International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

1,2

Abstract - The analysis and performance testing of milk pasteurization system that is based on the solar energy as a thermal source for pasteurizing the milk . This is adapted for using at remote areas and villages, communities where the small quantities of milk delivered by individual producers who are deprived of the availability of gas and electricity. A solar parabolic dish collector is used for heating milk and PV solar plates setup used for cooling purpose of milk. Milk pasteurization is a process which involves heating of milk to a temperature that kills diseases causing microorganisms and substantially reduces the level of spoilage organisms. In dairy the pasteurization of milk is very very important process. All milk produced at a processor and intended for consumption must be pasteurized, legally requiring it to be heated to at least 73°C then cooling it to 4°C to ensure any harmful bacteria are to be destroyed. For this process, heating of milk is necessary and it done by diesel energy or electric energy. The sources of this energy are very limited and currently India is facing with shortage of about 21% of electric energy. Hence solar energy is good option for this process. The changes in intensity of solar radiation had a direct impact on solar milk pasteurizer.

Keywords:-Solar Energy, Chilling Plant, Milk Pasteurization,Micro-organisms,Heater.

1.INTRODUCTION

The term 'solar energy' refers to energy generated from capturing the sunlight and heat from the Sun. Technology has developed several ways to utilize this abundant resource. It is considered as a green technology becauseofitdoesnotemitgreenhousegases.Solarenergy is abundantly available on earth and it has been utilized since long time for both as electricity and as a source of heat. The usage of this renewable energy sources can reducesthepollutantemissionsintotheatmosphere.Solar energy,especiallywhenusedefficiently,canplayacrucial roleindevelopinganddevelopednationsalike.

Solar energy has been used since pre-historic times, but in a most primitive manner. Before 1970, some researches and development works were carried out in a few countries to exploit solar energy more efficiently, but most of this work remained mainly academic. After the dramatically rising in oil prices in the

1970s most of the countries began to formulate and extensive research and development programs to exploit solarenergy. Wheneverwe hangout ourclothesto dry in the sun, we use the energy of the sun. In the same way solar panels absorb the energy of the sun to provide heat tothesystem.

Solarenergyistheenergyfromthesunintheformof radiated heat and light.Itdrives the climate and supports life on earth. Solar energy is freely available source of energy. It does not belong to anybody. It is the most important non-conventional source of energy because it does not pollute environmentand ithelpsin reducingthe greenhouse effect. Solar energy is the clean and natural sourceofenergyanditisavailableinhugeamount.

The development of inexhaustible, affordable and clean solar energy technologies will have been huge longer-term benefits. It will increase countries energy security through relianceon an inexhaustible, indigenous and mostly import-independent resource, enhance sustainability, reduce pollution, lower the costs of mitigating, reduce global warming and keep fossil fuel prices lower than otherwise.

Solar energy is the radiation from the Sun capable of producing heat, causing chemical reactions, or generating electricity.Ifsuitablyharnessed,solarenergyontheearth has the potential to satisfy all future energy needs to entire earth. India is a country in which solar energy is available in massive amount and also favorable place for theuseofthatsolarenergy.

The consumption of non-renewable sources like oil, gas,woodandcoalareincreasingat higherrate.Thetime has finally come to look after some other renewable sources of energy like solar, wind and geothermal energy. Many countries have started utilizing solar energycancovermostlytheirdemandsbuttheystillhave to goalongwaytoexploitthisrenewableenergytofulfill theirdailyneeds.

Somepeoplecreateacompletelywrongpictureofthe relevance,requirementandimportanceofsolarenergyfor India.Theyusuallyfocusonthecostandaffordabilityina short-sighted way and ignore the larger issues of energy availabilityandenvironmentalhealth.Indiahasamassive

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

advantage in terms of geography. Solar power is free and forever.Itiscleanandavailableeverywhere.

In the desert zone is having abundant solar energy available and it is suitable for harnessing solar energy for several applications. In areas with similar intensity of solar radiation, solar energy should be easily harnessed. Solar energy can also be used to meet our electricity requirements through solar photovoltaic (SPV) cells and that solar radiation gets converted into dc electricity directly. Thiselectricitycan eitherbeusedasitisoritcan bestoredinthebattery.Thisstoredelectricalenergythen can be used at night but such systems are costlier one & restrict the application of solar for producing electricity. This energy can be used for cooking, heating, drying, distillation,power.

There is a urgent and general need for rapid procedures, applicable to monitor, to control, to process food safety and quality. Pasteurization is a process in which certain packaged and non-packaged foods (such as milk and fruit juice) are treated with mild heat, usually less than 100 °C (212 °F), to eliminate pathogens and extend shelf life. The process of safeguarding foods by destroying or inactivating organisms that contribute to spoilage, including vegetative bacteria but not bacterial spores.

Pasteurization is the process of heating a liquid to belowtheboilingpointtodestroymicro-organisms.Itwas developed by Louis Pasteur in 1864 to improve the keeping qualities of wine. The process of heating milk for healthbenefitshasbeenrecognizedsincetheearly1800’s was used to reduce milk borne illness and mortality in infants inthelate1800’s.As societyindustrializedaround the turn of the 20th century, increased milk production and distribution led to outbreaks of milk borne diseases. Common milk borne illnesses during that time were typhoid fever, septic sore throat, scarlet fever, diphtheria, and diarrheal diseases. These illnesses were virtually eliminated with the commercial implementation of pasteurization in combination with improved management practices on dairy farms. In 1938, milk products were the source of 25% of all food and water borne illnesses that were traced to sources, but now they account for far less than 1% of all food and water borne illnesses.

Commercial pasteurization of milk began in the late 1800s in Europe and in the early 1900s in the United States. Pasteurization became mandatory for all milk sold within the city of Chicago in 1908 and in 1947 Michigan becamethefirststateintheworldtorequirethatall milk forsalewithinthestatetobepasteurized.In1924theU.S. public health service developed the standard milk ordinancetoassiststateswithvoluntarypasteurizationof

milkprograms. The grade A pasteurized milk ordinance (PMO), as it is now called a administered by the U.S. departments of health and human services and public health and the food safety and drug administration and provides practices relating to milk parlor and processing plant design, milking practices, milk handling, sanitation, and standards forthepasteurizationofgradea milk products. Each state still regulates milk processing within their own state but dairy products must meet the regulationsstatedinthePMOfordairyproducts.

Initial pasteurization conditions known as flash pasteurization,weretoheatthemilkto 68.3°Cto81°Cfor an instant followed by cooling. Pasteurization conditions were adjusted 61.7°C for 30 minutes or 71.1°C for 15 seconds to inactivate my urobacterium bevies, the organism responsible for tuberculosis. However, in 1957 these conditions were shown to be inadequate for the inactivation of coxiella burnetiid which causes fever in humans.

There is a dire need for reformulation of the environmental impact of traditional fossil fuel industries. Deforestation, global warming, CO2 emissions, air pollution, and global warming are just a few of the negative consequences of traditional fossil fuels. Additionally, fossil fuel reserves are depleting day by day andthesupplyislimited.

Normally for heating of milk, the fuels such as diesel or coal energy or electric energy arerequired, but these energy sources are going to deplete in the coming future days. With the increase in fuel costs as well as their decreasing availability, and with the rapid growth in the Indian population, solar energy is becoming more and moreimportant.Inthisstudy,effortsaredirectedtowards alternative methods for heating of milk for industrial processesthroughthermalroute.

In India, the proposed system may present the possibility of saving a significant amount of liquid and gaseousfossilfuelsusedinindustrialprocesses,aswellas electricity used in such processes, which are useful for reducing the overall shortage of energy are experiencing atpresent.

It has been reported on numerous occasions that there are different types of techniques used for pasteurization of milk and their uses for various applications. In this study, the construction, results and conclusionsofsuchpapersarediscussed.

Mekhilef. S et al. [1] have concluded that presently, solar energy conversion is widely used to generate heat andproduce electricity.Ithasfounded thatsolarthermal

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

is getting remarkable popularity in industrial applications. Solar thermal is an alternative to generate electricity,processchemicalsorevenspaceheating.Itcan be used in food, textile, non-metallic, chemical, building or even business related industries. On the other hand, solar electricity is wildly applied in telecommunication, agricultural, water desalination and building industry to operate lights, pumps, engines, fans, refrigerators and water heaters. The present work aimed to study of the solar energy systems utilizationin industrial applications and looked towards into the industrial applications which are more compatible to be anintegratedwiththesolarenergysystems.

Panchal H. et al. [2] have concluded that solar pasteurization system is used to kill harmful bacteria presentinthe raw milk.Itiscarriedout thatin the dairy industries with the help of boilerand using wood orcoal for heating of the milk. Due tothe regularly increment of global warming and its harmful effects, coal or wood shouldnotbeusedformilkpasteurizationsystem.Hence, researchers had been started working on renewable energy sources like solar energy for pasteurization system. Many scientists or researchers from all around the world have attempted to use solar energy for milk pasteurization system. The present paper shows the research works carried out by researcher on milk pasteurization system. After several reviews, it has been found that the solar energy is the best solution for milk pasteurizationsystem

Thu S. M. et al. [3] haveconcludedthatrefrigeration is the process of removing heat from substance or space to reduce its temperature and transferring that heat to another substance or refrigeration is providing and maintaining the temperature below that of the surroundingatmospherictemperature.Designcalculation of evaporator, compressor and cop of existing ice plant are determined. Ammonia(NH4) is used as refrigerant in this ice plant and to improve cop of ice plant, refrigerant changingcanbeconsidered.

Hafez A.Z. et al. [4] haveconcludedthattheeffectof solar dish design features and factors such as material of the reflector concentrators, the shape of the reflector concentrators and the receiver, the intensity of solar radiation at the concentrator, diameter of the parabolic dish concentrator, sizing the aperture area of concentrator, sizing the aperture area of receiver, the focal point diameter, focal length of the parabolic dish, geometric concentration ratio and rim angle had been studied.

Wankhede U.S. et al. [5] has concluded that for the chilling plant or ice plant prefer ethylene glycol is the better option as a secondary refrigerant as per the

requirement of the system.The reason behind choosing ethylene glycol as a secondary refrigerant because it has excellent thermodynamic and physical properties over theconventionallyusedbrinesolution.

Sunaris M. L. et al. [6] haveconcludedthatpipeisa closed conduit, usually of circular section, which is used for carrying fluids under pressure. The pipe running partially full, in such a case atmospheric pressure exists insidethe pipeandalso behaveslike an open channel.In general,energyorheadlossesonpipeconsistedofminor energy losses due to sudden enlargement of pipe, sudden contractionofpipe,bendinpipe,anobstructionin pipe, pipe fittings etc. and major energy losses due to friction to analyze energy losses in smooth pipes. There are several steps for analysis such as calculation of Reynolds number (Re) in order to determine flow type, calculationoffrictionfactorbyusingseveralformulas,and calculation of roughness value (k) on smooth pipe with differentvariousscenarios.

Vincent E. et al. [7] haveconcludedthatdespite the existence of pasteurization and its advocacy worldwide, most marketed milk in a developing country like Nigeria aresoldrawbythelocals.Itcosts hundredsofmillionsof nigerias money to set up a conventional pasteurization plant in Nigeria. Boiled milk ends up curdling which results in to a loss of nutrients from the milk, so it is not beneficialtotreatmilkbythismethod.

Raibhole V. N. et al. [8] have concluded that ice plant works on the principle of vapor compression cycle using eco-friendly refrigerant R134a. The refrigerant R134a is used as it is best alternative to R12 has zero ozone depletion potential (ODP) and have similar thermodynamic properties to R12. Performance of ice plant is very very much sensitive with operating parameters, so that continuous monitoring for this process is very much needed with the provision of data backup.

Panchal H. et al. [9] haveconcludedthatduetouse of fossil fuels for the human activities found a significant effect on the environment as well as people's health. Hence,theresearchpeoplesfromallaroundtheworldare searching for the sustainable solution through nonconventional sources of energy like biomass, wind, solar energy etc. Among all the non-conventional sources of energy, solar energy is prevalent. Pasteurization is a process of heating of food or liquid for the killing of bacteria. For pasteurization of milk, dairy industries require boiler or heat exchanger and it consumes energy andsometimestheyneedfossilfuels.

Yadav J. P. et al. [10] have concluded that refrigeration may be defined asthe process of achieving and maintaining a temperature below that of the

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

surroundings, the aim being to freeze ice, cool some product, or space to the required temperature. The basis concept of modern refrigeration system is the ability of liquids to absorb enormous quantities of heat as they boil and evaporate. One of the major important applicationsofrefrigerationisanicemaking plant.Inice plantmostofthetimesvapourcompressioncycleisused. The vapor compression cycle comprises four process compression,condensing,andexpansionandevaporation process.

Farjana S. H. et al. [11] have concluded that in developing countries, industries and manufacturing sectorsconsumeamajorportionofthetotalconsumption of energy, wheremostoftheenergyisusedforlow,high or medium temperature heat generation to be used for process applications known as process heat. The necessity to be commercialize clean, cheap and efficient renewable sources of energy in industrial applications emerges from increasing concerns about greenhouse gas emissions and global warming and decreasing fossil fuel use in the commercial sectors. Due to abundant and massivesourceof energy,solar energytechnologieshave beenprovenpotential.

Igweonu E. I. et al. [12] have concluded that solar energy as a source of renewable energy has been acknowledged to be a potential source of heat for domestic and industrial purposes. Efficiency of different types of solar collectors and the determining factors affectingtheefficiencyofcollectors,andpresentsthemas predeterminied factors in the choice of collectors at the userendforcostandoperationaleffectiveness.

Alarcon J. A. et al. [13] have concluded that the developmentofasolarparabolicdishcollectorprototype forruralareaswithhighsolarresourceavailabilitywhich have no access to electricity service or budget resources to purchase of stove (electric or gas). The solar collector prototypeproposesasolutionforthetosolvethesekinds of problems and use sunlight to work it. Through a polished stainless-steel parabolic dish collector, solar radiation is concentrated into a specific area called as focus.

Sah R. P. et al. [14] haveconcludedthatasthereisa time gap between milking and storage, milk spoilage is more in remote areas in India, hence, immediate pasteurization and storing facility is required. For pasteurizationheatingiscompulsory.InIndiamostofthe villages face scarcity of electricity, hence, solar related and biomass heat (easily available) is a good option for milkpasteurizationsystem.

Mohammed I. L. et al. [15] has concluded that for effective performance the design requires that parabolic dish collector track the sun continuously and an

automatic electronic control circuit was designed and developed for this purpose. The use of a linear actuator (Super jack) to track the sun eliminates the need for constant monitoring by a human operator and, thus, reducesthecostoflabor.

Rabab Zahira et al. [16] have calculated and discovered different techniques have been developed to make use of solar radiations such as solar milk pasteurizer and it is possible to pasteurize milk using solar energy with careful operation and the actual definition of pasteurization is; the heating of milk to a specific temperatures for a specific time to reduce undesirableenzymesandbacteriatonegligiblelevels.

Muhammad Azam et al. [17] have told that today theuse of modernfuel is so expensiveand evencount as one of the major pollution sources. In areas where sunlight is plentiful the use of sunshine to cook the food and pasteurize contaminated water and milk require our more concentration on industrial level to develop cheap andpollutionfreetechnologyandtheirsystemiscapable astoreducethepollutionandelectricityconsumption.

Zorraquino et al. [18] have told that the milk is a natural liquid food, is one of our most nutritionally complete foods. Milk contains bacteria when improperly handlescreateconditionswherebacteria canbemultiply Antibiotic residues inside milk due to use of antibiotics widelyinfoodproducinganimals,supposedproblemsfor the both dairy industries and consumers. To kill that bacteria's or microbes which develop slowly or create pores, suitable standerd temperature and time must be applied for processing and they applied same temperaturethentheygotthedesirableresult.

Marco Lucentini et al. [19] have analyzed that technical and economic feasibility of an innovative plant, through the operational simulations of each machinery, related to different radiation conditions during the year. The economic analysis has shown that this solution is worth-while, especially taking advantage from the

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

incentivesofferedbythenationalcampaignofrenewable energy diffusion Moreover, For a correct sizing of a solar plant it is necessary to resort to economic evaluation methods, where the plant is to be considered as an integral part of the conventional plant. An accurate analysis of costs and proceeds of the integrated plant must be carried out in all its planned life cycle. Income and expenditure over the various years must be actualizedandanappropriate economicvariable,suchas the recovery time, must be taken into account. The main research parameters, like the collector’s area and the storage tank capacity, are to be determined so as to minimizetheeconomicvariablechosen.

Atia et al. [20] they have described the application of solar collector in milk processing that involves liquid milk movement and it is an important operation which cannot be overlooked. The flowability of milk within a system is determined by its density and viscosity. The physics of these properties go a long way in the determination of developing a heat exchanger. Since in the food and dairy industry consumables are produced, paramountimportanceisplacedonthematerialsandthe thermal treatments of these foods. Through the thermal bacterial destruction kinematics studies, the time required for a specific fraction of pathogenic organism destructionhasbeenexamined.

Muhammad Usama Yaseen et al. [21] have fabricated a solar milk pasteurizer from standard applianceshippingcardboardwithmultiplelayersofthe regular aluminum foil glued onto cardboard which was insulated with a large card board box which contains the rectangularareaandaremovableglasswindowhasbeen used for work. The inner box having volume (52.5×24×36) cm covered on both sides with aluminum foil.Ametaltraypaintedblack.Thisexperimentwasdone attemperaturerangingbetween65to75˚C.

Nielsen et al. [22] have designed and developed a prototype solar panel-based pasteurization system. The system has been tested in the laboratory using a solar panel of 10 kW. They had found 71° is the best temperature for pasteurization process. They had also been concluded that the energy payback time is around 20 years. In this research a design process for solar base pasteurizer is presented. Different concept designs are generated and evaluated. Effect of tilt angle on solar pasteurizerisalsostudied.

Virgiliu et al. [23] have studied that, for better utilization of solar energy two components namely collector and storage unit are required. The collector absorbsthesunlightthatfallsonthecollectorandsends it to other forms like electricity, heat etc. The power storage unit is essential for the collection of energy

because during cloudy days, the energy generated is small. The storage unit can store energy during the periods of maximum radiation and Solar milk pasteurizationistheprocessofkillingbacteria frommilk and making it free of micro-organisms by using the sun rays.Thesun rays areutilizedtoproducethesteamwith the help of solar vacuum tube collector which produces hotwateratveryhightemperature.

Duffie et al. [24] have concentrated solar thermal energy system that is designed and constructed with the conventional parabolic concentrator. The receiver is placed along the line between the centre of the concentrator and the sun. The receiver used for this is coiled helically with specific design so that all the solar rays concentrated at centre have received without shadow.Manualtrackinghasbeenusedduringevaluation stage. This allows for effective collecting and concentrating of the incoming solar irradiation and they hotasrequiredtemperaturetorunthesystem.

Sharma A et al. [25] have described in their paper the effectiveness of a chiller is dependent on the ratio of flow in-between the product and the cooling media. A higher coolant flow rate gives as a greater average temperaturedifferencebetweenthemilkandcoolantand a higher coolant velocity between the plates that is increases the heat transfer coefficient of process. Many manufacturers suggest that minimum ratio of 2 is essential, it means the water flow rate doubles the milk flow rate. The flow of the milk from milk pump to a receiverisintermittent.Wheneverthelevelofmilkinthe receiverreachesattheupperprobe,thenthepumpstarts. The milk flow could be at least 25 gpm for the few secondsandafterthatstopforaminute.Testsonthetwo conventional receivers pumps in a double parlor shows thattheaveragemilkflowrateduringthemilkingprocess wasabout 12 gpm. Both the receiver pumps operated 26 percent of the time, meaning that the mean flow rate of the milk when a pump was operating was 44 gpm. To achieve a flow ratio of 2, the chilled coolant flow rate while the milk pump was operating should be 88 gpm which is much more difficult to achieve this on a dairy farm.

Hegde V. et. al. [26] have investigated that milk shouldbechilledto10°Cinsidefourhoursorlessinany casebacterialdevelopmentexpandssubsequentlycutting down the milk quality. Most appropriate refrigeration framework is mechanical refrigeration framework for Indian conditions. The significant favorable position of thisundertakingisthatthe milkchilledinthevancanbe utilized for optional preparing if bundling unit is found evenat4-5hrexcursiontime.Chillingplantsarenotvital which can be supplanted by portable chillers. The concentratedsolarthermalenergysystemisdesignedand

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

constructedwiththeconventionalparabolicconcentrator. The receiver is placed along with the line between the centreoftheconcentratorandthesun.Thereceiverused iscoiledhelicallywiththespecificdesignsothatalltheall solar radiations/rays concentrated at centre have receivedwithoutshadow. Manualtrackinghasbeenused during evaluation stage. This allows for effective collecting and concentrating of the incoming solar irradiation (Duffie and Beckman, the concentrated solar thermal energy system is designed and constructed with the conventional parabolic concentrator. Receiver is placed along the line between the centre of the concentrator and the sun. This receiver used is coiled helicallywiththespecific designsothatall thesolarrays concentrated at centre have received without shadow. Manual tracking has been used during the evaluation stage. This is allowing for the effective collecting and concentratingoftheincomingsolarirradiation/rays.

Bhadania et al. [27] havediscovereddairyindustry consists of various sections like raw milk reception, products section, processing section, production section storageanddispatchsection.Itisestimatedthatonethird oftheenergyusedbythedairyindustryisactuallyinthe processing operations and the refrigeration plant accounts about 50-60% of total electrical power consumption so that they installed Solar system then saved up to 50% of energy while on working or running projectorplant.

Janzekovic et al. [28] have discovered that by applying solar parabolic dish collector and related green energytechniquesinthedairyindustries,thecostofdairy products can be reduced. The new technological equipment like CIP technologysystemin food processing industry, replacing the depreciated one, will have to improve the competitiveness and efficiency of the companies,thebusinessactivityplansandwillpromoting tofulfillmentoftherequirementsofthedistrictEuropean Union(EU)legislationalso.

Srivastav P.P. et al. [29] have define the purpose behind the energy optimization and management for dairy plant is to control the energy consumption for gettingtheoverallmaximumefficiency.Forthecasestudy of the energy consumption in manufacturing of dairy products, a multi-product dairy plant was selected. The product, technology and dairy operations of different dairyproducts were exploredunder the batchprocess to identify the high energy consuming centers termed as a critical control point (CCPs). Various equations for heat andmasstransfer,electricalconsumption,flowrate,were used to find the actual utilities consumption (water, steam, electrical energy) in dairy operations. The data of this case study was compared with the previous studies

and found that the energy conserving status was declining.

Raymond F- Fuerschbach et al. [30] have told that their paper chiller has an inlet and outlet which is for a first fluid and there is a passage network there between the passage network being started comprised of various network defining structure, e.g., openings, being present in the flow and heat transfering plates. A similar type of inlet and outlet and passage network arrangement is provided for a second fluid. Each turbulator member is locatedinthe passage network of one of the fluids with the network so arranged that there is heat transfer between the fluids passing through them. The stacked platesandturbulatorsaresealinginterconnectedtoform themtogetherinunitarystructureformandtheassembly canbeprovidedwithtopandbottomplates.

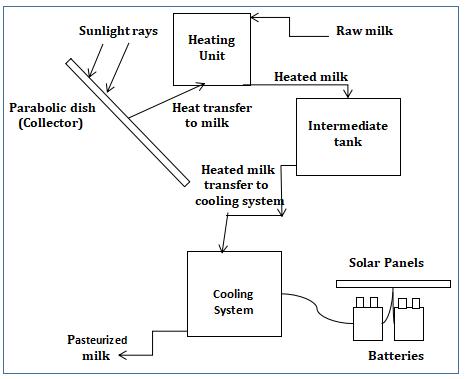

Pasteurization was invented by a French scientist called Louis Pasteur during the nineteenth century. Pasteur discovered that the heating of milk to a high temperature and then quicklycooling it before bottling or packaging it could keep it fresh for longer.The process of pasteurization involves heating milk to 71.7°C for at least 15 seconds (no more than 25 seconds). Because of the natureofthetreatmentofheatitsometimesreferredtoas the ‘high temperature short time’ (HTST) process. Once themilkhasbeenheated,itis then cooled very quickly to less than 4°C. The equipment which is used to heat and coolthemilkiscalleda‘Chillingplant’.Whenthemilkhas been pasteurized, it is bottled or packaged to be sold to consumers.Thefollowingfigureshowsthatsolaroperated milkpasteurizationsystem.

Fig. 3.1Layout of milk pasteurization system

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

Above modelshowsworkingcycleofsolaroperatedmilk pasteurization system. Whole system contains parabolic dish collector, receiver, intermediate receiver, raw milk storage tank, compressor, air cooled condenser, expansion valve, evaporator, solar panels,control panel, pump, testing and packing unit with some purpose. As pasteurization process involves heating of milk up to a specific temperature in order to kill harmful bacteria’s which are harmful to human being and cooled at specific temperaturetoincreaseitslifewhichindirectlymeansto stopbacteriagrowth.

Solar collectors convert solar radiation energy into energy stored in the transport medium by means of heat exchange shown in above fig. 3.1. The major component ofanysolarsystemisthesolarcollector.

Thisisa devicewhichabsorbs/collecttheincomingsolar radiation,convertsitintoheat,andtransferthisheatinto a fluid (usually air, water, or oil) flowing through the collector. The solar energy thus collected is carried from the circulating fluid either directly to the hot water or space conditioning equipment or to a thermal energy storage tank that is backup energy setup from which can be drawn for use at night and cloudy days. A parabolic dish solar generation unit is as like as small power plant with a reflector like a large satellite antenna like a solar toweritisapointfocusingconcentrator[31,32]butitcan achieve an even higher concentration ratio, theoretically as high as 2000 and an efficiency of up to 40%. Here, using the solar parabolic dish collector for collecting sun radiationsandconcentratingthoseradiationsonreceiver to heat milk up to desired temperature as required in pasteurizationprocess.

A cooling system cools heated milk that's been transferred from an intermediate receiver/storage tank and the temperature has dropped to near 35°C. Purpose of chilling plant is prior to cool and maintain milk about 4°C. As similar to every cooling system, chilling plant includes compressor, condenser, capillary tube, and evaporator. R22 and glycol are the two refrigerants/coolantsareusedinchillingplanttocoolthe milk and coolingfanisused tocoolthe condenser.Thisis the Actual section where exchange of heat between refrigerantandmilkhappens.Itismainsection ofsystem wherealltheheatedmilkiscooledatabout4°C.

The purpose of installing solar system is to fulfill the electricityneedrequiredfor the chillingplant. Thewhole chilling system runs on solar system.This solar panel contains energy that is received from the sun and stored inabatteryasDC.Thisenergyshouldbeusedforcooling systemtorunthecoolingprocess.

Pasteurizationmakessuremilkissafetodrink(bykilling anybacteria)andalsohelpstoprolongitsshelflife.When themilkhasbeenpasteurized,itisbottledorpackagedto besoldtoconsumers.

As per the analysis this research is practically possible. With the development of this small size solar operated milk pasteurization unit people from rural background where sufficient amount of electricity, milk collection dairies, transportation facilities such things are not available can pasteurize their own cows, buffalo’s milk with less cost required. In such a system, people can eliminate the need for electricity for the pasteurization process by using renewable energy sources like solar energy. These units help milk-producing individuals from rural areas start their own businesses, which leads to economic support for their families. According to the materialselectionfortheresearch,itsphysicalproperties, durability, structural analysis, and thermal analysis of selected parts, the further conclusions are made. We can cutoffthecostofelectricityrequiredforprocess.Selection ofpartshelpstoreducetheoverallcost.Paybackperiodis nearabout5years.

This review paper was supported by Solar research laboratory of N K Orchid’s college of engineering & technology,Solapur.

[1] Mekhilef S., 2010, “A review on solar energy use in industries”; department of electrical engineering, universityofMalaya,50603KualaLumpur,Malaysia.

[2] Paschal H., 2017, “A comprehensive review of solar milk pasteurization system”; mechanical engineering department, government engineering college, Patan 384002,Gujarat,India.

[3] ThuS.M.,2019,“Astudyoncopofexistingiceplant”; department of mechanical engineering technological university(Mawlamyine)Mawlamyine,Myanmar.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

[4] Hafez A.Z, 2016, “Energy conversion and management”; renewable energy engineering program,universityofscienceandtechnology,Zewail cityofscienceandtechnology,Egypt.

[5] Wankhede U.S., 2017, “Experimentation for design and fabrication of scaled down innovative mini ice plant”; department of mechamical engineering, G. H. Raisoni College of Engineering, Digdoh Hills, Hingna Road,Nagpur(M.S.)440016,India.

[6] Sunaris M.L, 2019, “Analysis of energy losses in smooth pipes”; department of civil engineering, MaranathaChristianuniversity,Bandung,Indonesia.

[7] Vincent E, 2019, “Re-designing and fabrication of the contactarea ofa solarmilk pasteurizer”; department of mechanical engineering, Modibbo Adama University of technology, Yola, Adamawa State Nigeria.

[8] Raibhole V. N., 2016, “Performance evaluation and continuous monitoring of ice plant with r134a refrigerantbyusingNILabVIEWTM DAQsofsystem”; department of mechanical engineering, M.E.S college ofengineering,Pune,Maharashtra,India.

[9] PanchalH.,2018,“Renewableandsustainable energy reviews”; mechanical engineering department, governmentengineeringcollegePatan,Gujarat,India.

[10] Yadav J. P., 2019, “Study on analysis and fabrication of an ice plant model”; Indian institute of management,Culcutta.

[11] Farjana S.H., 2010, Solar process heat in industrial systems, “A global review on sustainable energy systems engineering (SESE)”; school of engineering, MacquarieUniversity,Sydney,Australia.

[12] Igweonu E. I., 2011, “Solar collector efficiency: analysis and application”; electrical/electronic engineering department, Akanu Ibiam Federal Polytechnic Unwana, PMB 1007 Afikpo Ebonyi State,Nigeria.

[13] Alarcon J. A., 2013, “Design and construction of a solar collector parabolic dish for rural zones in Colombia”; Universidad Distrital Francisco José de Caldas,Bogotá,Colombia.

[14] Sah R. P., 2020, “Milk storage system for remote areas using solar thermal energy and adsorption cooling”;symbiosisinstituteoftechnology,symbiosis international (deemed)university Pune, 412115 Maharashtra,India.

[15] MohammedI.L.,2012,“Designanddevelopmentofa parabolic dish solar water heater”; mechanical engineering department, college of engineering, Kadunapolytechnic,Kaduna,Nigeria.

[16] Rabab Zahira, 1940, “The phosphatase test as an indicatorofpasteurizationofmilk”. CanadianJournal ofComparativeMedicine,4(5):128.

[17] Muhammad Azam, 2002, “Fluorimetric determination of alkaline phosphatase in solid and fluiddairyproducts”.ElsevierTalanta,56:1021.

[18] Zorraquino, 2000, “Buffalo milk enzyme levels, their sensitivity toheat inactivationand their possible use as markers for pasteurization. Journal of Food Protection”,63:970.

[19] Marco Lucentini, 2015, “System Design and Experimental Results of Progressive Freeze Concentration System”; International Journal of Application or Innovation in Engineering & Management;(Volume4,Issue7).

[20] Atia, 2014, “Investigation of Heat Transfer CoEfficient in Semi Elliptical Horizontal Bulk Milk Cooler”;(Vol.2,IssueII,pp.51).

[21] Muhammad Usama Yaseen, 2014, “Design of Mobile Raw Milk Chilling Unit for Rural Areas” SASTECH Journal;Volume13;Issue1,(pp.34).

[22] Nielsen, 2007, “Dynamic modeling of bulk milk cooler” 5th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics Sun City,SouthAfrica.

[23] Virgiliu., 2009, “Non-Conventional energy sources”, Department of Electrical Engineering, National InstituteofTechnology,Rourkela,India.47-54.

[24] Duffie, 2003, “Renewable Energy Its physics, engineering”, use, environmental impacts, economy and planning aspects, 3rd Elsevier Academic Press, Roskilde Univ., Energy & Environment Group, Ins. 2, Denmark.

[25] Shrama A., 2013, “Design and performance assessment of a flat‐plate solar milk pasteurizer for arid pastoral areas of Kenya”. Journal of Food ProcessingandPreservation,37(2),120-125.

[26] Hegde V., 1985, “Solar energy fundamentals and design”,JohnWiley&Sons,NewYork,USA.

[27] Bhadania,2009,“Fabricationandperformancestudy of a solar milk pasteurizer”, J. Agri. Sci., Pakistan Vol. 46(2).

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

[28] Janzekovic,2007,“Pasteurizationofgoatmilkusinga low-cost solar concentrator”, Solar Energy J., doi: 10.1016/j.solener.2007.10.011,USA.

[29] Srivastav P.P.,1994, “Design and performance characteristics of a parabolic-trough solar collector system”.ApplEnergy;47:341–54.

[30] Raymond F. ,2004, “Solar thermal collectors and applications, Progress in Energy and Combustion Science”,30:231-295.

[31] Papade, C. V., Kanase-Patil, A. B 2021. Day and night parabolic concentrating solar cooker 8sing nanomixed phase change material. AIP Conference Proceedings,2335.

[32] Papade, C. V., Kanase-Patil, A. B 2022, Binary salt phasechangematerialforconcentratedsolarcooker: storageandusages,EnergySources,PartA:Recovery, Utilization, and Environmental Effects, 44, 66986708.

Prof.CVPapade, Department of Mechanical Engineering,NKOCET,Solapur, Dr.BATU University.

SGGhodke, P.GStudent, Department of Mechanical Engineering,NKOCET,Solapur, Dr.BATU University.