International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

Alok Kumar1, Dr Shyam Birl2

1Mtech Scholar, dept of mechanical engineering, Oriental College of Technology Bhopal, Bhopal 2Dr Shyam Birla, dept of mechanical engineering, Oriental College of Technology Bhopal***

Abstract - A heat exchanger is a mechanical system that exchanges heat between two or more fluids Any heat exchange intensification technique or device consists in modifying or improving the performance of the energy carrier. In this review, we have tried to identify the techniques to perform the energy vector between the cold source and the hot source. There are two different techniques, one called passive and the other is active. Thus, we have cited some correlations that describe the heat exchange as a function of the Nusselt number. This review is closed by the scientific work which aims to demonstrate theinterestof usingthepassivetechnique.

The various sizes, positions, and orientations of obstructions inside exchanger tubes have been the focus of several scientific works, according to the literature. In order to better comprehend convective flow in a rectangularpipe

Pethkool et al. [1], For a Reynolds number ranging from 5500 to 60000, it was examined how blocking factor (e/D) a corrugated helical tube with monophasic turbulentwaterflowthatwasinfluencedconvectiveheat transfer. The findings demonstrate that the performance factor significantly rises with an increase in blocking factor and reaches a value of about 232 percent when compared to a smooth tube.[10], the evaluation of the Nusseltnumberiscarriedoutbythefollowingformula:

Promvonge's experimental work. [2], undertaken to assess the forced convection heat transfer for turbulent airflow in a channel with a 60°-V multiple deflector turbulator., the Reynolds number is between 5000 and 25000, and the blocking factor varies between 0.1 and 0.3. The Nusselt number is evaluated by the following empiricalformula:

(I.2)

(I.1)

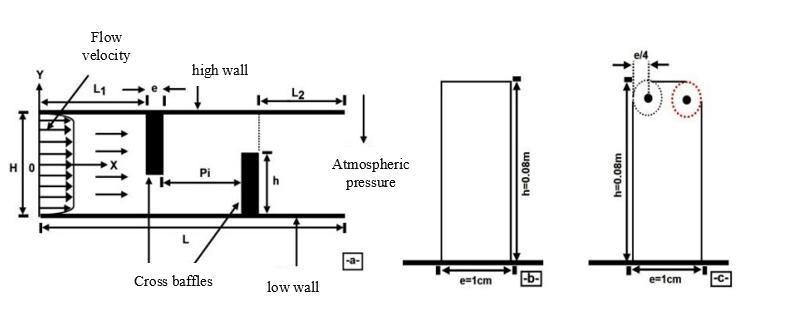

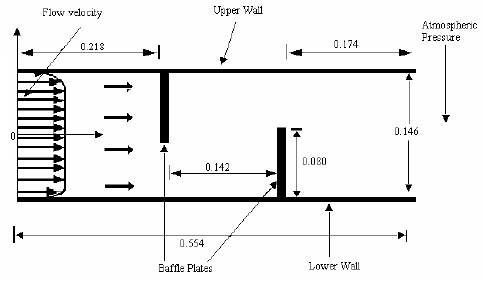

DeMartini et al. [19], We undertaken an intriguing computational and experimental analysis of flat transversebafflesforaturbulentairflowregimeinatwodimensional heat exchange channel. Additionally, they discovered that this issue is crucial in the area of heat exchangerssinceitaffectsflowcharacterisation,pressure distribution, and the potential existence and growth of recirculation’s A reasonably dense recirculation zone is visible above each chicane's facets and is moving in the direction of swallow on the profiles and axial velocity distribution. The impact of the flow field's distortion increases as the flow approaches the first chicane. The biggest disruption is seen upstream of the second chicane,theyalsodemonstrated.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

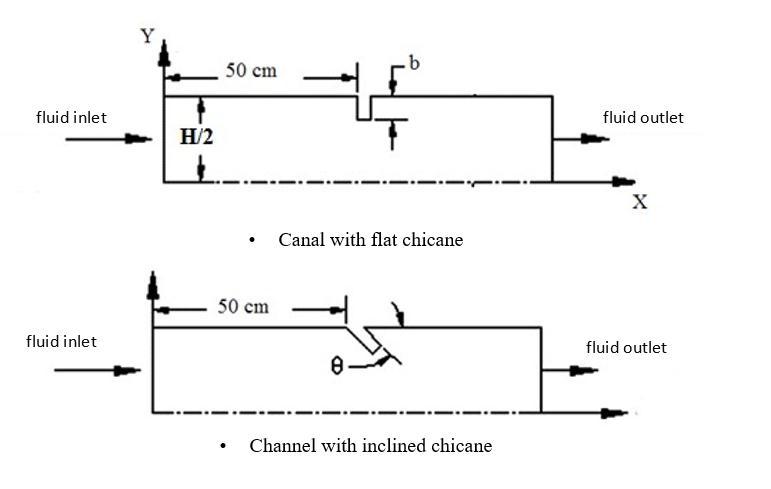

Tsayetal. [6],Theimprovementofheattransmissionofa flow in a channel with a vertical chicane was quantitatively examined. In the 100–500 Reynolds number range, the impact of chicane size and back coatingsontheflowstructureisthoroughlyinvestigated. They observed that by adding a baffle to the flow, the typicalNusseltnumbercouldbeincreasedby190%.They alsonoticedthatthechicane'spositionaffectsthethermal anddynamicpropertiesoftheflow.

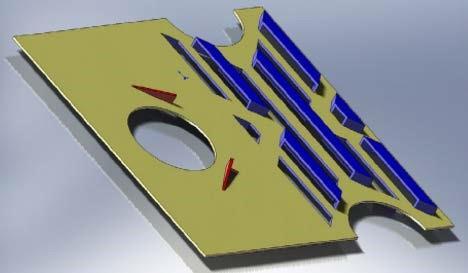

Fig -3 ChannelconfigurationstudiedbyDeMartinietal, [3]

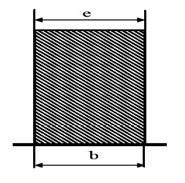

Bensenoucietal. [4], Forcedconvectionheattransferina rectangular pipe with baffles was investigated by numerical modelling. Convective heat exchange is promoted by the requirement to insert rows of fins and baffles in the vein of the emolument in heat exchangers. Research has revealed that the vertical portions nearest to the baffles are better heated than the distant vertical parts. The distribution of the temperature field in the channelfurthersupportsthisobservation.

Menni et al. [5], numerically studied the comparison between two different forms of fins and transverse baffles. The first is rectangular with a sharp tip, and the second rectangular iswitha roundedtip. In a horizontal, two-dimensional pipe with a rectangular cross-section, they are placed in overlap. The fluid (air) is of the Newtonian type, incompressible with constant thermophysical properties. The flow regime is considered permanent and purely turbulent. For a Reynolds number of between 5000 and 20000, calculations are conducted. The examination of the data showed that the addition of rectangular type baffles without rounding provides a significant increase in speed and improves the intensity ofheattransmissionwhenusedwithrectangularchianes.

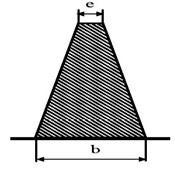

Bilen et al. [7], conducted an experimental study on the thermalandhydrauliccharacteristicsofturbulentairflow in tubes with different groove forms (circular, trapezoidal, and rectangular), with Reynolds numbers ranging from 10000 to 30000. When comparing the findings to a smooth tube, the circular groove configuration increases heat transmission by 63%, the trapezoidal groove configuration by 58%, and the rectangulargroovedtubeby47%.Theauthorsattributed the relatively poor thermal performance of rectangular grooves to the appearance of stagnation or recirculation zonesinthisconfiguration.Therelativelysimilarthermal performance of trapezoidal and circular grooves, despite a lower number of trapezoidal grooves, is explained by greaterflowdisturbanceinthisconfiguration.

Siddiqui et al. [8], The impact of placing baffles in a rectangular channel at various heights and inclination degrees on the increase in heat transmission was investigated experimentally and computationally. The findings demonstrate that the average Nusselt number is 120percentmorethaninthecasewithoutachicanefora Reynolds number range between 500 and 20000. They also discovered that the least amount of pressure loss occurs when the baffles are turned to face the channel's downstreamside.

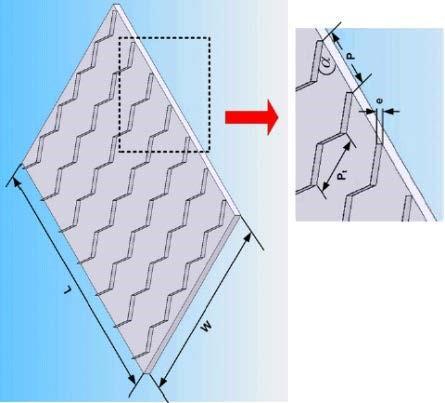

Fig -4 Rectangularwingwitharoundedtip:Testsection

Fig -5 Chicanedeviceinthecanal

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

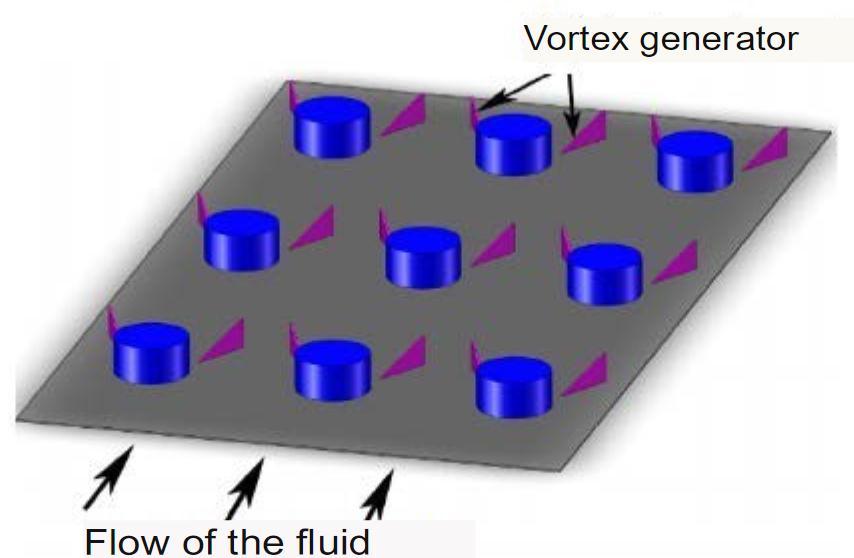

The work of Li et al. [9], a finned and flat tube heat exchangerwithlongitudinal vortexgeneratorstoprovide a 3D numerical assessment of heat transfer and airflow characteristics. The line of rectangular fins had a downstream direction and was set out in pairs. Impact occursat20°,30°,and40°angles.Between500and5000 istheReynoldsnumber. Thenumericalresultsshowthat these parameters may be changed to enhance heat transfer and friction coefficient in the Reynolds number range. They found that when fluid flows in the same direction as the fins' angle of inclination, the Nu number increasesby23-42%,from 23to46%,andincreasesby 23-31%,23-43%,and23-47%,respectivelyandfrom23 to 52 %, with equivalent inclination degrees of (20°, 30°, and40°)intheoppositedirection.

Wangetal. [10], Experimentaltestingoftwouniqueheat exchanger layouts using a novel type of baffles is done. The results of this investigation, which concentrated on theheattransfercharacteristicsofFB-STHXandSB-STHX, suggest that heat exchange has improved. According to the experimental findings, the Nusselt number for FBSTHX is almost 50% that of SB-STHX at the same Reynoldsnumberandtubegrillecircumstances,whilethe pressure drop of the first arrangement is roughly 30% thatofthesecond.However,thefirstchicane'stotalNu/p performanceis60%betterthanthesecondchicanes

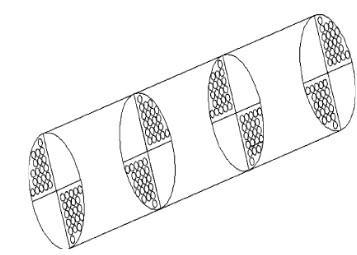

Throughtheuseofthreedifferentinserts,SelvaKumaret al experiential’s investigation [12] sought to enhance heat transmission in a circular copper tube with an internal diameter of 10 mm. The three inserts are either 15 mm, 20 mm, or 25 mm in pitch, with a rectangular form. Using inserts increases the rate of heat transmission, according to the results, which are supported by experimental pressure measurements and excellent fluid particle mixes inside the tube. Improved heat transmission is also related to a reduced pressure drop. They also discovered that the 20 mm pitch inserts hadthehighestthermalperformancefactor.

Benzenine et al. [11], numerical research on turbulent airflow using transverse baffles. In a rectangular section pipe, two distinct types of flat, trapezoidal rectangular baffles are positioned in overlap. The findings demonstrate how baffles affect heat exchange intensificationasafunctionofReynoldsnumber,whichis between 1.87 103 and 1.87 105. They also demonstrate how locations with rapid fluid acceleration lead to an increaseinfrictioncoefficient.

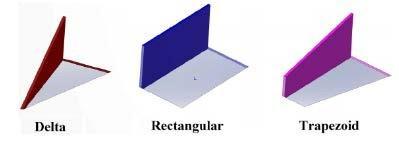

Xuedongetal. [13], 304to2130Reynoldsnumberswere used to study the performance of air-side heat transfer using numerical simulation. Analysis is also done on the mechanism causing enhanced heat transfer. Fins of the delta, rectangular, and trapezoidal forms were installed on the heat exchanger's surface. The results of the calculations reveal that some eddies have formed behind the fins, which disturbs the fluid flow and enhances heat transmission. When comparing delta-shaped fins to rectangularandtrapezoidalfins,theNusseltnumberrose by77.16percentand90.21percent,respectively.Adeltashaped fin's Nusselt number outperforms a flat surface channelby176%.

-8

Wu et al. [14], The impact of a pair of delta-shaped fins positioned longitudinally as a vortex generator in a rectangular tube of heat exchanger with various degrees of inclination changing between 15°, 30°, 45°, and 60° was conceptually and numerically evaluated; the fluid employed was air. The outcomes demonstrate that, in comparison to a level surface, the Nusselt number of a surface with a pair of delta fins rises when the angle of inclination is elevated. The average Nusselt number increases by8 to 11 percentforangles15°,30°,45°,and 60°, respectively, and by 15 to 20 percent, 21 to 29 percent, and between 21 and 34 percent. They also discovered that the 60° angle of inclination has a bigger impactthantheotherangles.

Khoshvaght et al. [15], compared and evaluated seven typical channel layouts utilised in finned plate heat exchangers through experimental study. Experimental testing was done on all channels, including smooth, perforated, offset,louvres,corrugated,vortex generators, andpins.ThefluidusediswaterwithaReynoldsnumber range of 480 to 3770. Three energy performance evaluation criteria were used to determine the optimal channel. The results show that the vortex generator channel considerably improves the heat transfer

coefficient and properly reduces the heat exchange surface. Thus, fin plate heat exchangers chose it as a premium surface. Additionally, low Reynolds values are wherethecorrugatedchanneloperatesthebest.

Saha et al [16], To understand the relationship between localflowbehaviourandthemechanismofimprovedheat transfer, the performance of a plate heat exchanger was quantitatively examined. The numerical simulation was performed in a rectangular channel with longitudinal vortex generators embedded in the bottom wall and spaced regularly in both flow directions. They used two different types of fluid flow with two different types of vortex generators, namely the pair of rectangle fins (RWP) and the pair of delta fins, to gauge the improvementinheattransfer(DWP).Theperformanceof vortex generators was compared using integral (integer) measurements such the Nusselt number, pressure loss, and performance evaluation factor. The results showed thatRWPenhancedheattransfermorethanDWPdid.

Du et al [17], two oval tube heat exchangers with fins were experimentally tested for their heat transfer and pressure drop properties (HE1: double rows of tubes, HE2: three rows of tubes). The fins are angled in the airflow direction. To achieve the best heat transfer and pressure performance, four air intake angles (30°, 45°, 60°, and 90°) were individually evaluated with Reynolds numbers ranging from 1300 to 13000. On the air side, experimental correlations between the Nusselt number and the coefficient of friction were found, and overall evaluations of heat transfer efficiency were performed. The findings demonstrate that for heat exchangers that are positioned obliquely, the improvement in heat transfer performance is dependent on the degree of inclinationoftheairintake.

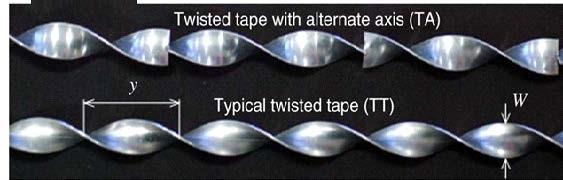

Wongcharee et al. [18], compared the effects of two distinct twisted band configurations (TA) and (TT), Figure 9. Experimental evaluations of the heat transfer and pressure drop characteristics of two oval tube heat exchangers with fins were performed (HE1: double rows oftubes, HE2: three rowsof tubes).The fins are directed toward the direction of airflow. Four air intake angles (30°, 45°, 60°, and 90°) were independently investigated with Reynolds numbers ranging from 1300 to 13000 to get the greatest heat transfer and pressure performance. On the air side, assessments of the total effectiveness of heat transmission were made, and experimental correlations between the Nusselt number and the coefficient of friction were discovered. The results show that the improvement in heat transfer performance for heatexchangersthatarepositionedobliquelydependson theangleoftheairintake.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

• Alternatingaxistwistedstriptubes(TA): (I.3)

• Typicaltwistedstriptubes(TT): (I.4)

through a channel with baffle plates. Journal of the Brazilian Society of Mechanical Sciences and Engineering,2004;26(2):153-159.

4. Bensenouci D, Aliane K, Sari-Hassoun Z. Thermal study of forced convection in a rectangular pipeequipped with baffles, 2nd International Conference of Renewable Energies CIER-2014. International Journal of Scientific Research & EngineeringTechnology(IJSET),2015;3:123-127.

5. Menni Y, Azzi A, Zidani C. Comparative numerical study between two types of baffles and fins, rectangular and rounded rectangular, used to improve the performance of flat air solar collectors, RenewableEnergies,2015;18(3):347–361.

Figure9:Twistedband

The experimental results obtained show that the VdeflectorprovidesanincreaseintheNusseltnumberwith theincreaseintheblockingfactor(e/H)ofabout187%at low Reynolds number compared to a channel without a deflector.

Review shows that the thermal performance at the level of this device depends essentially on the geometric parameters of the channel (thickness, length and width, blocking factor, etc.). Given the scientific interest, it was thoughtuseful to begina studyinthisdirection,withthe aimofdemonstratingtheimpactofinsertingtheelements inside the channel as obstacles in the opposite direction of the flow of the fluid on the intensification of heat exchanges. The shape, orientation, arrangement, and arrangement of the baffles by contribution to the flow of thefluid,thethermo-physicalparametersofthefluid,the flowregime.

1. Pethkool S, Kwankaomeng, S, Promvonge P. Turbulent heat transfer enhancement in heat exchange using helically corrugated tube. Int CommunicationsHeatMassTransfer,2011;38:340–347.

2. Promvonge P. Heat transfer and pressure drop in a channel with multiple 60° V-Baffles. International Communications in Heat and Mass Transfer, 2010; 37:335-840.

3. Demartini L. C, Vielmo H. A, Moller S.V . Numeric and experimental analysis of the turbulent flow

6. Tsay Y L, Chang T S, Cheng J C. Heat transfer enhancement of backward-facing step flow in a channelbyusingbaffleinstalledonthechannelwall, ActaMech,.2005;174:63–76.

7. BilenK,CetinM,Gul H,Balta T.Theinvestigationof groove geometry effect on heat transfer for internally grooved tubes. Applied Thermal Engineering,2009;29(4):761–769.

8. Nasiruddin M.H. Siddiqui K. Heat transfer augmentation in a heat exchanger tube using a baffle. International Journal of Heat and Fluid Flow, 2007;28:318–328.

9. J. Li, S. Wang, J. Chen. Numerical study on a slit fin and tube heat exchanger with longitudinal vortex generators. International journal of heat and mas transfer,2011;54:1743-1751.

10. Wang Y, Liu Z, Huang S. Experimental investigation ofshell andtubeheatexchangerwitha newtype of baffles,heatmasstransfer,2011;47:833-839.

11. BenzenineH,SaimR,AbboudiS,ImineO.Numerical simulation of the dynamic turbulent flow field through a channel provided with baffles: comparative study between two models of baffles: transverse plane and trapezoidal, Revue des EnergiesRenouvelables,2010;13(4):639–651.

12. Selvakumar P, Prakash J, Ponramsiva D, Ramesh R. Experimental investigationof Heat Transfer Enhancement Using Cross Inserts Having Different Pitch Rectangular Cuts. Journal of Thermal EngineeringandApplications,2014;2:2349-8994.

13. XuedongW,WenhuiZ,QiupingG,ZhimingL,YanliL. Numericalsimulationofheattransferandfluidflow

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

characteristics of composite fin. International journalofheatandmasstransfer,2014;75:414-424

14. Wu J. M, Tao W.Q. Effect of longitudinal vortex generator on heat transfer in rectangular channels. AppliedThermalEngineering,2012;37: 67–72.

15. Khoshvaght-A.M,HormoziF,Zamzamian A.Roleof channel shape on performance of plate-fin heat exchangers, Experimental assessment. International JournalofThermalSciences,2014;79:183-193.

16. Saha P, Biswas G, Sarkar S. Comparison of winglettype vortex generators periodically deployed in a plate-finheatexchanger–Asynergybasedanalysis. International Journal of Heat and Mass Transfer, 2014;74:292–305.

17. Du X.P, Zeng M, Dong Z.Y. Wang Experimental study of the effect of air inlet angle on the air-side performance for cross-flow finned oval-tube heat exchangers. Experimental Thermal and Fluid Science,2014;52: 146–155.

18. Wongcharee K, Eiamsa-ard S. Frication and heat transfercharacteristicsoflaminar swirl flow through the round tubes inserted with alternate clockwiseandcounter- clockwisetwisted-tapes. International Communications in Heat and Mass Transfer,2010;37:348-352.