International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

2

1M. tech student, National Institute of Technical Teachers Training & Research, Chandigarh 2Professor, Department of Civil Engineering, NITTTR Chandigarh ***

Abstract- Today's most popular building material, concrete, is also the subject of most civil engineering studies. It has applications not just in building constructionbut alsoinallthe structures created to support loads in some form. Even after years of study on this material, many researchers believe that our understanding of concreteis incomplete, andtherearestill many associated challenges; thus, the research should continue. One such issue is its weight, which prevents it from being used as a masonry unit when produced conventionally. This study is a small step towards the larger objective of creating a form of concrete that may effectively replacebricks as a masonry unit whose production results in significant carbon emissions during their burning stage.

Key Words: Aerated Concrete, Modified Aerated Concrete, Embodied Energy, Aerating Agent, Autoclaving, Compressive Strength, Lightweight Concrete

Numerousattemptshavebeenmadetomaketheconcrete lighter.Afewmethodsfoundtodosoare:

i) By replacing conventional aggregates with by cellular,porous,orlightweightaggregates.

ii) Byomittingsandfractionfromaggregatestomake 'nofinesconcrete'.

iii) By introducing air bubbles in mortar to make 'aerated concrete'

Thetechniquesmentionedabovecanproducelightweight concretewithadensityof300and1,850kg/m3;however, thedrawbackofthistypeofconcreteisthatitsstrengthis much less than that of concrete manufactured using the typical technique. This study involves the testing of 'modified aerated concrete' to make concrete lighter withoutsignificantlyreducingitsstrength.

Normally, aerated concrete is made by introducing air bubblesintoaslurrycomposedofcementandsandmixedin water by adding an air entraining agent. The concrete producedisautoclavedtoenhanceitsdimensionalstability andmakethestrength-gainingprocessquick,thusgivingit anothername-autoclavedaeratedconcrete(AAC).

For this study, coarse aggregates were added to aerated concretereplacing5%ofthesandinthe,whichisthencured conventionallyfor28days.Autoclavingisnotperformed,as is common with aerated concrete, thus referring to it as modifiedaeratedconcrete.

Thefollowingmaterialswereusedinthestudy:

Two different aerating agents: Aluminum Oxide (Al2O3) and Zinc Oxide (ZnO) added 0.4%, 0.5%, 0.6%and0.7%byweightofbindingmaterials. Coarseaggregatesoffollowingtwosizesreplacing 5%sandbyweight:

o 10mmgradedaggregates o 12.5mmgradedaggregates Grade53cementoftwodifferentbrands: o CementA o CementB

Theresearchwasconductedtodeterminetheoptimalmixof cement, sand, coarse aggregates, and aerating agent to producemasonryblockscomparableorsuperiortofirst-class bricksintermsofdensity,compressivestrength,andwater absorption.

Thestepwiseprocedurefollowedtomeettheobjectiveisas writtenbelow:

i) Reference Design: Fromthestudiesconductedon autoclavedaeratedconcretesofar,1partofcement, 0.11partsoflime,1.11partsofsandandwaterto binderratio0.5withaeratingagentdosageof0.5% bywightofbinderwasfoundtobeitsmostoptimal design. [5]

ii) Mould Formation: Forcasting,23cmx11.4cmx 7.6cmwoodenmoldsweremade.

iii) Reference Cubes: 24 reference cubes were cast usingthereferencedesignmentionedinstep1with differentcementtypesandaeratingagentslistedin theTable1below.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

iv) Test Cubes: 5%ofsandwasreplacedwithcoarse aggregates in the reference design. A total of 192 cubes,6eachof32distinctcombinationsofvarious componentsandproportions,asmentionedinTable 2belowwerecast.

Table -1: Combinationsofairentrainingagentsand cementtypesusedinthereferencecubes.

Sr. No. Air Entraining Agent Cement Type Count of Cubes

1 AluminiumOxide CementA 6

2 AluminiumOxide CementB 6

3 ZincOxide CementA 6

4 ZincOxide CementB 6

Table -2: Combinationsofairentrainingagents,cement typesandaggregatetypesusedinthetest(main)cubes.

Sr. No. Air entraining agent (% by wt. of binding material) Cement Type Size of Coarse aggregates (mm)

1 AluminiumOxide(04) CementA 12.5

2 AluminiumOxide(0.5) CementA 12.5

3 AluminiumOxide(0.6) CementA 12.5

4 AluminiumOxide(0.7) CementA 12.5

5 AluminiumOxide(0.4) CementA 10 6 AluminiumOxide(0.5) CementA 10 7 AluminiumOxide(0.6) CementA 10 8 AluminiumOxide(0.7) CementA 10 9 ZincOxide(0.4) CementA 12.5 10 ZincOxide(0.5) CementA 12.5 11 ZincOxide(0.6) CementA 12.5 12 ZincOxide(0.7) CementA 12.5 13 ZincOxide(0.4) CementA 10 14 ZincOxide(0.5) CementA 10 15 ZincOxide(0.6) CementA 10 16 ZincOxide(0.7) CementA 10 17

AluminiumOxide(0.4) CementB 12.5 18 AluminiumOxide(0.5) CementB 12.5 19 AluminiumOxide(0.6) CementB 12.5 20

AluminiumOxide(0.7) CementB 12.5 21

AluminiumOxide(0.4) CementB 10 22 AluminiumOxide(0.5) CementB 10

Factor value:

23

AluminiumOxide(0.6) CementB 10 24 AluminiumOxide(0.7) CementB 10

25 ZincOxide(0.4) CementB 12.5

26 ZincOxide(0.5) CementB 12.5

27 ZincOxide(0.6) CementB 12.5

28 ZincOxide(0.7) CementB 12.5

29 ZincOxide(0.4) CementB 10

30 ZincOxide(0.5) CementB 10

31 ZincOxide(0.6) CementB 10

32 ZincOxide(0.7) CementB 10

Six cubes of each set of materials and composition were cast, two each for compressive strength on the seventh day, compressive strength on the twenty-eighth day, and water absorption & density.

Followingtestswereperformedonthecubescast: i) WaterAbsorptionTest ii) CompressiveStrengthTeston7th and28th Day

TheInferencesfromtheresultsobtainedareasfollows:

i) Much less bulging (aeration) was found than is claimedinmostoftheresearchworksdonesofar, whichmaybebecauseofthefollowingreasons:

a. No autoclaving done:

In almost all the works, the major bulging (aeration) occurred during the autoclaving, suggesting that a significant portion of the reaction between cement and the aerating agentoccurredinautoclaves.

b. Inclusion of coarse aggregates:

Onlyfineaggregateswereusedinalltheworks carried out thus far on aerated concrete to keep its weight light. However, in this work, 5% of fine aggregates were replaced with coarseaggregates,makingtheaerationprocess difficult.

Also, since lesser aeration took place, more material was required to fill the blocks, increasingtheweight.

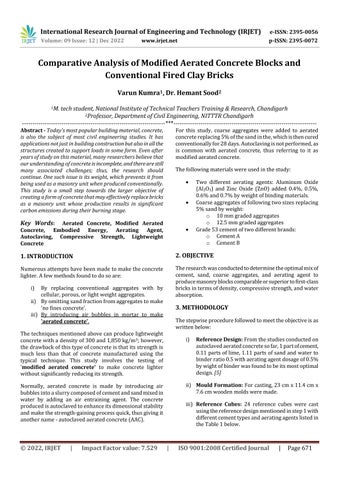

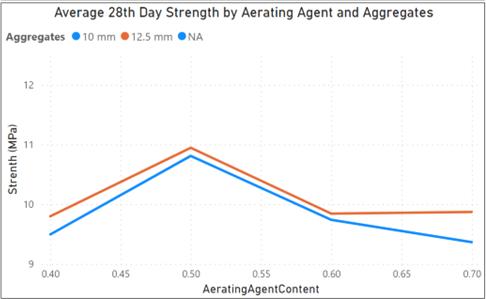

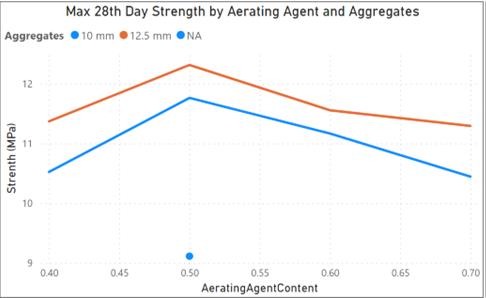

ii) Thebestresultswereobtainedattheaeratingagent dosage of 0.5% by weight of the binder. [Error! Reference source not found., Error! Reference

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

source not found., Error! Reference source not found. & Error! Reference source not found.]

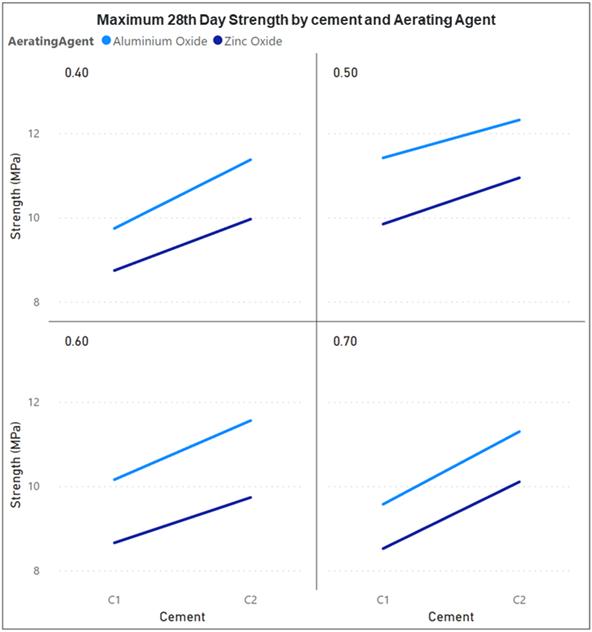

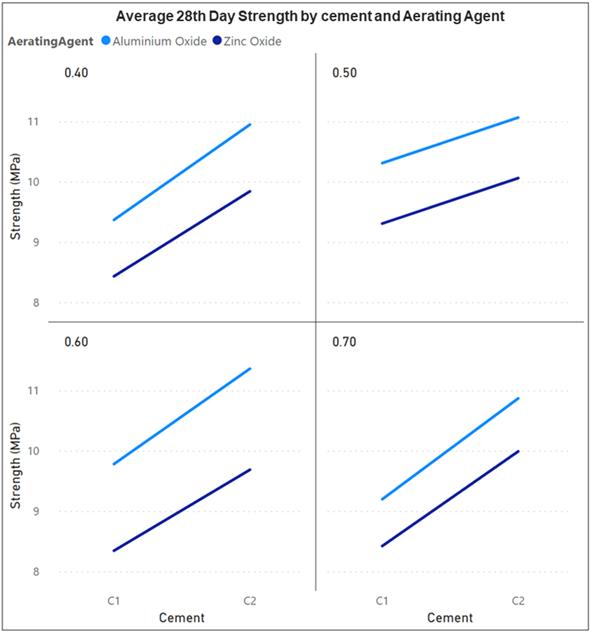

iii) BetterresultswereobtainedinsampleswhereAl2O3 was used as an aerating agent rather than ZnO. [Evidentfrom Error!Referencesourcenotfound. & Error! Reference source not found.]

Chart -1:Maximum28DayStrengthv/sAeratingAgent Content

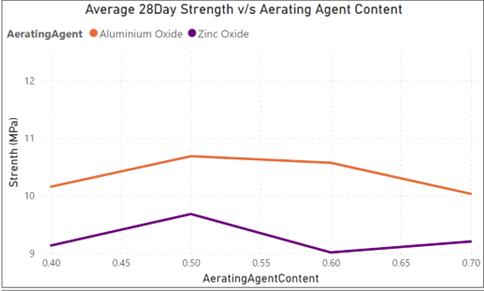

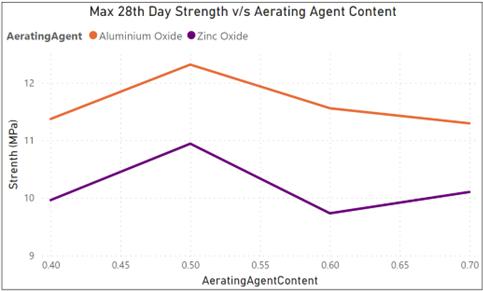

Chart -3:Maximum28DayStrengthv/sAggregateSize

Chart -2: Maximum28DayStrengthv/sAeratingAgent Content

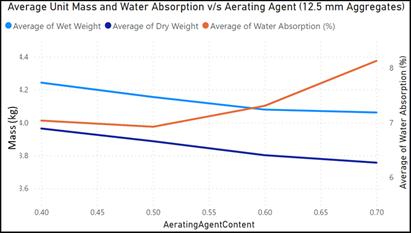

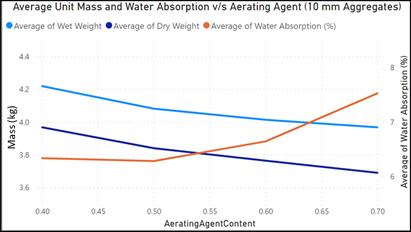

iv) 12.5mmaggregatesgaveabetterresultintermsof strength,asevidentfrom Error!Referencesource not found. and Error! Reference source not found..

Chart -4:Average28DayStrengthv/sAggregateSize

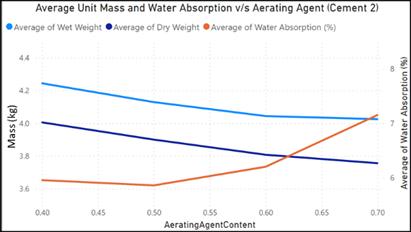

v) Overall,Cement2wasabetterperformerintermsof strength,asseenin Error! Reference source not found. and Error! Reference source not found.. However,slightlyhigherunitweightsareobtained in the samples prepared by it [Error! Reference source not found. and Error! Reference source not found.].

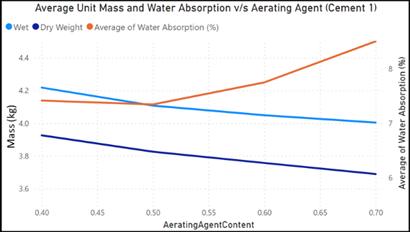

vi) Mass Decreases with the increased dosage of the aeratingagent.However,theleastwaterabsorption wasfoundatthedosageof0.5%bymassofbinder, suggestingthebestworkabilityandleastconnected pores[Figure7,Figure8,Figure9andFigure10].

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page673

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Chart -5:Average28th DayStrengthv/sAeratingAgent ContentandCementType.

Chart -7:AverageMassandWaterAbsorptionv/sAerating AgentforCementA

Chart -6:Maximum28thDayStrengthv/sAeratingAgent ContentandCementType.

Chart -8:AverageMassandWaterAbsorptionv/sAerating AgentforCementB.

Chart -9:AverageUnitMassandWaterAbsorptionv/s AeratingAgentfor12.5mmAggregates.

Chart -10:AverageUnitMassandWaterAbsorptionv/s AeratingAgentfor10mmAggregates.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Theresultsdiscussedandanalyzedabovesuggestthatthe best strength was found with the combination when aluminiumoxidewasusedatadosageof0.5%byweightof thebinder,cement-2with12.5mmaggregatesreplacing5% ofsand.

Althoughtheblockswerefoundtobeeffectiveintermsof strengthbutwereslightlyontheheaviersidecomparedto thefirst-classbricks,whichweighonly3.2kg,incontrastto the block with the best compressive strength of 12.32 kN, whichweighs4.04kg.Thisincreasedmassisbecauseoftwo significantreasonsmentionedbelow:

i) Coarseaggregatesareaddedtotheconcrete.

ii) Normal curing is done in place of autoclaving, leading to the aerating agent's slower and lesser activity,thusdecreasingtheamountofairentrained intheconcrete.

Duetohigherunitweightthanthebricks,theseblocksare currently not fit to be used in load bearing, replacing the bricksasmasonryunits.However,thepotential thatthese blockshaveshownishighlyencouragingandthusthestudy tofindimprovementsintheirdesignshouldcontinue.

[1] Begum,Razia&Habib,Ahsan&Mostafa,Shah.(2014). EffectsofRiceHuskAshontheNonAutoclavedAerated Concrete.IJEIR.3.2277-5668.

[2] Fudge, C., Fouad, F., &Klingner, R. (2019). Autoclaved aerated concrete.Developments In The Formulation And Reinforcement Of Concrete, 345-363. doi: 10.1016/b978-0-08-102616-8.00015-0

[3] Habib,Ahsan&Begum,Ara&Hafiza,Eng.(2015).Study onproductionofAeratedconcreteblockinBangladesh.

[4] He,T.,Xu,R.,Da,Y.,Yang,R.,Chen,C.,&Liu,Y.(2019). Experimental study of high-performance autoclaved aeratedconcreteproducedwithrecycledwoodfibreand rubber powder.Journal Of Cleaner Production,234, 559-567.doi:10.1016/j.jclepro.2019.06.276

[5] Kunchariyakun, K., Asavapisit, S., &Sombatsompop, K. (2015). Properties of autoclaved aerated concrete incorporatingricehuskashaspartialreplacementfor fine aggregate. Cement And Concrete Composites,55, 11-16.doi:10.1016/j.cemconcomp.2014.07.021