International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1BM College of Technology, RGPV, Indore MP

2Reseaech Scholar, BM College of Technology, RGPV, Indore MP ***

Abstract - The analysis of variance (ANOVA) results for a single optimization corroborate the previous finding by showing that the depth of cut has the greatest influence (92.06%), followed by the cutting speed(4.65%) andfeedrate (0.94%) with the least influence on the MRR values. The calculation of the grey relational grade in equation(7)results in a value of 0.4413, indicating that the ideal collection of input control parameters is A2B3C1. Table 5.9 displays the results of the confirmation experiment for the response parameters. Itshouldbe notedthat the experimentalvaluesof Cutting Speed (VC) in rpm, Depth of Cut mm, and Feed Rate mm/rev are all greatly improved by GRA.

Key Words: cylindrical grinding, material removal rate, anddesirabilityfactor.En9alloysteel,singleoptimization

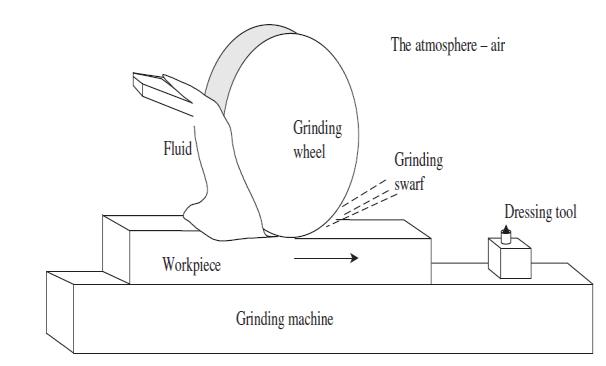

In modern production, machining that uses high-speed abrasive wheels, pads, and belts are referred to as "grinding." Grinding wheels come in a wide range of diameters, contours, and abrasive kinds. The following chapters will go through the most common wheel and abrasive kinds. Grinding is one abrasive machining technique.Abrasivemachiningmethodsincludepolishing, lapping, honing, and other sophisticated finishing treatments.Thereareseveralaspectsofgrindingtechnology thatoverlapwiththisbroadrangeoftasks.Theonlyfactor that distinguishes grinding from other processes is their kinematics, some of which, like lapping, need quite little frictionalforce.Rarely,theabrasiveprocesscanbeaidedby chemical or electrochemical principles, extending the grindingprocess.

The concepts and methods given in this book can be appliedtootheraspectsofsuperfinishing,eventhoughthe mechanical friction process is the primary focus of the majorityofthetechniquesandprinciplesdiscussed.Grinding isa processusedtoremove material andincreasesurface area in order to condition and polish metal and other materials. Ten times more accuracy may be achieved throughsurfacefinishingandgrindingthanthroughmilling oreventurning.Asubstantialabrasiveproduct typicallya rotatingwheel makescontactwiththeworksurfacewhen grinding.[3]

This chapter explores the role that grinding plays in modernproduction,includingitsorigins,howitworks,and howitrelatestostrategy.Astopconcerns,cost,quality,and manufacturing speed are cited. ability to learn from machinesLowsurfaceroughness,goodsurfaceintegrity,and high precision with very hard materials like steel and ceramics are distinctive characteristics. Current trends include accelerating production rates, using tougher and more advanced abrasives, and developing machines and control systems with ultra fundamental mechanisms and components of grinding systemsaredescribed.Themainobjectiveandcontentofthe book are describ Otherrelevanttextsarereferenced

Figure 1.1.Four fundamental grinding techniques are shown in there are four types of grinding: face surface grinding,facecylindricalgrinding,andperipheralcylindrical grinding.

The following information is included in a system specification.

Work piece material: Form, stiffness, hardness, and chemicalandthermalcharacteristics.

Type, control system, precision, rigidity, temperature stability,andvibrationsofgrindingmachines

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

optimized on MRR using the Taguchi technique, response surfaceanalysis,andtheGREYconnectionanalysisapproach. Thethreecharacteristicsknownas"cuttingspeed,""depthof cut," and "feed rate" are thought of as the ideal cutting parameters. The precise objectives are listed below. a) To practice design ofexperiments(DOE)using thecylindrical grinding method (CGP). b) To determine the ideal cutting conditionsforraisingMRR.

Figure1.2showsexternalcenterlessgrinding,external anglegrinding,andinternalcylindricalgrinding.[17]

The movements and geometry that control how the grindingwheelmakescontactwiththeworkpieceareknown as kinematics. The speeds and feeds of the wheel and the workpieces.

• The features of grinding wheels in terms of abrasive, particlesize,bond,structure,hardness,speed,stiffness,and chemicalcomposition.

• Dressing circumstances: the kind of tool, feeds and speeds,cooling,lubrication,andmaintenance.

•Theflowrate,velocity,pressure,physical,chemical,and thermalcharacteristicsofthegrindingfluid.

Temperature,humidity,andtheimpactoftheatmosphere ontheenvironment.

•Riskstothepublicandmachineoperators'healthand safety.

•Wastemanagement.

•Costs.

The full spectrum of grinding operations, which includes single-sided or double-sided face grinding of numerous components placed on a planar surface, is very broad in actuality. The range also contains operations for creating profiles and copying profiles. Grinding spiral flutes, screw threads,spurgears,andhelicalgearsemployingtechniques akin to gear cutting, shaping, planning, and robbing with cuttingtoolsareallexamplesofprofilingoperations.Other techniquescanbeusedtogrindcampmates,rotarycams,and balljoints.[17]

Thegoalofthisworkistoidentifythemachiningparameters inanexternalcylindricalgrindingoperationthatshouldbe

DESIGN OF EXPERIMENT: Experiment design is a method createdtocomprehendthebehaviorofamechanicalsystem. Dataareaccumulatingfromthevariablesetsets,andtheycan be used to qualitatively explain the current situation. Therefore, it is commonly recognized that the goal of any research is to construct an experiment with a minimal number of variables and use this experiment to gather as many data as feasible. Every experiment focuses on the majorityofthevariablesthatcanhaveadirectimpactonthe outcomes. Quantities that have a significant impact on the resultsofstudiescanbeusedtodetectthesetypesoffactors. Oneofthemostcrucialideasinscienceistheories,whichare usedtoguidefurtherexperiments.

AlloysteelEN6ischosenastheworkpiecematerialinthe studypresentedin[1]

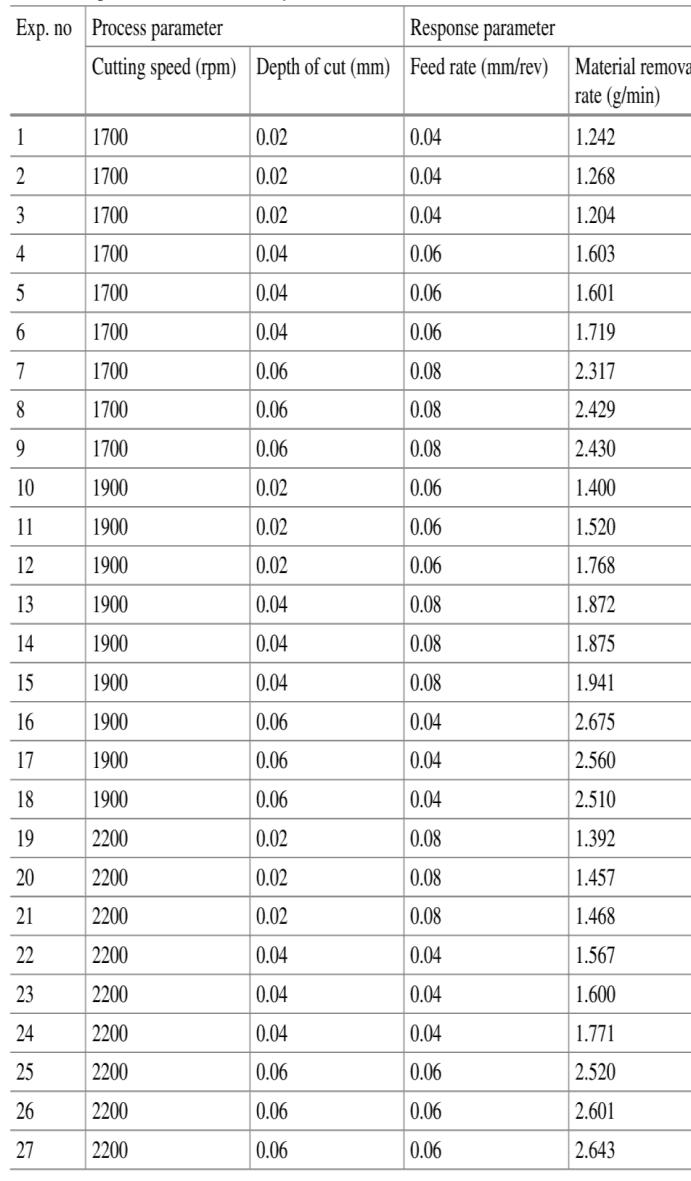

Table 3.1 L27 orthogonal array and results

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

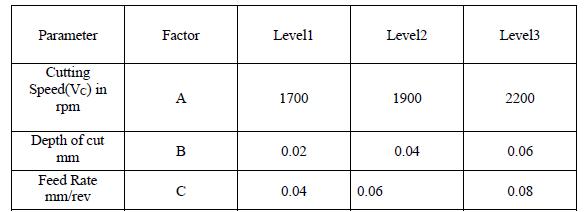

Table 3.2 Control Parameters and their levels [1]

Thenumberofcomponentsandthelevelschosenforthesets ofvariablesdeterminehowmanyduplicatesarepresentin theexperiment;asthenumberofexperimentsincreases,so willthenumberofreplicates.Differentmethods,suchasthe TaguchiMethod,ResponseSurfaceMethod,MixtureDesign, and Full Factorial Method, are employed in the design of experiments.Eachexperimenthasitsownsignificance,and the ideal approach depends on the circumstances or the differenttypesandweightsofthemanycomponents.

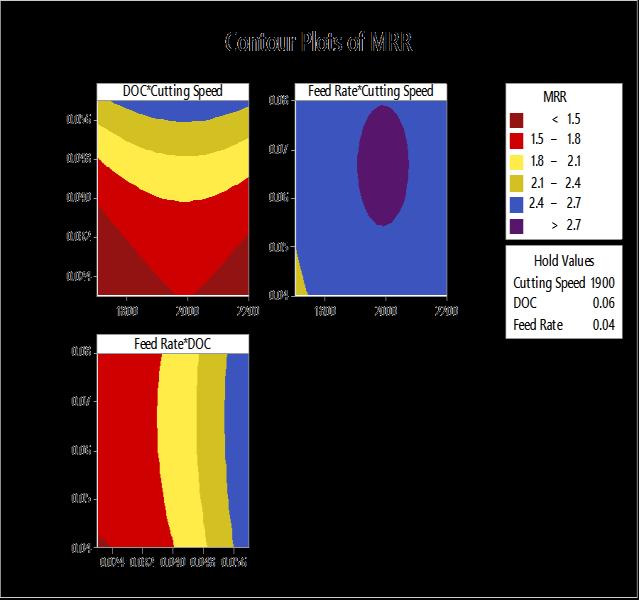

Model Summary: Finally the regression equation is shown give the exact model equation or it will show the relationshipbetweentheinputandtheoutputvariables.

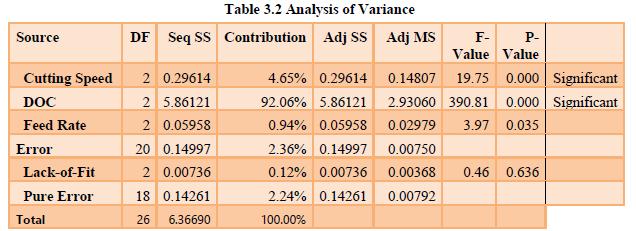

Fig3.1MainEffectsPlotforSNratiosofMRR

Table3.2ResponseTableforSignaltoNoiseRatios

Largerisbetter

Level CuttingSpeed DOC FeedRate 1 4.568 2.920 4.790 2 5.846 4.711 5.433 3 5.233 8.017 5.425 Delta 1.278 5.097 0.643 Rank 2 1 3

Because MRR is a larger-is-better kind of quality characteristic,themajoreffectplot(Figure3.1)showsthat thesecondlevelofcuttingspeed(A2),firstlevelofdepthof cut(B1),andthirdleveloffeed(C3)offerthehighestMRR value.Relativelyslightly,theMRRincreasesalongwiththe feed rate and cutting speed. The MRR, on the other hand, increasesconsiderablyifthedepthofincisionisincreasedby 0.02mm.

The Effectof the machiningparameters(cuttingspeed, feed,anddepthofcut)ontheresponsevariablesMRRhas beenpredicted.ItcanbeseenfromFig.3.1,TheMRRtendsto increasesignificantlywithincreaseinfeedrateanddepthof cutforanyvalueofgritsize.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

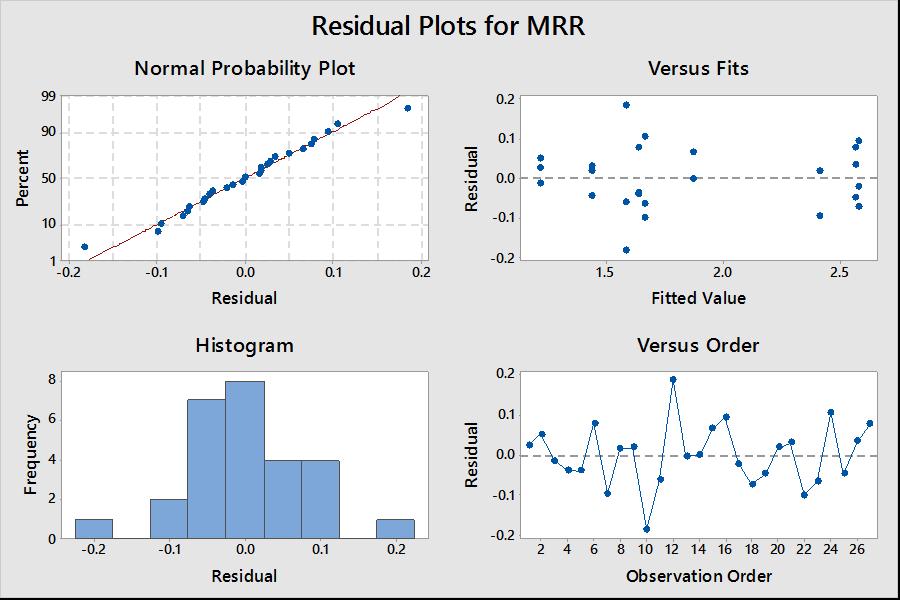

The residual plot for the Material Remover Rate is displayedabove.Thefirstgraphinthisgraphisthenormal probabilitygraph,inwhichallthepointsarelocatedalong thenormalprobabilityline.Thisindicatesthatthedataare well fitted for the observation and that there must be a significant correlation between the input and the output variablesThesecondgraphisahistogramplotinwhichthe greatestvalueisplottedat0,indicatingthatthemajorityof the data were either zero or that there is no difference between the residual probability graph and the normal probabilitygraph.Theresidual'sdeflectionisdisplayedasthe number of observations in the final graph. The final graph displays the deflection in the residual with respect to the numberofobservations.Themaximumdatainthehistogram plot are on 0, which also means there isn't a lot of space betweenthedataandthenormalprobabilityline.

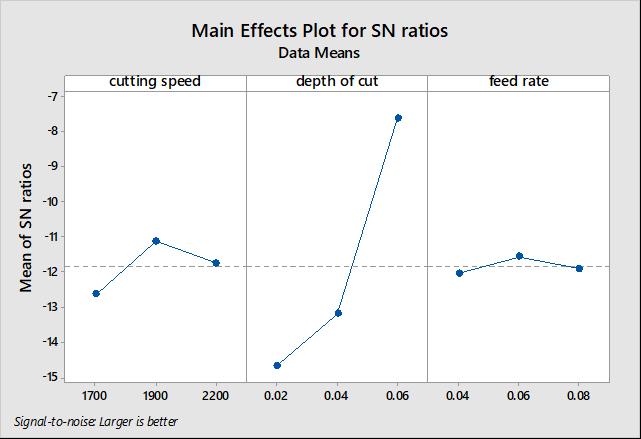

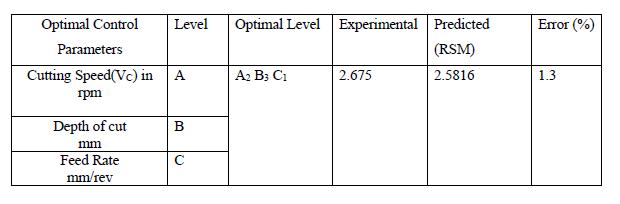

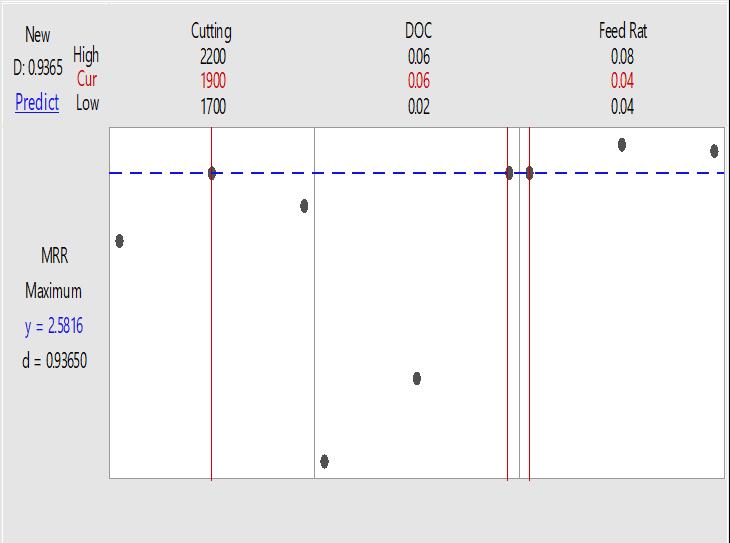

Thepurposeofthisresearchistofindthebestparametric settings to achieve maximum Material Removal Rate of grindingprocess atthesametime, whichisideal forgood grinding efficiency. The desirability analysis is used to determinethebestparametricsettingtoobtaintheabsolute MaterialRemovalRateofthegrindingprocess.Thegrinding process is optimized using the Minitab18 program. The common steps and procedures that are followed in the Minitabsoftwarearedescribedindetailhere.Theresultsof multi-objectiveoptimizationforMaterialRemovalRateare shown in fig. 4.1. Optimal Material Removal Rate 2.816(Gm./Min)hasbeenobtainedat(a)CuttingSpeed(VC) inrpmA21900rpm(b)Depthofcut(mm),B30.06mm.(c) FeedRate 0.04(mm/rev)C1ThemixeddesirabilityfactorD hasavalueof0.93650.

Fig.4.1OptimizationresultsofMaterialRemovalRateby RSM

Theobtainedoptimizationtechniqueswereconfirmedusing validation studies. Table 4.1 shows the results of confirmatory tests performed under ideal conditions. It is seen from the table that the error in terms of percentage between the estimated and experimental results is very small and is less than 1%. This indicates for single optimization, for cylindrical grinding, there is significant improvement with the experimental alloy steel EN9.Parameters.Threefreshexperimentsareconductedfor confirmation of models Eqs. (3) And (4), with achieved optimal values of Material Removal Rate. The average of measuredvaluesforOptimalMaterialRemovalRate2.816 (Gm./Min)hasbeenobtainedat(a)CuttingSpeed(VC)inrpm A21900rpm(b)Depthofcut(mm),B30.06mm.(c)Feed Rate 0.04 (mm/rev) C1. The accuracy of the models is analyzedonthebasispercentageerror..Sincetheerroris less than10%, it is evidently proved that there is a good agreement between experimental and predicted values [38].Finally,withinexperimentalconstraints,anattemptwas madetoestimatetheoptimalcylindricalmachiningposition toprovidethebestdesiredresults.

4.1Multi-objectiveoptimizationresults

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

4. The studies led to the following conclusions:

1. The Taguchi orthogonal array has been utilized successfully to determine the ideal level of process parametersetting.

2. Because MRR is a larger-is-better type of quality characteristic,themaineffectplot(Figure3.1)demonstrates thatthethirdleveloffeed(C3),thefirstlevelofdepthofcut (B1),andthesecondlevelofcuttingspeed(A2)providethe highest values of MRR between the input and output variables. Consequently, there is a significant correlation betweentheinputandoutputvariables.

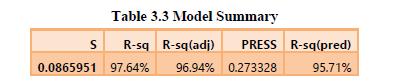

3. For a single optimization, the analysis of variance (ANOVA) results based on the estimated MRR values are shown in Table 3.3. These results demonstrate that the depthofcuthasthehighestcontribution(92.06%),followed bytheminimuminfluencefromcuttingspeed(4.65%)and feedrate(0.94%),indeterminingtheMRRvalues,thereby validatingtheconclusionreachedabove.

4.R-sq:Inordertoanticipateagoodagreementbetweenthe inputandoutputvalues,theR-sqvaluemustbeover40%, according to the research technique. The R-sq value is 97.64% in the table below, which illustrates the good agreement between the input and output variables. As a result, there is a significant correlation between the input andoutputvariables.

1. Pravin Jadhav, Pranali Patil, Sharadchandra Patil.: Optimization ofCylindrical GrindingforMaterial Removal RateofAlloySteelEN9byUsingTaguchiMethod.Advances inIndustrialandProductionEngineering,SelectProceedings ofFLAME2020(pp.851-859)

[2] JitenderKundu and Hari Singh, Production & ManufacturingResearch:AnOpenAccessJournal,2016VOL. 4, NO. 1, 228–241 http://dx.doi.org/10.1080/21693277.2016.1266449

[3]SwatiSSangale,Dr.A.D.Dongare,optimizationofthe parameterincylindricalgrindingofmildsteelrod(en19)by taguchimethodIJCIRAS|ISSN(O)-2581-5334September 2019|Vol.2Issue.4

[4] S. Shaji, V. Radhakrishnan, Analysis of process parameters in surface grinding with graphite as lubricant basedontheTaguchimethod,J.Mater.Process.Technol.141 (2003) 51–59, https://doi.org/10.1016/S09240136(02)01112-3.

[5] M.S. Dennison, N.M. Sivaram, D. Barik, S. Ponnusamy, Turning operation of AISI 4340 steel in flooded, near-dry and dry conditions: a comparative study on tool-work

interfacetemperature,Mech.Mech.Eng.23(1)(2019)172–182.

[6] M. Manikandan, S. Prabagaran, N.M. Sivaram, M.S. Dennison,Astudyonoptimizationofmachiningparameters in cylindrical traverse rough and finish cut grinding processes,i-Manager’sJ.Mech.Eng.10(1)(2019)51.

[7] S. Rajarajan, C. Ramesh Kannan, M.S. Dennison, A comparative study on the machining characteristics on turningAISI52100alloysteelindryandmicrolubrication condition,Aust.J.Mech.Eng.(2020)1–12.

[8] N. Alagumurthi, K. Palaniradja, V. Soundararajan, Materials and manufacturing processes optimization of grinding process through design of experiment (DOE) a comparativestudyoptimizationofgrindingprocessthrough designofexperiment(DOE) a comparativestudy,Mater. Manuf. Processes 21 (2006) 19–21, https://doi.org/10.1081/AMP-200060605

[9]SahuPurushottamKumar.,SharmabSatyendra.Multiple objective optimization of a diesel engine fueled with karanja biodiesel using response surface methodology MaterToday:Proc(52)(2022),pp.2065-2072

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |