International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

HIGH STRENGTH CONCRETE USING GGBS: A REVIEW

Vishvjeetsinh Dilipsinh Rana1 , Aakash Rajeshkumar Suthar 2

1 Student Civil Engineering Department, L.J.I.E.T. Ahmadabad, Gujarat, India

2 Professor Civil Engineering Department, L.J.I.E.T. Ahmadabad, Gujarat, India ***

Abstract - The cement industry can be one of the key sourcesofenvironmentalpollution,soreducingthedemand forcementshouldbeimproved.Silicafume(SF)andground granulated blast furnace slag (GGBS) are industrial byproducts and should be reused to reduce waste pollution. Therefore, this study is aimed at developing a better understandingofthecombinedperformanceofSFandGGBS onthestrengthpropertiesofternaryconcreteversusregular concrete. This work mainly deals with strength characteristics such as compression test, shear test and bendingstrength.Inordertofindtheoptimalreplacementof cementwiththeabove-mentionedmaterial,differentmixture ratiosweretestedtochecktheinfluenceofwastematerialon the mechanical properties of high-strength concrete. On differentdays,compression,bendingandsheartestswillbe performed. In this study, we include the concept of triple mixing of cement with silica and GGBS. This triple cement utilizesthebeneficialpropertiesofbothpozzolanicmaterials toproducebetterconcrete.

Key Words: high strength, super plasticizer, GGBS, flyash, silica.

1. INTRODUCTION

Concreteisamixtureofingredientssuchascement,sand, aggregateandwaterthatarenatural,affordableandreadily available.Cementisthesecondmostwidelyusedcommodity in the world after water. The rapid processing of cement causes huge pollution problems. The first environmental problemistheemissionofcarbondioxideduringthecement production process. Carbon dioxide emissions are very harmful and cause major environmental changes. It is estimated that1 ton ofcarbon dioxide is releasedinto the atmospherewhen1tonofregularPortlandisproduced.[1]

Thestrengthoftheconcretestructure(bearingcapacity) is the most important aspect when assessing concrete. Deterioratingagentscanbechemicalsulfates,chlorides,CO2, acids, etc., or mechanical causes such as abrasion, impact, temperature,etc.[2].Strongconcretestepsincludestructural designanddetailing,mixingratioandprocessing,adequate on-site quality control, and selection of proper concrete admixtures.[1]

Aconcretestructurecanmeetdifferentmodesofloading andexposuredependingontheoperationalenvironmentin whichitisintendedtooperate.Differentstrengthsofcement arerequiredtomeetperformancerequirements.

Thedevelopmenttodatecanbedividedintothreephases. See; Normal strength concrete (NSC), containing only four primaries.Thedevelopmenttodatecanbedividedintothree phases.See;Normalstrengthconcrete(NSC),containingonly four basic components (cement, water, fine aggregate and coarseaggregate).Increaseddemandsforhousingintheform of high-rise buildings;longbridges etc.required increased compressive strength. The next stage was therefore to develop a cement with an inherently higher compressive strength, i.e. the development of high strength concrete (HSC). However, over time it became clear that high compressive strength was not the only major factor in designing concrete mixes. The last stage was to optimize everything.tothemaximumextentpossibleintheeconomy andthesepropertiesAgentlewaytotheenvironment.The triplemixconceptisgivenhereConcretemix.[1]

2. LITRATURE REWIEW

1. Vijaya Bhaskar Reddy, Dr.P.Srinivasa Rao, “Experimental study of compressive strength of ternary blended concretes at different levels of microsilicaandggbs”@2016ElsevierLtd.Allrights reserved.

In thisarticle, the world finds alternative materials in concrete technology that are partially able to replace ordinary Portland cement (OPC) and also meet industrial requirements for strength and durability. Optimization of ordinaryPortlandcement(OPC)/GGBS/microsilicaforthe developmentofternaryblendedconcreteiscarriedoutusing paperbasedexperimentalanalysis.

In this paper, experimental work has been provided to evaluatethecompressivestrengthofternarymixedconcrete after 7, 28, 60 and 90 days for different combinations of MicroSilicaandGGBS.MicroSilica0%,5%,10%and15% alongwithGGBSisreplacedby20%,30%,40%and50%.A water-cementratioof0.45wasusedforallmixes.

Experimental results

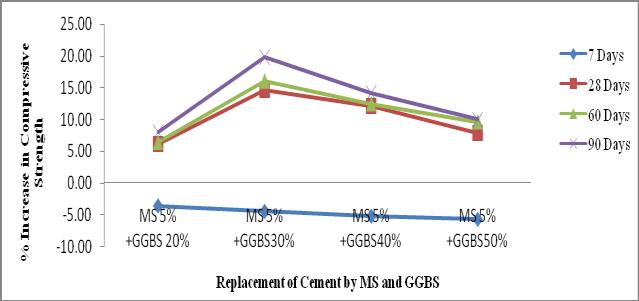

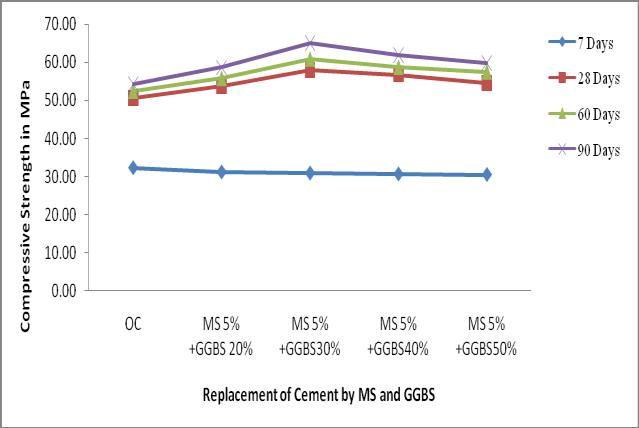

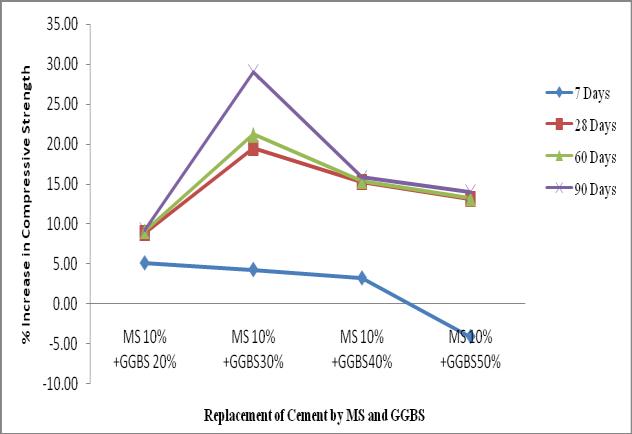

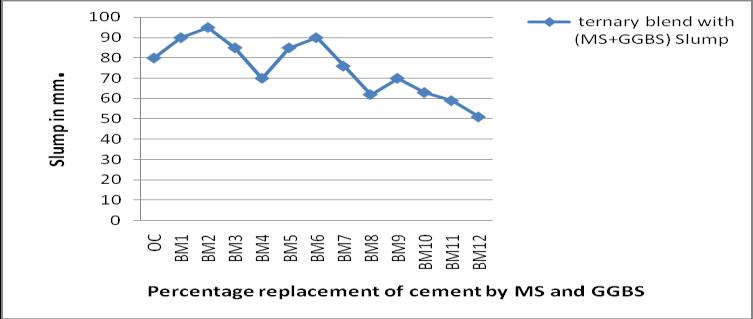

Improvedworkabilityoffreshconcretebyupto30 percent by replacing GGBS and improved density of fresh mixes of micro silica and GGBS. 7 days of ternary mixing compressionbyincreasingMScontentby5percentGGBSand increasingMSby10to15percent.Themixture(MS10%+ GGBS%)offersgreatercompressivestrengthandworkability compared to ordinary concrete at all setting days.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Experimental studiesshow that mineral mixtures perform verywellintheeconomicdevelopmentofternarymixtures. We can make the environment more sustainable by using industrialwastematerials.

Fig.1:SlumpvalueswithvariousproportionsofMSand GGBS

Fig.8:%IncreaseinCompressiveStrengthofTBCw.r.t NormalConcrete(MS10%andGGBS20%,30%, 40%50%)

2. Balakrishna Y, V. Lavanya, Naresh A, S. Vijaya Bhaskar Reddy, “Triple Blending Of Cement ConcretewithMicroSilicaandGroundGranulated High Furnace Slag” @2016 international research journal of engineering and technology (IRJET). All rightsreserved.

TheauthorstatedinthisanalysisthatMicroSilica(MS) andGroundgranulatedblastfurnaceslag(GGBS)becamea by-productandcouldbereusedtoreduceemissionsfromthe waste. Within this article, a better understanding of the success of the MS and GGBS connection is established regarding the strength properties of triple concrete comparedtoconventionalconcrete.

Fig.2:CompressiveStrengthofTBCw.r.tNormalConcrete with5%MicroSilicaanddifferent%ofGGBS.

Thispapermainlyfocusesonstrengthpropertiessuchas compressive strength, split tensile strength and flexural strength.Atotalof12differentconcretemixeswerecastand testedwithdifferentsubstitutionlevels(5%,10%and15%) forMicroSilicawithGGBS(20%,30%,40%and50%).Atthe ageof7,28,60and90daysfordifferentcombinations

Micro Silica and GGBS. All mixtures were studied at a water-cementratioof0.55.Themixeshavethecompressive strength, tensile strength and flexural strength of Blend Concrete.

Experimental results

•Microsilicaisappliedtoconcrete,whichsignificantly increases the performance of buildings at an early age. Optimum7-daystrengthwasachievedwith15%microsilica, butafter28daysthestrengthwasreducedto10%.

Fig.3:%IncreaseinCompressiveStrengthofTBCw.r.t Normal

•Ternaryconcretewithamaximumcompressivestrength of 7 days replaces OPC with MS and GGBS in a maximum amountof35%.And8.36%higherthantheconcretecontrol Whilethemaximumcompressioncapacityis28,60daysand 90days,itis21.02%,22.84%and24.56%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

• The increase in compressive strength in ternary concreteis67.32%,76.20%and87.27%with respectto7 days.

•Tensilestrengthofternaryconcreteishighestat35% replacementofOPCMSandGGBS,whichis5.39%morethan controlconcreteat7days.Butat30%cementreplacement after28days,60daysand90days,itis15.47%,18.10%and 21.44%morethantheconcretecontrols.

•Theincreaseinsplittensilestrengthofternaryconcrete is46.28%,53.35%and60.33%withrespecttothevalueof7 days.

•7daysTernaryconcretehasoptimalflexuralstrengthat 35% cement replacement and 6.05 percent greater than control concrete. Although 28 days, 16.52%, 18.91% and 22.24%werereplacedby30%ofthestrengthof28days,60 daysand90days.

• Flexural strength increases by 46.85%, 55.07% and 62.19%comparedto7daysstrengthoftripleconcrete.

3. Zuraidah Hashim and Roszilah Hamid, “Effect of silicafumeonstrengthandporesizedistributionof concrete” @ (2015) Trans Tech Publications, Switzerland.Allrightsreserved.

This work would investigate the effect of silica cement replacement(0%,7%,9%and12%)oncompressivestrength at 3, 7, 14 and 28 days Water/cement ratio for wet cured concrete 0.4 and design capacity 40 MPa. The work propertiesofthenewconcretewereassessedbysettlement andcompactiontestfactor.

Experimental results

•Theeffectofcementsubstitutionby7%,9%,and12% MK reduced the workability of all MK mixtures by almost 80%comparedtothecontrolconcrete.

• With an increase in the MK cement replacement, the intensityalsoincreaseswith12%oftheMKreplacement,the createdcompressivestrengthis48.5MPacomparedto

41.5MPa.Therateofincreaseis7%.

•Themaximumporediameterofthe9%MKsubstituteis thelowest.Thisamountis93%smallerthantheaveragepore diameter of the control concrete, which improved the strength.

4. YatinhPatel,p.j.patel,prof.JigneshmPatel,Ph.D.Hs Patel,“StudyOnthedurabilityofhigh-performance concrete with Alcofin and fly ash”@2013 International Journal Of Advanced Engineering ResearchAndStudies.Allrightsreserved.

Inthisarticle,evaluatethepropertiesofconcrete(HPC) containingadditionalcementitiousmaterialsuchasflyash and Alccofine. This research evaluates the performance of concretemixincompressivestrength,chloridetest,seawater testandacceleratedcorrosiontestsat28and56daysofage. Findoutmoreaboutthemixedratio,theoptimaldosageof Alccofineandflyash.

Experimental results

•Alccofine(8%)andflyash(20%)achievedcompressive strengths of 54.89 MP and 72.97 MP for 28 and 56 days, respectively.

•Lessweightreductionandlossofconcretecompressive strengthinchlorideresistancetestandseawatertestdueto fine application. As a specific result of Chloride, Attack becomes a more robust and less penetrating attack. This converts the leachable calcium hydroxide into a nonleachable, insoluble cementitious product. This pozzolanic action is responsible for the impermeability of concrete. Second, the removal of calcium hydroxide reduces the susceptibilityofconcretetochlorideattack.

• M70 grade concrete with an RCPT value below 500 coulombscanbedeveloped.TheRCPTvalueinAlccofinewas found to be lower due to pore filling and particle pore refinement.

• The weight loss of steel was found to be lower in an accelerated electrical corrosion test with Alccofine, which meansthattheusualalkalinecoverpreventsthesteelfrom corrodingduetoitsporesandparticlerefinement.

5. Sunny A. Jagtap, Mohan N. Shirsath, Sambhaji L. Karpe, “Effect of Silica Fume on Properties of Concrete.”@2017InternationalResearchJournalof Engineering and Technology (IRJET). All rights reserved

SilicaFumeisalsousedasabinderinthisarticle,inwhich it partially replaces the cement and part of the response during the hydration reaction. Silica Fume cement replacement should be studied in the range of 5% to 25% withanintervalof5%.Attheageof7.28daysitwastested for compressive strength, tensile strength and flexural strength and compared with the results of conventional concrete.

Experimental results,

• Silica concrete effectively increases compressive and flexural strength compared to conventional concrete. An increased amount of siliceous fumein concrete reduces workability.

•Thestrengthofconcreteincreaseswithanincreasein silicacontentinthecementsubstitutebyupto15%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

• As theamountof Silica Fume powder in the concrete increases,theworkabilityoftheconcretedecreases.

3. MATERIAL

Cement: Cement is the primary ingredient for making concrete.PozzolanicPortlandcement(53grade)conforming to IS12269-1987 was used here. The specific gravity of cementis3.15

Fine Aggregate: Locallyavailablesilt-freeriversandas perIS383-1970withaspecificgravityof2.65isused

Coarse Aggregate: Crushedaggregateof10-12mmsize isaddedfromnearbyquarrywithspecificgravityof2.74as perIS383-1970

Superplasticizer:ThehyperplasticizermustbeADDMIX 389, a highly water-reducing polycarboxylic ether super plasticizer.Theproductmusthaveaspecificweight1.1anda solidscontentofnotlessthan40%byweight.

Mineral additives: GGBS, silica fume, fly ash , Super plasticizers

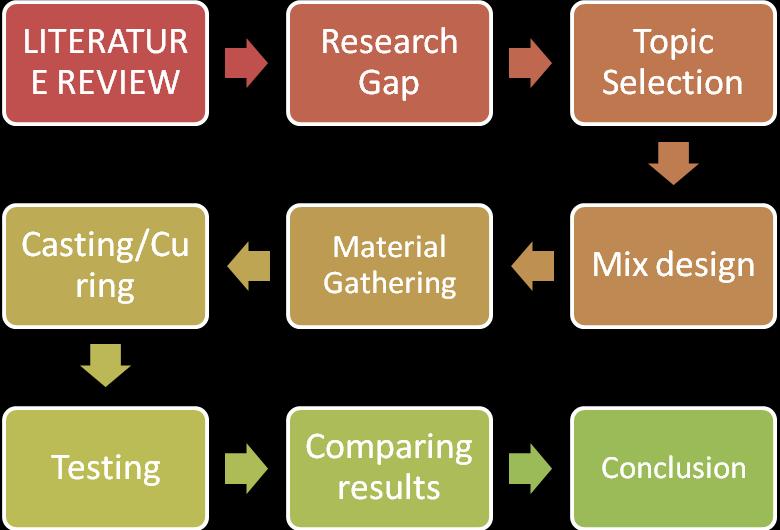

4. METHODOLOGY

4. CONCLUSIONS

1) Since the water-cementratio isexpected to below inhigh-strengthconcreteformulations, high performance water reducing agents arerequired for workability.

2) Concretewith12mmcrushedgraniteaggregatehas highercompressivestrength.

3) The strength of concrete increases withdecreasing water-cement ratio anddecreases withincreasing water-cementratio.

4) The use of metakaolinas a partial cementsubstitute reducedtheplasticdensityofthemixture.

5) Itisalsoobservedthatincreasingtheadditionrateof silica fume and metakaolindecreases the machinability, while adding fly ashincreasesthe machinability.

6) The optimum percentage of cementto cementationsmaterialis10-20%.

Collection of Material like Pozzolana Portland Cement, Coarse aggregate, Fine aggregate, Metakaolin,Flyash,silicafume,Admixture.

Laboratory test on basic ingredients of concrete likeCement,Coarseaggregate,Fineaggregate.

FinalizeMixdesignforconcrete.

Partial replacement of cement with Metakaolin, Flyash,Silicafumeincariouspercentages.

Checkworkabilityofconcrete.

Castingofcubespecimen

DetermineCompressivestrengthofconcrete.

7) Higher concrete quality lowerssteelcosts.Forhighstrengthconcrete,thewater-to-cementratioshouldbe keptlow.

8) Flyashgivesgreenconcretefrommetakaolin.

REFERENCES

1 Vijaya Bhaskar Reddy, Dr.P.Srinivasa Rao, “ExperiSFental Studies on CoSFpressive Peck Of ternary blended Concretes at different Levels of SFicroSilicaandGgbs”@2016ElsevierLtd.Allrights reserved.

2 BalakrishnaY,V.Lavanya,NareshA,S.VijayaBhaskar Reddy, “Triple Blending Of CeSFent Concrete with SFicro Silica and Ground Granulated Blast Furnace Slag” @2016 International Research Journal Of Engineering And Technology (IRJET) . All rights reserved.

3 Zuraidah HashiSF and Roszilah HaSFid, “Effect of SFetakaolin

4 TheStrengthAndPoreSizeDistributionOfConcrete” @(2015)Trans TechPublications,Switzerland.All rightsreserved.

5 Yatinhpatel,p.j.patel,prof.JigneshSFPatel,Ph.D.Hs patel, “Study on durability of high performance concrete with alkofine and fly ash” International Journal of Advanced Engineering Research And Studies.Allrightsreserved.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072