International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Revathi S1, Vidhya K2 , Kavitha E3 , Shivasakthivadivelan R A4

1 Research Scholar, Department Of Civil Engineering, Mahendra Engineering College, Namakkal 637503, Tamilnadu, India.

2 Professor and Head, Department Of Civil Engineering, Mahendra Engineering College, Namakkal 637503, Tamilnadu, India.

3,4 Research Scholars, Department Of Civil Engineering, Mahendra Engineering College, Namakkal 637503, Tamilnadu, India.

***

Abstract - Bricks are the most predominantly used construction materials since the ancient period owing totheir availability, economy, and simplicity of manufacturing. The traditionally available clay bricks usage is gradually depleted due to scarcity and raw material depletion. Industrial byproducts of high potential are of interest in thecurrentdays to develop various greener building products.Geopolymerbricks are remarkable amongst various construction products for their extraordinary properties under various strength and longevity parameters. The geopolymer bricks find vast application in various developed and developing countries owing to their significant properties.Thearticledealswiththe development of a greener geopolymer brick with industrial wastes. The properties of the bricks are assessed and the results are interpreted.

Key Words: Bricks, Geopolymer bricks, Industrial byproducts, properties of bricks.

Due to the population boom and increased demand for natural resources, there is a huge demand for housing globally. In recent years, there has been a lot of interest worldwide in creating sustainable construction materials usingpossibleindustrialbyproducts.Theuseofcementin the production of concrete will be eliminated thanks to a newtechnologydevelopedinthe1980sbyFrenchscientist Davidovits[6]. By doing away with natural clay, the same idea is currently applied in the production of bricks. Substituting an alkaline solution for water in the dry raw mixture made it possible to cause the fly ash in brick to cement.GeopolymerizationofbricksdependsontheAlion's capacitytoproducecrystallographicandchemicalvariations with Si content and a variety of other factors, such as the type of source materials, the type of curing, the curing temperature,thecuringtime,theageofthetesting,andthe type and concentration of alkaline solution[3] Utilizing supplementalcementitiousmaterialsinplaceofcementhas reduced CO2 emissions, making the application of geopolymertechnologymoreimportant[2.Theutilizationof industrial by products of good silica alumina potential materials support and favour geopolymerization. The buildingindustrycontributesabout39%oftheannualglobal

CO2 emissions, according to "World Energy Statistics and Balancedatabase2019."[4].Itiscrucialandtheidealtimeto focusmoreonindustrialwastesandeffectivelyreducethe consumptionofnaturalresources.

Geopolymerbrickbehaviourwastestedwithby[8]under thecombinedinfluenceofpressure,temperature,andcuring. Pressure was changed between 0 and 20 and 40 MPa, together with ambient and high temperature fluctuations, and behaviour was examined with variable curing times between 7 and 28 days. Longer curing times and high pressureof40MPaduringhotcuringresultedinsuperior geopolymer properties for bricks. The combined physiomechanical behavior of the geopolymerized bricks hadalsobeenconfirmedbythemicrostructureinvestigation.

Thedurabilityandfundamentalpropertiesoftheindustrial ash brick were investigated with by [10] The best percentageofpondash-basedashbrickisestablished,and theviabilityofpondashinclusioninbrickmanufacturingis estimated. The microlevel characterisation of pond ash is investigated, and the performance of the ash bricks is assessed.

Fly ash (FA), electric arc furnace slag (EAF), and waste foundry sand were used in the investigation by (Apithanyasaietal.2020)onthegeopolymermanufactureof bricks (WFS). Utilized were sodium silicate and sodium hydroxide,bothofwhichhavemolaritiesof10M.Therewas an excellent compressive strength as a result of the percentageofwastefoundrysand,flyash,andelectricarc furnace slag, which was 40:30:30. Assessments of toxicity andenvironmentaleffectsweremadeusingtheleachingtest.

The construction and characterisation of eco-permeable bricks made from industrial waste was tested by [7]. Gypsum,flyash,blastfurnaceslag,andsteelslagareusedto make the bricks. At a curing temperature of 60oC, the maximumcompressivestrengthof27.4N/mm2isobtained. Theecopermeablebrickisfoundtohaveaflexuralstrength of4.5N/mm2.Itisnotedthat96%ofsolidwastewasused intheproductionoftheeco-permeablebricks.Theresultsof

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

the toxicity tests lead to the conclusion that the ecopermeablebricksaresafefortheenvironment.

Thematerialsusedinthisinvestigationtomanufacture thegeopolymerbricksare.

FineAggregate(M-Sand)

AlkalineActivators(NaOH&Na2SiO3)

Flyashistheashobtainedasabyproductfromthermal power plants during coal combustion for electricity generation.TheflyashisofclassFtypeasperASTMC618 Standards and is obtained from Mettur Thermal Power Plant,Tamilnadu,India.

A by-product of the blast furnaces used to create iron, GGBS (Ground Granulated Blast-furnace Slag) is a cementitiousmaterialthatismostlyutilisedinconcrete.Itis coolectedfromJSWcementsPvt.Ltd,salem,Tamilnadu.

M sand is currently most frequently utilised in constructionprojects.Ithadanicetextureandappearance. Forbrickmasonrycasting,readilyavailableMsandisused.

Theactivatorsutilisedinthegeopolymerizationprocess are sodium hydroxide (NaOH) and sodium silicate (Na2SiO3).Inordertobalancecostandeffectiveness,sodium hydroxidewithanormalcyof8Misutilised[9].

Gypsum enhances both the reduction of strength loss owingtosoakingevenatshortcuringtimesaswellasthe stability of stabilised fly ashes over repeated cycles of wettinganddrying.Sodiumhydroxideandsodiumsilicate are used as alkaline activators. The molarity of sodium hydroxideismaintainedas8Mforallthemixes.

Thephysicalpropertiesofthematerialsusedispresented intable1.

S.No Property GGBS Fly ash M sand

1 Specificgravity 2.59 2.23 2.32

2 Surface area(m2/kg) 325 350 252

3 Bulk density (kg/m3) 1299 1160 1453

The mix proportion of various materials used for the geopolymerbrickispresentedintable2.

Table 2 Mix proportion for geopolymer brick

S.No Brick ID GGBS Fly ash M sand Gypsum

1 GP1 10 60 25 5 2 GP2 20 50 25 5 3 GP3 30 40 25 5 4 GP4 40 30 25 5 5 GP5 50 20 25 5 6 GP6 60 10 25 5

Experimental determinations of the several basic brick parameters,suchascompressivestrength,waterabsorption, and weight density of the bricks, are made, and the test resultsarepresented.

Table 3. Test results for the basic properties of bricks

S. No Brick ID

Compressive strength at 28 days in MPa

Water absorption in %

Weight density (kN/m3)

1 GP1 11.58 9.52 15.69

2 GP2 12.95 9.06 15.78 3 GP3 15.69 8.84 16.12 4 GP4 17.58 8.90 16.89 5 GP5 15.24 8.96 16.52 6 GP6 10.69 9.11 16.45

7 Fly ash brick(FB) 7.66 12.12 16.36

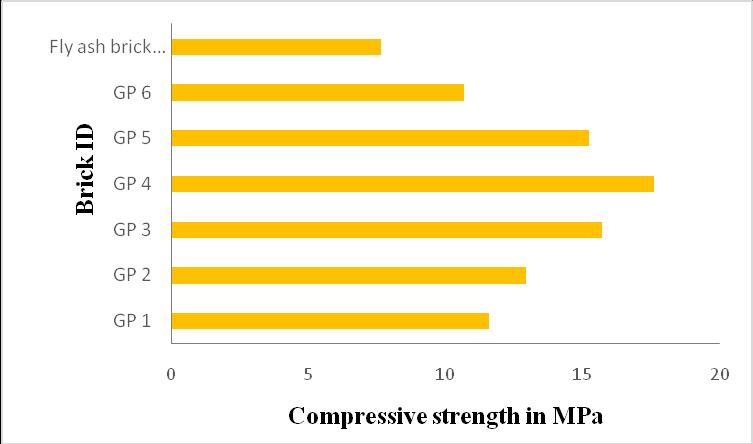

Thecompressivestrengthofthegreengeopolymerbrick is determined from the experimental findings and the pictorial representation of the compressive strength is presentedinFigure4.1.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

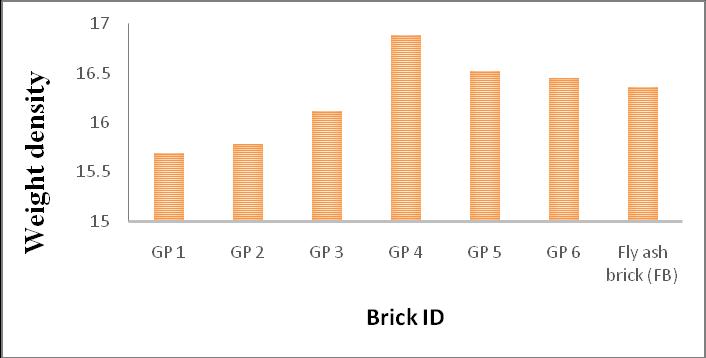

The weight density of the geopolymer bricks and flash bricksispresentedinFigure4.3.

From the figure 4.1 it is inferred that the geopolymer bricks possessed a very significant compressive strength comparedwiththetraditionallyavailableflyashbricks.The geopolymerbrickwithIDGP4possesshighestcompressive strengthwhencomparedtoallothergeopolymerbricks.The composition of flyash constituting 30% GGBS constituting 40%resultedinhighestcompressivestrength.

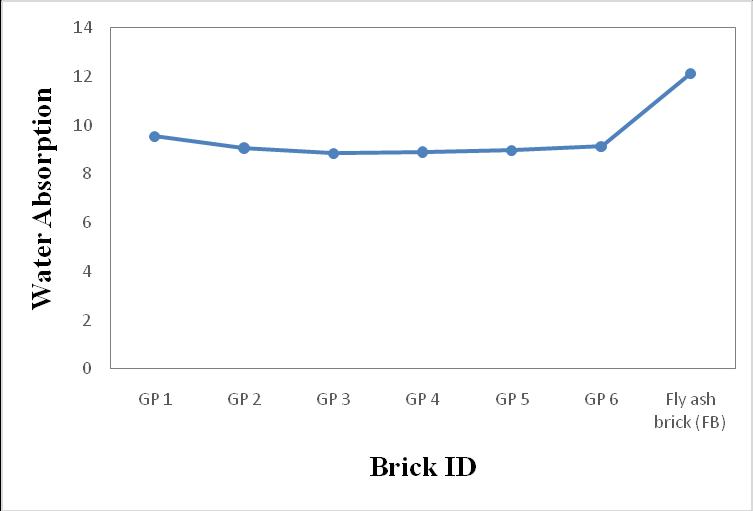

Thewaterabsorptionrepresentationofthegeopolymer brickandtheflyashbrickispresentedinfigure4.2.

Three brick samples are chosen for determining the weightdensityforeachmixcomposition.Theweightdensity representationisdepictedinfigure4.3.Thedensityofthe geopolymer bricks is increased, corresponding to the increaseincompressivestrengthofthebricks.Thereexistsa directrelationship between thecompressivestrengthand weightdensityofthebricks.Duetotheirlargesurfacearea and fineness, Fly ash and GGBS, when added to brick specimens,helpminimiseporesizeandfavourweightgain uptoaspecificthreshold.

Thefollowingconclusionsaredrawnfromtheexperimental findings,

1. Geopolymer bricksappeartobea reasonable strategy that enables the preservation of the environment, further reduction of pollutants, andadvancementtowardsgreenertechnology.

2. The green Geopolymer brick paves a way for significant industrial waste utilization for constructionproducts.

Thewaterabsorptionrepresentationinfigure4.2reveals thefactthatthegeopolymerbreaksprocessveryminimal waterabsorptionpropertywhencomparedwiththeflyash bricks.Itcouldalsobeinferredthat.Fivenumbersofbrick samples for each mix combination are tested for water absorption property determination.The waterabsorption value is very minimum for the geopolymer brick GP4 comparedwithallothertrialmixes.Thegeopolymerbricks possessadense,complicatedmicrostructureandasaresult theporesareminimizedandhencethewaterabsorptionis veryminimal.

3. Thegeopolymer brick with IDGP4possessed highest compressive strength among all the geopolymer mixes which is 2.29 times the strengthofthetraditionalflyashbricks.

4. The water absorption and weight density parameters of the geopolymer brick were within the prescribed standards of IS 3495:1992.

5. The geopolymer bricks possessed superior propertiescomparedwiththetraditionalbricks and it is one of the future technology for the construction-relatedactivities.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

[1] Apithanyasai,S.,Supakata,NandPapong,S.2020.The potentialofindustrialwaste:usingfoundrysandwithfly ashandelectricarcfurnaceslagforgeopolymerbrick production. Heliyon. Vol.6, Issue. 3, e03697:1-11. https://doi.org/10.1016/j.heliyon.2020.e03697.

[2] D. Hardjiyo and BV. Rangan, Development and properties of low calcium flyash based geopolymer concrete,CurtinsUniversity,Australia2005

[3] G.SivaChidambaram,M.Natarajan,V.Karthik,K.Vivek., “InvestigationonStrength Properties ofFlyash Based GeopolymerConcreteAndPartialReplacementofFine Aggregate With M-Sand”, Pakistan Journal of Biotechnology,ISSN:1812-1837,Vol15(4)1003-1005 (2018).

[4] IEA. 2019. World Energy Statistics and Balances (Database).Availableonline:www.iea.org/statistics.

[5] IS3495:1992.PartItoIIIMethodsoftestforburntclay buildingbricks.BureauofIndianStandards,NewDelhi.

[6] J.Davidovits,GeopolymerChemistry&Applications,2nd Ed., Chapters 15-16,Institute Ge´opolyme`re, SaintQuentin(2008)pp.333-365.

[7] LeiLiu,XiangCheng,XiwangMiao,YonglinShi,Meixia Zhang, MinGuo, Fangqin Cheng & Mei Zhang 2020, ‘Preparation and characterization of majority solid waste based eco-unburned permeable bricks’, Construction and Building Materials, vol. 259, no.120400, pp.1-11.

[8] MadihaAhmad,KhuramRashid,RizwanHameed,Ehsan Ul Haq, Hira Farooq & Minkwan Ju 2022, ‘Physicomechanical performance of flyash based geopolymer brick: Influence of pressure - temperature –time’, Journal of Building Engineering, vol. 50, no. 104161,https://doi.org/10.1016/j.jobe.2022.104161.

[9] Revathi, S & Vidhya, K 2021, ‘Eco-sustainable alkali activated brick using municipal incinerated ash’, InternationalJournalofCoalPreparationandUtilization, DOI:10.1080/19392699.2021.2007480

[10] VidhyaKumarasamy,RevathiSampathandKandasamy, S.2021. Experimental Study onHardened Mechanical andDurability Properties ofIndustrial Ash Bricks. IranianJournalofScienceandTechnology,Transactions of Civil Engineering, Vol. 46: 1929-1936. https://doi.org/10.1007/s40996-021-00783-9.