International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Prof. Preethi AV1 , Dr. Rajendra S 2 , Mr. Sanjay HN 3

1Assistant Professor, Department of Civil Engineering, Vijaya Vittala Institute of Technology, Bengaluru, Karnataka, India

2 Principal, Vijaya Vittala Institute of Technology, Bengaluru, Karnataka, India

3 Student, Department of Civil Engineering, Vijaya Vittala Institute of Technology, Bengaluru, Karnataka, India ***

Abstract - In order to produce the concrete, a significant amount of natural resources are needed, particularly in the developing nations like India where urbanization and infrastructure development are on the rise. The fine aggregate is one such resource. Due to the gradual depletion of natural sand resources and the major issues they pose to both the environment and humanity, it has led to the exploration for other acceptable alternatives. The present work investigates about the development of a novel construction material by utilizing Recycled Concrete Aggregate (RCA) as substitution of natural fine aggregates in the production of concrete. The replacement is done from 0% to 30% at an interval of 5%. The grade of concrete used is M20 and w/c ratio maintained is 0.5. The experimental investigations have been done to examine the effect of RCA on the characteristics of concrete, including workability, compressive strength, split tensile strength and flexural strength. The results of the experimental investigation depict that the workability of the concrete reduces with increase in percentage of RCA and the optimum replacement of fine aggregates by RCA is 25%.

Key Words: Construction, Concrete, Fine Aggregates, Workability,Strength.

The combination of cement, fine aggregates, coarse aggregatesandwatermakeupconcreteanddependingon therequirements,admixturesorfibersorotheradditivesare also added. It's a heterogeneous composite and without a doubt,themostfrequentlyutilizedconstructionmaterialin the whole world. A semi-fluid mass may be created in the presenceofthesecomponentsandcanbemoldedintoany desiredshape.Usingpropercuringtechniques,concreteis turned into a hard solid material that may survive for hundreds of years. The versatility, dependabilityand sustainability of concrete, as well as its strength, rigidity, durability,mouldability,efficiencyandeconomyarereasons foritswidespreaduseintheconstructionsector

In influencing the fresh and curing properties, mix proportions and costs of concrete, the fine and coarse aggregatesthatmakeup60to70percentofthevolumeare criticalfactors.Aggregatequalityandtypearecrucialfactors

in concrete construction, since they are the basic building blocksofthefinishedproject.Gravelandstoneareoftenused in concrete as coarse aggregates, whereas river sand or naturalsandisgenerallybenefittedasfineaggregates.River sand,agranularsubstancemadeupoffragmentedrockand mineralparticlesthatoccursnaturally.Sandfromtheriver hasthepotentialtoreplenishitself.Silica(silicondioxide),in the form of quartz, accounts for the majority of the sand's composition, due to its chemical inertness and substantial hardness. The cost of natural sand grows as the supply diminishes near the point of consumption, increasing the entirebuildingcost.Findinganalternatematerialthatfitsthe technicalcriteriaoffineaggregateanditswideaccessibility wouldhelpensurelong-terminfrastructureexpansion.Civil engineershavebeenconductingabroadvarietyofstudiesin anefforttolocateanalternativesupplyoffineaggregates.

The bulk of the world's infrastructure is built using concrete.Asaconsequenceofthemanyconcretestructures have started to deteriorate due to the complicated interactions between concrete and its surrounding environment, as well as the lack of routine maintenance, concrete recycling is becoming increasingly popular when concreteconstructionsareremovedorrepaired.Itispossible to ensure the long-term viability of concrete structures by concrete recycling. Many locations can provide recycled concreteaggregates.Demolitionwasteandprecastconcretes arethemostcommonsourcesoftheseaggregates.Recycled concrete aggregates may be made from many crushing of concrete debris. Cementitious renderings and masonry mortarsasanaturalsandalternative,roadconstructionand fillermaterialforgeo-syntheticreinforcedbuildingsandsoil stabilization are all examples of low-grade applications wheretheyarenowemployed

Thevariousmethodsthatareemployedinthisstudyare asfollows

Thematerialsneededforthedevelopmentofconcrete, including cement, river sand, RCA, and coarse aggregatesareobtainedfromvarioussources.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Theprocuredmaterialsaresubjectedtobasictesting inthelaboratory.

Sl.No. Properties Results

ThemixdesignforconcretegradeM20isperformedin accordancewithIS:10262-2009,withaw/cratioof 0.5.

1 SpecificGravity 3.09

2 StandardConsistency 36%

3 InitialSettingTime 35min.

The various mix combinations are determined by replacingaportionofthefineaggregatesinconcrete withRCAat0%,5%,10%,15%,20%,25%,and30%.

4 FinalSettingTime 360min.

Before casting the specimen, the workability of concrete is examined in accordance with IS: 11991959.

The specimens are casted on various mix combinations and cured in accordance with the test requirements.

The compressive strength test isperformed in accordancewithIS:516-1959on150mm*150mm*150 mmcubespecimenscuredfor3days,7days,and28 days.

The split tensile strength is performedaccording to IS:5816-1999 on cylindrical specimens with a diameterof150mmandaheightof300mmthatcured for3days,7days,and28days.

Natural sand which is predominately utilized as fine aggregates, which is a key component of concrete. The hardened properties of the concrete are significantly impacted by the quality and fine aggregate density. By choosing fine aggregates based on grading zone, particle form,surfacetexture,abrasionandskidresistance,onecan increase the strength, durability and affordability of the concrete or mortar combination. The structural filler in concrete mix formulas that takes up the majority of the volume is fine aggregate. The significant outcome may be affectedbyvaryingthecomposition,shape,sizeandother characteristics of fine aggregate. The natural sand that is readilyavailableintheareaisutilized.Thesizeofthefine aggregates passing through 4.75mm is considered. Tests werecarriedoutinaccordancewithIS2386(PART3)-1963 Thebasicpropertiesofnaturalsandaregiveninthebelow table2.

The flexural strength is performedon 100mm* 100mm*500mm beam specimens cured for 28 days accordingtoIS:516-1959.

In a broader sense, cement refers to any adhesive substance, but in more specific it refers to the binding materialusedinbuildingandcivilengineeringprojects.The cement is made of finepowder, that when combined with water,solidifytoformasolidmass.Hydration,thechemical reaction of the cement compounds with water to produce minutecrystalsoragellikesubstancewithalargesurface area,iswhatcausessettingandhardening.Constructional cement,which will even set and solidify under water, are frequentlyreferredtoashydrauliccementsbecauseoftheir hydrating qualities. Of these, Portland Cement is the most significant. The OPC cement of Ambuja of grade 53 in accordance to IS: 12269-1987 is utilized throughout the study.Thebasicpropertiesofcementaregiveninthebelow table1.

Sl.No. Properties Results

1 SpecificGravity 2.57

2 SieveAnalysis 2.67

3 Bulking 4%

Stonethathasbeenshatteredintosmall piecesand is shaped erratically areconsidered ascoarse aggregates. In constructionprojects,aggregateslikelimestone,graniteand river aggregate are used. Although there are numerous elementsorcomponentsusedtomakeconcretemix,coarse aggregatesaccountforthemajorityofthemixvolumeand areoneofitsmostimportantconstituents.Themajorityof thetimes,theseaggregatesareobtainedbyblastingatstone quarries, breaking them by hand, or using crushing equipment.Thecoarseaggregateutilizedinthisprojecthas a maximum size of 20mm. The tests were carried out accordingtotheprotocoloutlinedinIS2386(PART3)-1963

The basic properties of coarseaggregatesare giveninthe belowtable3.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Table -3: PropertiesofCoarseAggregates

SN. Properties Results

1 SpecificGravity 2.67 2 SieveAnalysis 7.16 3 WaterAbsorption 0.45%

Multiple crushing of destroyed concrete yields the recovered fine aggregates needed for new concrete construction. For this project, 150 micron retained sieve aggregatesareemployed.ThepropertiesofRCAaregivenin thetable4.

Table -4: PropertiesofRCA

Sl.No. Properties Results

1 SpecificGravity 2.34 2 Bulking 9% 3 SieveAnalysis 3.52

Cement is mixed with water since it is the most cost effectiveandappropriatecomponent.Whenmakingconcrete, it is important to use water that is free of any dangerous impurities, such as oil or alkalis or acids. In general, only potableisimportantthatthemanufactureofconcreteinclude theusageofwater.SolongasthepHofthewaterremains constant is within the range of 6.5 to 8.5 and the organic materials are removed, it may be utilized to produce concrete.

ThemixdesignofconcretewithM20gradeiscarriedout asperIS:10262-2009.Thewatertocementratiomaintained is0.5.Theobtainedmixproportionsaregiveninthetable5 andvariousmixdesignationsaregiveninthetable6.

Sl.No. Materials

Proportion Weight(Kg/m3)

1 Cement 1 394.3 2 FineAggregates 1.58 624.9 3 CoarseAggregates 2.93 1157 4 Water 0.5 197

Table -6: MixDesignation

Sl.No. Mix Designation

1 R0 0%RCAReplacement 2 R1 5%RCAReplacement 3 R2 10%RCAReplacement 4 R3 15%RCAReplacement 5 R4 20%RCAReplacement 6 R5 25%RCAReplacement 7 R6 30%RCAReplacement

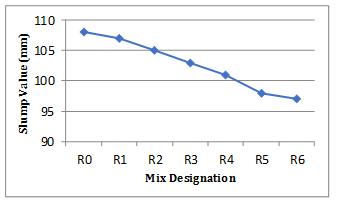

Theresultsoftheslumpconetestofconcretearegiven inthetable7.Itcanbeobservedthattheworkabilityofthe concretedecreaseswithincreaseinpercentageofRCA.This trend is observed because the water absorption of RCA is more when compared to the natural sand. The graphical resultsofworkabilitytestaregiveninthechart1.

Table -7: WorkabilityTestResults

Sl.No. MixDesignation SlumpValue(mm) 1 R0 108 2 R1 107 3 R2 105 4 R3 103 5 R4 101 6 R5 98 7 R6 97

R0 R1 R2 R3 R4

Chart -1:WorkabilityTestResults

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

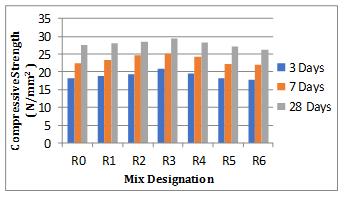

Theresultsofcompressivestrengthtestaregivenin thetable8 Thecompressivestrengthat28daysishighestfor R3 i.e., 29.33 N/mm2 and strength is increased by 6.42% when compared to conventional concrete R0. The compressivestrengthincreasesuptoR3 andfurtherrisein RCAreducestheconcrete’scompressivestrength.Itcanalso beseenthatthecompressivestrengthofR4isslightlyhigher compared to the conventional concrete R0 and has the satisfactory results. The graphical results of compressive strengthareshowninthechart2.

Sl.No. Mix

Designation

CompressiveStrength(N/mm2)

3Days 7Days 28Days

1 R0 18.32 22.35 27.56

2 R1 18.78 23.44 27.95

3 R2 19.32 24.67 28.44

4 R3 20.88 25.22 29.33

5 R4 19.64 24.33 28.20

6 R5 18.20 22.28 27.22

7 R6 17.67 22.12 26.20

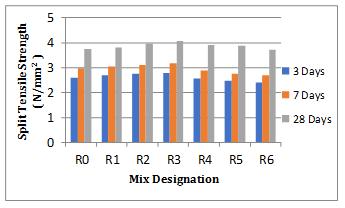

Sl.No. Mix Designation

Split-tensileStrength(N/mm2)

3Days 7Days 28Days

1 R0 2.61 2.97 3.74

2 R1 2.68 3.04 3.82

3 R2 2.75 3.11 3.96

4 R3 2.78 3.16 4.08

5 R4 2.56 2.89 3.92

6 R5 2.48 2.75 3.86

7 R6 2.40 2.68 3.72

Theresultsofthesplit-tensilestrengthtestaregiven inthetable9 Thesplit-tensilestrengthishighestforR3 i.e., 4.08 N/mm2 and strength is increased by 9.1% when compared to the conventional concrete R0. The further increaseinpercentageofRCAreducesthetensilestrengthof concrete.Itcanbeobservedthatthesplittensilestrengthof R5alsohassatisfactoryresultscomparedtotheconventional concreteR0 Thegraphicalresultsofthesplittensilestrength aredrawninthechart3

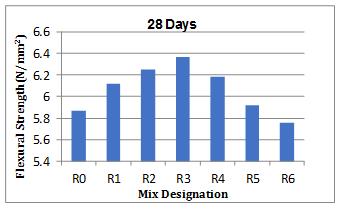

Theresultsofflexuralstrengthtestaregiveninthetable 10.TheflexuralstrengthofconventionalconcreteR0 at28 daysis5.87N/mm2.TheR3hasthehighestflexuralstrength of 6.37 N/mm2 at 28 days which is 8.5% more when comparedtotheR0.ItcanbeobservedthatR5hasresultthat issatisfactorytoR0.Thegraphicalresultsofflexuralstrength testaregiveninthechart3.

SN. MixDesignation

FlexuralStrength(N/mm2)

1 R0 5.87

2 R1 6.12

3 R2 6.25

4 R3 6.37

5 R4 6.18

6 R5 5.92

7 R6 5.76

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

[4] CatarinaNeno,JorgedeBritoaandRosárioVeiga“Using Fine Recycled Concrete Aggregate for Mortar Production” Materials Research,2014.

[5] Mohd Monish, Vikas Srivastava1, V. C. Agarwal and RakeshKumar“Utilizationofdemolishedwasteasfine aggregateinConcrete”JournalofArtificialIntelligence Research,Vol.1(7)December2012

[6] Sami W. Tabsh, Akmal S. Abdelfatah “Influence of recycledconcreteaggregatesonstrengthpropertiesof concrete”ConstructionandBuildingMaterials23(2009) 1163–1167.

The conclusions that can be drawn from the study are as follows.

The workability of the concrete decreases with increaseinpercentagereplacementofRCA

[7] L. Evangelista and J. de Brito “Mechanical behavior of concretemadewithfinerecycledconcreteaggregates” CementandConcreteComposites,Vol.29,Issue5,May 2007

TheR3hasthehighestcompressivestrengthof29.33 N/mm2 at 28 days which is 6.42% more when comparedtotheR0.

The highest split-tensile strength of 4.08 N/mm2 is examinedforR3 whichis9.1%morewhencompared totheR0at28days.

Theflexuralstrengthat28daysishighestforR3which is8.5%morewhencomparedtotheR0.

TheoptimumreplacementoffineaggregatesbyRCA inconcreteis15%.

[1] MarijaNedeljkovi´c,JeanetteVisser,BrankoSavija,Siska ValckeandErikSchlangen“Useoffinerecycledconcrete aggregates in concrete” A critical review Journal of BuildingEngineering38 (2021)102196

[2] Ritesh Vishwakarma and Pratiksha Malviya “An experimentalstudyonpropertiesofconcreteusingRHA andRFAasapartialreplacementoffineaggregatesand fly ash as a cement” International Journal of Trend in ResearchandDevelopment, Vol.3,Issue3,2019

[3] SMuthuLakshmiandRRNivedhitha“Effectofpartial replacementofaggregatesbyrecycledconcretedebris on strength of concrete” Malaysian Journal of Civil Engineering27(2):250-259,2015