International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Prathamesh Pawar1 , Bharat Kulkarni2

1 Student , 2 Professor Department of Electronics & Telecommunication Engineering Dr. V.P.S.S.Ms Padmabhooshan Vasantraodada Patil Institute of Technology, Budhgaon, Sangli, Maharashtra 416304 India. ***

Abstract - Vertical framing is becoming very much popular practice Now a days. It is a new generationmethodoffarming. Vertical framing helps to maintain the food production chain without disturbing the agricultural misbalance. Among main three types; 1. Aeroponics technique, 2. Hydroponics technique, 3. Aquaponics technique; here we are going to focus on AEROPONICS TECHNIQUE. In this technique we are monitoring few major environmental parameters which are basic need of the crops to grow healthy. Thus, to monitoring such parameters, we take the help of IOT.

Key Words: Aeroponics, ESP32, Artificial Environment, IOT, Vertical farming, indoor.

India is 2nd largest country in agricultural production. India is an agriculture dominated country in which 65% to 70% population depends on agriculture. AccordingtoIndianGDP,currentlyagriculturecontributes near about 16% -17% of Indian GDP. In India most of the farmersuseconventionalmethodforagriculturalfarming. Conventional agricultural farming means the soil based agricultural farming. Conventional agricultural farming mainlyrequires80%ofsoiland65to70%ofglobalfresh water. The main drawbacks of Conventional agricultural farmingare: i)extremedependencyweatherandii)wastage of 45 to 67% global fresh water due to leakage and evaporation. India’s dependency on weather and environment leads some time conventional agricultural farmingtounsustainableusageofresources.[3]

Nowdays a nutritionloadvaluesoffoodarevery muchimportantfactorinday-to-daylifeofhuman.Dueto huge increase of population, there is a vast demand in agriculturalproductionsofullfillthisdemandmostofthe farmersareusingchemicalfertilizersforgettingmoreand moreproductioninlessdurationoftimeandthusfarmers arecompromisingnutritionloadvaluesofproductsorcrops.

To overcome all these issues Vertical Farming incorporates all planning and design of agricultural farms togetherinahigh-risebuilding.InVerticalFarmingdifferent typesofcrops,fungiandplantsaregrowninverticalstacks. Recently,VerticalFarmingisbeingimplementedsuccessfully

in many countries. This agricultural farming technology helps to produce a lot of crops inside the city. [2] The technique which is focused / used in our project is an Aeroponicstechnique.

Richard J. Stoner II was first developed use of AeroponicsforgrowingEdiblePlantsin1983.Inthistypeof farming, the water which is to be provided is mixed with some compounds which are not hazardous for human anatomyaswellasplantanatomy.Suchwateriscirculated via pipes. Due to creation of artificial environment and indoorimplementationofagriculturalfarmingproject,there isvery-verylesschancesofinsectsandpestssothereisno needofinsecticidesaswellaspesticides.Thus,wecanavoid useofinsecticidesaswellaspesticides.

But if we look into 1990s, NASA had brought attentiontoaeroponics.Itbeganinvestigatingsoillessways of raising food that could be used in the low-gravity conditionsthatarepresentinspacetravel.NASAhadcarried outresearch/investigationonaeroponicsonboardofthe international space research station ‘MIR’. Since then, a number of commercial aeroponics systems have been developedforresearch,industrialandhomeuse.

We have tried to build a prototype / structural modelofverticalfarmingandinthattriedtomaintainthe necessary environmental conditions required to cultivate crops / vegetables. In this project, tried to maintain those fewbasicparameterswhichareminimalrequirementsfor the crops to grow healthy and those are Temperature, Humidity,LightandpHofnutritiousWater.

Inthatmodel/structure,wedidprovidewaterpipe linesforsupplyingwaterwhichistobepumpedfromwater tank.Thissupplywatertankisfilledwithsolutionofmixture of fertilizer and water in appropriate proportion. The pH valueofthistanksolutionismaintainedasperourcrops/ vegetables.Byusingtheabovedevelopedenvironment,we cultivatedmintplants

For maintaining temperature, moisture, light intensity and Nutritious Water supply etc. we required

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

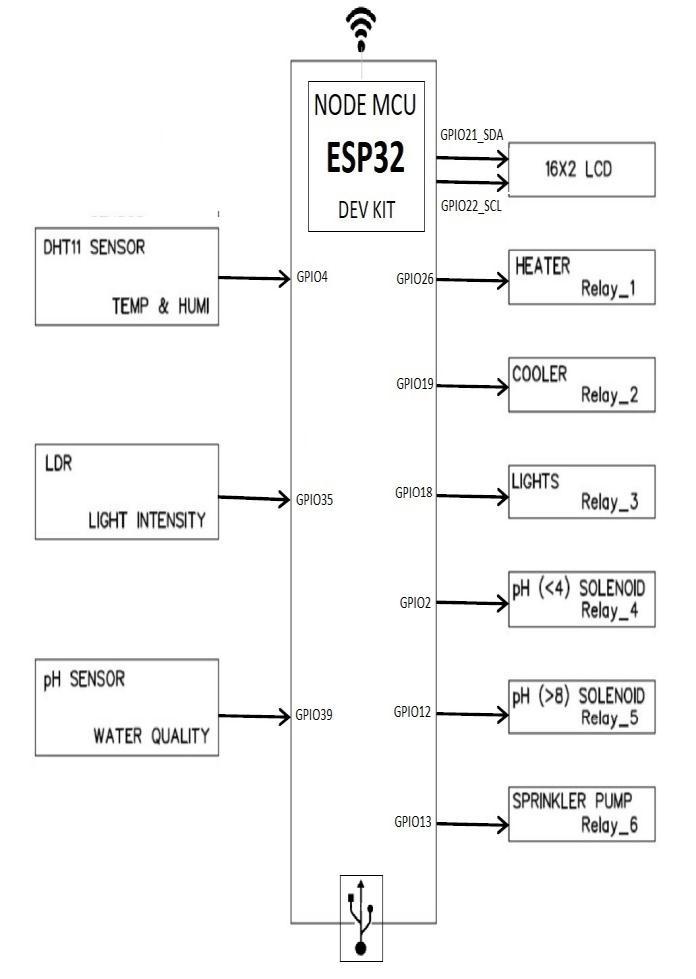

microcontroller / node MCU. To achieve our this goal, we have used node mcu / ESP32 Development Kit Board in connectionwithDHT11asTemperature/HumiditySensor, LDR asLightSensorand pH Sensor to measure nutritious water.ForsoftwareprogrammingforESP32Development Kit Board, we used Arduino IDE platform. For working of ESP32,itrequired5Vsupply.

Therearethreetechniquesofverticalfarming:

1.Aeroponicstechnique

2.Hydroponicstechnique

3.Aquaponicstechnique

Here we are going to use aeroponics technique. In this technique there is a tank which contains water and nutrients.Inthetankthereisonesubmersiblepumpwhich isusedtopumpthewaterfromthattanktospraythatwater on the roots of the plants. Sprinklers nozzles are used to spraywaterontherootsofplant.

1)ESP32:ESP32isaseriesoflow-cost,low-powersystem onachipmicrocontrollerswithintegratedWi-FianddualmodeBluetooth. The ESP32 series employs either aTensilicaXtensa LX6 microprocessor in both dual-core andsingle-corevariations, Xtensa LX7 dual-core microprocessororasingle-coreRISC-Vmicroprocessorand includes built-in antenna switches,RFbalun, power amplifier, low-noise receive amplifier, filters, and powermanagement modules. ESP32 is created and developed byEspressif Systems, a Shanghai-based Chinese company, andismanufacturedbyTSMCusingtheir40nmprocess.Itis asuccessortotheESP8266microcontroller.

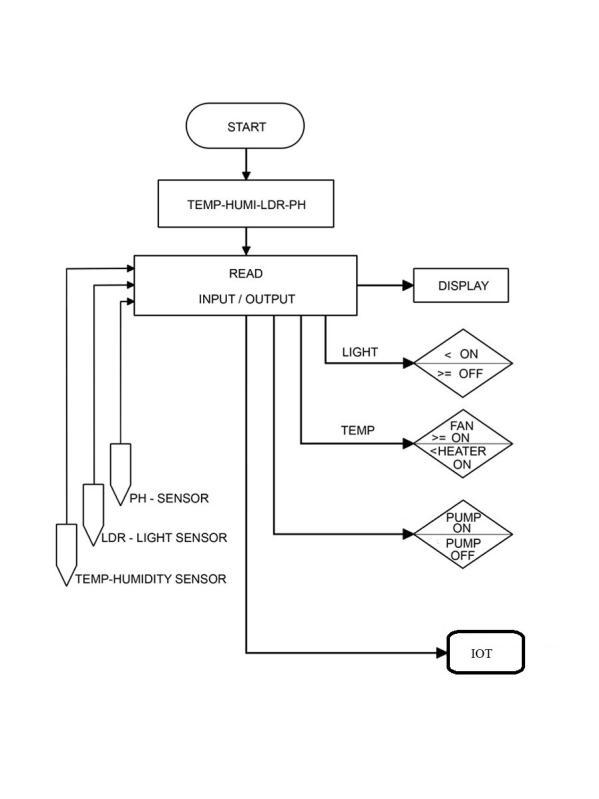

Intheindoorplacetocreateanartificialenvironmental,we needtomonitorfourbasicparameters:

i)Temperature

ii)Humidity, iii)Light,

iv)pHvalueofwater.

Itcontainsdigitalaswellasanalogpinswhicharehelpsusto reducethecomplexityofourproject.Itisusedtosensethe various inputs from variety of sensors and acts as main controllingelement.

2)pHSensor:pHprobescontaintwoelectrodes(asensor electrode and a reference electrode) that measure the hydrogen-ion activity in a solution. The exchange of ions generates a voltage that is measured by the pH meter converting the voltage into a readable pH value. pH(the potential of Hydrogen) measures the interaction between hydrogenandhydroxideionswithinawater-basedsolution. Asolutionwithahighamountofhydrogen-ionactivityisan acid.Incontrast,asolutionwithahighamountofhydroxide ionactivityisabase.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Itisusestofindtheconcentration ofhydrogenionsusing electriccurrentinwaterbasedsolution.WeusedpHsensor tochecktheacidic/alkalinevaluesofwaterforexchanging thatwaterfromthetank.

3) LDR: A Light Dependent Resistor (LDR) is also called a photoresistororacadmiumsulfide(CdS)cell.Itisalsocalled aphotoconductor.Itisbasicallyaphotocellthatworkson theprincipleofphotoconductivity.Thepassivecomponentis basicallyaresistorwhoseresistancevaluedecreaseswhen theintensityoflightdecreases.

LDRsorphotoresistorsareoftenusedincircuitswhereitis necessarytodetectthepresenceortheleveloflight.They canbedescribedbyavarietyofnamesfromlightdependent resistor,LDR,photoresistor,orevenphotocell,photocellor photoconductor.

4)DHT11: DHT11sensorconsistsofacapacitivehumidity sensingelementandathermistorforsensingtemperature. The humidity sensingcapacitorhas two electrodes with a moisture holding substrate as a dielectric between them. Changeinthecapacitancevalueoccurswiththechangein humidity levels. The IC measure, process this changed resistancevaluesandchangethemintodigitalform.

For measuring temperature this sensor uses a Negative Temperaturecoefficientthermistor,whichcausesadecrease initsresistancevaluewithincreaseintemperature.Toget larger resistance value even for the smallest change in temperature, this sensor is usually made up of semiconductor ceramics or polymers. The temperature range of DHT11 is from 0 to 50 degree Celsius with a 2degreeaccuracy.Humidityrangeofthissensorisfrom20to 80%with5%accuracy.Thesamplingrateofthissensoris 1Hz .i.e. it gives one reading for every second. DHT11 is small insizewithoperating voltagefrom3to5volts.The maximumcurrentusedwhilemeasuringis2.5mA.

5) LED grow Light: LED grow lights are composed of multipleindividuallight-emittingdiodes,usuallyinacasing with aheat sinkand built-in fans. LED grow lights do not usually require a separate ballast and can be plugged directlyintoastandardelectricalsocket.

IndividualLEDsusuallyprovideonlyasinglenarrowrange ofcolours,andsodifferentcolourLEDsaremixedingrow lights in proportions depending on the intended use. It is known from the study ofphotomorphogenesisthat green, red, far-red and blue light spectra have an effect on root formation, plant growth, and flowering, but there are not enough scientific studies or field-tested trials using LED grow lights to recommended specific colour ratios for optimalplantgrowthunderLEDgrowlights.

6) 16X2LCDDisplay :It will be usedtovisualize the data locallyitwillhelptooperatethedevicestandalone.

LCD(LiquidCrystalDisplay)screenisanelectronicdisplay moduleandfindawiderangeofapplication.

A16x2 LCD displayis very basic module and is very commonly used in various devices and circuits. A16x2 LCDmeans it candisplay16 characters per line and there are2suchlines.

7) Submersible Pump : A submersible pump is a device whichhasamotorclosejoinedtothepumpbody.Thewhole structureissubmergedinthefluidtobepumped.Weused pumpforcirculatingthewatertosprinklersthroughoutthe structure.

8)Fan:Fanisusedforcoolingpurposeofthesystem.Ifthe temperatureofthesystemincreasesthefanwillturnonto cooldownwork.

Duringthisprojectweselectmintasafarmingmaterial For better growth of mint, always kept its temperature in between15to25degreeCelsiusalsomaintainpHfactorof waterinbetween6.0to7.5becauseminthaswiderangefor pHwhichis6.1to7.8.butideallyitshouldbeinbetweenas giveabove.

Duringworkingonthisprojectweobservedthatmintcan sustaininbetween21to29degreeCelsius,alsopHupto7.5.

Sr No Parameter Observed

01 Temperature 21-29 C 02 Humidity 72% 03 pH 6.1-7.8

Inaeroponicstechnique,wecangrowdifferenttypesof plants throughout the year by maintaining the respective parametersliketemperature,humidity,pH,LEDlight with thehelpofIOT BecauseofIOTwecanmonitorparameters from anywhere, any time. Due to indoor structure and monitoredenvironment,thereislesschancesofbecoming diseased plants and need very less of pesticides and insecticides.Attheend,wecangetfresh,cleanandhealthy foodproduction.

[1] “Automated Aeroponics System for Indoor Farming using Arduino”, Ferdousi Rahman, Israt Jahan Ritun, Md.Ryad Ahmed Biplob, Nafisa Farhin, Jia Uddin. DepartmentofComputerScience&EngineeringBRAC UniversityDhaka,Bangladesh,October2018.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

[2] “AsurveyonVerticalFarming”, SaravananM&Saravana

KrishnanM(StudentSKCET),SrivaishnaviD(Assistant ProfessorSKCET).InternationalJournalofEngineering Research&Technology(IJERT),September-2018,Vol.7 Issue09,September-2018.

[3] “Smart Vertical Farm Using IOT” , Abhishek A M, ChandrakanthR,MaheshC,ManojMMarigiri,RamyaB K, B. E. Students, Department of ISE, SJB Institute of Technology,Bengaluru,India.‘InternationalJournalof InnovativeResearchinComputerandCommunication Engineering’(IJIRCCE),April2018,Vol.6,Issue4,April 2018.

[4] “An Innovative Approach on Vertical Farming Techniques”, M. Jegadeesh, Dr. J.Verapandi, Research scholar, Assistant Professor, Department of Environmental Science Bharathiar University, India. Department of Environmental Science, Bharathiar University(SSRG-IJAES),October2014,volume1Iusse1 October2014.

[5] “Aeroponics technology : blessing or curse”, (1)GagandeepKaur,(2)DilipKumar,(1)Academicand ConsultancyServices-Division,CentreforDevelopment ofAdvancedComputing(C-DAC),Mohali,India.(2)Sant Longowal Institute of Engineering and Technology (SLIET),Longowal,India(IJERT),July2014,Vol.3Issue 7,July-2014

[6] ‘Smart Agriculture System using IoT Technology’ Muthunoori Naresh, P Munaswamy International JournalofRecentTechnologyandEngineering(IJRTE) ISSN:2277-3878,Volume-7Issue-5,January2019

[7] ‘Exploring Economical & Environmental Benefits Of VerticalFarmingUsingMultiStoryPanels’

1 Archan.B.Bhangaonkar, 2 Munir.P.Joshi, 3 Sahil S.Huseni

1 Student, Department of Civil Engineering, Sardar VallabhbhaiPatelInstituteofTechnology,India

2 Student, Department of Civil Engineering, Sardar VallabhbhaiPatelInstituteofTechnology,Vasad,India

3AssistantProfessor,DepartmentofCivilEngineering, SardarVallabhbhaiPatelInstituteofTechnology,India

International Journal of Advance Engineering and ResearchDevelopment(IJAERD)NCAN-2017,February2017

1(CivilEngineering,REVAInstituteofTechnologyand Management,Bangalore),

2 (CivilEngineering,REVAUniversity,Bangalore)

InternationalJournalofEngineeringandTechniquesVolume4Issue3,May2018

[9] ‘AReviewofVerticalFarmingTechnology:AGuidefor Implementation of Building Integrated Agriculture in Cities’

Fatemeh Kalantari 1 , Osman Mohd Tahir 2, Ahmad MahmoudiLahijani3andShahaboddinKalantari4, 1,2 Department of Landscape Architecture, Faculty of DesignandArchitecture,

University Putra Malaysia, 43400 UPM Serdang, Selangor,Malaysia

3 Department of Mechanical Engineering, Faculty of Engineering, University Putra Malaysia,43400 UPM Serdang,Selangor,Malaysia

4 Department of Civil Engineering, Islamic Azad University of Chalous, Chalous, Iran. Advanced EngineeringForumISSN:2234-991X,Vol.24,pp76-91 Accepted:2017-09-05Online:2017-10-11

[10] ‘Monitoring Parameter Of Plant In Vertical Farming UsingAeroponicsTechnique’

1GaikwadSuvarna2PawarPrathamesh 3PatilPriyanka

IRJET (International Research Journal of Engineering andTechnology)Volume:07Issue:05|May2020

[8]

‘VerticalFarming:AConcept’

1RashmiMariaRoyston,2PavithraM.P.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal