineering, ASCE, Vol.121, No.3,468-477.

[26] Saenz, L.P., (1964) Discussion of paper “Equation for stress–strain curve of concrete” by DesaiPandKrishnanS.JournalofACI,Proceedings 61(9):1229–1235.

[27] Razvi, S., and Saatcioglu, M., (1999) “Circular High-Strength Concrete Columns under

Concentric Compression” ACI Structural Journal Vol.96,No.5,817-825.

[28] Saatcioglu M. andRazvi S. (1998)“HighStrength Concrete Columns with Square Sections under Concentric Compression” Journal of StructuralEngineering,ASCE,Vol.124,No.12,14381447.

[29] Nagashima,T.,Sugano,S.,Kimura,H.,and Ichikawa A. (1992)“MonotonicAxialCompression Test on Ultra-High-Strength Concrete Tied Columns” 10th World Conference on Earthquake Engineering,2983-2988.

[30] Bing Li., Park, R., and Tanaka, H., (2001) “Stress-StrainBehaviorofHigh-StrengthConcrete Confined by Ultra-High-strength and NormalStrength Transverse Reinforcements” ACI StructuralJournal,Vol.98,No.3,395-406.

[31] Shah S. . Rangan B.V. (1970)“Effectsof reinforcementsonductilityofconcrete”. rocASCE ;96(576):1167–84.

[32] M.S.Shetty(2013)“concretetechnology” 6thedition,S.Chand&companylimited,Delhi.

[33] Neville. A.M. (1997) “ roperties of concrete” 4th edition pitman publishing limited London.

[34] ACI: 211.4R-08 Guide for selecting proportions for high-strength concrete using Portlandcement&othercementationsmaterial.

[35] ACI: 211.4R-93 Guide for selecting proportions for high-strength concrete with Portlandcementandflyash.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1022