International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1,2,3 UG Student, Department of Mechanical, PVG's College of Engineering and Technology & G. K. Pate (Wani) Institute of Management, (Mechanical), Pune, (Maharashtra), India ***

Abstract - Fisheries are theprimary source of livelihood for several communities. Fishing in India is a primary industry, employing 14.5 million people and contributing to1.07%ofthetotalGDPofIndia(2020, “Fishing in India - Wikipedia). Currently, most aquaculture systems are bioflocsystemsorpondfarmingsetups.Whilewildfishing is slowly becoming unsustainable, aquaculture faces the problem of people using incorrect filtration methods, which leads to a high mortality rate. A 3-stage filtration system for freshwater aquaculture or recirculating aquaculturesystem(RAS)wasbuilttotacklethisproblem. The RAS prototype was designed to satisfy compactness, efficiency, longevity, and financial requirements. The culturetank(mainfishtank)hasacapacityof1000Land isstockedwith100fish.Thestockingdensitycomesoutto be almost double as compared to bio floc systems. The three stages of filtration are mechanical filtration, biological filtration, and ultraviolet (UV) filtration. The fishusedtotestthisprototypearemono-sextilapia(200g) (GIFT)(2019, “An Excellent Candidate Species for World Aquaculture:AReview)

must have high fish stocking densities to operate economically, and many researchers are currently conductingstudiestodetermineifRASisaviableformof intensiveaquaculture.

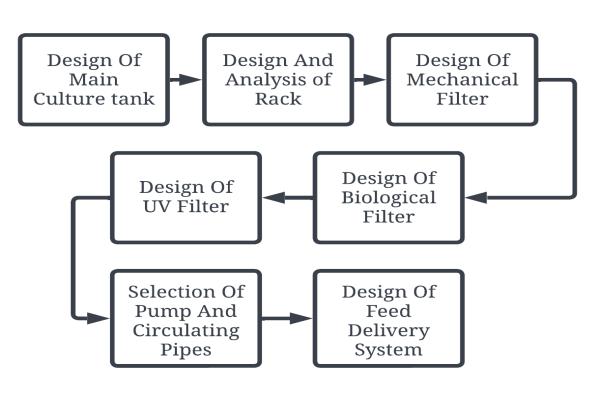

Many fish farmers are using incorrect filtration techniques for recirculating Water Filtration, which results in a high mortality rate of fish and heavy losses. This project should increase the survival rate of fish to 90%. To design and develop a three-stage water filtration system in Recirculation Aquaculture System was to satisfy the following conditions: Compactness, Efficiency, Longevity, and Economical. The final result expected from this project was the “design of a threestage water filtration system that can filter solid waste, biological waste and bacteria, and pathogens from the water.” Additionally, understanding the primary goal of thisprojectallowedittobedividedintomanytopicsand sub-topics. These new topics were mainly divided into threestagesoffiltration.ATHREE-STAGEWATER

using CAD software was designed and modeled. Using the designed parts in the CAD software, the structure of the circular tank, mesh filter, stand, and biological filter wasbuilt.

TheadvantagesoffarminginRASare:

Fullycontrolledenvironmentforthefish

Lowwateruse

Recirculating aquaculture systems (RAS) are used for fish production where water exchange is limited, and biofiltration is required to reduce ammonia toxicity. Other types of filtrations and environmental control are oftenalsonecessarytomaintaincleanwaterandprovide asuitablehabitatforfish.TheprimebenefitofRASisthe ability to reduce the need for fresh, clean water while maintainingahealthyfishenvironment.CommercialRAS

Factor value:

Efficientenergyuse

Efficientlanduse

Optimalfeedingstrategy

Easygradingandharvestingoffish

Fulldiseasecontrol

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

There are a few constraints in respect of infrastructure, feedsandstaff:

Availabilityofelectricity24/7

Goodwatersource,preferablybore-well

Good fish feed quality, preferably high protein andfatextrudeddietswithhighdigestibility

Technically skilled staff able to work in a medium-techenvironment.

Recirculating Aquaculture System is the best option for locations close to or in cities, with good availability of electricity. Next, using RAS technology is the only possibility for farming tropical fish species indoors in moderatetocoldclimates.

With a survey of the literature, the project was begun. Many RAS industries near our area were visited. The technologies already in place were investigated, and areas to lower the mortality rate of tilapia fish were optimized. In RAS industries, the mortality rate for Tilapiafishisnowcloseto12%-15%(Howell,M.,2022). In order to learn more about the RAS systems, a lot of internationalresearchpublicationswerestudied.

RAS must be built to accommodate 100 fish, and the primarytankshouldhavetherequiredvolumeofwater. Thefollowingcalculationswereperformedtodetermine the precise volume of water in the culture tank: AccordingtoPurdueUniversity,fishweighing454grams needs7.6litersofwater(ThesisandDissertationOfficePurdue University). A tank for 100 Tilapia fish was needed,andtheweightofonefishwasrestrictedto500 grams.Themaximumweightof100fishwasthus100× 0.5, or 50 kg. In light of the calculations, 8.37 liters of waterwasrequiredfor500gramsoffish.Forsafety,we considered 10 liters of water for a fish weighing 500 grams, and therefore a thousand liters figure was selected.

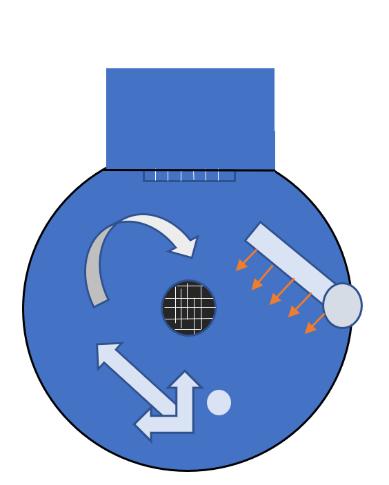

When it comes to water filtration, the water tank's designiscrucial.TheCornell-Typetank(Hydrodynamics of Octagonal Culture Tanks with Cornell-Type DualDrainSystem),inthisinstance,waschosen.Thecircular tank had an intake for tangential water flow at the top and a submersible pump at the bottom. This tank was white and covered in three defense layers against fungus.ThetankhadUVstabilizationaswell.

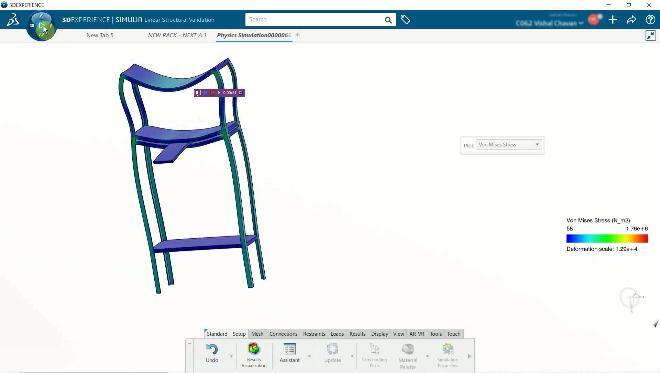

Therack,whichwill houseall threefilters,servesasthe heart of our entire RAS system. Therefore, this rack's design was essential. In the initial design phase, the maximumcombinedweightofthreefilters,aswellasthe total amount of space needed for three filters was considered.

The rack should be separated into two tiers in accordancewiththespecifications.Themechanicalfilter will be at the top level, while the biological filter will be atthelowerlevel.ExtendedroomfortheUVfiltershould be provided on the second level, maybe using a cantilever construction to move the UV filter a little bit fartherawayfromthebiologicalfilter.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

A slotted angle rack was chosen. It has four L-section slotted angles, a shelf, a nut bolt, and a reinforcing triangular plate are its four constituent parts. Now, we changed the following things to accommodate all three filters in place: The first shelf should be placed at the very top, the second one in the middle, and two additional shelves can be fastened immediately below it to create a cantilever construction. To provide the structure with stability, the final shelf is at the lowest position.

This slotted angle rack is made of galvanized iron. Whetheritcouldsustaintheweightofthreefilterswasa difficulty. To ascertain such, we performed static structural analysis. The results of the analysis satisfied our needs. To stop the structure from rusting, we additionallypainteditwithredoxideandcovereditwith blackpaint.Nowthatwehavethisrack,wecanuseitin ourtowertankdesign.

500grams whendesigning themaximumfiltrationload, thedailyfeedrequirementcomesoutto be500x0.03= 15 grams per fish. Total daily feed requirement for a hundredsuchfishis100x15=1.5kg.

Considering the food-to-waste conversion rate of 1:2, thatis,ifafisheats2kgoffood,thenitwillproduce1kg of biomass (“FAO: Feed Formulation,” FAO: Feed formulation). Thus, 1.5 kg per day of feed will produce 0.75kgofbiomass,whichneedstobecleaned.

Thisbiomassisofthreetypes:

1. Sedimentary: composed of fish waste and uneaten food that settles out when water velocity is sufficiently low.

2. Suspended: Tiny food or waste particles that are neutrallybuoyant thatis,theyneitherfloatorsinkand areinsteadtransportedbythewaterflow.

3. Dissolved: They are dissolved, largely in the form of ammonia released by the gills or created by the mineralization of fish waste. Water can contain microbiologicalcontamination.

In order to remove sedimentary and some suspended waste,ahybridsedimentationtypemechanicalfilterwas designed. It consists of an 80-liter crate, 800-micron nylonmesh,200-micronstainlesssteelmesh,40-micron stainless steel mesh, aquarium sponges, and aquarium gravel.

The recommended daily feeding rate for tilapia fish in recirculating aquaculture systems is 1% of their bodyweight ( 2019, “Tilapia RAS Farming). A daily need of 3% of their body weight was considered as a safety measure. Considering the maximum weight of fish to be

The size of the mechanical filter, which is 80 liters, was determined by keeping in mind the filtration rate per day.The800-micronmeshwassetuptofilterfishscales and uneaten food. A further 40 micron and 200-micron meshwillremovefishsuspendedbiomassandrelatively large amounts of waste. Sponges were kept to absorb dissolved biomass and relatively small amounts of suspended waste. Finally, gravel will remove any remainingsuspendedandsedimentarywaste.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Once the majority of the particles have been eliminated fromthesystem,itistimetopromoteammonificationof anyleftoversuspendedanddissolvedmaterialsinorder to turn the ammonia produced into nitrites and eventuallynitrates.

Thecolonizationofthehelpfulbacteriathatareessential to any recirculating aquaculture system is facilitated by theuseofstraightforwardbiologicalfilters.Thebiofilter exposes the leftover particulates to the nitrifying bacteriawhenthefishtankeffluentrunsthroughit.

The decision to construct a moving bed biofilter was taken, by taking into account the capacity of the culture tank, the quantity of fish, and the water flow rate throughthesystem. With16kgof bimedia,thisbiofilter canstoreupto80litersofwater.Bio-Ceramicringswere theprimarybimedia.Becauseoftheirefficiencyandcost, theirusewasthebestoption.

Awavemakerwasintegratedinthebiofiltertomakeita moving bedtypefilter, ensuring thatwhen water enters the biological filter it will bestirredaboutand will have sufficient time to react with the nitrifying and denitrifyingbacteriapresentinthefilter.Twoairstones were added to the biological filter to oxygenate the water.Thefilter'sefficacywas increasedbytheaddition ofactivatedcharcoal.

Thebiologicalfilterwasconfiguredtoacceptwaterinput fromthemechanicalfilterandoutputittotheUVfilter.

economic losses. Due to its vast number of advantages, ultraviolet(UV)disinfectionisacommonlyusedmethod for protecting the intake water supply. By causing damagetotheirDNAandRNA,UVlightrendersbacteria inactiveandstopsthemfromproliferatingandspreading illness. The product of UV light intensity, residence duration, and UV transmittance through water, the applied UV dosage (also known as fluence), which is commonly defined in terms of mJ/cm2 or J/m2, determines the capacity of UV to inactivate microorganisms. The germicidal range of 200–300 nm has strong DNA absorption, which will produce a successful initial disinfection at 254 nm (2022, “UV Disinfection System for Water Treatment - Alfaa UV). Cells have ways of repairing DNA and RNA damage. A microorganism's likelihood of undergoing photoreactivation (light-catalyzed repair) and dark space repair processes increases with decreasing UV dosage. However, using any popular UV lamp technology, there is essentially little chance for photoreactivation over a UV dosage of 15 mJ/cm2. In ordertosuccessfullydisinfecttheincomingwatertothe farm, it is essential to determine the desired UV dosage. BacteriaareoftenmoreUV-sensitivethanthemajorityof otherviruses.

In recirculating aquaculture systems (RAS), the microbiological safety of the intake water is crucial to guarantee that no diseases are introduced into the controlled environment, as it possesses a huge threat to the high value production that can lead to significant

All these requirements were taken into consideration, and a four-watt UV tube was employed. Water will be exposed to UV radiation when it passes through a UVtransparent tube on its way from the biological filter to the UV filter input. The translucent tube's length and diameter were chosen to destroy most waterborne fatal microorganisms. The tube was 0.0127 meters in diameter and 0.02 meters in length. The material of the tube was important since it needed to be both sturdy enough to withstand water pressure and transparent to UVlight.Asaresult,weusedquartzglassinthisinstance tocreateatransparenttube.Extremelypurequartzglass can withstand severe temperatures in both the visible andinfraredspectrums(QuartzGlass:WhatIsIt?HowIs It Made? Properties, Uses,” Quartz Glass). It is suitable for permanent operation at temperatures up to 1100

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

°C and even higher for brief operation due to its excellent thermal shock resistance, low coefficient of thermal expansion, and good UV light transmission behavior.

According to the design of the culture tank (Cornell type), the swirl effect causes the majority of solid waste tocollectnear the bottom ofthe tank.Asa result, water for filtration should ideally be collected from the center ofthebase.Asubmersiblewaterpumpwasusedinstead ofalteringthetankfurtherforoutput.Requirementsfor the pump were very particular as it must work in accordance with the viscosity of waste water and pump thatwaterfurther.

The pump has to be powerful, compact with substantial and rugged construction and be able to pass on the fish excreta without getting clogged. Thus an open-type pump was selected, which could readily lift the waste water without getting clogged. At least 1000 liters of watershouldbedischargedeachhourfromthepumpat a height of 2.18 meters. Due to its ability to meet all specifications, including a maximum discharge height of up to four meters and a maximum flow rate of up to 4,000litersperhour,the"SUNSUNSUBMERSIBLEPUMP HQB4500"wasselected.

Half-inch class-2 UPVC pipes were selected for the flow andconnectionpurposeduetothefollowingreasons:

Ability to maintain a 1000-liter-per-hour flow rate.

PVC pipes last a long time with a minimum of maintenance, and they are easily recyclable up to10times.

Moreover,theultra-smoothsurfaceofPVCpipes reduces pumping costs and energy use, and theirleak-freefittingseliminatewaterloss.

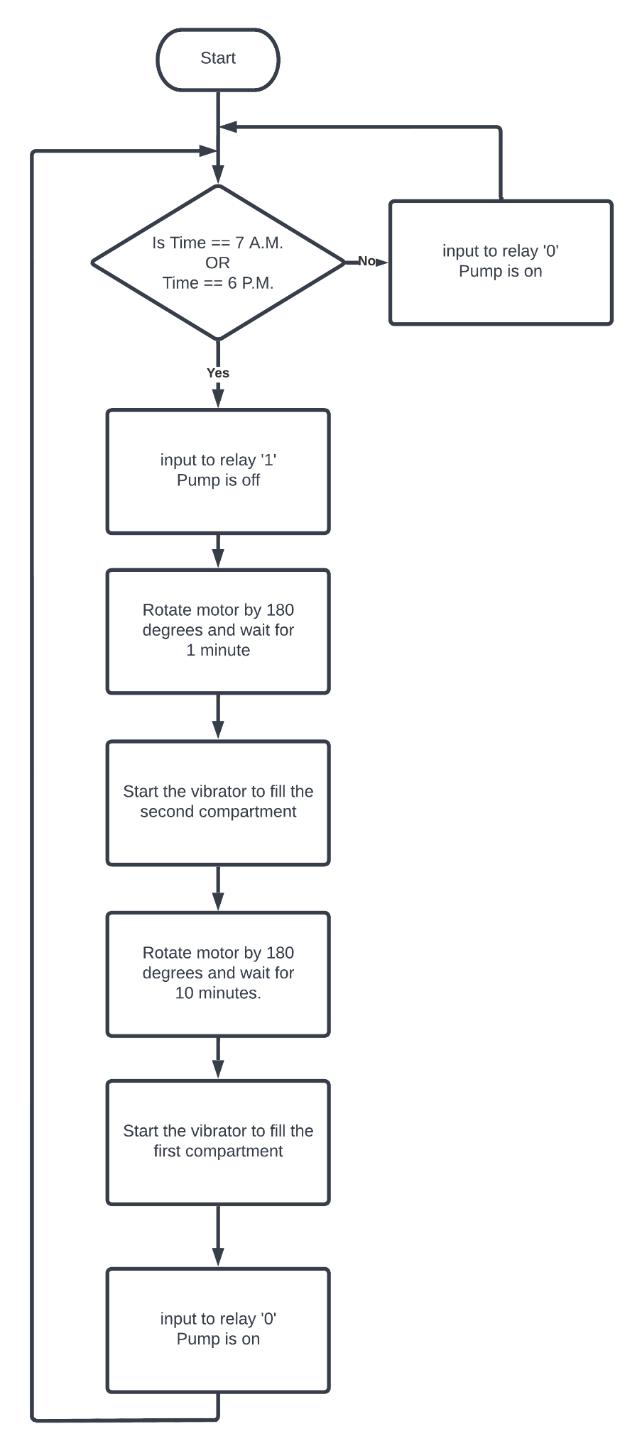

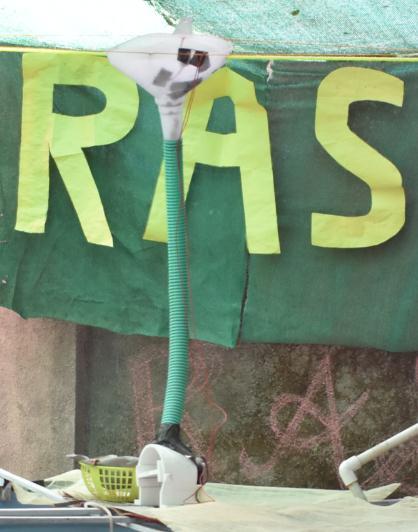

As per the calculations done during the design of the mechanical filter the 100 fish have a requirement of 1.5 kg of feed per day. An automated feed delivery system wasdesignedtominimizehumanlaboranddependency. Itincludestwocompartments;eachhasacapacityof400 grams for feed. There is a hopper (funnel) with a small vibrator at the top that can store additional feed and supply the compartments as needed. After 180 degrees ofrotation,theculturetankcanreceivestoredfeedfrom the upper compartment through a bottom aperture. Following the rotation of the compartments, feed from thehooperisusedtofillthesecondcompartment,which hasmovedtothetop,andthecycleisrepeatedasperthe feedingtimesandrequirementsofthefish.

High degree of inertness and resistance to corrosion.

Free from biofilm contamination that can be a breedinggroundforbacteria.

Because it is used below its glass transition temperature(80°C),PVCcanbeconsideredasa functionalbarrier,preventinganylowmolecular weight substances from migrating into culture tankwater.

TheexpectedlifespanofaPVCpipeis100years ormoreforundergroundpipes.

PVCwatermainsshowamuchlowerfailurerate thannon-plasticmaterials.

PVCpipeshaveclear environmental advantages over traditional materials. PVC is intrinsically a low-carbon plastic, as 57% of its molecular weightischlorinederivedfromcommonsalt.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

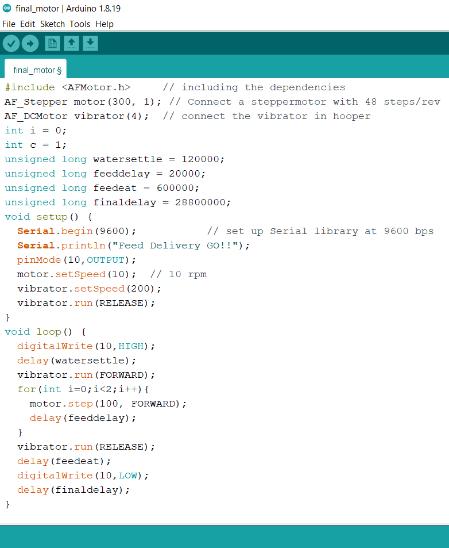

evening.Figure9showstheflowchartfortheentirefeed deliveryprocedure,andFigure10showsthecodeitself.

Fig 10:CodeforfeeddeliverysysteminArduino.cc 3.3. Manufacturing and Assembly

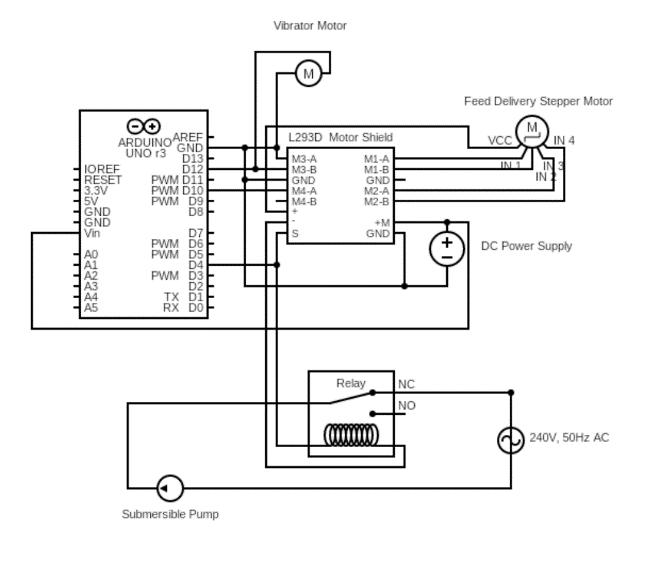

To ensure exact rotation of the compartments, NEMA17 (4.2kg/cm)steppermotorwasusedastheprimemover. Arduino Uno microcontroller (Atmega328p) along with the Arduino Motor Shield (L293D) was utilized to regulate the time-to-time motion of this motor. During feeding, the filtration system was turned off so that the fish may consume their food in peace. This was facilitatedbytheuseofamechanicalrelaymodulewhich was connected to the submersible pump to act as a switch. In one day, the compartment has to rotate four timestomeetthefeedneedsbecauseeachcompartment canonlyhold 400 grams of feed. The feed issupplied in two portions, one in the morning and the other in the

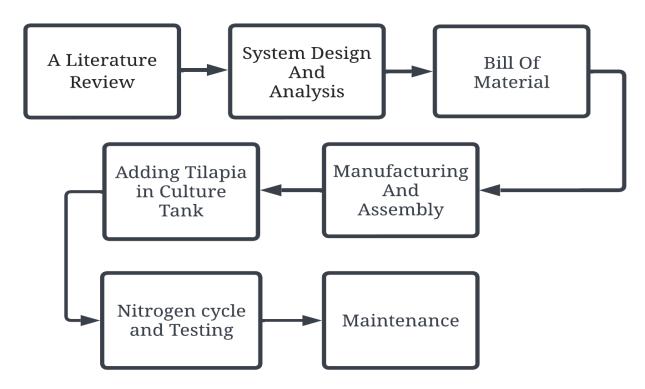

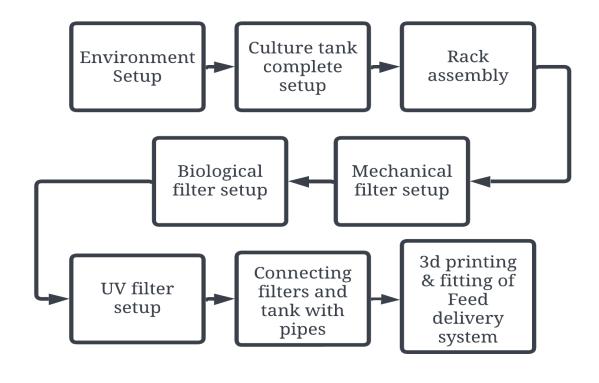

Fig 11:Flowchartfrombasicsetuptothefinalstageof manufacturing

3.3.1.

InordertosetupanRASenvironment,itisnecessaryto chooseanappropriatelocation,cleantheregion,createa temperature-controlled environment, ensure means of safeguarding the fish from predators, and make preparationsfor24-hourelectricitysupply.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

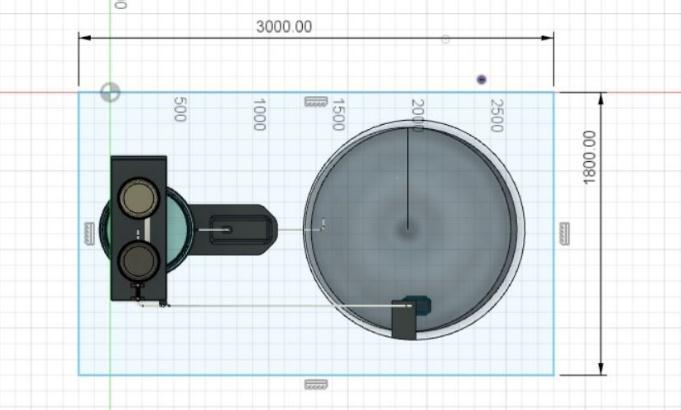

First,abasicestimateandanalysisofthesetupareawas performed. Figure 3 depicts its dimensions (in mm). A room measuring 3m x 1.8m x 2.5m was constructed using90%shadegreennet.Thisspaceallowsustokeep thesystemattherighttemperaturewhileprotectingthe setupfrommostpredators.

Fig 14:Modificationoftankbyremovalofuppersection andpaintingitwhitetomaintainthesystem temperature

After adding 1000 liters of water, 200 milliliter of dechlorinator liquid was added to the water in order to eliminate the chlorine & chloramine content present in water making it suitable for fish. Culture tank was covered with the 800-micron nylon net as a protection againstbiologicalcreaturesandwastessuchasbirdsand leaves considering the requirement of the right amount ofsunlight.

The tank type chosen above (Cornell-Type Tank (Hydrodynamics of Octagonal Culture Tanks with Cornell-Type Dual-Drain System)) was realized by converting a 1500-liter tank into a culture tank by removing its top cover. Perimeter reinforcement was provided using plywood strips to bolster lateral tankwall strength. Additionally, the exterior of the tank was paintedwhite,toarrestfungusgrowthandtomaintaina cool temperature inside. The central-base area housed the submersible pump with an exclusion screen. Two air-pumpswiththreeair-stoneswereaddedtothemain tank,whichensuredthatthewaterhadenoughoxygen.

Fig 15:Settingupexclusionscreenatwaterinletandair pumpsintothetankandcoveringitwith800-micron nylonnet

Aslottedanglerackhasfourmaincomponents:G.Isheet shelves, reinforcing triangular plate, L-section slotted angles and nut-bolts (fasteners). To satisfy the requirements of the placement of the three filters, a cantilever structure was created in such a way that the first shelf was attached at the very top, the second and third in the center, the fourth shelf towards the bottom of the structure to provide stability. The fifth and last

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

shelf was fixed in between the second and third shelf, forminga cantileverstructurecapableof supportingthe ultravioletfiltrationunit.

Water from the main tank was pumped into the mechanical filter using the submersible pump. It flows through the 800 200 40-micron mesh filter arrangement. The gravel and sponges at the bottom provide additional filtration via sedimentation of the waste particles. The bottom of this container offers gravel,whichrestsontopofthespongesthatrestontop of a raised surface. The outlet of the filter is situated below the sponges, ensuring that the water passes through every stage of the filter before it can exit. The mesh arrangement guides the water through the 800micron mesh, the 200-micron mesh, and the 40-micron mesh in this order respectively. Sizable metallic paper clips were used to secure the entire arrangement to the cratewalls.

The output of the mechanical filter was in the form of two half-inch holes drilled into the bottom of the sidewallofthecrate.UPVCpipescarriedthefilteredwaterto the biological filter for further treatment. In order to prevent gravel from exiting the mechanical filter, an additionalexclusionscreenwasprovidedatthetwohalfinchoutlets.

A 200-liter HDPE barrel was altered to make the biological filtration unit. The upper one-third portion wascutoffandtheperipherywascoveredwitharubber coating as a safety measure. A half-inch hole in the side of the barrel provided an exit for water. The outlets of the mechanical filter drop down to the bottom of the barrel. After adding 16 kg of bio-ceramic rings, the biologicaltankwasfilledwithwateruntilitjustreached the exit hole. A wavemaker was placed at the bottom of thebarreltofacilitatetangentialflow.Activatedcharcoal was added in the biological filter to reduce the smell of water as well as to improve color (2013, “Advances in PretreatmentandClarificationTechnologies).

Fig 18:Removingexcesspartofthetankand introducingbiomediaforsettingupthebiologicalfilter

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

To prevent water leakage, "PVC cement solvent" was usedtoconnectthepipes.Allinnersurfacesofthejoints were coated with the cement solvent to ensure zero leakage.Supports wereplaced where possibleto reduce theoverhangsinpipes.

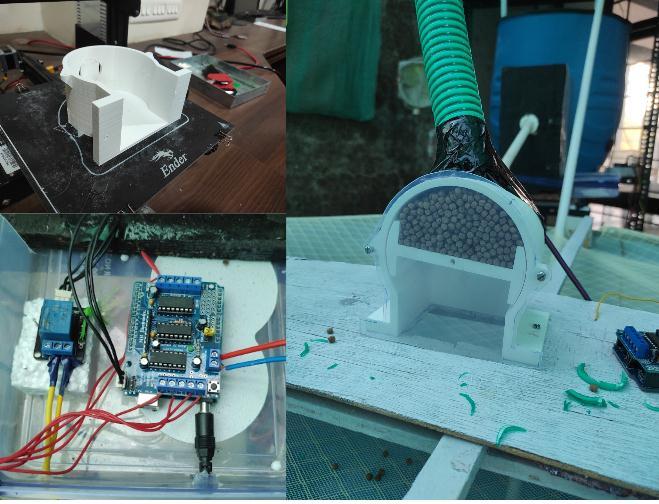

A wooden shell was created to house all the UV filter components (a two-side open cuboid). The position of theUVfilterhastobeattherightheightandangletofit between the biological filter and the culture tank. PLA (poly-lactic acid) connectors with the required hole inclinationweredesignedand3DprintedontheEnder-3 3D printer. These connectors were used to connect the UV filter pipe and PVC pipe coming from the biological tank. To fit the quartz tubes into the connector, little UPVC pipes were connected to the ends of the tubes usinghoseclips.Withthisconfiguration,the4WUVtube wasattachedtocompletetheUVfilter.

Fig 21:EntiresetupofRASsystem

3.3.8. 3D printing and fitting of feed delivery system

The automatic feed distribution system was designed and realized using the Ender-3 3D printer using PLA (poly-lactic acid). The stepper motor and the delivery flapwereinstalled.TheArduinoUnoboardwasstoredin a box, coated with plastic wrap, along with the L293D stepper motor driver and a relay module. A one-inch cross section pipe was used to provide a pathway for feedtotravelfromthehoppertothecontainer.

Fig 20:ManufacturingofUVfilterusingconventional methodsaswellasmodernCADprocess

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

formation which would check the capacity of filters at the fullest. Salt water was introduced to the fish transportcontainer.Asosmosisattemptstoequalizethe saltcontentoneachsideofasemipermeablemembrane, water is drawn out of the bacterium, fungus, and/or parasite's membrane or skin. Because the fish have greater water reserves and mass, the infections eventually succumb before their hosts do. Floating excreta was observed after a day because of sudden environment change while transferring fishes into tank and changed feeding conditions indicating the gases problem in fish. Metrogel-500 tablet was given along with the 4 days of starvation period and the gases problem was cured. Fish cornering the tank was observedonceortwiceindicatingthelessoxygensupply andhigherammonialevels.20%waterchangewasdone for immediate reduction of ammonia. Extra air pump wasintroducedforimprovingDOlevelinsidethetank.

For the purpose of validating our RAS system, 100 fish, eachweighing200gramswereintroducedtothesystem. Considering the time constraint fingerlings of tilapia were not used as they take time to grow up. 200g adult fish were the choice considering the extreme waste

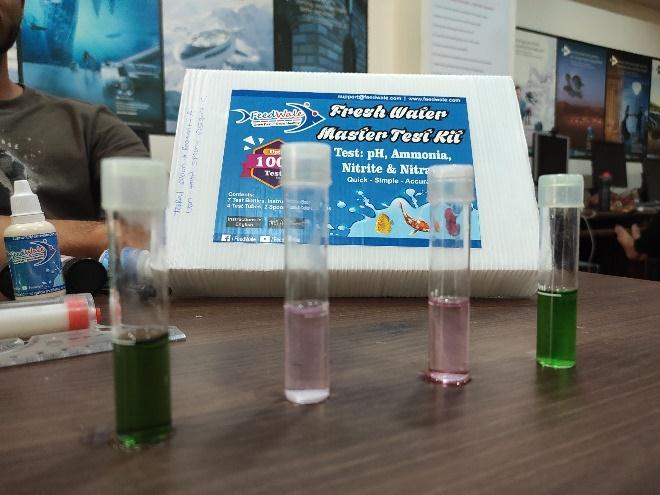

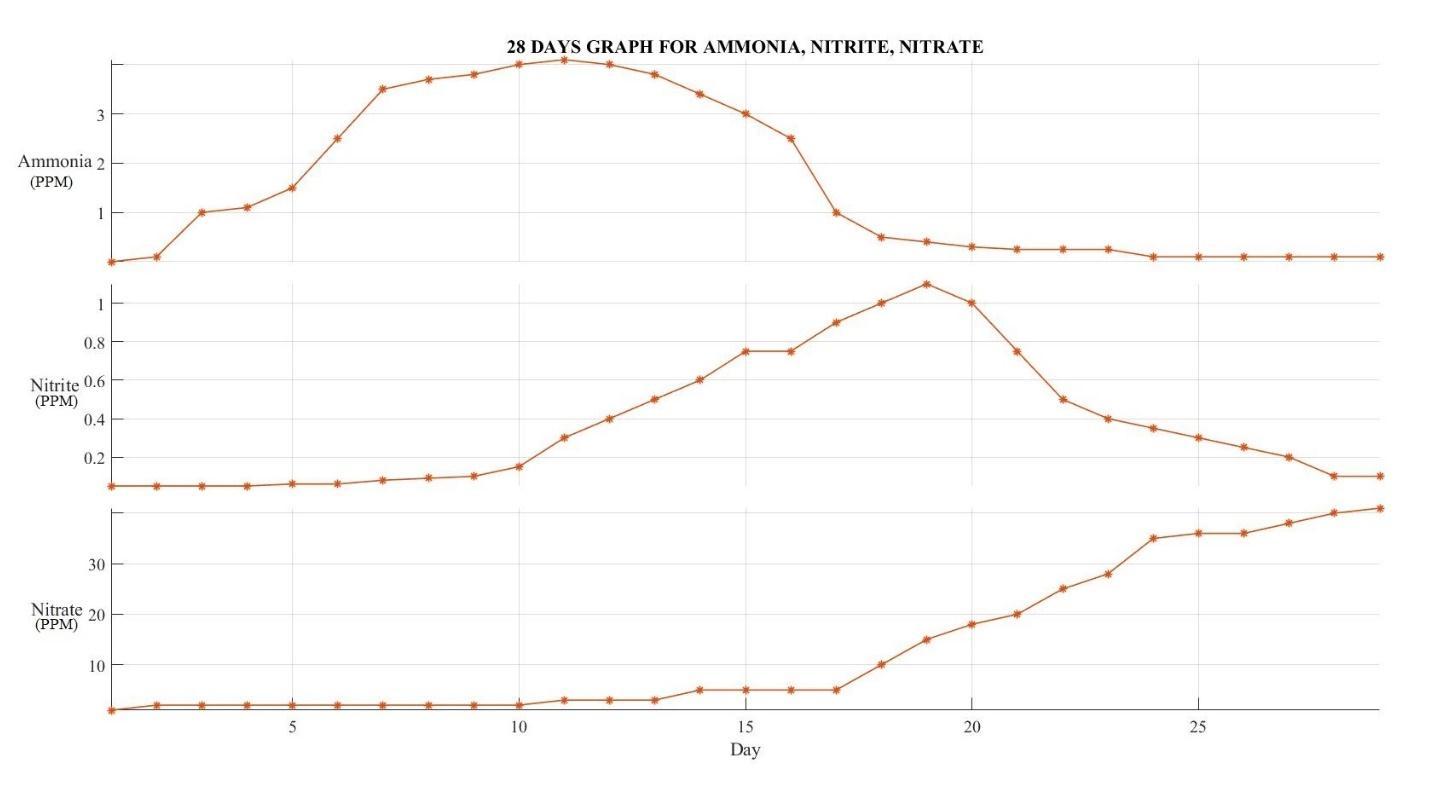

Thenitrogencycleisnecessaryforanybiologicalfilterto function. It was initiated just before the introduction of the fish. In order to reduce the cycle time, "Re-ocean Starter Bacteria", a ready to use bio-culture, was introducedtothe biofilter. Ourentire nitrogencyclecan bedividedintothreephases:(PPM)

PhaseOne(from1to10days):

Fishwasteformsammonia,whichishighlytoxictomost fish.Ammonialevelsbeganrisingfromday2.

PhaseTwo(from11to18days)

As nitrite-forming bacteria (Nitrosomonas) developed, ammonia was converted to nitrite, and while ammonia levelsdecreased,nitritelevelsincreased.

PhaseThree(from19to28days)

As nitrate-forming bacteria developed (Nitrobacter), nitrite levels decreased, and nitrate levels increased.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

When nitrates were produced, and ammonia and nitrite levels were zero, indicating that the tank was fully cycled, and the biological filter was fully functioning. At lowlevels,nitratesarenothighlytoxictofish.

Fig 28:28Daysgraphforammonia,nitrite,nitrate

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

entiredevice byallowingus tomaintain the wateratan ideal temperature for fish growth as well as the biofiltration.

The design of the mechanical filter can be optimized to allow it to run for longer periods without the need of maintenance. Self-Cleaning mechanisms can be incorporatedtoreducemanpowerdependency.

In a culture tank, hydroponics might be utilized to produce plants that provide fish food while simultaneouslyloweringammonialevels(Aquaponics,G. G., 2022). The plants would provide the biofilter with additional surface area for the colonization of the bacteria.

Different mechanical and biological filter types were researched,andtherightfilterunitswereputintoplace.

Maintenance included water exchange, topping up feed, cleaningmechanicalfilters,andregularinspection.Inthe summer, water has to be replenished more frequently than every two weeks due to increased evaporation. Every two days, cleaning was required for all three meshesandspongesinthemechanicalfilter.

Introduction of temperature control devices and temperature sensors will improve the efficiency of the

The primary objective of this project was to design and develop a three-stage sustainable water filtering system for freshwater aquaculture. The whole RAS system was designed, manufactured, verified, and maintained in accordancewiththestructuralcriteria.

Ideation, market survey, product definition, design, prototyping and testing, were the product development stagesfollowedduringthecoursetime.

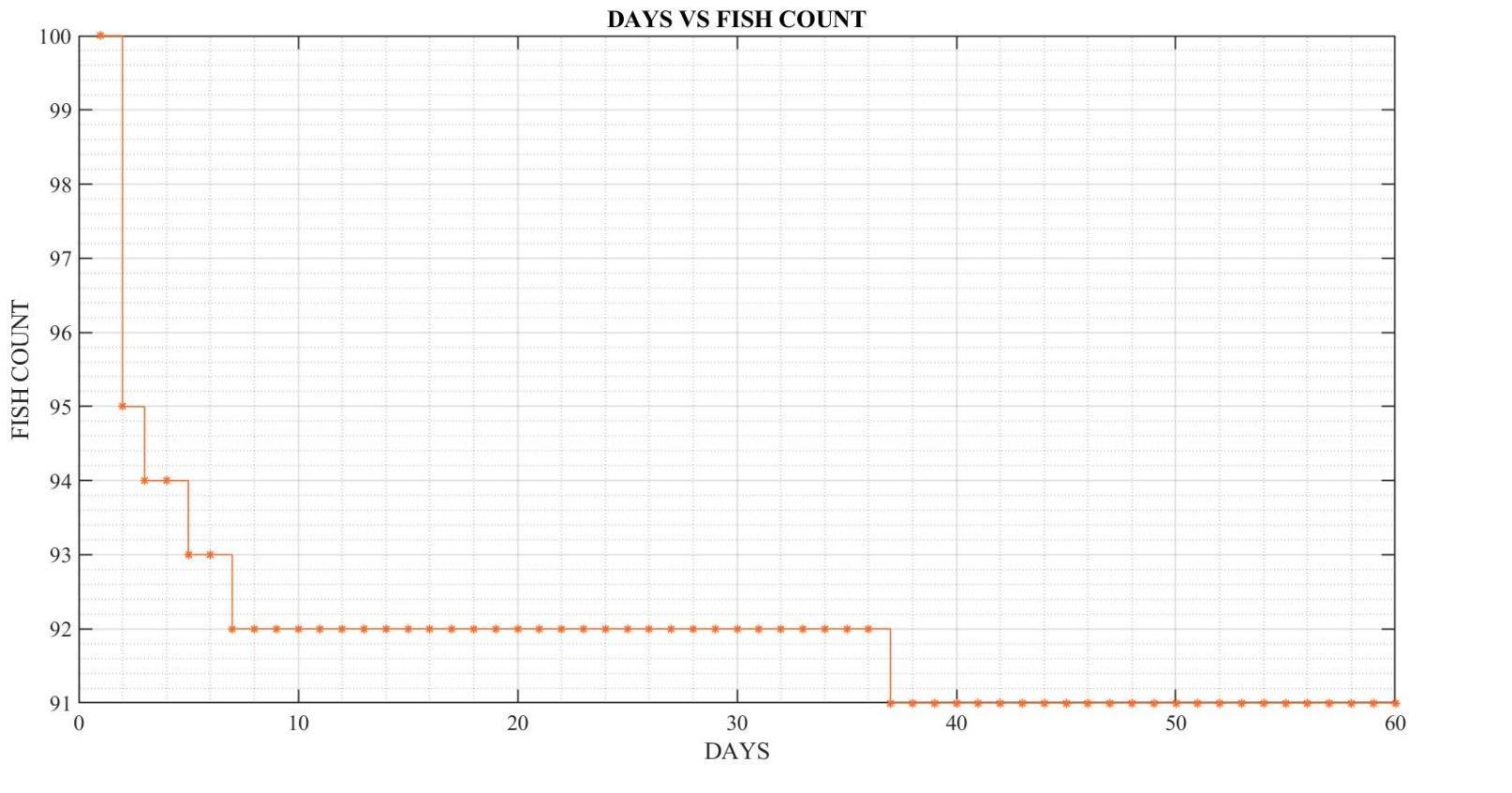

Remarkable success in lowering the death rate - 91 fish werestillaliveaftersixmonths.Inotherwords,wewere abletolimitthemortalityrateto10%.

Fig 30:FishvsDayscountgraphshowinghighmortalityatthebeginning andnomortalitiesafterwards

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Ethicsapproval (2020Reportinganimalresearch)

This article does not contain any studies containing animals performed by any of the authors. For clarification purposes, all procedures performed in the study were in accordance with the ARRIVE guidelines 2.0andafullauthor'schecklisthasbeensubmitted.

Funding

Theauthorshavenorelevantfinancialintereststodisclose. Authorcontribution

All authors contributed equally to the study conception,

design, analysis, results interpretation, and manuscript drafting.

[1]2020,“FishinginIndia-Wikipedia,”Fishingin India - Wikipedia [Online]. Available: https://en.wikipedia.org/wiki/Fishing_in_India#Referen ces.[Accessed:3-Jan-2022].

[2] Howell, M., 2022, “RAS May Not Be the Tilapia Industry’sPathtoProfit|TheFishSite,”RASmaynotbe the tilapia industry’s path to profit | The Fish Site [Online]. Available: https://thefishsite.com/articles/rasmay-not-be-the-tilapia-industrys-path-to-profit-ganeshkumar.[Accessed:6-Jan-2022]

[3] Graduate School, A. B. P. U., “Thesis and Dissertation Office - Purdue University,” Thesis and Dissertation Office - Purdue University [Online]. Available: https://www.purdue.edu/gradschool/research/thesis/ [Accessed:16-Oct-2022].

[4] Gorle, J. M. R., Terjesen, B. F., and Summerfelt, S. T., 2018, “Hydrodynamics of Octagonal Culture Tanks with Cornell-Type Dual-Drain System,” AGRIS: International Information System for the Agricultural Science and Technology [Online]. Available: https://agris.fao.org/agrissearch/search.do?recordID=US201800260705 [Accessed:6-Jan-2022].

[5] 2019, “Tilapia RAS Farming (Recirculating Aquaculture System) | Agri Farming,” Agri Farming [Online]. Available: https://www.agrifarming.in/tilapiaras-farming-recirculating-aquaculturesystem#:~:text=Tilapia%20fish%20generally%20are% 20fed,can%20seriously%20degrade%20water%20quali ty.[Accessed:6-jan-2022].

[6]2022,“UVDisinfectionSystemforWaterTreatmentAlfaa UV,” Alfaa UV [Online]. Available: https://www.alfaauv.com/blog/uv-disinfection-systemwater-treatment/.[Accessed:6-Jan-2022].

[7]“QuartzGlass:WhatIsIt?HowIsItMade?Properties, Uses,” Quartz Glass: What Is It? How Is It Made? Properties, Uses [Online]. Available: https://www.iqsdirectory.com/articles/glasscutting/quartz-glass.html.[Accessed:16-Jan-2022].

[8] 2013, “Advances in Pretreatment and Clarification Technologies,” Advances in Pretreatment and Clarification Technologies ScienceDirect [Online].Available: https://www.sciencedirect.com/science/article/pii/B9780 123821829000293 [Accessed:6-Jan-2022].

[9] Aquaponics, G. G., 2022, “Aquaponics and Hydroponics: What’s the Difference? - Go Green Aquaponics,” Go Green Aquaponics [Online]. Available: https://gogreenaquaponics.com/blogs/news/hydroponi cs-with-fish-and-aquaponics [Accessed:7-Jan-2022].

[10] “FAO: Feed Formulation,” FAO: Feed formulation [Online]. Available: https://www.fao.org/fishery/affris/speciesprofiles/nile-tilapia/feed-formulation/en/. [Accessed: 7Jan-2022].

[11] Percie du Sert N, Ahluwalia A, Alam S, Avey MT, Baker M, Browne WJ, et al. (2020) Reporting animal research: Explanation and elaboration for the ARRIVE guidelines 2.0. PLoS Biol 18(7): e3000411. Available: https://doi.org/10.1371/journal.pbio.3000411 [Accessed:16-Oct-2022]

[12] 2019, E. Prabu1, C.B.T. Rajagopalsamy, B. Ahilan, I. JeganMichaelAndroJeevagan1andM.Renuhadevi(2019), “Tilapia – An Excellent Candidate Species for World Aquaculture: A Review,” Annual Research & Review in Biology [Online], Available: https://journalarrb.com/index.php/ARRB/article/view/3 0052[Accessed:6-Jan-2022]

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page919