1

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

2

Abstract - An Abstract - Soil stabilization is done to improve its engineering performance such as shear strength, compressibility and permeability. Soil stabilization may be physical, chemical, biological or combined methods to meet an engineering purpose. Soft clay is a problematic soil from civil engineering construction point of view. To make them more feasible to construction purposes, numerous materials have been used. In this paper stabilization of clayey soil using Nylon Fibre and Sugarcane Bagasse Ash was evaluated. Experiments were conducted on soil treated with Rice Husk Ash only and soil treated with both Sugarcane Bagasse Ash and Nylon Fibre. The methodology used was first to find out the optimum Sugarcane Bagasse Ash that can be utilized in untreated soil. Further various percentage of Nylon Fibre (1.0, 1.5 and 2.0) was added at various Sugarcane Bagasse Ash percentages (15, 20, and 25) and the optimum was found out. The optimum percentage was obtained from standard proctor test, and the strength was obtained from unconfined compressive strength test and California bearing ratio test. The optimum percentage of Nylon Fibre and Sugarcane Bagasse Ash was obtained as 1.5 and 20% by weight of soil, respectively. Result of optimum percentage on unconfined compressive strength,California bearing ratio test and plasticity characteristics of treated soil were determined over a curing period of 1 day and 7 days. The strength of soil stabilized with Nylon Fiber and Sugarcane Bagasse Ash was found to be improved, and the strength of treated soil was more in the case of combination of Sugarcane Bagasse Ash and Nylon Fibre.

Words: Sugarcane Bagasse Ash1, Nylon Fibre2,CBR test3 , UCS test4

Expansivesoilsarethesoilswhichhavehighshrinkageand swellingcharacteristicsandlowerstrengthwhenitcamein contact with water. These soils are very sensitive to variations in water content and show excessive volume changesandhashighcompressibility.Thishighlyplasticsoil maycreatecracksanddamagetheconstructionworkdone abovethesetypeofsoils.

InIndia,expansivesoilcoversnearlyabout20%oftheland andincludesapproximatelytheentireDeccanPlateau.They

are mostly black and reddish brown in colour and are generallyfoundwithlayerthicknessbetween0.5mto10m below the surface. Because the expansive soil is prone to volumechanges whenitcameincontactwiththewaterby rain or water table capillary action, it will get expand and maycauseliftingofthestructuresbuiltoverit.So,thesesoils are not suitable for construction works until they are properly stabilized which can increase the low bearing capacityofexpansivesoils.

InIndia,nearly46%oftotallandiscoveredbyAlluvialsoil whichisthemostimportantsoiltypeoforcountry.Other soilssuchasBlackcottonsoil,desertsoil,lateritesoiland marinesoilarealsotheimportantsoilgroupsofIndia.The Alluvialsoilandtheblackcottonsoilmainlyconsistsofclay which is very fine soil and it’s the main constituent of expansivesoilsandduetothecohesivenatureofclay,these soils absorb large amounts of water and show swelling characteristicswhichcreateproblemssuchasbulgingofsoil, low bearing strength of soil, and can cause cracks in the foundations

Al.-Jaberi et al. (2017) In their study, they improved the properties of poor subgrade soil using Cement Kiln Dust.TheyinvestigatetheeffectsofCKDonthepropertiesof the poor subgrade soils using CBR testing method with different doses of CKD (5%, 10%, 15%, 20%, 25%, and 30%bythedry weight of the selected soil) in combination withdifferentcuringperiods(1day,3days,7days,14days, and28days).Theyconcludedthattheoptimumamountof CKDtobeusedis20%andtheoptimumcuringperiodfor thiscametobe14days.

Keerthi et al.(2017)Thestabilizationofclayeysoilisdone usingCKD.InwhichtheCKDproportionsisvariedfrom0to 50% by weight of soil. In their study, it is found that the UncomfinedCompressiveStrengthofsoilisincreasedwhen CKD is added 50% as compared to 0% CKD. They also concluded that the optimum quantity of CKD for light applicationsisvariedbetween12-30%howeverforheavy applications,CKDcontentofupto50%canbeused.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Rokade et al. (2017)Additionofnylonfibrealongwithfly ash to measure the change in the strength parameters of black cotton soil. The CBR of the soil was determined by conductingthreeseriesoftests.Testswerecarriedouton theBCsoilmixedwithvaryingpercentageofflyash,from 10% to 40% out of which 20% came out to be optimum Then,nylonfibrewithaspectratios(length/diameter)20, 40,60and80andfibercontentswerevariedfrom0.25%to 1.5% with 0.25% interval, out of which 0.75% of fibre contentisconsideredasoptimumonthebasisofMDDand maximumCBRvalue.

Mahesh et, al.(2016)Soilstabilizationisusedtoreducethe permeability and compressibility of the soil mass in earth structures and to increase its shear strength. Soil stabilizationisrequiredtoincreasethebearingcapacityof foundationsoils.However,themainuseofstabilizationisto improvethenaturalsoilsfortheconstructionofhighways and airfields. CBR value is high at 10% lime + 1.5% fiber whencomparedtotheremainingproportions.CBRvaluefor (soil +10% lime) and (soil + 40% lime) is same. CBR graduallyincreaseswithincreaseinfibersupto2%(soil+ 5%lime).

Wang et al.(2016)`TheUnconfinedCompressionStrengthof expansive soil is very less without the addition of certain additiveswhichcanincreasetheirstrength.CKDwaschosen toaddinvariousproportions.2,4,6,8,10,12,14,16,18,20%of CKDwastheproposedquantity.TheUCSvaluerisestill10% CKD content after that when CKD quantity is further increased, the value of UCS started to decline gradually. Whichconcludedthat10%istheoptimumvalueofCKDat thecuringperiodof28days.

Tiwari et al.(2016)Theystudiedthestabilizationofblack cottonsoilusingflyashandnylonfibre.Intheirstudy,they useddifferentcombinationsofflyashas10%,20%,30%& 40%. 20% was their optimum value. After which they calculated the optimum value of nylon fibre from various valuesas0.25%,0.50%,0.75%,1%,1.5%.Fromwhich0.75% nylon fibre comes to be the optimum. The CBR value of soil+20% fly ash+0.75% fibre was maximum of all other readings. And the MDD was also maximum of this mix proportion.

Phanikumara et al. (2013)Thispaperpresentstheswellconsolidation characteristics of remoulded expansive clay specimens reinforced with randomly distributed nylon fibre.Inthecaseofnylonfibre,thelengthofthefibre(l)was variedat15mmand20mm.Asthediameterofthefibres was1mm,theaspectratioofthefibresusedwasequalto15 and 20, respectively. The fibre content (fc) used in the testingprogrammewasvariedat0%,0.05%,0.1%,0.15%, 0.2%,0.25%and0.3%bythedryweightofthesoil.Their resultshowsthattheswellpotential(S%)andthevertical swelling pressure also decreased with an increasing fibre content (fc) for a given fibre length. & thesecondary compression decreased with an increasing length of fibre.

Thevalueofthesecondaryconsolidationcoefficient(Cα)for fibre-reinforced specimens was less than that for the unreinforcedspecimen.

Ismaiel et al. (2013)This work dealt with a chemical stabilizationofanexpansivehighplasticsoilofusingcement kiln dust (CKD) and cement kiln dust with lime (CaO) to reduce their swelling and improve their geotechnical properties.Varioustestswereconductedsuchasplasticity tests, compaction test, Unconfined Compressive strength test.Accordingtothetestresults,optimumcontentofthe cementkilndustwas16%(CKD)&Theoptimumcontentof thecementkilndustwiththelimewas14%(CKD)with3% (Cao).

Praveen et al. (2011)Studied the effect of Polypropylene fibre on CKD stabilized soil. The soil they used is Black cottonsoilandthevariousproportionsofCKDwere3%,5%, & 8%. The proportions of PP fibre were taken as 0.25%, 0.50%&1%.UCStestandCBRtestwereconductedandthe valueofbothUCStestandCBRtestwasmaximumatCKD contentof8%andfibrecontentof1%.Sothisproportion wasconsideredtobetheoptimum.

Kameshwar Rao Tallapragada et al.(2009)Theirworkis undertaken to research the benefits of fiber reinforced subgrade. They used two fibres: nylon fibre and monofilament.ThemaintestsperformedwereCBRtest & UCS test to check the strength. Three proportions were preparedas0.75%,1.5%&2.25%.TheirresultshowsCBR valueofBlackCottonsoilalsoincreasesconsiderablydueto additionofthefibersinsoil.FromUCStestitwasfoundthat Maximum Stress value of soil increases with increasing aspectratioofnylonfibre.

Section 2.1- Sugar Cane Bagase Ash and Nylon Fiber as stabilizer

Sugarcanebagasseash(SCBA)isanabundantbyproductof thesugarandethanolindustry.SCBAisgenerallyusedasa fertilizer or is disposed of in landfills, which has led to intensified environmental concerns.Inrecentyears,SCBA research has mainly been focused on utilization in constructionmaterialsduetotheabundanceandpozzolanic characteristics of SCBA. In this paper, a comprehensive review of the state-of-the-art morphology, physical properties, chemical composition, and mineralogical compositionofSCBAispresented.StudiesindicatethatSCBA is a potentially promising construction material. The applicationsofSCBAasapozzolanicmaterial,anewsource forpreparingalkali-activatedbinders,aggregates,andfillers inconstructionmaterials,aresummarized.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

theoptimummixshouldalwaysbehigherthanpure soil.

[3] California bearing ratio test is conducted to calculateCBRValuesatdifferentproportionswith material [4] Unconfinedcompressionstrengthtestisconducted to calculate UCS Values at different proportions withmaterial

Table-1: Propertiesofsoilused

Nylonisapolymerdevelopedtoreproducethepropertiesof nylon66.Itisasemicrystallinepolyamide.Nylon6fibres are tough, possessing high tensile strength, as well as elasticityandlustreandhasexcellentabrasionresistance. Nylon6isgenerallywhitebutcanbedyedtoinasolution bath prior to production for different color results. Nylon fibreisusedinsoilstabilizationtoincreasetheloadcarrying capacityofsoilbythefrictionalinteractionbetweenthesoil andthereinforcementanditshouldberandomlymixedwith soil in proper proportions.Nylon fibre has good elasticity behaviours and it is highly resistant to abrasion and temperaturesoitcanbeusedinhightemperaturesalso.The aspectratioofnylonfibreie.L/Dratiooffibreisthedeciding factorforthesizethatistobeused.

The present project can serve as an effective method to utilizeindustrialwastesSugarcaneBagasseAshandNylon Fibreintheconstructionoflowcostruralroadsandstabilize the subgrade of pavements where the soil is expansive in nature. These various tests needs to be carried out on samplesselectedforstudy:

[1] LiquidLimittestandplasticlimittestneededtobe performed with the help of Cassegrande’s Apparatusfirstonvirginsoilandthenthevarious proportionsofthemix.ThePlasticityIndexofthe Optimum Mix should be always less than that of virginsoil.

[2] Standard Proctor Test is carried out to calculate Optimum Moisture Content (OMC) and Maximum Dry Density (MDD) of virgin soil which is then comparedtoMDDofmixproportions.TheMDDof

Table-2: PropertiesofSugarcaneBagasseAsh Table-3:PropertiesofNylonFibre

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

The soil used in this project was collected from local soildeposits in jammu. Then the soil is prepared by doing sieveing with 4.75mm sieve, the quantity retaining on 4.75mm sieve is taken out of the sample soil and the soil passing4.75mmsieveisoverdriedwitha temperature of 105℃for24hours.Allthelumpsifpresentinthesoilwere clearedwithhammer.

Testsconductedinthelaboratoryfordifferentobjectivesare asfollows:

[1] LiquidLimitTest(Casagrande’smethod)

[2] PlasticLimittest(Threadmethod)

[3] StandardProctortest(OMCandMDD)

[4] CaliforniaBearingRatiotest

[5] UnconfinedCompressionstrengthtest

Differentproportionsofdifferentmaterialswereusedinthe project work. Sugar Cane Bagasse Ash was 10%, 20%, & 30% and Nylon fibre used was 1%, 1.5% & 2.0% Now, S=Soil,SCBA=SugarCaneBagasseAsh,N=Nylonfibre

Section:1-StandardProctorTest

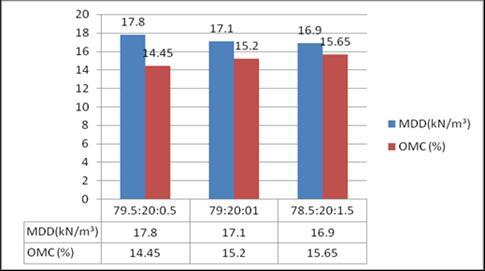

Table no:4- ResultsofOMCandMDDformixproportions ofSoil,SCBAandNylonFibre

SOIL:SCBA:NYLON FIBRE MDD(kN/m³) OMC (%) 795:20:05 1780 1445 79:20:1 17.10 15.20 785:20:15 1690 1565

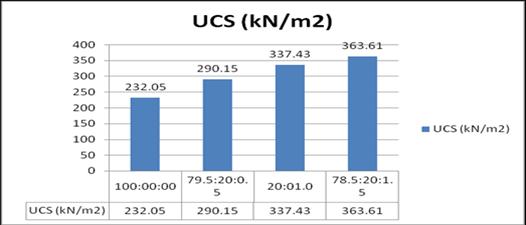

Section-2:UnconfinedCompressionStrengthTest

Table-5:ResultsofUCSofSugercaneBagasseAshand NylonFibreMixwithSoil

Clayey Soil :SCBA: N.F Curing Period (Days) UCS (kN/m2) 100:00 7 232.05 79.5:20:0.5 7 290.15 79:20:10 7 33743 785:20:15 7 36361

Chart-1:variationsb/wMDDandOMCofSCBA,Nylon Fibre&soilwithdifferentproportions

proportions

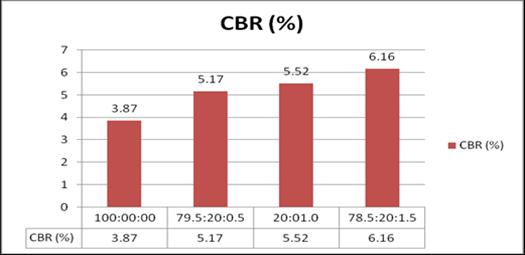

Section-3:CaliforniaBearingRatioTest

Table-6: ResultsofCBRofSugarcaneBagasseAshandNylon

Chart-2: Variationsb/wUCSValuesofClayeysoil, SugercaneBagasseAshandNylonFibrewithdifferent FibreMixwithSoil.

CS: SCBA: N.F CBR (%) 100:00:00 387 795:20:05 517 79:20:1.0 5.52 785:20:15 616

Chart-3: Variationsb/wCBRValuesofClayeysoil, SugercaneBagasseAshandNylonFibrewithdifferent proportions

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

•AnincreaseofOMCfrom13.6to15.10% anddecreaseof M.D.D. from 18.25 to 17.10% when the percentages of Sugercane Bagasse ash are used as 15%, 20% and 25% respectively.

•ThereisanalsoincreaseofOMCfrom13.6to15.20% and decrease of MDD from 15.14 to 14.55% when the percentagesofNylonFibreareusedas1.0%,1.5%and2.0% respectively.

•ThereisanalsoincreaseofOMCfrom14.45to15.65%and decrease of MDD from 17.80 to 16.90% when the percentagesofNylonFibrevaryfrom 0.50%,1.0%and1.5% andSugercaneBagasseashisfixedat20%.

•SpecificgravityofSugercaneBagasseashislowerthanas comparedtosoil.SoMDDisdecreasedandOMCisincreased.

•There is an expansion in OMC when the amount of Rice husk ash is expanded. The purpose for of this pozzolanic response of Rice husk powder with soil that needs more waterforcompletionofcationtraderesponse.

•With Sugercane Bagasse ash kept constant at 20% MDD decreaseswithanadditionofNylonFibrecontentinsoiland Sugercane Bagasse ash mix. The reason behind of such behaviorisSugercaneBagasseashislighterinweightandit hashighwaterabsorptionpropertiesbecauseofpresenceof calcium oxide and hence OMC increases with increase of SugercaneBagasseashcontent.

•PresenceofpozzolaniccompoundsinSugercaneBagasse ash and CaOH available in soil might be increase the CBR valueduetoformationofcementitiouscompoundsinsoil. Due to excess of Sugercane Bagasse ash in soil ultimately occupies spaces within sample because of this Sugercane Bagasseashcouldnotbemobilizedforthereactionat20% ofSugercaneBagasseashinsoil.

•TheCBRvalueofvirginsoilis3.87anditincreasesto1.31 times with addition of 20% Sugercane Bagasse ash when observedinsoakedconditions.Thisenhancementisbecause ofbindingactionofSugercaneBagasseash.

•TheCBRvalueofvirginsoilis3.87anditincreaseto1.59 times when Sugercane Bagasse ash 20% and Nylon Fibre 1.5%isaddedtovirginsoil.ThisenhancementinCBRmay bebecauseofthegradualformationofhydrationcompounds inthesoilduetothereactionbetweenthestabilizersandthe essentialsparticlepresentinthesoil.

•UCS value of virgin soil enhances fundamentally with expansionofSugercaneBagasseashcontents.TheUCSvalue increment from 232.05kN/m² to 312.73kN/m² with expansionofSugercaneBagasseashupto20%inthewakeof curing time of 7 days. U.C.S. value decreases with more expansionofSugercaneBagasseash.TheexpansioninU.C.S. valuemightbeadirectresultoftheslowadvancementofthe cementitious mixes in the soil by the response between pozzolanic mixes in Sugercane Bagasse ash and CaOH accessibleinsoil.

•The UCS values of virgin soil also improves considerably with expansion of Sugercane Bagasse ash 25% and Nylon Fibre 1.5%. The value increases from 232.05kN/m² to 363.61kN/m²withadditionofSugercaneBagasseashand NylonFibre.

•ThereasonbehindofthiswhenSugercaneBagasseashand Nylon Fibre comes in contact with water, pozzolanic reactionstakesplaceduringthecuringperiod.

Following conclusions can be inferred on the basis of the experimentsperformed:

[1] SugarcaneBagasseashisawasteproductofcement manufacturing process which can be effectively used in the stabilization process of soil due to its cementitiouspropertiesthathelpsinincreasingthe strengthofsoil.

[2] Nylonfiberontheotherhandisacheaplyavailable material which can be added to soil in less quantities to make big changes in its strength parameters.

[3] The optimum value of Sugarcane Bagasse ash is used for this work was 20% because of the optimum value of C.B.R. is found at 20% of SugarcaneBagasseashwhenaddedtosoil.

[4] 4.TheC.B.RvalueincreaseswithincreaseofNylon FibrealongwithfixedquantityofRiceHuskAsh.It increased1.59timesfromtheuntreatedsoil.

[5] TheoptimumvalueofNylonFibreandSugarcane Bagasseashrequiredforsoilstabilizationis1.5% and20%byweightofsoilrespectively.

[6] Unconfined compressive strength increases with increaseofquantityofNylonFibreandwithfixed quantity of Sugarcane Bagasse ash. The value of Unconfinedcompressivestrengthisincreased1.34 timesfromtheuntreatedsoil.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

[1] Ahmed Mancy Mosa, Amer Hasan Taher, Layth A. Al-Jaberi(2017) “improvement of poor subgrade soilusingcementkilndust”.

[2] B.R. Phanikumar, Ravideep Singla (2016) “Swellconsolidation characteristics of fibre reinforced expansivesoils”.

[3] Dr. Siddhartha Rokade, Rakesh Kumar, Dr. P.K. Jain(2017)“EffectofInclusionofFly-AshandNylon Fiber on Strength Characteristics of Black Cotton Soil”.EJGEVol.22[2017].

[4] Hesham A. H. Ismaiel (2013) “Cement Kiln Dust ChemicalStabilizationofExpansiveSoilExposedat El-KawtherQuarter,SohagRegion,Egypt”.

[5] M.Heeralal,G.V.Praveen(2011)“Astudyoneffect of fiber on cement kiln dust stabilized soil”. JERS/Vol. II/ Issue IV/October-December, 2011/173-177

[6] M.K.Rahman,S.Rehman&O.S.B.Al-Amoudi(2011) “Literaturereviewoncementkilndustusageinsoil and waste stabilization and experimental investigation”.

[7] KameshwarRaoTallapragada,AnujKumarSharma, TarulataMeshram(2009)“laboratoryinvestigation of use of synthetic fibers to minimize swell in expansivesubgrades”.IGC2009,Guntur,INDIA

[8] Pallavi, Pradeep Tiwari, Dr P D Poorey(2016) “StabilizationofBlackCottonSoilusingFlyAshand Nylon Fibre”. IRJET Volume: 03 Issue: 11 | Nov2016

[9] IndianStandardCodeIS2720-16,IS2720-10.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page825