International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1PG Student, Department of Civil Engineering, University college of Engineering JNTUK (A), Andhra Pradesh, Kakinada, India-533001

2 Professor of Civil Engineering, Department of Civil Engineering, University college of Engineering JNTUK (A), Andhra Pradesh, Kakinada, India-533001

3 PhD Student, Department of Civil Engineering, University college of Engineering JNTUK (A), Andhra Pradesh, Kakinada, India-533001 ***

Abstract - We are aware that the production of cement causes significant environmental harm involves carbon dioxideemissionsalongpollutants.Thereisanurgentneedto restrict cement use since studies have revealed that each tonneofcementmanufacturedemitshalfatonneofcarbon dioxide.Ontheotherhand,itmightbedifficulttodisposeof materialwasteslikethebagasseashfromsugarcane,which ishazardoustotheenvironment.

Thisstudyprimarilyfocusesonsubstitutingcementwith analysis of the effects of hydrochloric acid and sodium sulphate on concrete with SCBA and bagasse ash in predeterminedamounts.Thecubesarecastandagedfor28, 56,and90daysinstandardwater,3%hydrochloricacid,and sodium sulphate solution. By varying the Bagasse ash amounts for 0%, 10%, the concrete mix is created. Additionally,findingsfromtestsonfreshconcrete,suchas the slump cone test, and hardened concrete, such as the compressivestrength,splittensilestrength,andflexuraltest, wereobtainedatagesof28,56,and90days.

Key Words: Sugar Cane Bagasse Ash (SCBA), Fine Aggregate (FA), Coarse Aggregate (CA), Compressive Strength,SplitTensileStrength,FlexuralStrength,Durability

Aregulatedmixtureofcalciumsilicates,aluminates, and ferrate is used to make regular Portland cement. Gypsumandothermineralsareusedtogrindthe mixture intoafinepowder.Thecommonconstructionmaterialthat istrulyaccountableforbetween5%and8%ofworldwide CO2 emissions is ordinary Portland cement. Due to the exponentialgrowthindemandforregularPortlandcement, thisenvironmentalissuewillundoubtedlygetworse.

Themostpopularandessentialmaterialusedinall kinds of construction projects is concrete. Cement, aggregates,water,andadmixturesmakeupconcrete.Over 10billiontonnesofconcreteareusedworldwideeachyear. Concrete has strong mechanical strength and adequate durabilityperformance.Outofconcernfortheenvironment and in support of sustainable development, cement

companies are increasing their output by a number of means, such as by increasing the production of blended cementsorusingrenewablefuels.AccordingtotheDanish Centre for Green Concrete, all of these precautions have helpedtolowerCO2 emissions,whichmaybedecreasingby upto30%.

Aroundtheworld,scientistsareexploringwaysto utilise industrial or agricultural waste as a supply of raw materialsforindustry.Blastfurnaceslag,flyash,andsilica fumesareafewmoretypesofindustrialwastethatcanbe used to substitute cement Sugarcane is one of the most important crops farmed in over 110 countries, with an annual productionofover1500milliontonnes.Withover 300 million tonnes of sugarcane produced in India alone eachyear, around10milliontonnesofsugarcane bagasse ashisleftbehindaswaste.

About 40–45 percent of the sugarcane's fibrous residue, which is utilised in the same sector as fuel for boilers to generate heat, remains after all economically viable sugar has been extracted, leaving 8–10 percent as waste material known as sugarcane bagasse ash (SCBA). Sugarcane bagasse ash contains high levels of unburned materials,silicon,aluminum,andcalciumoxides.Asaresult, theashbecomesanindustrialwastewithdisposalproblems. Several studies have been undertaken in the past on the usage of bagasse ash obtained directly from industries to investigatethepozzolonicactivityandusefulnessasbinders bypartiallysubstitutingcement.

Becauseconcreteisfrequentlyexposedtogroundor waterwithsomeacidityor alkalinity,thedurabilityofthe concreteisimportantinformationforextendingtheservice lifeofconcrete.Thisacidicorbasicatmospherewillshorten the life of the concrete. The current study examines the strengthandlongevityofconcretethatcontainssugarcane bagasseash(SCBA)

1. Thecurrentstudy'sgoalistomix-designM25gradeof concreteandidentifiesitsnecessarycomponents.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

2. To research the effects of using bagasse ash as a pozzolonicalternativeforcementinconcrete.

3. Inordertocomparethefreshpropertiesofbagasseashbasedconcretewithcontrolledconcrete,itisnecessary todeterminetheimpactofbagasseashasanalternative cementitiousmaterialwith10%ofcementbyweight.

4. Todeterminetheimpactofbagasseashasanalternative cementitiousmaterialwith10%percentagesofcement by weight ofcement on hardened properties including compressivestrengthandsplittensilestrength,flexural strength of bagasse ash based on concrete to be comparedwithconventionalconcrete.

5. To determine the performance of bagasse ash blended concrete under various exposure situations, durability testssuchasacidresistancetestsandsulphateresistance testsareconducted.

To ascertain its different qualities, the Ordinary PortlandCementistestedinaccordancewithISstandard (IS:12269-1983).Cementis53gradeingrade.Cement's physicalcharacteristicsarelistedintablebelow.

Table -1: Physicalpropertiesofcement

SNo Tests

Values obtained IS Code

1 Specificgravity 313 IS4031:1988 2 Normal Consistency 30% IS4031(Part-4): 1988 3 InitialSetting Time 92mins IS4031(Part5):1988 4 FinalSetting Time 194mins IS4031(Part5):1988 5 Fineness 75% IS4031:1988

Locally-purchased fine aggregate that complied with IndianStandardSpecificationsIS:383-1970toZoneIIwas employedintheexperimentalprogramme.ZoneIIiswhere thefineaggregateislocated.Table2containsasummaryof thefineaggregate'scharacteristics.

Table -2: PhysicalpropertiesofFineaggregate

SNo Tests Values obtained IS Code

1 Specificgravity 262 IS2386: 1963(Part3)

2 Fineness 283 IS 2386 :1963(Part1) 3 Bulk Density(Loose) 1520kg/m3 IS2386:1963 (Part3) 4 Bulk Density(Dense) 1644kg/m3 IS2386:1963 (Part3) 5 Grading Zone-II IS2386:1963 (Part3)

ThestudyfollowedIS383:1970testingproceduresand employedlocallyavailablecrushedgranularaggregateswith amaximumparticlesizeof20mm.Thephysicalpropertiesof coarseaggregatearementionedinTable3below.

Table -3: PhysicalpropertiesofCoarseaggregate

SNo Tests

Values obtained IS Code

1 Specificgravity 276 IS 2386 : 1963(Part3) 2 Fineness 712 IS 2386 :1963(Part1) 3 Bulk Density(Loose) 1487kg/m3 IS 2386 :1963 (Part3) 4 Bulk Density(Dense) 1603kg/m3 IS 2386 :1963 (Part3)

The ash from sugarcane bagasse is grey. The collectedashisrunthrougha90μmstandardsizeISsieve. SCBA has around 50% cellulose, 25% hemicellulose, and 25%lignininit.Foreverytonneofsugarcane,approximately 26%ofbagasseand0.62%residualasharegenerated.Table 4liststheSCBA'sphysicalcharacteristics.

Table - 4: PhysicalpropertiesofSugarcanebagasseash

SNo Tests

Values obtained

1 Specificgravity 2.2 2 Fineness 8% 3 Density(g/cm3) 253 4 Color Grey 5 InitialSettingTime 32min 6 FineSettingTime 410min

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

The concrete mix design has been made with potablewaterthatisreadilyavailableonthecollegesite.The followinglisttable5includeswaterphysicalcharacteristics.

Table - 5: PhysicalpropertiesofWater SNo Tests Values obtained 1 PH 7.1 2 Taste Agreeable 3 Appearance Clear 4 Turbidity 1.75

Table

Molecularformula HClinwater(H2O)

Molarmass 35.47g/mol

Appearance Clear colourless to light yellowliquid Density 1.8g/cm3 Meltingpoint 27.320c Boilingpoint 1100c Solubilityinwater Miscible Acidity (pka)-8.1 Viscosity 1.9mpaat250c

Molecularformula Na2SO4 inwater(H2O)

Molarmass 142.04g/mol(anhydrous)

Appearance WhiteCrystallineSolid Density 2.66g/cm3

Meltingpoint 8840c(anhydrous)

Boilingpoint 14290c(anhydrous)

Solubilityinwater Solubleinwater,glycerol

Refractiveindex 1.468(anhydrous)

Forthisinvestigation,cement,sugarcanebagasse ashfineaggregateandcoarseaggregate,wereallused.The mixratiofortheconcretemixwasdeterminedaccordingto IS10262:2019,anditislistedintable9.

SCBA was used to replace cement in all combinationsatreplacementlevelsof0%(controlmix)and 10% for specimens, with a constant w/c ratio of 0.50 for M25grade.

Table8showsthemixdetailsforSCBA,cement,fine aggregate,andcoarseaggregate,and cubes,cylinders,and prisms were cast, with compressive strength, split tensile strength,andflexuralstrengthcalculatedat28,56,90days.

Table-8 Proportionsofallmixes

S NO Mix Cement Kg/m3 SCBA kg/m3 F.A kg/m3 C.A Kg/m3 W/C

1 SCBA0% 330 0 716.83 1232.06 0.50

2 SCBA10% 297 33 716.83 1232.06 0.50

Table-9 MixproportionsofM25

Cement (kg/m3) Fine aggregate (kg/m3) Coarse aggregate (kg/m3) Water (kg/m3) 330 716.83 1232.06 165litres 1 2.17 3.73 0.50

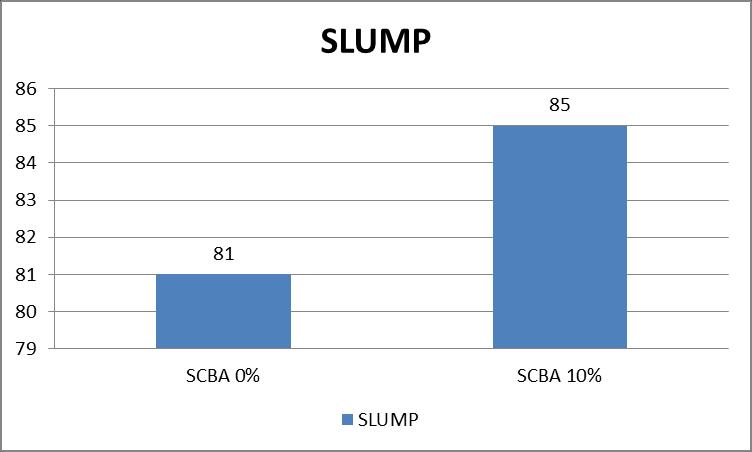

The slump cone test identifies workability of concrete Table10displaystheslumpConetestresultsfor eachmix.

Table 10: Slumpfordifferentmix

SNO Mix proportions Slump value(mm)

1 SCBA0% 81

2 SCBA10% 85

Fig 1: Slump

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

The slump values for SCBA 0% and SCBA 10% successively fluctuate regularly by 81mm and 85mm, accordingtothegraph.Theinclusionofsugarcanebagasse ashwasassumedtohaveimprovedthemix's workability. Whensugarcanebagasseashisusedinplaceofcontrolmix, cementationmixturesrequiremuchmorewater.Thedecline wasseentobeatrueslumpinthenature.Forworkability, noplasticizerwasused.

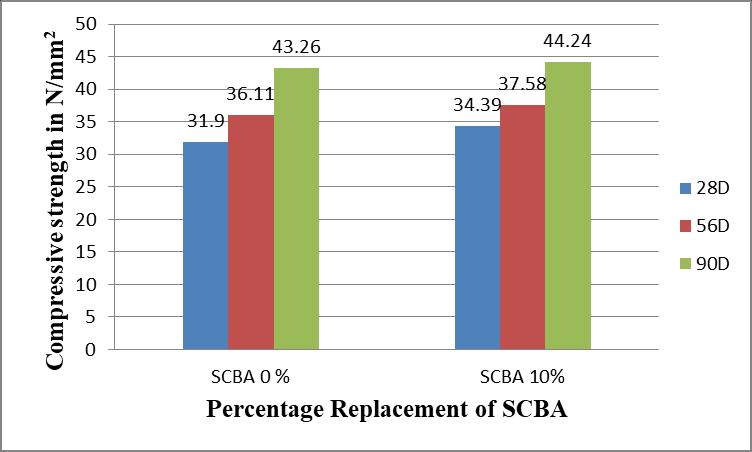

Table11showstheresultsofanexperimentaltest onthecompressivestrengthofM25gradeconcreteat28,56, and90days.

Table

strengthof

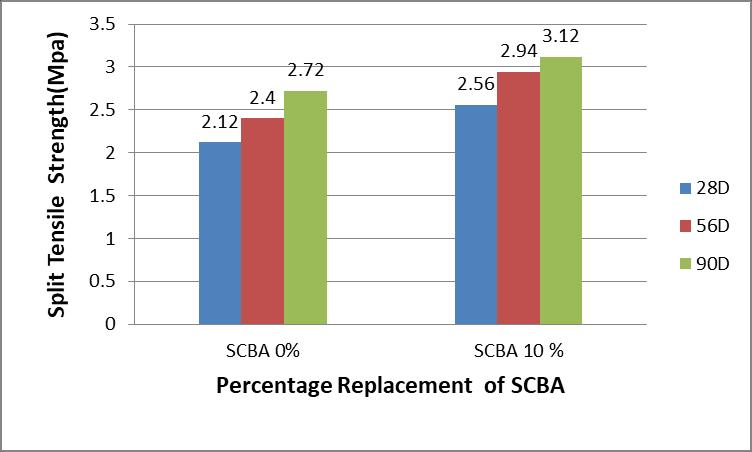

Table12showstheresultsofanexperimentaltest ontheSplittensilestrengthofM25gradeconcreteat28,56, and90days.

Table 12: SplittensilestrengthofM25

Split Tensile Strength(Mpa)

SNO Mix proportions

28days 56days 90days

1 SCBA0% 2.12 2.40 2.72

2 SCBA10% 2.56 2.94 3.12

According to the graph above, the compressive strengthofSCBA10%resultedingoodcompressivestrength whencomparedtotheconventionalmix..At28,56,and90 days,partial replacement of SCBA10% exhibitsimproved compressivestrengthtrends.Allofthemixturesarestronger thanthetargetstrength.Whencomparedtostandardmixes, the compressive strength of M25 SCBA 10% at 90 days is greaterduetotheinclusionofsugarcanebagasseashasfiller inthegapsoremptyspaces

Fig 3: SplittensileStrengthvsPercentageReplacementof SCBA

Whencomparedtotheconventional mix,thesplit tensilestrengthofSCBA10%providedgoodsplitstrength, according to the graph. At 28, 56 and 90 days, partial substitution of SCBA 10% shows improved split tensile strengthtrends.Thecombinationsareallstrongerthanthe desiredstrength. M25SCBA10%hasa highersplittensile strength at 90 days than conventional mixes due to the inclusion of sugarcane bagasse ash as a filler in voids or emptyareas.

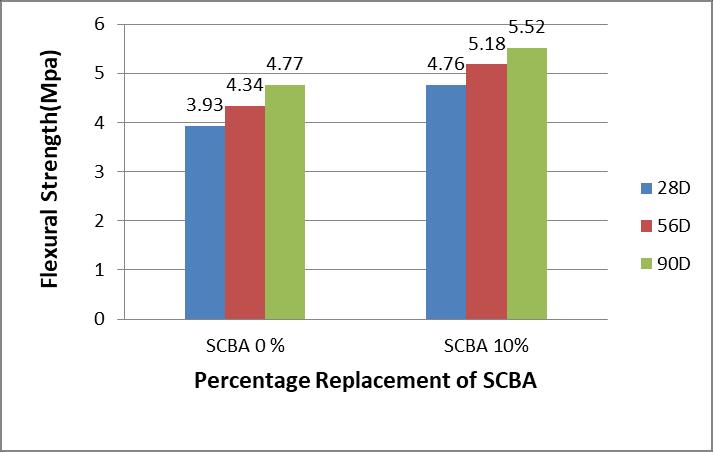

Table 13 below shows the results ofan experimental testontheFlexuralStrengthofM25gradeconcreteat28,56, and90days.

Table 13: FlexuralstrengthofM25

Flexural Strength(Mpa)

SNO Mix proportions 28days 56days 90days

1 SCBA0% 3.93 4.34 4.77

2 SCBA10% 4.76 5.18 5.52

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Fromthegraph,ItwasnotedthattheSCBA10%testfor flexural strength produced good flexural strength when compared to the normal mix. At 28, 56, 90 days partial substitutionofSCBA10%showsimprovedFlexuralstrength testtrends. The combinations are all stronger than the desiredstrength.Duetotheuseofsugarcanebagasseashas fillerinthegapsoremptyspaces,theflexuralstrengthtestof M25SCBA10%attheageof90daysisgreaterthanthatof normalmixes.

Eachspecimeniscastandcuredinamouldfor24 hoursbeforebeingtakenfromthemouldandmaintainedin a curing tank for 28 days. All specimens are weighed and immersedina3%hydrochloricacidsolutionfor28,56,and 90days.Thespecimensareremovedfromthehydrochloric acid solution after 28,56,90 days and washed in running water before being left in the atmosphere for two days to maintainweight.Thespecimenswerethenweighed,andthe weightlossandcompressivestrengthlossweredetermined aspercentages.

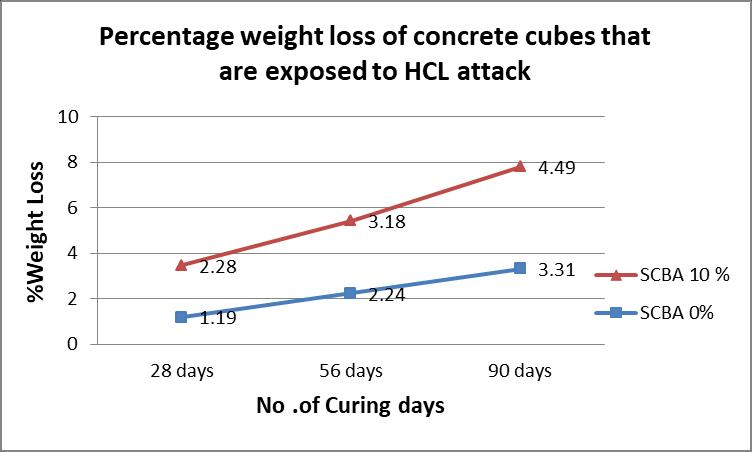

Acidattacktestwasconductedonpartialreplacement of SCBA with cement (0, 10%) parameters such as loss in weightwasevaluatedafterimmersingthespecimensinthe3 % acidat28,56,90days.

Table 14 Lossofweightofcubesatdifferentcuringperiod

SNO Mix proportions 28days 56days 90days

1 SCBA0% 1.19% 2.24% 3.31%

2 SCBA10% 2.28% 3.18% 4.49%

Inthisstudy,thevaluesforweightlossofthecubes attheconclusionofthecuringperiods(28,56and90days) are reported for different replacement amounts of SCBA (0%, 10%). On a graph, these values are plotted. This illustrates the variance in weight loss of cubes containing SCBAatvariouscuringages.Fromourresearch,thelossof weight of cubes is increase in replacement of sugar cane bagasseashcomparetoconventionalconcrete.

4.3.1(b)

Compressive strength of the specimen were evaluated after immersing them in acid for 28, 56 and 90 daysandresultsarepresentedinfollowingtable15,16,17

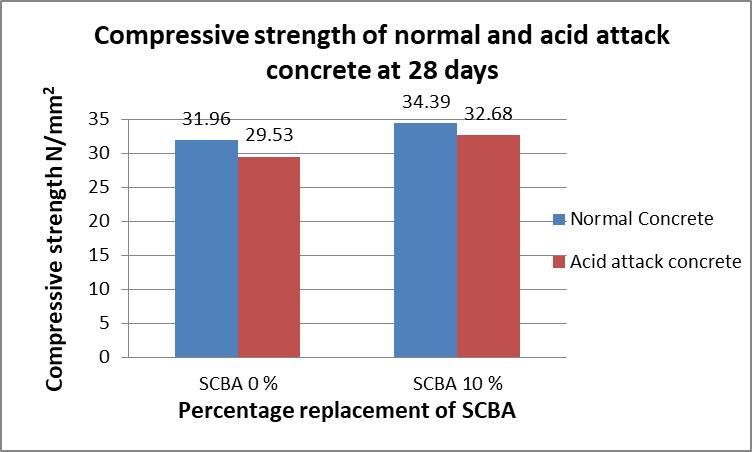

Table 15: ComparisonofCompressivestrengthofNormal andAcidattackConcreteat28days

Partial replacement in cement

Compressive Strength at 28 days in N/mm2

Normal Concrete Acid attack Concrete

%Decrease in Strength

SCBA0% 31.96 29.53 7.60%

SCBA10% 34.39 32.68 4.97%

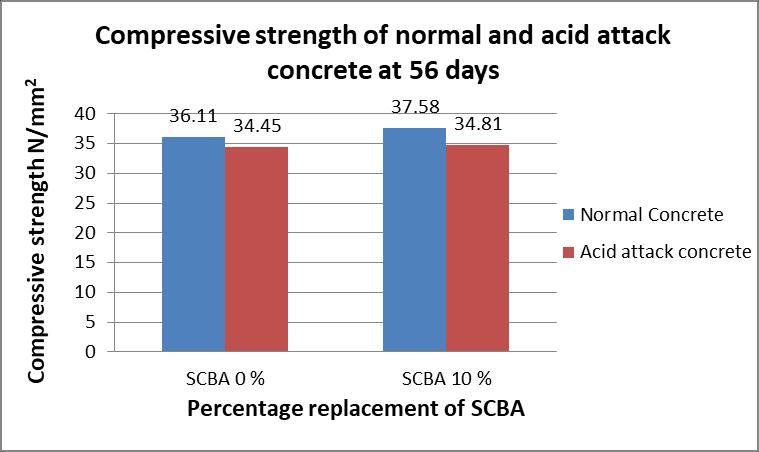

Table 16: ComparisonofCompressivestrengthofNormal andAcidattackConcreteat56days

Partial replacement in cement

Compressive Strength at 56 days in N/mm2

Normal Concrete Acid attack Concrete

%Decrease in Strength

SCBA0% 36.11 34.45 4.59%

SCBA10% 37.58 34.81 7.37%

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

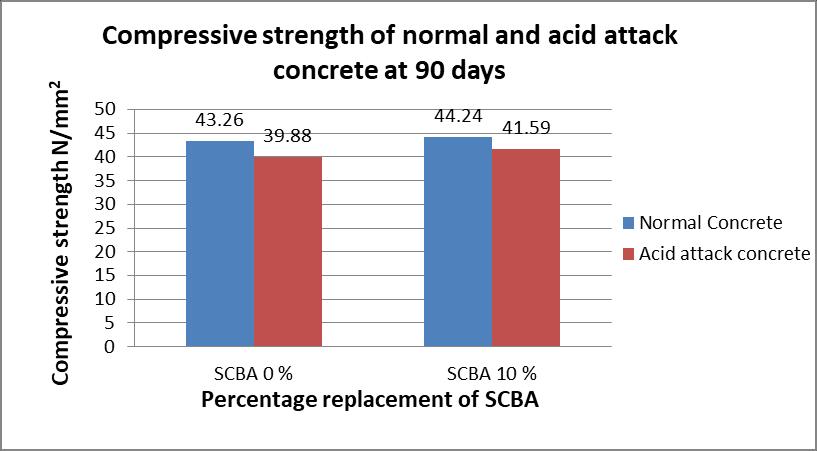

Table 17: ComparisonofCompressivestrengthofNormal andAcidattackConcreteat90days Partial replacement in cement

Compressive Strength at 90 days in N/mm2 Normal Concrete Acid attack Concrete %Decrease in Strength

Inthisstudy,thevalueofCompressivestrengthof concreteforvariouslevel ofSCBA replacement(0%,10%) intowaterandhydrochloricacidduringthePeriodof28,56, 90daysandgivenintheabovetable15,16,17.Thevalues areplottedingraph.

SCBA

Fig6: ComparisonofCompressivestrengthofNormaland AcidattackConcreteat28days

From our research, compressive strength of SCBA 0%isreduceddueto hydrochloricacidattack at28,56,90 daysis7.60%,4.59%,7.81%respectivelycomparedtonormal concreteandCompressivestrengthof SCBA10%isreduced due to hydrochloric acid attack at 28,56,90 days is 4.97%,7.37%,5.99% respectively compared to normal concrete.

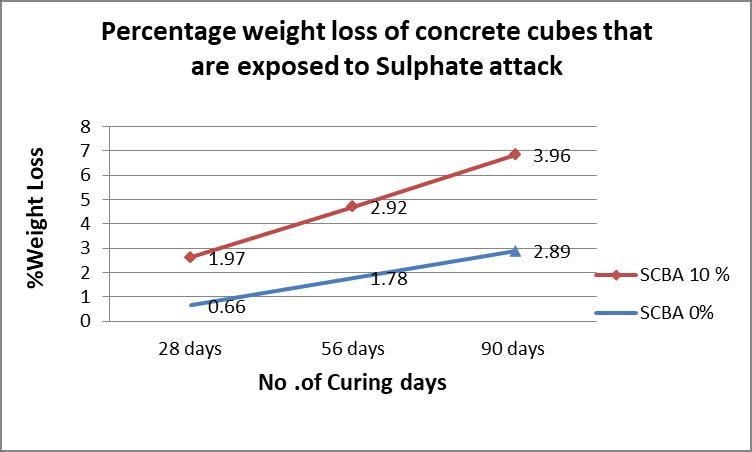

Eachspecimeniscastandcuredinamouldfor24 hoursbeforebeingtakenfromthemouldandmaintainedin a curing tank for 28 days. All specimens are weighed and submergedina3%Sodiumsulphatesolutionfor28,56,and 90daysThespecimensare removedfromthe 3%Sodium sulphatesolutionafter28,56,90daysandwashedinrunning water before being left in the atmosphere for two days to maintainweight.Thespecimenswerethenweighed,andthe weightlossandcompressivestrengthlossweredetermined aspercentages.

Sulphate attack was conducted on partial replacementofSCBAwithcement(0,10%)parameterssuch as loss in weight was evaluated after immersing the specimensinthe3%sodiumsulphateat28,56and90days

Table 18 Lossofweightofcubesatdifferentcuringperiod

loss

Fig7: ComparisonofCompressivestrengthofNormaland AcidattackConcreteat56days

Fig8: ComparisonofCompressivestrengthofNormaland AcidattackConcreteat90days

Fig 9: Lossofweightofcubesatdifferentcuringperiod

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Inthisstudy,thevaluesforweightlossofthecubesat theconclusionofthecuringperiods(28,56and90days)are reported for different replacement amounts of SCBA (0%, 10%).Onagraph,thesevaluesareplotted.Thisillustrates the variance in weight loss of cubes containing SCBA at variouscuringages.Fromourresearch,thelossofweightof cubesisincreaseinreplacementofsugarcanebagasseash comparetoconventionalconcrete.

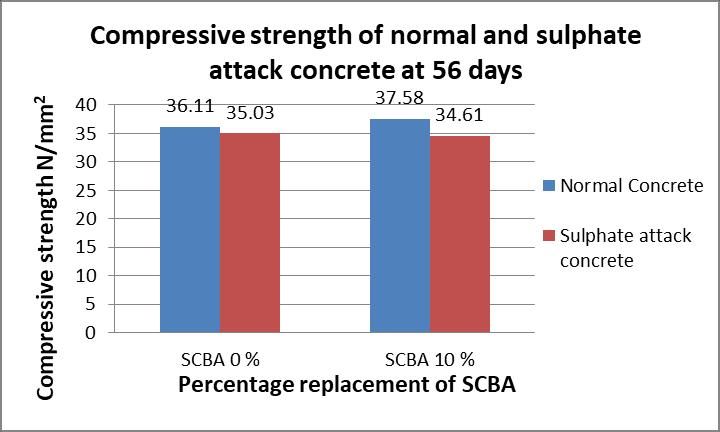

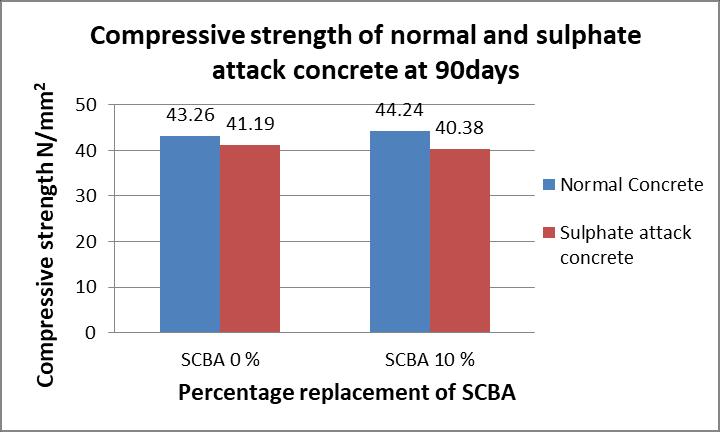

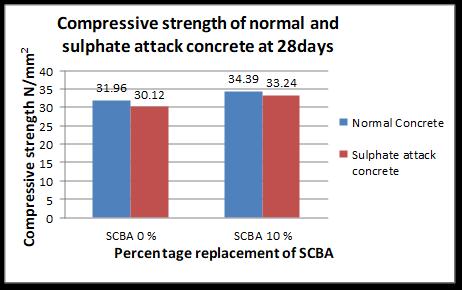

Compressive strength of the specimen were evaluated after immersing them in 3 % sodium sulphate solutionfor28,56and90daysandresultsarepresentedin followingtable19,20,21

Table 19: ComparisonofCompressivestrengthofNormal andSulphateattackConcreteat28days

Partial replacement in cement

Compressive Strength at 28 days in N/mm2

Normal Concrete Sulphate attack Concrete %Decrease in Strength

SCBA0% 3196 3012 575%

SCBA10% 3439 3324 337%

Table 20: ComparisonofCompressivestrengthofNormal andSulphateattackConcreteat56days

Partial replacement in cement

Compressive Strength at 56 days in N/mm2

Normal Concrete Sulphate attack Concrete %Decrease in Strength

SCBA0% 3611 3503 299%

SCBA10% 3758 3461 790%

Table 21: ComparisonofCompressivestrengthofNormal andSulphateattackConcreteat90days

Partial replacemen t in cement

Compressive Strength at 90 days in N/mm2

Normal Concrete Sulphate attack Concrete %Decrease in Strength

SCBA0% 4326 4119 478%

SCBA10% 4424 4038 872%

Fig10: ComparisonofCompressivestrengthofNormal andSulphateattackConcreteat28days

Fig11: ComparisonofCompressivestrengthofNormal andSulphateattackConcreteat56days

Fig12: ComparisonofCompressivestrengthofNormal andSulphateattackConcreteat90days

In this study, the value of Compressive strength of concreteforvariouslevel ofSCBA replacement(0%,10%) intowaterandsodiumsulphatesolutionduringthePeriodof 28, 56, 90 days and given in the above table19,20,21. The valuesareplottedingraph.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Fromourresearch,compressivestrengthofSCBA0% isreducedduetosodiumsulphateattackat28,56,90daysis 5.75%,2.99%,4.78% respectively compared to normal concreteandcompressivestrengthof SCBA10%isreduced due to sodium sulphate attack at 28,56,90 days is 3.37%,7.90%,8.72% respectively compared to normal concrete.

Thefollowingconclusionsshownbelow.

1. Theuseofbagasseashinconcreteandmortareliminates theissueofitsdisposal,preventingcontaminationofthe environment.

2. From the compressive strength results ofcubes, itis foundthat10%ofbagasseashreplacementwithcement

yield increases in compressive strength 2.26% as comparedtocontrolledconcreteat90daysofcuring.

3. From the split tensile strength results, it is found that 10% of bagasse ash replacement with cement yield increases in tensile strength 14.7% as compared to controlledconcreteat90daysofcuring.

4. FromtheFlexural strength testresults,itisfoundthat 10% of bagasse ash replacement with cement yield increase in flexural strength 15.72% as compared to controlledconcreteat90daysofcuring.

5. From the total rate of percentage weight loss of the specimensubjectedtoacidexposure10%SCBAblended concrete shows more reduction in weight lost 35.6% whencomparedtocontrolledconcrete

6. From the total rate of percentage weight loss of the specimen subjected to sulphate exposure 10% SCBA blendedconcreteshowsmore reductioninweightlost 37.02%whencomparedtocontrolledconcrete.

7. Compressive strength of SCBA 0% is reduced due to hydrochloric acid attack at 28,56,90 days is 7.60%,4.59%,7.81%respectivelycomparedtonormal concreteandSCBA10%isreducedduetohydrochloric acid attack at 28, 56 ,90 days is 4.83%,7.37%,5.99% respectivelycomparedtonormalconcrete.

8. Compressive strength of SCBA 0% is reduced due to sodium sulphate attack at 28,56,90 days is 5.75%,2.99%,4.78%respectivelycomparedtonormal concrete and Compressive strength of SCBA 10% is reducedduetosodiumsulphateattack at28,56,90days is3.37%,7.90%,8.72%respectivelycomparedtonormal concrete.

9. Use of the waste materials It is advantageous to substitute sugar cane bagasse ash for cement when makingconcrete.

1. “A study of the parameters that determine the reactivityofsugarcanebagasseashes(SCBA)foruseas a binder in construction”- Figueiredo, R. Lima, and S. Pavia,SNAppliedSciences,Volume2,Issue9,(2020)

2. “Mechanical and durability characteristics of high performanceconcretecombinedwithbagasseash”-G. SankarasubramanianandS.Praveenkumar,SNApplied Sciences,Volume1,Issue12,(2019)

3. "Microstructure,strength,anddurabilityofeco-friendly concretescontainingsugarcanebagasseash."-Zareei, SeyedAlireza,FarshadAmeri,andNasrollahBahrami. Construction and Building Materials184 258268(2018).

4. “Utilization of sugarcane bagasse ash in concrete as partial replacement of cement” - Sajjad Ali Mangi, Jamaluddin,WanIbrahim,AbdHalidAbdullah,Abdul Awal,SamiullahSohuandNizakatAli,IOPConference Series,MaterialsScienceandEngineering(Vol.271,No. 1,pp.1-8),IOPPublishing,(2017)

5. “StudyonConcretewithSugarcaneBagasseAshasa PartialReplacementofCementusingHCLSolution”,-S. Nagabhargavi,Y.Anandbabu,IJSETR,Vol.05,Issue.16 June-2016

6. “Performance evaluation of sugarcane bagasse ash blendedcementinconcrete”-A.Bahurudeen,Deepak Kanraj, V. Gokul Dev, Manu Santhanam, Cement and Concrete Composite, volume 9 , Pages 77-88, May (2015)

7. “An Experimental Study on Concrete with Sugarcane BagasseAshasaPartialReplacementofCementunder SulphateAttackUsingMgso4Solution”-Mohananganga RajuPuppala,MKMVRatnam,-InternationalJournal of Innovative Research in Science, Engineering and TechnologyVol.3,Issue12,December2014

8. “EffectofuseofBagasseAshonStrengthofConcrete”U.R.Kawade,V.R.Rathi,VaishaliD.Girge,International JournalofInnovativeResearchinScience,Engineering andTechnologyVol.2,Issue7, ISSN:2319-8753,July (2013)

9. "Effectofgroundflyashandgroundbagasseashonthe durability of recycled aggregate concrete."- Somna, Rattapon, Chai Jaturapitakkul, and Amde M. Amde.Cement and concrete composites34.7 (848854(2012).

10.“Useofbagasseashinconcreteanditsimpactonthe strength and chloride resistivity” - Noor-ul Amin, Journal of materials in civil engineering, 23(5), 717720,(2011)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

11.“UseofBraziliansugarcanebagasseashinconcreteas sandreplacement”-Sales,Almir,andSofiaAraújoLima: Wastemanagement30.6:1114-1122,(2010).

12.“Pozzolanic activity and filler effect of sugar cane bagasseashinPortlandcementandlimemortars”-G.C. Cordeiro , R.D. Toledo Filho, L.M. Tavares , E.M.R. Fairbairn Cement and Concrete composites,30(5), pp.410-418,(2008)

13.“Evaluation of bagasse ash as supplementary cementitiousmaterial"-Ganesan,K.K.Rajagopal,andK. Thangavel,Cementandconcretecomposites29.6:515524,(2007)

14.Journal of Chemical Technology & Biotechnology - J Paya,JMonzo,MVBorrachero,LDiaz-PinzonandLM Ordonez,Journal of Chemical Technology & Biotechnology: International Research in Process, Environmental & Clean Technology, 77(3), 321-325, (2002)

15.IS516:1959,“MethodofTestsforStrengthofconcrete”, BureauofIndianStandards,NewDelhi,India

16.IS 383 -1970, “Specifications for Coarse and Fine AggregatesfromNaturalSourcesforConcrete”,Bureau ofIndianStandards,NewDelhi,India

17.IS 12269-1987,” Specification for 53 Grade Ordinary Portland Cement”, Bureau of Indian Standards, New Delhi,India.

18.IS10262 -2019“ISMethodofMixDesign”,Bureauof IndianStandards,NewDelhi,India.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |